8 minute read

FEATURE ARTICLE

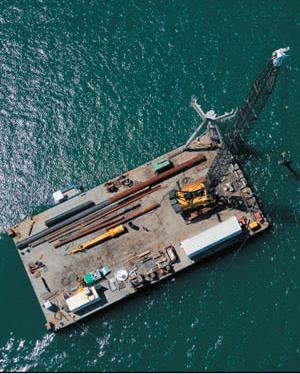

Selecting the right barge and the right crane for an over-water project

By ALBERT SMITH, Lifting Matters Chief Sponsor

Advertisement

Engineering and planning for crane lifts on dry land is complex enough, requiring consideration of load dimensions, pick and place positions and boom radius, ground conditions and environmental factors. But what about when you don’t have the luxury of solid earth under your crane wheels or tracks? When your lift requires you to place your crane on the water, things get a lot more complicated. Crane barge work adds additional risks to the usual crane industry management and safety issues. On a barge, the crane is subject to the heal and list of the barge, and the barge is subject to the ebbs and flows of water. Crane barge work is exciting for lift engineers and planners, crane drivers, and dogmen alike as we get the opportunity to use our machinery in interesting and unique locations. But the added complexity and safety risks of cranes on barges must be taken seriously. There have been some catastrophic accidents where proper consideration has not been given to the unique factors at play when we put heavy machinery onto the water. You will read about several incidents in this issue that in some cases sadly resulted in fatalities and in other cases thankfully just near misses. There are a few common misunderstandings about cranes on barges, some of which I will talk about here.

Crane and barge size

A common question is “What size barge do I need for a particular size crane?” To confidently answer this question for a specific lift, a qualified Naval Architect should be engaged to analyse the stability and suitability of a barge for any crane, configuration and load. I can provide some general guidelines as a starting point here, but a Naval Architect must look at your specific lift circumstances.

Barges are often described by their loaded mass or the carrying capacity. For example, a 50m x 18m barge is often described as a 1000t capacity barge. This information is not really relevant when considering barge sizes for a crane. It is better to describe crane barges by length and width, as these are the important parameters for determining what is required to carry a certain sized crane. The other important characteristic to consider when selecting a barge for cranes is the ratio of the length to the width. Flat top barges suitable for cranes typically range from 4:1 to 2:1 length to width ratio. Longer (4:1) is better to tow, but shorter and wider is better for crane stability. A basic guide for barge width, assuming a length and width ratio of 3, is as follows:

Crane Capacity (tonnes) 50 100 150 200 250 400

Barge Width (metres) 9m 12 m 15 m 18 m 21 m 24 m This table is provided as a very simple guide only. There are many other factors you must consider when selecting a barge, some of which include: • Boom height/length • Crane max lift load • Required lift radius • Barge shape

Required working sea/waterway conditions

Required working wind conditions

It is therefore important to establish these parameters before selecting possible barges. Then, as I mentioned earlier, it is essential to have a qualified Naval Architect complete a stability analysis to check the suitability of the barge for any particular requirement of crane, configuration and load.

De-rating cranes on barges

Another common misunderstanding is what percentage de-rate to apply to the crane chart for use on a barge. The answer is not so simple as it depends on the heal and list of the barge under load. Heal is the longitudinal tilt angle of the deck relative to horizontal, and list is the side tilt angle. It can be hard to wrap your head around this. To demonstrate - if the crane is a mini crane on a huge aircraft carrier then the deck slope is almost nil, and thus it is likely no de-rate is required. Conversely, if the crane is a very long boom crane on a relatively small barge, then the tilt angle is higher and therefore the required de-rate percentage is significant. The calculations to accurately establish this are complex and specialised. For this reason, crane manufacturers generally do not issue percentage de-rate advice for their cranes on barges. Some crawler crane manufacturers issue barge charts for various maximum barge deck tilt angles.

Kurilpa Bridge Installation, Tank Street, Brisbane, QLD

These need to be used in conjunction with a professional Naval Architect for specialist calculations of the maximum tilt angles for a particular crane load and boom configuration combination.

Between the crane and the barge

Another question to ask is “Do I need crane running beams, or timber mats, or can the crane go directly on to the barge deck?” Again, this is not so simple to answer with many factors to consider. The characteristics of the barge will affect the answer such as the deck strength, the spacing of the lateral and longitudinal bulkheads, and the position of the strong points in the barge, all of which vary between different barges. Then, the crane itself must be considered. The crane track or outrigger geometry and the resulting loads on the barge deck is different for every crane. Plus, every available configuration on any crane and the load to be lifted transfers a different load to the barge deck.

As you can see, determining the need for mats or the design of heavy crane running beams is highly complex and needs careful engineering analysis.

There have been many expensive and dangerous mistakes over the years caused by a lack of understanding of the applied crane loads and the barge deck strength.

Hydraulic mobile cranes on barges

A common misunderstanding by the mobile crane industry is that hydraulic mobile cranes cannot be used on barges. It is a myth! Mobile cranes can be used safely on barges, providing there is appropriate consideration of the inherent attributes of mobile cranes:

Modern hydraulic all terrain cranes have complex electrical systems that are not generally designed for a corrosive marine environment. Special consideration should be given to maintenance including extra corrosion protection and reliability.

Mobile cranes apply concentrated loads via outriggers to the supporting deck or ground below. Deck strength needs to be considered under critical outrigger loads. Cantilever telescopic booms are heavier than conventional strut boom crawler cranes. This needs special consideration in calculation of barge deck tilt angles.

Cantilever telescopic booms are not designed for any out of level slew rings and are generally weak in side bending. Safe load capacity reduction for deck tilt angles is significantly more for cantilever telescopic booms than that of lattice strut booms. This usually pushes the crane selection of barge cranes towards conventional crawler cranes.

So, the use of hydraulic mobile cranes on barges is not entirely impossible! But, there are additional matters to consider and higher capacity reduction factors are required.

Mooring Systems

The barge moving and mooring system also needs to be carefully selected as the crane barge is no use if it cannot be correctly positioned, moved and controlled. There is a very wide range of systems available including: • Simple bollards and man-handled mooring lines.

Individual winches to anchors independently controlled.

Complex centrally controlled electric or hydraulic 4-8 point mooring systems.

Drop down mooring systems to keep nearby water space clear.

Self-elevating, crane lifted, spuds including moveable or fixed.

Jack up leg systems.

Sophisticated sucker or mechanically connected mooring arms.

The barge mooring system often costs more than the crane or the barge itself. It is often an afterthought in the planning process but is critical to the success of barge mounted crane lifts.

Deck buildings, equipment and layout

To be functional and provide a safe working environment for the on-barge team, the barge deck will usually require an office, lunch room, tool shed, toilets, sewer system, water system, communications, power, and hydraulics. The lay down area needs to be carefully planned, along with suitable access and egress points. This is almost like a game of Tetris, as real estate on barge decks is always restricted.

An important rule is to minimise the wastage of barge deck real estate and wherever possible use multilevel to double the effective space.

Safely lift from barges with the right lift planning

Placing cranes on barges enables us to carry out important lifts on exciting projects such as bridge and wharf construction. However, the unique factors at play do require us to carry out highly specialised analysis on the barge selection, crane de-rate percentage, mats and/or running

beams, and the overall crane configuration. Do not undervalue the significantly different nature of operating a crane on a barge versus on solid ground!

Together with my team we have designed, set up and operated many crane barge combinations in recent years, ranging from 5 tonne teleboom minicranes on small pontoons up to 800 tonne capacity superlift crane barges. If you need planning advice for your next crane barge opportunity, please do not hesitate to contact me and I can put you in touch with some of our trusted and specialised barge crane engineers.