12 minute read

Artifical intelligence: The role of artificial intelligence in designing baking ovens

from f2m Automation Book

by landmagd

Investigation on the baking ovens performance are conducted typically either through expensive experiments or by means of numerical methods. With advancements in data science, many engineering disciplines have taken advantage of machine learning techniques to discover new aspects of science and develop methods that outperform conventional ones.

+Specifically, when it comes to modeling of fluid dynamics problems, due to the inherent complexity of fluids dynamics, neural networks and deep learning have found plenty of applications to facilitate the fast and accurate estimations. The novel techniques of the artificial neural network can be employed to modelling and optimization of different parts of the baking oven with lower efforts which was not possible previousely. Fan is one of the critical components of convection ovens that influences the quality of baked products and baking time by controlling the air flow and temperature distributionin in the oven. This chapter reviews the different steps of simulation of fan flow and the use of deep learning in modelling the fan flow from data of simulation.

Introduction

Optimization of the baking process has been a topic of interest for decades because of its associations with people’s daily life and energy use. This has given rise to a huge demand for baking units with higher performance, which deliver better baking quality while respecting lower energy consumption. Baking is a complex process involving a set of physicochemical and biological phenomena, such as heat and mass transfer, chemical reactions, and volume expansion. These transformations contribute to important quality features such as color, texture, crumb, and size. Therefore, understanding all aforementioned phenomena and effective terms will provide us with enriched background towards designing efficient baking systems. Computational methods are proposed as an alternative to costly experimental approaches, in which the mathematical approaches are applied to solve the governing equations of the problem. Numerical methods like finite element method(FEM) and finite volume method (FVM), have been widely used by literature due to their strength in facilitating the analysis of the baking process Simulation of foaming in proofing step is one of the application of numerical methods that visualizes the effect of chemical reactions in microscale. Furthermore, it was shown that this methodology can be applied for modelling the two phase phenomenon such as evaporation and moisture transportation that take place during the baking of the bread. However, developing a model that represents the entire process thoroughly demands high computational

resources or even might be impossible and that is the reason why researchers usually focus on specific phenomenon at certain scale. More details regarding the estimation of temperature and Brownian index in baking process are found [1], [2] and [3]. As the temperature and moisture are the driving forces in all transformations happening in the baking, the temperature distribution inside ovens plays an important role in the baking process, and the best baking quality is subject to uniform temperature distribution over the surface of baking objects. Investigating the temperature distribution and improving the temperature uniformity appeared as another topic of interest for scientists to push efforts towards novel and optimum oven designs both in domestic and industrial scales. There are some studies that performed a simulation of oven geometry to verify the effect of geometrical characteristics on pre-heating time [4] and temperature uniformity of the drying ovens [5] [6]. Simulation of the baking oven on an industrial scale is another interesting topic in which the U-movement of dough is considered into calculations [7] [8]. It is obvious that excellent performance of simulations task is subject to faithful representation of the system physic, scale and properties. It becomes more challenging when the systems is experiencing a multiscale and multiphysics phenomena, where the first-principle based representations in numerical simulations fail to fulfill all expectation. Fortunately the availability of observation data and recent development of artificial intelligence techniques has prepared a platform to address the issues of traditional computational methods.

Artificial Intelligence

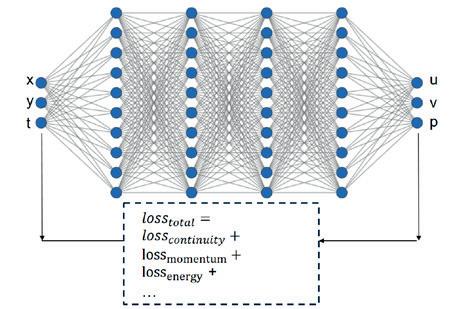

Artificial intelligence, since its advent, has increasingly drawn scientist attentions from all branches. Especially with the advancement of machine learning and, most prominently, deep learning algorithms, the data-driven approach of computational mechanics became an active area of study. This method soon was employed in many tasks like, solving the partial differential equations and optimization problems. The core of the deep learning algorithm is a neural network with multiple layers that aim to model a nonlinear relationship between the inputs and outputs through an iterative process, in which the parameters of the network are adapted to minimize the cost function. Since deep learning methods deal with huge amounts of data to extract meaningful pattern, establishing a robust and reliable method has always been challenging.

To tackle the problem of handling massive datasets, Physics Informed Neural Network (PINN), firstly proposed by Raissi et al. [9] appeared as a robust framework for solving computational mechanics problems while demanding for a lower amount of data. Afterward, other method has been proposed, which need only limited information of boundary condition and initial conditions [10]. Except some rare works concerning the application of artificial intelligence in baking [11] the literature in this field is insufficient. Considering the current capability of AI in modeling fluid dynamics problems, its applications can be further extended into the food industry, including the baking process and ovens design. Ovens typically consist of certain elements whose functions influence the air circulation accordingly the temperature distribution of the oven. The advantage of using neural network models compared to conventional methods is their ability to accelerate the optimization process of oven design for a set of given parameters.

Training a Neural Network and results

Training a NN model needs data that can be either experimental measurements or the result of computational methods. CFD study provides a rich resource of information for different problems, which deals with fluids. Performing a CFD study consists of several steps; as a first step, the geometry and domain of the solution should be created. A typical three-dimensional convection oven model is shown in Figure 1, including a fan for circulating the air, a heater that supplies hot air, and a baffle with circular holes.

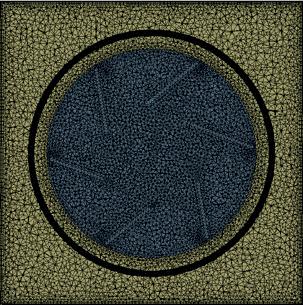

Afterwards, the continuous geometric domain needs to turn into discrete geometric cells for numerical calculations in the next step. Mesh

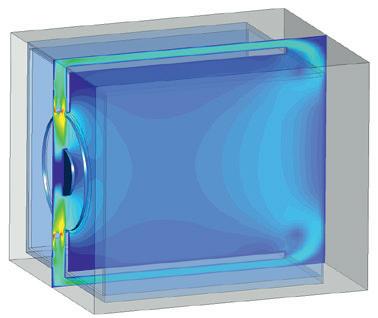

generation was done by Ansys Meshing with tetrahedral mesh for the whole domain, as shown in Figure 2. The finite volume method implemented in Ansys Fluent is used to solve conservation equations of continuity, momentum and energy to simulate the fluid dynamics in the geometry of the oven. In this study, the working fluid is assumed to be an incompressible 3D unsteady state fluid flow, and K-ω SST model is applied for modeling the turbulent flow. For simulation of fan flow, typically, there are three ways established in Ansys Fluent. When the airflow characteristics around the blades matter, moving reference frames and sliding mesh methods are suggested, bringing about more computational costs. 3D Fan zone model is a relatively straightforward method compared to those abovementioned methods, in which only the angular velocity of the domain is taken into account. The results of simulations of temperature and velocity distribution on a cross-section across the oven without baffle are presented in Figure 3 and Figure 4. As shown, the airflow induced by the fan is pushed through the channel leading to the baking room. Meanwhile, due to exposure to the heater located near the fan, the airflow warms up repeatedly.

Once the simulation is done, the results can be fed to the PINN to train a desirable model. Simulation of fan flow using MRF or Mesh motion is more accurate and computationally expensive as well.

1 2

© TUM Figure 1: A representation of a convection oven

Figure 2: A cross-section view of generated grids for computational domain

Figure 3: Temperature distribution in the oven chamber

Figure 4: Velocity distribution in the oven chamber

3 4

© TUM

INTERVIEW THE ROLE OF ARTIFICIAL INTELLIGENCE IN DESIGNING BAKING OVENS

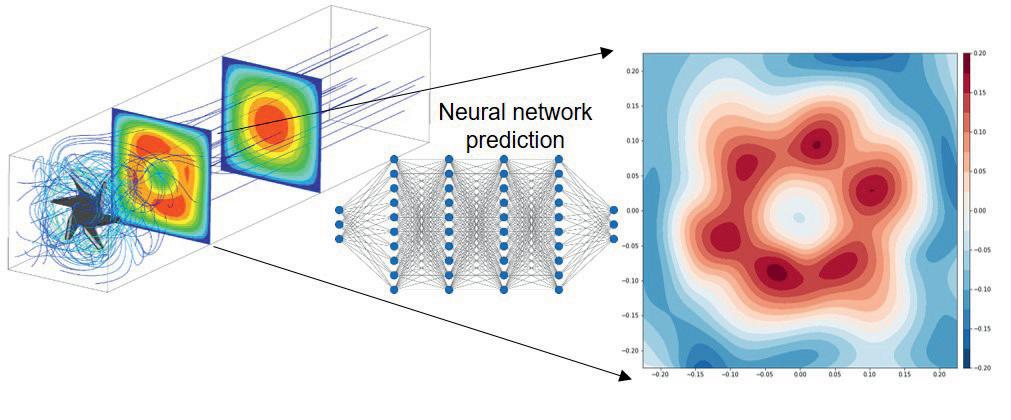

Figure 5: Velocity distribution around the fan blade

Figure 6: Schematic representation of PINN model

Figure 7: Velocity profile prediction by PINN It becomes more challenging when the simulation process needs to be repeated several times during the optimization process. The beneficial combination of artificial intelligence, especially PINN with CFD results, makes it possible to avoid high-cost computational methods by substituting the costly methods with a predictive neural network model that can make estimations with an acceptable level of accuracy.

Developing a surrogate model for fan flow that provides predictions for the whole baking chamber is the topic of our ongoing research. Here the concentration will be on modeling fan flow itself. For this purpose, the CFD results of fan flow using the MRF method (shown in Figure 5) are used as training data of PINN (Figure 6). The input of the model is the Spatio-temporal features of each node, and the outputs are velocity components and pressure.

The number of hidden layers and neurons are determined in a trial and error way. In current work the neural network consists of 8 hidden layers and 20 neurons for each layer. Adam optimizer is used as an optimization algorithm in the backpropagation phase. Once the model has been trained, it can make predictions of fluid properties for the entire training domain at a different time step. Besides, PINN can predict

5 6

variables involved in governing equations, which have not been used during the training.

Here we have trained the model using the sparse information of domain velocity, aiming to extract the information of entire domain. Figure 7 shows the result of velocity distribution of PINN model at an arbitrary length far from fan location. In addition, since this model has been integrated with Navier-Stokes equations other parameters like pressure has been obtained, while the information of pressure was not used in training the model. The application of PINN can be further exploited by applying additional parameters, like energy equations for estimation of the entire domain temperature. This helps designers speed up the process of design optimization by examining different working conditions with no extra computational costs.

Conclusion and outlook

Applying artificial intelligence methods in CFD problems is a promising framework for monitoring, optimization, and dimensionality reduction of complexity. This article aimed mainly at reviewing possible applications in the baking industry and oven design. Further investigation in this field can be oriented more on the estimation of fluid flow and heat transfer inside the baking room, modeling moisture diffusion and temperature evolution in baking products and geometrical optimization for oven interior design. +++

Literature

[1] J. Bikard, T. Coupez, G. Della Valle und B. Vergnes, “Simulation of bread making process using a direct 3D numerical method at microscale: Analysis of foaming phase during proofing”, Journal of Food Engineering, Jg. 85, Nr. 2, S. 259–267, 2008, doi: 10.1016/j.jfoodeng.2007.07.027. [2] A. Mondal und A. K. Datta, “Two-dimensional CFD modeling and simulation of crustless bread baking process”,

Journal of Food Engineering, Jg. 99, Nr. 2, S. 166–174, 2010, doi: 10.1016/j.jfoodeng.2010.02.015. [3] N. Chhanwal, D. Indrani, K.S.M.S. Raghavarao und C.

Anandharamakrishnan, “Computational fluid dynamics modeling of bread baking process”, Food Research

International, Jg. 44, Nr. 4, S. 978–983, 2011, doi: 10.1016/j. foodres.2011.02.037. [4] C. O. Díaz-Ovalle, R. Martínez-Zamora, G. González-

Alatorre, L. Rosales-Marines und R. Lesso-Arroyo, “An approach to reduce the pre-heating time in a convection oven via CFD simulation”, Food and Bioproducts

Processing, Jg. 102, Suppl. 1, S. 98–106, 2017, doi: 10.1016/j. fbp.2016.12.009. [5] J. Smolka, A. J. Nowak und D. Rybarz, “Improved 3-D temperature uniformity in a laboratory drying oven based on experimentally validated CFD computations”, Journal of Food Engineering, Jg. 97, Nr. 3, S. 373–383, 2010, doi: 10.1016/j.jfoodeng.2009.10.032. [6] J. Smolka, Z. Bulinski und A. J. Nowak, “The experimental validation of a CFD model for a heating oven with natural air circulation”, Applied Thermal Engineering, Jg. 54, Nr. 2,

S. 387–398, 2013, doi: 10.1016/j.applthermaleng.2013.02.014. [7] S.-Y. Wong, W. Zhou und J. Hua, “CFD modeling of an industrial continuous bread-baking process involving

U-movement”, Journal of Food Engineering, Jg. 78, Nr. 3, S. 888–896, 2007, doi: 10.1016/j.jfoodeng.2005.11.033. [8] N. Therdthai, W. Zhou und T. Adamczak, “Three-dimensional CFD modelling and simulation of the temperature profiles and airflow patterns during a continuous industrial baking process”, Journal of Food Engineering, Jg. 65,

Nr. 4, S. 599–608, 2004, doi: 10.1016/j.jfoodeng.2004.02.026. [9] M. Raissi, P. Perdikaris und G. E. Karniadakis, “Physicsinformed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations”, Journal of Computational Physics, Jg. 378, S. 686–707, 2019, doi: 10.1016/j. jcp.2018.10.045. [10] J. Berg und K. Nyström, “A unified deep artificial neural network approach to partial differential equations in complex geometries”, Neurocomputing, Jg. 317, Nr. 9, S. 28–41, 2018, doi: 10.1016/j.neucom.2018.06.056. [11] H. Isleroglu und S. Beyhan, “Prediction of baking quality using machine learning based intelligent models”, Heat

Mass Transfer, Jg. 56, Nr. 7, S. 2045–2055, 2020, doi: 10.1007/ s00231-020-02837-6.

Authors

MSc, Seyedalborz Manavi, Dr. Ehsan Fattahi, Prof. Dr. Thomas Becker

Chair of Brewing and Beverage Technology, TUM School of Life Sciences, Technical University of Munich, Freising, Germany

Seyedalborz Manavi, master graduated in the field of mechanical engineering at Babol University of Technology, Iran. He is a research assistant in the simulation/modeling unit at the chair of brewing and beverage technology of the Technical University of Munich since 2019. His research field is focused on the application of deep learning in fluid mechanics problems.

Dr. Ehsan Fattahi Evati received his Ph.D. in numerical mathematics with a focus on highperformance simulation of porous media from the Technical University of Munich. Currently, he is pursuing his habilitation at the chair of brewing and beverage technology and, focusing on computational fluid dynamic and artificial intelligence. From 2017 to present, he is the leader of simulation/modeling unit.

Prof. Thomas Becker studied at the Technical University of Munich, where he obtained his doctorate in 1995 with his doctoral thesis entitled “Development of a computer-assisted enzyme-integrated flow injection system and its use in biotechnology process control engineering and quality monitoring”. In 2002, he concluded his habilitation on the topic “Management of bioprocesses through modeling and cognitive tools” at the Chair of Fluid Mechanics and Process Automation of the Technical University of Munich. From 2004 to 2009, he was a professor at the Chair of Process Analysis and Cereal Technology at the University of Hohenheim. He became professor of the Chair of Brewing and Beverage Technology of the Technical University of Munich in 2009. He was also Dean of the TUM School of Life Sciences of the Technical University of Munich, from 2016 to 2021.