4 minute read

The steady growth of the Pharmacy and Manufacturing Unit at KNH p. 18

History Check:

The steady growth of the Pharmacy and Manufacturing Unit at KNH

Advertisement

By Philip Etyang

The growth and development of pharmacy in Kenya is closely linked to the development of the Native Civil Hospital, now Kenyatta National Hospital (KNH).

In the beginning, KNH Manufacturing Unit was compounding various combinations to come up with medicines. However, a 2015 Business Monitor Report on Pharmaceutical industrial base in Kenya, claimed that the country plays host to the largest pharmaceutical industrial base in the East African region.

The main unit was to compound various combinations because at that time there were very few, if any factory prepared drugs. All prescriptions were given with instructions on how to compound and mix different ingredients in a particular prescription.

The production of pharmaceuticals requires a broad range of packing and raw materials. This was a challenge during the pre and post-independence period for Kenya and therefore, the industry started relying more on imports as opposed to locally produced pharmaceuticals which were much more expensive than their imported counterparts.

Since Latin was the lingua franca of scientific work in the West during the Middle Ages, it was the language of the prescriptions used as well at the KNH Manufacturing Unit. Majority of the ingredients used were plant derived and hence the use of Latin for descriptions for example; Oleum Gossypii semis (cotton seed oil), Aurantii Gortex Siccatus (dried bitter orange peels).

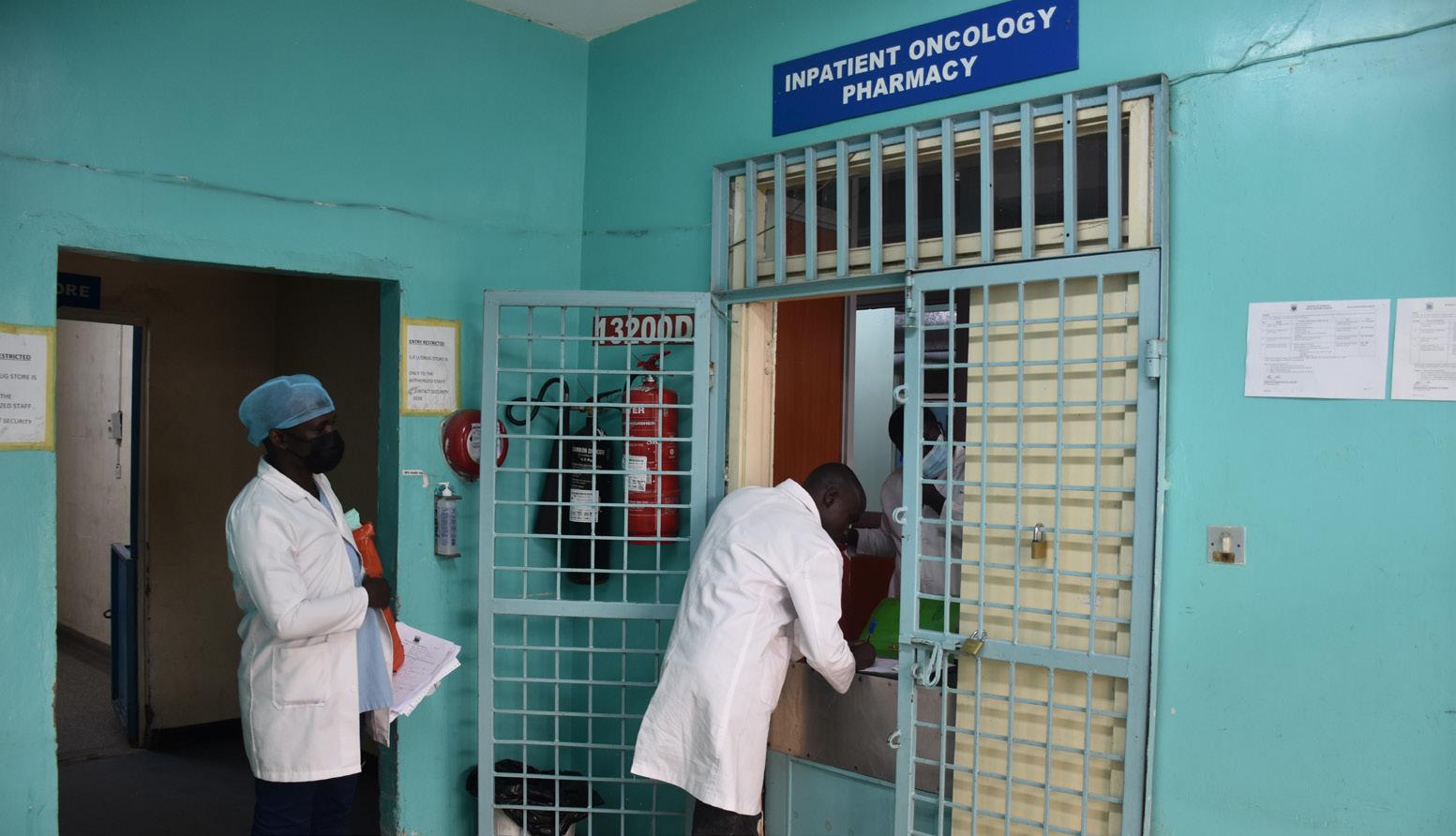

Inpatient oncology pharmacy at KNH

PHOTO | STEVE ARWA

The KNH Drug store

PHOTO | STEVE ARWA

Records at KNH indicate in the early years, the pharmacy personnel included one European Dispenser and one Hospital Compounder, both very important agents in the manufacturing process.

The then Kenya Medical Training Center (K.M.T.C) which was spearheaded by the British during the advent of colonialism at the Medical Training Depot situated in Kabete in the early 1920s and eventually becoming the Buller Camp for military personnel is indeed the cradle of pharmacy training in Kenya. By 1960, training of pharmacists intensified and dispensers were now being trained at the facility.

Between 1950 and 1969, the Pharmacy Department at KNH which was made up of the Main Pharmacy, Sterile Preparations Unit, and the Drug Store were situated at the present Supply Chain Department block which also houses the biological parents of this great production ‘Newsline,’ the Marketing and Communication Department as

well as the Central Registry. The main Pharmacy mainly dispensed pharmaceuticals to the wards as well as the issuing of drugs classified as dangerous drugs. Out-patients on the other hand, were being served at the present incinerator site near the old bus terminal.

Sterile preparations Unit/ Manufacturing Unit (SPU)

The Sterile Preparation Unit at KNH has been in existence since its inception in 1972 when it moved to its present site. The main objectives of the unit upon set-up were:

- To provide creams, simple syrups and suspensions, IV fluids and injectable drugs to the Hospital where possible.

- To sell the excess drugs to outside markets and hence generate income for the hospital.

- To assist the ordinary Kenyan who cannot afford expensive drugs to acquire them more cheaply where possible.

In the 1970s, the Unit was operating on a small-scale basis, yet there was increased demand from government hospitals for Intravenous Fluids (I.V) from SPU. By the late 1980s, the equipment that was in use was old, dilapidated and inefficient with a tendency to breakdown at inopportune times leaving staff idle and the hospital buying vital I.V fluids. The Unit also faced problems in the importation of rubber stoppers and infusion bottles.

During the Rehabilitation Project, SPU received new equipment. With the delivery of the long-awaited distiller and the Unit went into full time production and therefore, meeting the increased demand from its production line. Pharmaceutical manufacturers face constant competitive and regulatory pressure to upgrade their technological capabilities, and therefore the arrival of the distiller at KNH revolutionalised pharmaceutical production not only at the facility but in the country as a whole.

Currently, Kenya is the largest manufacturer of pharmaceutical products, supplying around 50% of the products, in the COMESA (Common Market for Eastern and Southern Africa) region.