16 minute read

Baking Technology

Steel belts for bakery and wafer production

There are few companies that have had a more enduring relationship with the bakery industry than IPCO, suppliers of bake oven belts for almost 100 years

Advertisement

While the decades have seen the development of high performance steel grades, it would be fair to say that the steel belt of 2020 doesn’t look all that different from the one that went into service in 1925.

So what is it about the steel belt that has maintained its position as the conveying medium of choice to this day? What are the qualities that see steel belts used not only for wafer production, but also for products as diverse as bread, biscuits, brownies, crackers, pastries, sponges, all-butter cookies and pizza bases?

There are number of answers of course, but the USP of a steel bake oven belt lies in its physical form: no other material can compete when it comes to a steel belt’s baking qualities.

Not only does it deliver reliable operation in applications where temperatures can reach as high as 400 °C, but it does so with outstanding reliability. Good tensioning and tracking characteristics plus excellent resistance to stretching result in minimal maintenance requirements and a belt life of 20 or more years.

A steel belt is able to transfer heat from the heating media to the product in an even way. The colour of the belt surface is important in this respect: a consistent, dark belt colour maximizes heat transfer and ensures an even bake across the full width of the belt, vital in the production of thin products like wafers.

Another important quality as far as wafer baking is concerned is the smooth, flat surface of a steel belt, ensuring clean release of even thin, relatively fragile products. This flat surface has another benefit in that it provides a crisp base that cannot be achieved on any other conveying medium, making the solid steel belt ideal for the production of American-style cookies. As these products use real butter, and often chocolate chips too, they need to be baked on a solid belt to eliminate the risk of melted product dripping a causing a fire, or simply drying out.

The excellent heat transfer and thermal conductivity of the belt delivers the desirable combination of a crisp base and rich, buttery cookie and the combined result of these qualities is a baking medium of exceptional versatility.

Wide belts for enhanced productivity

One area of increasing interest to many oven builders is IPCO’s ability to produce bake oven belts up to 3500 mm wide. This makes it possible to build wider ovens, increasing productivity without having to invest in factory extensions or new facilities. An oven with a 1500 mm wide belt offers almost twice the productivity of one with an 800 mm belt without any increase in the line length. Upgrade to an oven with a 3200 mm belt or larger and throughput is increased by a factor of four.

Using a steel belt also has the potential to reduce baking times. The combination of excellent heat transfer and comparatively low weight often means that belt speed can be increased, cutting baking time by as much as 25-30% - this can deliver savings in other areas too: the lighter the belt, the less energy required to heat and move it.

IPCO technical and service support

In terms of supply, IPCO can provide as much – or as little – input as an oven builder needs. This ranges from straightforward belt supply, though technical advice or consultancy to ensure that the belt delivers maximum return on investment, to the supply of key conveyor components such as tracking systems and graphite stations.

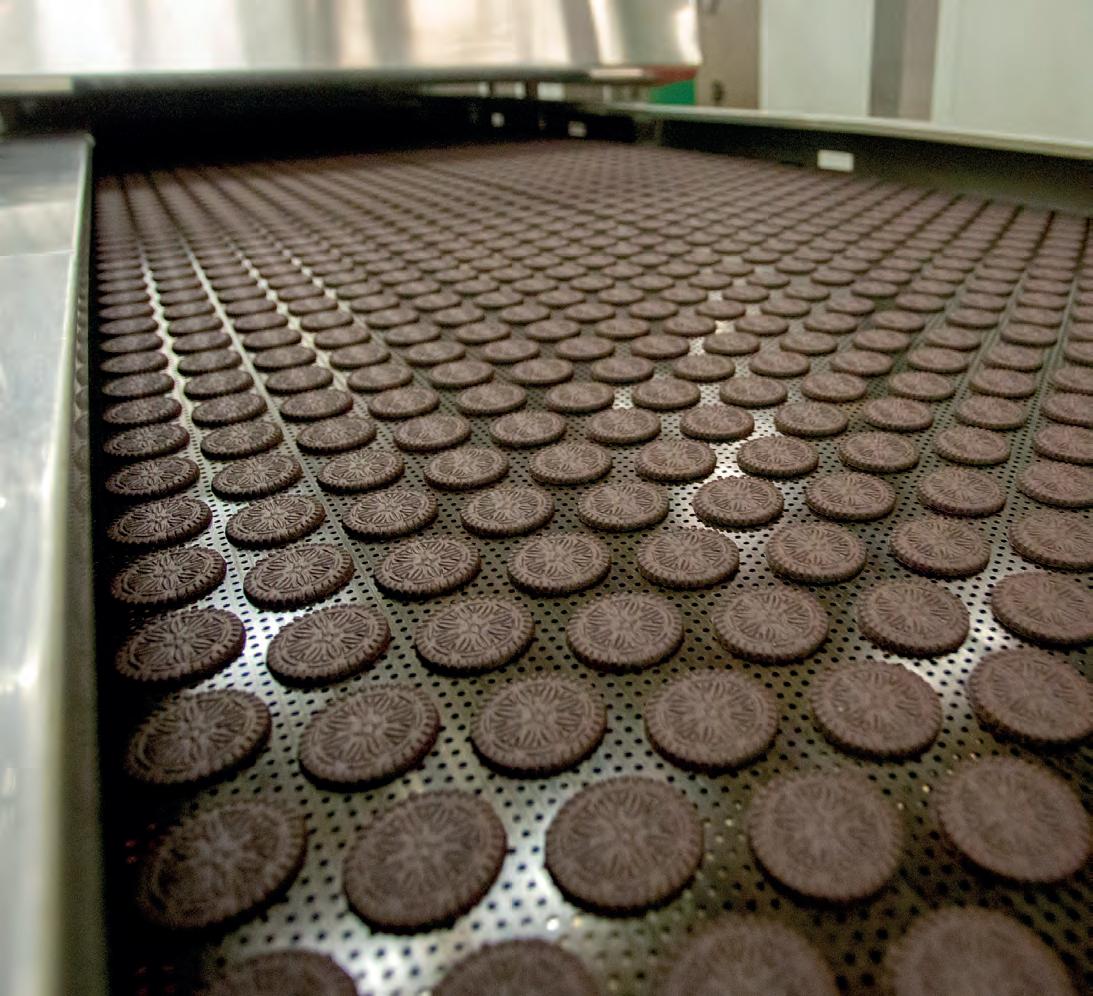

Above and left: IPCO perforated bake oven belt in operation at a bakery in Southern Europe. IPCO steel bake oven belts can be supplied in solid or perforated form and can be manufactured up to 3500 mm wide

Are plastic alternatives doing more harm than good?

UK developer of innovative packaging solutions, ULMA Packaging, has revealed that firms replacing plastic packaging with alternative materials could potentially be more harmful for the environment

Across-party parliamentary group warning that firms are replacing plastic with potentially more harmful alternatives for the environment is a wakeup call for companies to redouble their sustainability efforts, says an industry expert. Dave Berriman, Technical Sales Support Manager at ULMA Packaging UK, commented: “Recent cross-party parliamentary warnings surrounding replacing plastic packaging in the wake of the Green Alliance’s recent report on the topic indicates that alternative materials aren’t always better for the environment. The problem stems from replacing plastic with new packaging materials that have not always been properly assessed in terms of recyclability and carbon footprint.” Research from the report reveals that several supermarkets, for instance, are selling more drinks in coated cartons under the assumption that they can be recycled. Other perceived greener alternatives to plastic such as glass actually contributes more carbon due to being much heavier and therefore more polluting to transport. Dave added: “For processors and retailers striving to respond to consumers who are increasingly looking for environmentally-friendly packaging solutions, it is crucial to find a solution that works. Clearly, cutting out plastic completely isn’t currently meeting this objective.” To achieve amore circular approach to plastic packaging, ULMA Packaging UK is working with a number of material suppliers to develop recyclable mono base materials. Ongoing development of its packaging machinery to reduce the amount of plastic required and make it easier for consumers to recycle in the first place is central to ULMA’s approach. Dave, concluded: “It is crucial to redouble sustainable innovation efforts given that packaging accounts for 40% of the plastic processed each year. As part of the #ULMAweCare project we have pledged to reduce the amount of packaging material required by introducing more innovations like ourLeafSkinTM solution, that reduces plastics usage by up to 80% and is based on a 100% recyclable flat cardboard tray. “Overall, we believe that reducing overall environmental impact, without compromising process efficiency, product integrity and consumer safety is achievable. We hope to act as an example to those in the broader circular economy and help facilitate change.”

Bundled expertise guarantees results

Gerhard Schubert GmbH builds on an interplay of simple mechanics, intelligent control technology and high modularity and have developed successful relationships with renowned partners over the years, including Selpak and esbe plastic

Today, the packaging of a light croissant, frozen spring rolls and small spirit bottles is about so much more than just product protection. The demands of producers and consumers are constantly increasing which also affects the manufacturers of packaging lines who need to ensure that their machines fulfil the wishes of their customers. With the right partner, these tasks can be taken on economically and reliably.

The look, shape and feel play a vital role in the sales success of confectionery, dairy products, beverages and cosmetic goods, as do local consumer habits and packaging materials, the use of which should be minimised in line with sustainability. Moreover, the product needs to be quickly accessible and the packaging easily resealable.

The challenges throughout the packaging process are manifold. In order to master them, collaboration between the companies involved is of great benefit. Gerhard Schubert GmbH, headquartered in Crailsheim (Germany), which works closely with its various partners, is a clear example of this.

Max Schwaiger, Product Support, KHS

Two down to one: the Innopack TLM

The KHS GmbH, an international manufacturer of filling and packaging systems, is one of these partners. “Our companies are a very good match. A strong customer focus, a commitment to innovative solutions and a holistic view are firmly anchored in both company DNAs,” highlights Marcel Kiessling, Managing Director – Sales and Service at Schubert.

“The transfer of decades of experience and sound knowledge has led to an outstanding result: our Innopack TLM. It is compact, very flexible and therefore ideal to meet tomorrow’s requirements already today,” summarises Max Schwaiger, Product Support at KHS. The blocked packaging system was jointly developed upon an order from Schützengarten brewery. The company wanted to fill and package beer in a variety of bottles and secondary packaging formats. With the Innopack TLM, the increasing demands of consumers can be met efficiently. The multifunctional block solution consists of a KHS packer and a Schubert TLM packaging

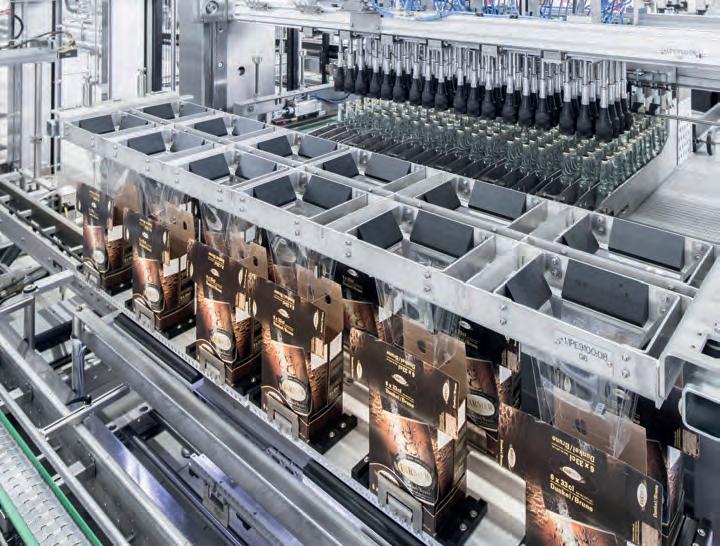

Above: With the new packaging line, Australian ice cream manufacturer can now significantly increase its production capacity and position itself internationally as well Inset pic (above): Schubert and KHS joined forces for the Innopack TLM to offer beverage manufacturers a complete package for filling and packaging their products

Left: Schubert and esbe plastic worked together to develop the new trays for the 20 different formats.

Above: The Innopack TLM block solution impresses with performance, flexibility and reliability.

line and packs beer, wine and other spirits in different primary and secondary packages – with a performance up to 86,400 containers per hour. These versatile possibilities are in line with Rotkäppchen-Mumm Sektkellereien and their extensive assortment.

Thirteen sub-machines with a total length of 33 metres package the large and small bottles in different formats: from single gift-wrapped bottles to clusters of 4 bottle to wrap-around cartons of 24. KHS and Schubert also support their customers when it comes to reducing their CO2 footprint.

For example, the Innopack TLM allows shrink-wrap to be replaced by cartons. This reduces the plastic percentage of the packaging significantly. Thus, the benefits of this partnership for beverage manufacturers are significant. They receive a space-saving, flexible and low-maintenance packaging block that delivers sellable products from the very first packaging, even after every format change.

A successful long-distance relationship

As early as in the mid-1980s, Schubert’s representatives were looking for a suitable business partner for the faraway Australian market to be able to guarantee customers there the same outstanding quality as in all other countries to which Schubert sells its machines. The decision was made in favour of Selpak, a company founded in 1948 by a German emigrant.

Its experts know the local market inside out and, after just a few years of collaboration, the Schubert technologies as well. Shane Sipthorp, Managing Director and owner of Selpak, looks back on the beginnings of the successful business relationship: “In 1985 Schubert was still a relatively small company. However, it didn’t take long for Gerhard Schubert and his visions to convince us to enter into this partnership. An excellent decision!”

The employees support Schubert every time a packaging line is commissioned in Australia and ensure that the machines perform well for years to come with a fully equipped service and spares team. “Manufacturers in all sectors, from ice cream to cosmetics to technical articles, benefit from fast commissioning and high machine availability. All our Australian customers trust Selpak when it comes to their Schubert machine,” says Helmut Fuchs, Sales Account Manager at Gerhard Schubert GmbH, explaining the many advantages for manufacturers. So, it’s no wonder that, according to Selpak, no other country in the world uses more F44 robots per inhabitant than Australia.

Optimisation of plastic trays

Another partner, esbe plastic, is located just a few kilometres from Schubert’s headquarters. Together, the two companies develop thermoformed packaging that is ideally suited to the respective producer and processing on the Schubert lines. The focus is on trays for automatic separation, as well as filling and sealing of the packaging. The short distance between the two partners also makes it possible to exchange ideas face to face, and to efficiently and effectively implement customer requirements – from the initial drawings to sampling to series production.

The most recent example is a manufacturer of high-quality baked goods for which more than 20 formats had to be standardised. At the same time, the trays had to be optimised in terms of material use. “Together with esbe plastic and the customer, we successfully implemented a streamlined packaging concept. The various formats were combined into modules and the wall thicknesses of the trays were optimally reduced,” says Kanellos Tzinieris, Area Sales Manager at Gerhard Schubert GmbH, explaining the approach.

Picking up the trays with their exceptionally thin plastic walls is more challenging as before. To ensure that only one tray is taken from the stack at a time, they need to be turned slightly, rather than simply pulled off vertically. This works perfectly with Schubert’s unique technology. The confectionery manufacturer benefits from faster format changes and lower packaging costs. This clearly shows that it is worthwhile for your own company and for customers to enter into partnerships with other market leaders and to become even stronger by working together.

Manifold solutions

Wymbs Engineering produces pressurised manifold depositing systems for light, aerated products across the bakery and confectionery sectors and their recent case study on continuously cutting Apple Turnover puff pastries involved a unique process, modified to the customer’s needs

For the last 20 years, Wymbs have been producing the best kept secret in the The only question is how do you get fresh patisserie and confectionery industry. whipped cream inside a choux pastry when A machine that is highly specialised you can easily crush it between your fingers? and yet can be adapted to different products Wymbs Engineering have developed some and demands that the customer places on it. unique methods of product handling and In their present configurations, this depositing that maintains an artisan process machine can finish produce Eclairs, but takes it to an industrial scale. doughnuts, custard slices, profiteroles. Both ‘Pressurised Volumetric Depositing’ creates for the injected filling and the decoration. an accurate and hygienic solution for this But this is not its only use - with its bank high-risk product. This is coupled with fully of multi-station depositing units, cutters/ up to date controls from Allen Bradley and slicers, transfer units and integral custom using the latest CompactLogix-5380 PLC and designed conveyor - this machine can be used Kinetix-5500 Servo Drives on a 17-servo axis in any industry where a multi stage process is platform. required. Kevin Wymbs, Director, states: “This “Wymbs are uniquely Rockwell Automation (Owning Company of Allen Bradley) recently produced a paper machine has helped our customers as a leading supplier of patisserie products to placed to offer a solution on the leaps forward that Wymbs have achieved for their innovative approach to the mass market. The labour that would be required to produce at this kind of throughput for a wide range of profile generation, user interface and factory integration, and in particular, the way Wymbs (typically 9,000 an hour for three shifts) would be astronomical, as well as the variance and process problems…” is writing the in-house code for better user interface and its adoption of Factory 4.0 product waste, so ultimately automation was principles. the only solution.” Kevin Wymbs, Director The longevity of the machine is also

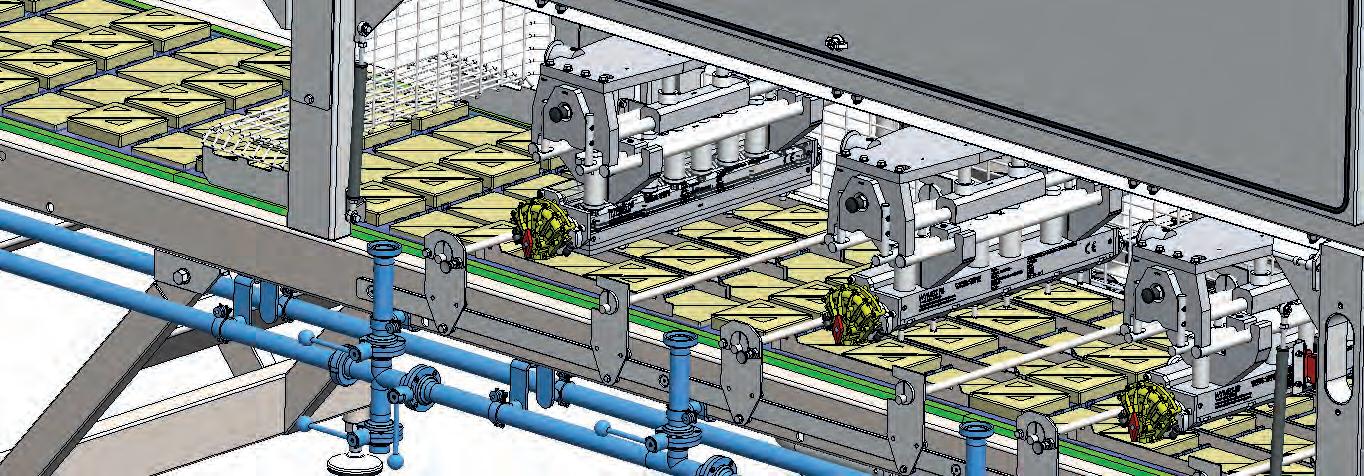

Above: Wymbs’ processing lines are well sealed and positioned to prevent water that can damage sensitive controls when depositing delicate, aerated products

proven; the original design features lend itself to be particularly suitable for harsh cleaning environments. The control and mechanism cabinets are well sealed and positioned to prevent water or steam ingress that can damage sensitive controls and reduce the life of the mechanism bearings. “With our own in-house design, manufacture, software and 38 years’ operating in the confectionary, dairy and bakery industries, Wymbs are uniquely placed to offer a solution for a wide range of process problems,” adds Kevin. “With a proven record with the multi station processing line, we still had to prove to the customer that we could develop a process to cut and transfer the products. I believe this attitude to R&D is what won us the business. We see are customers as partners and work to help them achieve their goals. We still call it ‘our’ machine, years after it left our building!”

Case Study: Apple Turnover

“The labour that would be required to produce at this kind of throughput would be astronomical…” Kevin Wymbs, Director

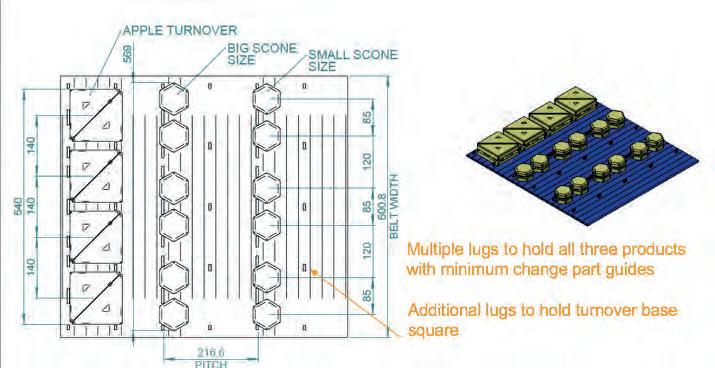

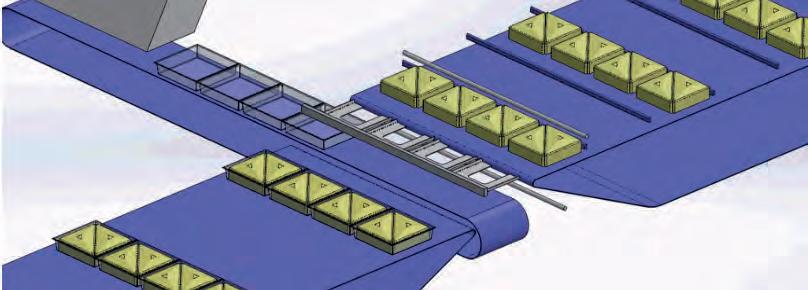

Wymbs were recently asked to continuously cut Apple Turnover puff pastry and scones in half, opening up the cut and placing the bases and lids (one behind the other) onto a travelling flighted conveyor. This involved depositing jam or apple sauce on to the base, then aerated cream on to the turnover or scone along the Wymbs Processing Conveyor.

At the end of the line, the made-up Apple Turnovers and Scones from the Processing Conveyor were continuously transferred into a waiting skillet and then onwards to a nitrogen tunnel infeed conveyor for freezing.

Wymbs did this by employing multiple loading plates that shuffle around to three different positions: de-nest, product load and then transfer to freezer conveyor. This is done by automatically de-nesting a skillet from a stack and placing on a waiting shuffle plate. This plate indexes around to the loading position of the made produce whilst a new skillet is being de-nested onto another shuffle plate.

This, in turn, indexes around to the third position to transfer to the next conveyor.

The customer’s concern to Wymbs was to match the throughputs below (9,000 products per hour), reduce labour cost for this loading (which is manual at the moment) and to crucially, maintain the running of this system even when/ if the de-nester faults or runs empty.

Wymbs managed to develop some concept simulations and modified these to the current design. According to the technical team, the conveyor belt is a special design being able to accept multiple products and hold the pastry shells in position for cutting and depositing.

Kevin concludes: “Designing bespoke equipment like this has always been our strong point but does comes with its challenges. It’s not every day you meet someone who wants to make 9,000 apple turnovers an hour! We understand a customer has to invest themselves into the project just as much as we do, and that is why we are mindful of the responsibility we have to get it right.”

Turnover Turnover! The numbers.

Turnovers - 19 row/min = 4.1m/min. Therefore – 3.1seconds cycle to cycle Scones - 25 row/min = 5.5m/min. Therefore – 2.4seconds cycle to cycle