4 minute read

INTRODUCTION

T orque

Use the torques this chart when special torques are not These torques apply fasteners with both UNC and UNF threads received from suppliers dry , when lubricated with engine Not applicable special graphite lubricants, Molydisulfide greases, other extreme pressure lubricants are used.

Advertisement

NOTE: Use thick nuts with Grade 8

Grade 12.9 bolts, nuts, and studs

/ T ypically the torque values specified for grade 10.9 hardware can used satisfactorily grade 12.9 hardware.

Markings for Grade hardware

O - ring boss end fitting lock nut

Abbreviation Measurements

Introduction

Capacities

crank case

T ransmission

Front drive axle - T wheel drive

Front drive axle - Four wheel drive

Brake master cylinder fluid supplied the

Consumables

Engine oil recommendations

AKCELA 1 ENGINE OIL 15W - recommended for use your

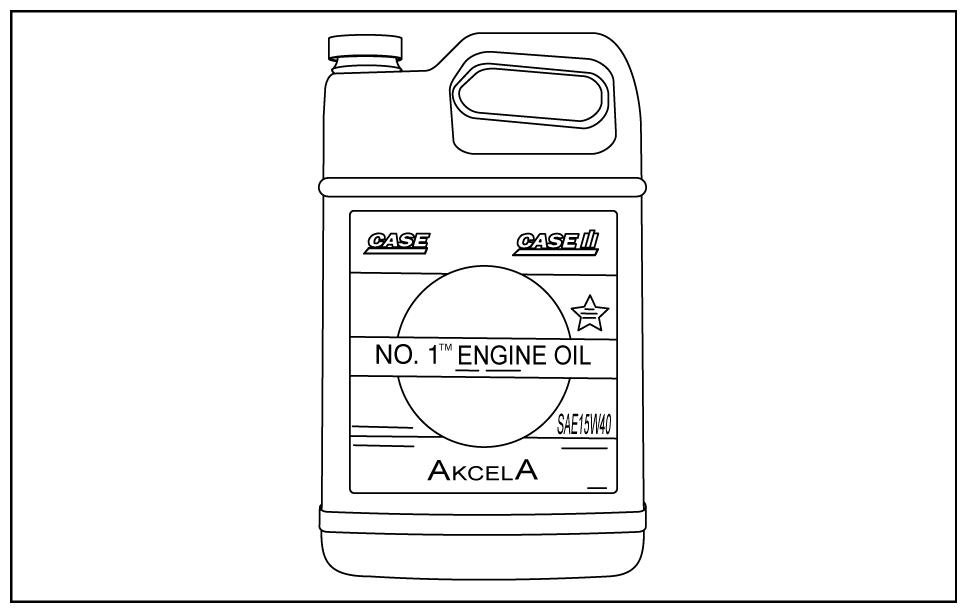

The recommended oil will lubricate your engine correctly under all operating the recommended oil not available a multi - viscosity grade engine oil, okay use a single grade engine oil the recommended oil the recommended engine oil not available multiviscosity single only use oil meeting API engine oil service category -

Refer the chart for recommended viscosity ambient air temperature ranges.

NOTE: not put

Performance

Additives other oil ditive products the engine The oil intervals given the operators manual and service chart are cording tests with CASE AKCELA

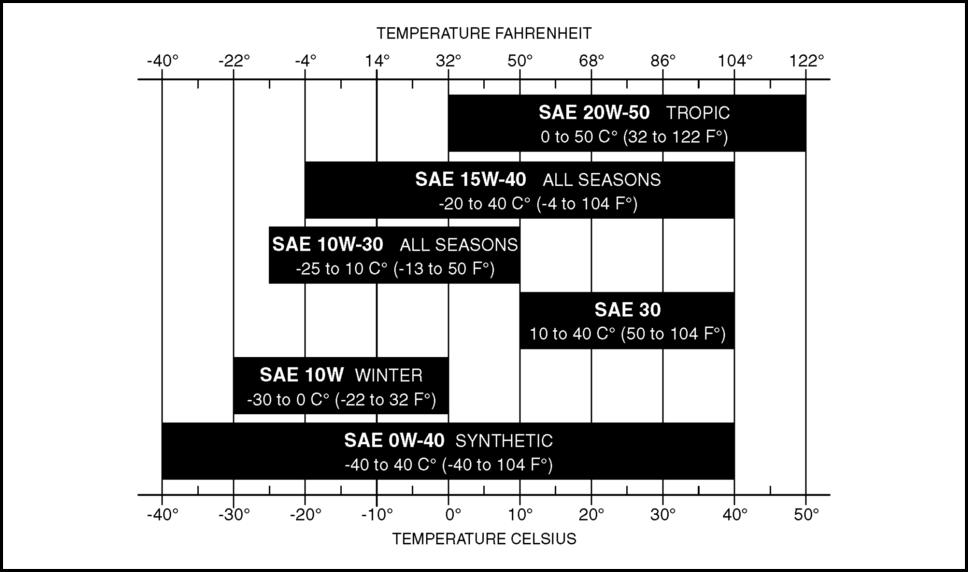

Dye and black light procedure for detecting oil leaks

Oils and grease have natural phosphors and will illuminate dif ferently under the black bluishbrilliant - anti - greenish - yellow , sealing red Kit

NOTE: Each dye formulated work conjunction with a specific therefore the dyes are not interchangeable and should only used

Prior adding connect the black light the machines battery and investigate suspected

Once suspected leak areas are attempt trace the leak completely the origin.

NOTE: At the origin, the leak should the brightest color

After confirmation the suspected leak, thoroughly clean the area the leak remove any existing Recheck the area with the black light assure the area Good cleaning important for the following reasons:

• Fluids captured threaded joints other cavities will continue show signs leakage unless completely

• Casting surfaces can hold residual

Use the entire contents the bottle dye the system / systems the suspected

Run the unit for 5 minutes and cycle through suspect system functions ensure that the dye available all possible leak

NOTE: The hydraulic oil should heated ( 160 ) , engine normal operating temperature, and transmission should the normal operating range the

Use a clean cloth and wipe the dipstick the inside surface the filler tube each the 3

V iew traces dyed fluid the cloth under the black light ensure good

Use these 3 samples your baseline when ing the unit with the black

NOTE: High hour engine oil can reduce the tiveness the dye. this event change the oil. A void common

• Fan airflow blowing leaking fluid.

• Gravity pulling leak paths

• When paint a joint not broken, the joint not

NOTE: not necessary change oils after this

RCPH10TLB245ACL 3

Diesel fuel

Use No. 2 diesel fuel the engine this machine. The use other fuels can cause the loss engine power and high fuel very cold a mixture 1 and 2 diesel fuels temporarily

NOTICE: See your fuel dealer for winter fuel requirements your the temperature the fuel below the cloud point (wax appearance wax crystals the fuel will cause the engine lose power not start.

The diesel fuel used this machine must meet the specifications the chart Specification D975 - the ican Society for T esting and

Fuel Storage

you keep fuel storage for a period you can get foreign material water the fuel storage tank. Many engine problems are caused water the

Keep the fuel storage tank outside and keep the fuel cool Remove water from the storage tainer regular periods

Exploded view Hydraulic Pump 580SN and 590SN

Exploded view - Hydraulic gear pump 580N only

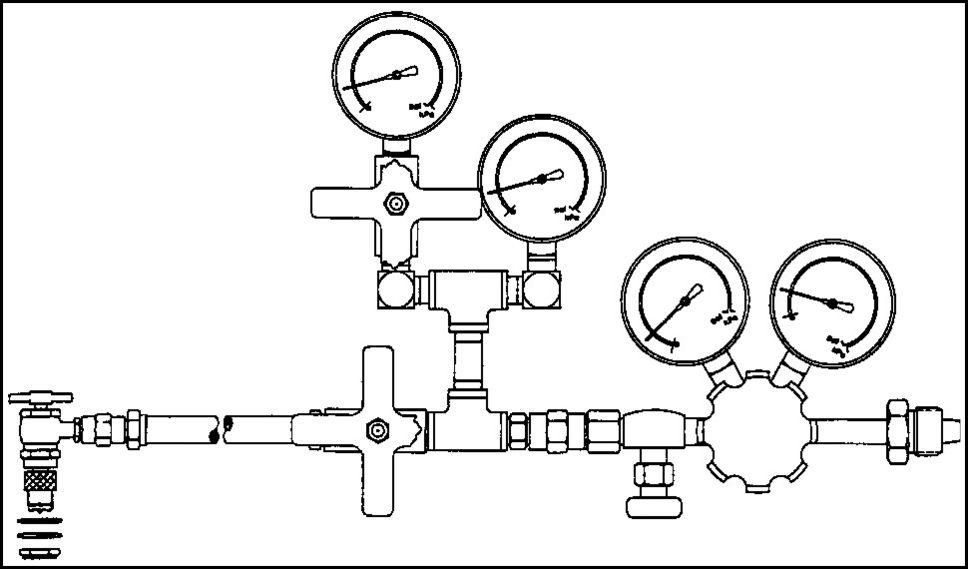

Hydraulic schema Regulated manifold hydraulic Pilot Controls Only

Exploded view - Regulated Pilot Controls only

Exploded view 580N Pilot Machines only

Exploded view 580SN and 590SN machines with pilot controls

Remote valve Component diagram - Pilot control color codes

Drawing Remote Clam V alve for 580SN, 580SN and 590SN with Pilot Controlled Backhoe . . . . . .

Drawing 580N Mechanically Controlled Machines

Drawing 580SN and 590SN Mechanically Controlled Machines

Relief valve

Drawing Swing and - Dir Aux Backhoe Control V alves for 580SN and 590SN Pilot Controlled

Drawing Relief V Loader Backhoe Swing mechanically controlled Backhoes

Drawing Relief V 4000 psi Spike Clipper for Loader V alve 580SN and 590SN machines with mechanical backhoe

Drawing Single Stage Relief V 580 Main Relief with mechanical backhoe controls

Drawing Relief V Main System Dual Stage for 580N with Pilot Controlled Backhoe

Drawing Load Sense Relief V 580N with Pilot Controlled Backhoe

Hydraulic pump

Sectional view Hydraulic 580N only 84516378 05/07/201 1

Sectional view Hydraulic 580SN and 590SN with Power Lift

Drawing - Output T est Hose 580SN and 590SN

Drawing Power Lift V alve 580SN and 590SN machines with Mechanical Controls

Drawing Power Lift V alve 580SN and 590SN machines with Pilot Controlled Backhoe Filter

Sectional view Accumulator Exploded view - Ride control . .

Detailed view - Ride control . . . . . . . . . . . . . . .

Control valve

Drawing Backhoe Control V 8 Extendahoe with Pilot 580SN and 590SN machines

Drawing Backhoe Control V alve, 8 Spool, Extendahoe with Pilot Controls, 580N machines . . . . . . . . . .

Drawing Loader V 2 Spool for 580N with mechanical controls

Drawing Loader V 2 Spool for 580N with pilot controls

Drawing Loader V 3 Spool for 580N with mechanical backhoe controls

Drawing Loader V 3 Spool for 580N with pilot controls

Drawing Loader 3 Spool for 580SN and 590SN with mechanical backhoe controls

Drawing Loader V alve, 3 Spool for 580SN, 580SN and 590SN with Pilot Controls . . . . . . . . . . . . . .

Drawing Backhoe V 8 Spool foot swing

Sectional view Stabilizer 580SN and 590SN machines with Pilot Controls

Sectional view Dipper , Extendahoe 580SN and 590SN chines with Pilot Controls . . . . .

Exploded view - Ride control solenoid valve

Exploded view - Boom lock solenoid valve

Primar Y Hydraulic Power System

Primar Y

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading