62 minute read

3.3.6 Nature and significance of radioactive waste

Enhanced CANDU 6, which was developed by Atomic Energy of Canada Limited (AECL); and System 80+, a Combustion Engineering design.

Only four Gen III reactors, all ABWRs, are in operation today. No Gen III plants are in service in the United States. Hitachi carefully honed its construction processes during the building of the Japanese ABWRs. For example, the company broke ground on Kashi- wazaki-Kariwa Unit 7 on July 1, 1993. The unit went critical on November 1, 1996, and began commercial operation on July 2, 1997—four years and a day after the first shovel of dirt was turned. If the U.S. nuclear power industry can learn from Hitachi’s construction techniques, many billions of dollars and years of time might be saved. The Shaw Group and Westinghouse have adopted modular construction practices in launching a joint venture for a Lake Charles, Louisiana, facility that will manufacture modules for the AP-1000.

Safety Features of Gen-III reactors:

The third generation started in the late nineties and features evolutionary reactor designs, built on Gen-II but improving them in all respects by reducing lead times, costs, and waste volume and improving (capacity factors, efficiency, and safety by introducing passive safety systems.

Passive Safety Systems are those Safety Systems that use natural forces like Gravity, Natural Circulation, Pressure of compressed gas, etc. for ensuring safety of the reactors. These systems do not need external power for functioning.

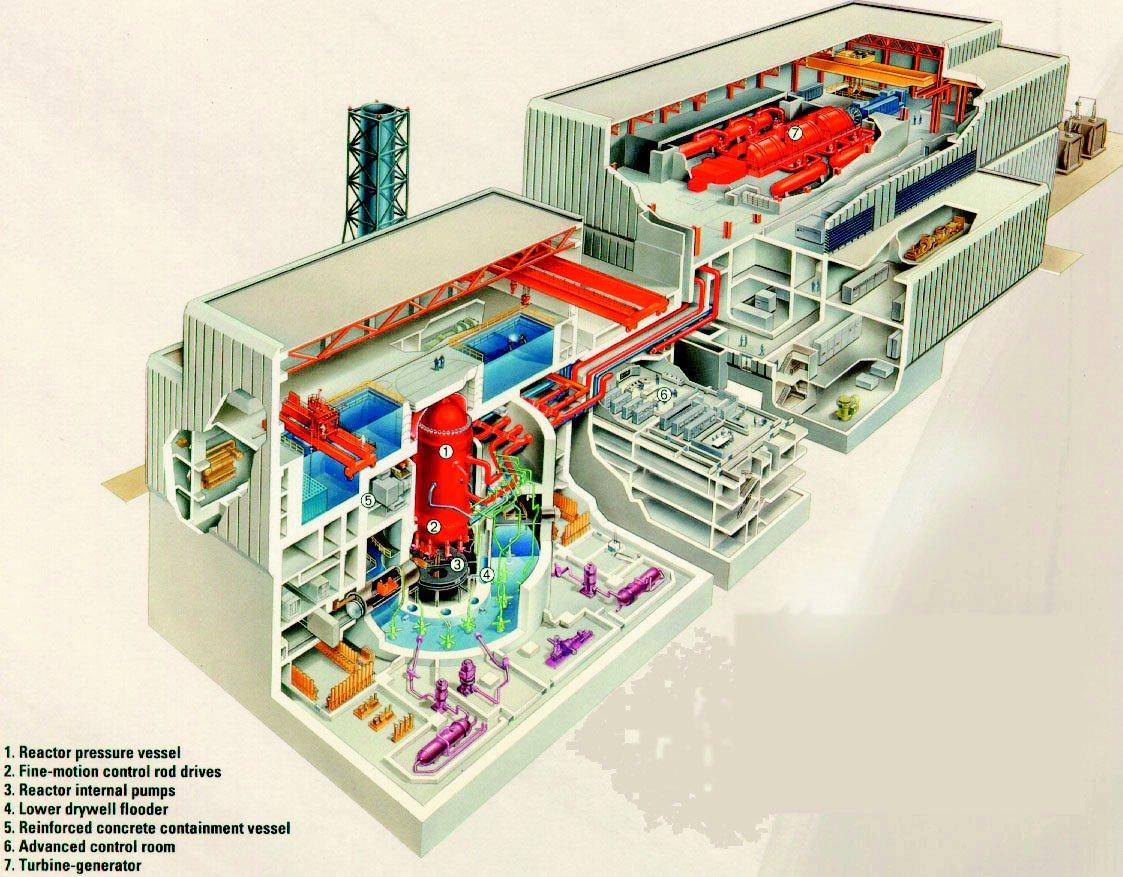

Fig 3.8: Generation III Nuclear ractor safety features

3.2.4 Generation III+

Gen III+ reactor designs are an evolutionary development of Gen III reac- tors, offering significant improvements in safety over Gen III reactor designs certified by the NRC in the 1990s. In the United States, Gen III+ designs must be certified by the NRC pursuant to 10 CFR Part 52.

Examples of Gen III+ designs include:

• VVER-1200/392M Reactor of the AES-2006 type

• Advanced CANDU Reactor (ACR-1000)

• AP1000: based on the AP600, with increased power output

Fig 3.9: GE Hitachi Gen III+ Reactor

Manufacturers began development of Gen III+ systems in the 1990s by building on the operating experience of the American, Japanese, and Western European LWR fleets.

Perhaps the most significant improvement of Gen III+ systems over secondgeneration designs is the incorporation in some designs of passive safety features that do not require active controls or operator intervention but instead rely on gravity or natural convection to mitigate the impact of abnormal events. The inclusion of passive safety features, among other improvements, may help expedite the reactor certification review process and thus shorten construction schedules. These reactors, once on line, are

expected to achieve higher fuel burnup than their evolutionary predecessors (thus reducing fuel consumption and waste production).

More than two dozen Gen III+ reactors based on five technologies are planned for the United States (Table 2 lists applications and their status as of November 2010).Gen III and III+ designs have a defined safety envelope based on Western safety standards and set the worldwide standards for safeguards and security. However, they have also produced a legacy of significant quantities of used fuel, require relatively large electric grids, and present public-acceptance challenges.

3.2.5 Generation IV

Generation IV reactors (Gen IV) are a set of theoretical nuclear reactor designs currently being researched. Most of these designs are generally not expected to be available for commercial construction before 2030. Current reactors in operation around the world are generally considered second- or third-generation systems, with most of the first-generation systems having been retired some time ago. Generation V reactors refer to reactors that may be possible but are not yet considered feasible, and are not actively being developed.

Fig 3.10: Gen IV reactor systems

Many reactor types were considered initially; however, the list was downsized to focus on the most promising technologies and those that could most likely meet the goals of the Gen IV initiative. Three systems are nominally thermal reactors and three are fast reactors. The Very High Temperature Reactor (VHTR) is also being researched for potentially providing high quality process heat for hydrogen production. The fast reactors offer the possibility of burning actinides to further reduce waste and of being able to "breed more fuel" than they consume. These systems offer significant advances in sustainability, safety and reliability, economics, proliferation resistance and physical protection.

Relative to current nuclear power plant technology, the claimed benefits for 4th generation reactors include:

Nuclear waste that remains radioactive for a few centuries instead of millennia

100-300 times more energy yield from the same amount of nuclear fuel The ability to consume existing nuclear waste in the production of electricity Improved operating safety

One disadvantage of any new reactor technology is that safety risks may be greater initially as reactor operators have little experience with the new design. Nuclear engineer David Lochbaum has explained that almost all serious nuclear accidents have occurred with what was at the time the most recent technology. He argues that "the problem with new reactors and accidents is twofold: scenarios arise that are impossible to plan for in simulations; and humans make mistakes".[6] As one director of a U.S. research laboratory put it, "fabrication, construction, operation, and maintenance of new reactors will face a steep learning curve: advanced technologies will have a heightened risk of accidents and mistakes. The technology may be proven, but people are not".

A specific risk of the sodium-cooled fast reactor is related to using metallic sodium as a coolant. In case of a breach, sodium explosively reacts with water. Fixing breaches may also prove dangerous, as the noble gas argon is also used to prevent sodium oxidation. Argon is an asphyxiant, so workers may be exposed to this additional risk. This is a pertinent problem as can be testified by the events at the Prototype Fast Breeder Reactor Monju at Tsuruga, Japan.

3.3 Nuclear Fuel Management

Nuclear fuel management [40] involves making the following decisions: the quantity and attributes of the fresh fuel assemblies that will be purchased, the partially burnt fuel assemblies that will be reinserted, the locations of both the fresh and partially burnt fuel assemblies within the core, i.e. core loading pattern (LP), and for a boiling water reactors the control rod program/core flow (CRP/CF) strategy. These decisions need to be made for each reload cycle. Since fuel assemblies are irradiated several core cycles, the nuclear fuel management decisions made for the current cycle will impact those made in subsequent cycles. The objective of nuclear fuel management is to minimize the nuclear fuel cycle cost while satisfying the cycle energy requirement. This must be done such that all safety and operational constraints are satisfied with sufficient margin.

It consists of steps in the front end, which are the preparation of the fuel, steps in the service period in which the fuel is used during reactor operation, and steps in the back end, which are necessary to safely manage, contain, and either reprocess or dispose of spent nuclear fuel. If spent fuel is not reprocessed, the fuel cycle is referred to as an open fuel cycle (or a once-through fuel cycle); if the spent fuel is reprocessed, it is referred to as a closed fuel cycle. Bangladesh is planning to adopt an open fuel cycle policy.

Fig 3.11: Nuclear Fuel Cycle

3.3.1 Fundamental conception:

Nuclear power relies on fissionable material that can sustain a chain reaction with neutrons. Examples of such materials include uranium and plutonium. Most nuclear reactors use a moderator to lower the kinetic energy of the neutrons and increase the probability that fission will occur. This allows reactors to use material with far lower concentration of fissile isotopes than nuclear weapons. Graphite and heavy water are the most effective moderators, because they slow the neutrons through collisions without absorbing them.

Reactors using heavy water or graphite as the moderator can operate using natural uranium. A Light water reactor (LWR) uses water in the form that occurs in nature, and require fuel that is enriched in fissile isotopes, typically uranium enriched to 3-5% in the less common isotope U-235, the only fissile isotope that is found in significant quantity in nature.

One alternative to this low-enriched uranium (LEU) fuel are Mixed Oxide (MOX) fuels produced by blending plutonium with natural or depleted uranium, and these fuels provide an avenue to utilize surplus weapons-grade plutonium. Another type of MOX fuel involves mixing LEU with thorium, which generates the fissile isotope U-233. Both plutonium and U-233 are produced from the absorption of neutrons by irradiating fertile materials in a reactor, in particular the common uranium isotope U-238 and thorium, respectively, and can be separated from spent uranium and thorium fuels in reprocessing plants.

Some reactors do not use moderators to slow the neutrons. Like nuclear weapons, which also use un moderated or "fast" neutrons, these Fast-neutron reactors require much higher concentrations of fissile isotopes in order to sustain a chain reaction. They are also capable of breeding fissile isotopes from fertile materials; a Breeder reactor is one that generates more fissile material in this way than it consumes.

During the nuclear reaction inside a reactor, the fissile isotopes in nuclear fuel are consumed, producing more and more fission products, most of which are considered radioactive waste. The buildup of fission products and consumption of fissile isotopes eventually stop the nuclear reaction, causing the fuel to become a spent nuclear fuel. When 3% enriched LEU fuel is used, the spent fuel typically consists of roughly 1% U235, 95% U-238, 1% plutonium and 3% fission products. Spent fuel and other high-level radioactive waste is extremely hazardous, although nuclear reactors produce relatively small volumes of waste compared to other power plants because of the high energy density of nuclear fuel. Safe management of these byproducts of nuclear power, including their storage and disposal, is a difficult problem for any country using nuclear power.

Radioactive wastes are wastes that contain radioactive material. Radioactive

wastes are usually by-products of nuclear power generation and other applications of 49

nuclear fission or nuclear technology, such as research and medicine. Radioactive waste is hazardous to most forms of life and the environment, and is regulated by government agencies in order to protect human health and the environment.

Radioactivity diminishes over time, so waste is typically isolated and stored for a period of time until it no longer poses a hazard. The period of time waste must be stored depends on the type of waste. Low-level waste with low levels of radioactivity per mass or volume (such as some common medical or industrial radioactive wastes) may need to be stored for only hours or days while high-level wastes (such as spent nuclear fuel or byproducts of nuclear reprocessing) must be stored for a year or more.

Current major approaches to managing radioactive waste have been segregation and storage for short-lived wastes, near-surface disposal for low and some intermediate level wastes, and deep burial or transmutation for the high-level wastes.

A summary of the amounts of radioactive wastes and management approaches for most developed countries are presented and reviewed periodically as part of the International Atomic Energy Agency (IAEA) Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management.[41]

Exploration:

A deposit of uranium, such as uraninite, discovered by geophysical techniques, is evaluated and sampled to determine the amounts of uranium materials that are extractable at specified costs from the deposit. Uranium reserves are the amounts of ore that are estimated to be recoverable at stated costs. Uranium in nature consists primarily of two isotopes, U-238 and U-235. The numbers refer to the atomic mass number for each isotope, or the number of protons and neutrons in the atomic nucleus. Naturally occurring uranium consists of approximately 99.28% U-238 and 0.71% U-235. The atomic nucleus of U-235 will nearly always fission when struck by a free neutron, and the isotope is therefore said to be a "fissile" isotope. The nucleus of a U-238 atom on the other hand, rather than undergoing fission when struck by a free neutron, will nearly always absorb the neutron and yield an atom of the isotope U-239. This isotope then undergoes natural radioactive decay to yield Pu-239, which, like U-235, is a fissile isotope. The atoms of

U-238 are said to be fertile, because, through neutron irradiation in the core, some eventually yield atoms of fissile Pu-239.

3.3.2 Mining:

Uranium ore can be extracted through conventional mining in open pit and underground methods similar to those used for mining other metals. In-situ leach mining methods also are used to mine uranium in the United States.

Fig 3.12: A Uranium Mine

In this technology, uranium is leached from the in-place ore through an array of regularly spaced wells and is then recovered from the leach solution at a surface plant. Uranium ores in the United States typically range from about 0.05 to 0.3% uranium oxide (U3O8). Some uranium deposits developed in other countries are of higher grade and are also larger than deposits mined in the United States. Uranium is also present in very low-grade

amounts (50 to 200 parts per million) in some domestic phosphate-bearing deposits of marine origin. Because very large quantities of phosphate-bearing rock are mined for the production of wet-process phosphoric acid used in high analysis fertilizers and other phosphate chemicals, at some phosphate processing plants the uranium, although present in very low concentrations, can be economically recovered from the process stream.

3.3.3 Milling

Mined uranium ores normally are processed by grinding the ore materials to a uniform particle size and then treating the ore to extract the uranium by chemical leaching. The milling process commonly yields dry powder-form material consisting of natural uranium, "yellowcake", which is sold on the uranium market as U3O8.

3.3.4 Uranium conversion

Milled uranium oxide, U3O8, must be converted to uranium hexafluoride, UF6, which is the form required by most commercial uranium enrichment facilities currently in use. A solid at room temperature, uranium hexafluoride can be changed to a gaseous form at moderately higher temperature of 57 °C (134 °F). The uranium hexafluoride conversion product contains only natural, not enriched, uranium. Triuranium octaoxide (U3O8) is also converted directly to ceramic grade uranium dioxide (UO2) for use in reactors not requiring enriched fuel, such as CANDU. The volumes of material converted directly to UO2 are typically quite small compared to the amounts converted to UF6.

Fig 3.13: Technicians working in a uranium conversion facility

3.3.4 Enrichment

The concentration of the fissionable isotope, U-235 (0.71% in natural uranium) is less than that required to sustain a nuclear chain reaction in light water reactor cores. Natural UF6 thus must be enriched in the fissionable isotope for it to be used as nuclear fuel. The different levels of enrichment required for a particular nuclear fuel application are specified by the customer: light-water reactor fuel normally is enriched to 3.5% U235, but uranium enriched to lower concentrations is also required. Enrichment is accomplished using one or more methods of isotope separation.

Gaseous diffusion and gas centrifuge are the commonly used uranium enrichment technologies, but new enrichment technologies are currently being developed. The bulk (96%) of the byproduct from enrichment is depleted uranium (DU), which can be used for armor, kinetic energy penetrators, radiation shielding and ballast. Still, there are vast

quantities of depleted uranium in storage. The United States Department of Energy alone has 470,000 tones.[41]

About 95% of depleted uranium is stored as uranium hexafluoride (UF6). Fabrication Nuclear fuel cycle 4 for use as nuclear fuel, enriched uranium hexafluoride is converted into uranium dioxide (UO2) powder that is then processed into pellet form. The pellets are then fired in a high temperature sintering furnace to create hard, ceramic pellets of enriched uranium. The cylindrical pellets then undergo a grinding process to achieve a uniform pellet size. The pellets are stacked, according to each nuclear reactor core's design specifications, into tubes of corrosion-resistant metal alloy. The tubes are sealed to contain the fuel pellets: these tubes are called fuel rods. The finished fuel rods are grouped in special fuel assemblies that are then used to build up the nuclear fuel core of a power reactor.

The alloy used for the tubes depends on the design of the reactor. Stainless steel was used in the past, but most reactors now use a zirconium alloy. For the most common types of reactors, boiling water reactors (BWR) and pressurized water reactors (PWR), the tubes are assembled into bundles with the tubes spaced precise distances apart. These bundles are then given a unique identification number, which enables them to be tracked from manufacture through use and into disposal.

Fig 3.14: Uranium enrichment process

3.3.5 Transport of radioactive materials

Transport is an integral part of the nuclear fuel cycle. There are nuclear power reactors in operation in several countries but uranium mining is viable in only a few areas. Also, in the course of over forty years of operation by the nuclear industry, a number of specialized facilities have been developed in various locations around the world to provide fuel cycle services and there is a need to transport nuclear materials to and from these facilities.

Most transports of nuclear fuel material occur between different stages of the cycle, but occasionally a material may be transported between similar facilities. With some exceptions, nuclear fuel cycle materials are transported in solid form, the exception being uranium hexafluoride (UF6) which is considered a gas. Most of the material used in nuclear fuel is transported several times during the cycle. Transports are frequently international, and are often over large distances. Nuclear materials are generally transported by specialized transport companies. Since nuclear materials are radioactive, it is important to ensure that radiation exposure of both those involved in the transport of such materials and the general public along transport routes is limited. Packaging for nuclear materials includes, where appropriate, shielding to reduce potential radiation

exposures.

In the case of some materials, such as fresh uranium fuel assemblies, the radiation levels are negligible and no shielding is required. Other materials, such as spent fuel and high-level waste, are highly radioactive and require special handling. To limit the risk in transporting highly radioactive materials, containers known as spent nuclear fuel shipping casks are used which are designed to maintain integrity under normal transportation conditions and during hypothetical accident conditions. In-core fuel management A nuclear reactor core is composed of a few hundred "assemblies", arranged in a regular array of cells, each cell being formed by a fuel or control rod surrounded, in most designs, by a moderator and coolant, which is water in most reactors.

Because of the fission process that consumes the fuels, the old fuel rods must be changed periodically to fresh ones (this period is called a cycle). However, only a part of the assemblies (typically one-third) are removed since the fuel depletion is not spatially 55

uniform. Furthermore, it is not a good policy, for efficiency reasons, to put the new assemblies exactly at the location of the removed ones. Even bundles of the same age may have different burn-up levels, which depends on their previous positions in the core. Thus the available bundles must be arranged in such a way that the yield is maximized, while safety limitations and operational constraints are satisfied. Consequently reactor operators are faced with the so-called optimal fuel reloading problem, which consists in optimizing the rearrangement of all the assemblies, the old and fresh ones, while still maximizing the reactivity of the reactor core so as to maximize fuel burn-up and minimize fuel-cycle costs. Nuclear fuel cycle 5 This is a discrete optimization problem, and computationally infeasible by current combinatorial methods, due to the huge number of permutations and the complexity of each computation. Many numerical methods have been proposed for solving it and many commercial software packages have been written to support fuel management. This is an on-going issue in reactor operations as no definitive solution to this problem has been found. Operators use a combination of computational and empirical techniques to manage this problem.

Radioactive waste typically comprises a number of radioisotopes: unstable configurations of elements that decay, emitting ionizing radiation which can be harmful to humans and the environment. Those isotopes emit different types and levels of radiation, which last for different periods of time. The radioactivity of all nuclear waste diminishes with time. All radioisotopes contained in the waste have a half-life—the time it takes for any radionuclide to lose half of its radioactivity—and eventually all radioactive waste decays into nonradioactive elements (i.e., stable isotopes). Certain radioactive elements (such as plutonium239) in “spent” fuel will remain hazardous to humans and other creatures for hundreds or thousands of years. Other radioisotopes remain hazardous for millions of years. Thus, these wastes must be shielded for centuries and isolated from the living environment for millennia.[42] Since radioactive decay follows the half-life rule, the rate of decay is inversely proportional to the duration of decay. In other words, the radiation from a long-lived isotope like iodine-129 will be much less intense than that of a short-lived isotope like iodine-131.[43]

The two tables show some of the major radioisotopes, their half-lives, and their radiation yield as a proportion of the yield of fission of uranium-235.

The energy and the type of the ionizing radiation emitted by a radioactive substance are also important factors in determining its threat to humans.[44] The chemical properties of the radioactive element will determine how mobile the substance is and how likely it is to spread into the environment and contaminate humans.[45] This is further complicated by the fact that many radioisotopes do not decay immediately to a stable state but rather to radioactive decay products within a decay chain before ultimately reaching a stable state.

3.3.7 The way of producing radioactive waste from Nuclear Power

Plant

Front end:

Waste from the front end of the nuclear fuel cycle is usually alpha-emitting waste from the extraction of uranium. It often contains radium and its decay products. Uranium dioxide (UO2) concentrate from mining is not very radioactive - only a thousand or so times as radioactive as the granite used in buildings. It is refined from yellowcake (U3O8), then converted to uranium hexafluoride gas (UF6). As a gas, it undergoes enrichment to increase the U-235 content from 0.7% to about 4.4% (LEU). It is then turned into a hard ceramic oxide (UO2) for assembly as reactor fuel elements.[46]

The main by-product of enrichment is depleted uranium (DU), principally the U238 isotope, with a U-235 content of ~0.3%. It is stored, either as UF6 or as U3O8. Some is used in applications where its extremely high density makes it valuable, such as the keels of yachts, and anti-tank shells.[47]

It is also used with plutonium for making mixed oxide fuel (MOX) and to dilute, or down blend, highly enriched uranium from weapons stockpiles which is now being redirected to become reactor fuel.

Back end:

The back end of the nuclear fuel cycle, mostly spent fuel rods, contains fission products that emit beta and gamma radiation, and actinides that emit alpha particles, such as uranium234, neptunium-237, plutonium-238 and americium-241, and even sometimes some neutron emitters such as californium (Cf). These isotopes are formed in nuclear reactors.

It is important to distinguish the processing of uranium to make fuel from the reprocessing of used fuel. Used fuel contains the highly radioactive products of fission (see high level waste below). Many of these are neutron absorbers, called neutron poisons in this context. These eventually build up to a level where they absorb so many neutrons that the chain reaction stops, even with the control rods completely removed. At that point the fuel has to be replaced in the reactor with fresh fuel, even though there is still a substantial quantity of uranium-235 and plutonium present. In the United States, this used fuel is stored, while in countries such as Russia, the United Kingdom, France, Japan and India, the fuel is reprocessed to remove the fission products, and the fuel can then be re-used. This reprocessing involves handling highly radioactive materials, and the fission products removed from the fuel are a concentrated form of high-level waste as are the chemicals used in the process. While these countries reprocess the fuel carrying out single plutonium cycles, India is the only country known to be planning multiple plutonium recycling schemes.[48]

3.3.8 Fuel composition and long term radioactivity

Long-lived radioactive waste from the back end of the fuel cycle is especially relevant when designing a complete waste management plan for spent nuclear fuel (SNF). When looking at long term radioactive decay, the actinides in the SNF have a significant influence due to their characteristically long half-lives. Depending on what a nuclear reactor is fueled with, the actinide composition in the SNF will be different.

An example of this effect is the use of nuclear fuels with thorium. Th-232 is a fertile material that can undergo a neutron capture reaction and two beta minus decays, resulting in the production of fissile U-233. The SNF of a cycle with thorium will contain

U-233. Its radioactive decay will strongly influence the long-term activity curve of the SNF around 1 million years. A comparison of the activity associated to U-233 for three different SNF types can be seen in the figure on the top right. The burnt fuels are thorium with reactor-grade plutonium (RGPu), thorium with weapons-grade plutonium (WGPu) and Mixed Oxide fuel (MOX). For RGPu and WGPu, the initial amount of U-233 and its decay around 1 million years can be seen. This has an effect in the total activity curve of the three fuel types.

The absence of U-233 and its daughter products in the MOX fuel results in a lower activity in region 3 of the figure on the bottom right, whereas for RGPu and WGPu the curve is maintained higher due to the presence of U-233 that has not fully decayed.

The use of different fuels in nuclear reactors results in different SNF composition, with varying activity curves.

3.3.9 Classification of radioactive waste

Classifications of nuclear waste varies by country. The IAEA, which publishes the Radioactive Waste Safety Standards (RADWASS), also plays a significant role.[49]

Uranium tailings:

Uranium tailings are waste by-product materials left over from the rough processing of uranium-bearing ore. They are not significantly radioactive. Mill tailings are sometimes referred to as 11(e)2 wastes, from the section of the Atomic Energy Act of 1946 that defines them. Uranium mill tailings typically also contain chemically hazardous heavy metal such as lead and arsenic. Vast mounds of uranium mill tailings are left at many old mining sites, especially in Colorado, New Mexico, and Utah.

Low-level waste:

Low level waste (LLW) is generated from hospitals and industry, as well as the nuclear fuel cycle. Low-level wastes include paper, rags, tools, clothing, filters, and other materials which contain small amounts of mostly short-lived radioactivity. Materials that

originate from any region of an Active Area are commonly designated as LLW as a precautionary measure even if there is only a remote possibility of being contaminated with radioactive materials. Such LLW typically exhibits no higher radioactivity than one would expect from the same material disposed of in a non-active area, such as a normal office block. Some high-activity LLW requires shielding during handling and transport but most LLW is suitable for shallow land burial. To reduce its volume, it is often compacted or incinerated before disposal. Low-level waste is divided into four classes: class A, class B, class C, and Greater Than Class C (GTCC)

Intermediate-level waste:

Intermediate-level waste (ILW) contains higher amounts of radioactivity and in some cases requires shielding. Intermediate-level wastes includes resins, chemical sludge and metal reactor nuclear fuel cladding, as well as contaminated materials from reactor decommissioning. It may be solidified in concrete or bitumen for disposal.

As a general rule, short-lived waste (mainly non-fuel materials from reactors) is buried in shallow repositories, while long-lived waste (from fuel and fuel reprocessing) is deposited in geological repository. U.S. regulations do not define this category of waste; the term is used in Europe and elsewhere.

Removal of low-level waste

Modern medium to high level transport container for nuclear waste Fig 3.15: Nuclear waste removal

High-level waste:

High-level waste (HLW) is produced by nuclear reactors. It contains fission products and transuranic elements generated in the reactor core. It is highly radioactive and often thermally hot. HLW accounts for over 95 percent of the total radioactivity produced in the process of nuclear electricity generation. The amount of HLW worldwide is currently increasing by about 12,000 metric tons every year, which is the equivalent to about 100 double-decker buses or a two-story structure with a footprint the size of a basketball court.[50] A 1000-MW nuclear power plant produces about 27 tones of spent nuclear fuel (un reprocessed) every year.[51]

Transuranic waste:

Transuranic waste (TRUW) as defined by U.S. regulations is, without regard to form or origin, waste that is contaminated with alpha-emitting transuranic radionuclides with half-lives greater than 20 years and concentrations greater than 100 nCi/g (3.7 MBq/kg), excluding high-level waste. Elements that have an atomic number greater than uranium are called transuranic ("beyond uranium"). Because of their long half-lives, TRUW is disposed more cautiously than either low- or intermediate-level waste. In the U.S., it arises mainly from weapons production, and consists of clothing, tools, rags, residues, debris and other items contaminated with small amounts of radioactive elements (mainly plutonium). Under U.S. law, transuranic waste is further categorized into "contact-handled" (CH) and "remote-handled" (RH) on the basis of radiation dose measured at the surface of the waste container. CH TRUW has a surface dose rate not

greater than 200 Roentgen equivalent man per hour (to millisievert/hr), whereas RH TRUW has a surface dose rate of 200 Rontgen equivalent man per hour (2 mSv/h) or greater.

CH TRUW does not have the very high radioactivity of high-level waste, nor its high heat generation, but RH TRUW can be highly radioactive, with surface dose rates up to 1000000 Rontgen equivalent man per hour (10000 mSv/h). The U.S. currently disposes of TRUW generated from military facilities at the Waste Isolation Pilot Plant.[52]

3.3.10 Prevention of waste

A theoretical way to reduce waste accumulation is to phase out current reactors in favour of Generation IV Reactors or Liquid Fluoride Thorium Reactors, which output less waste per power generated. Fast reactors can theoretically consume some existing waste, but the UK's Nuclear Decommissioning Authority described this technology as immature and commercially unproven, and unlikely to start before 2050.[54]

3.3.11 Management of waste

Of particular concern in nuclear waste management are two long-lived fission products, Tc-99 (half-life 220,000 years) and I-129 (half-life 17 million years), which dominate spent fuel radioactivity after a few thousand years. The most troublesome transuranic elements in spent fuel are Np-237 (half-life two million years) and Pu-239 (half-life 24,000 years).[55] Nuclear waste requires sophisticated treatment and management to successfully isolate it from interacting with the biosphere. This usually necessitates treatment, followed by a long-term management strategy involving storage, disposal or transformation of the waste into a non-toxic form.[56] Governments around the world are considering a range of waste management and disposal options, though there has been limited progress toward long-term waste management solutions.[57]

Fig3.16: Nuclear waste disposal pool

In second half of 20th century, several methods of disposal of radioactive waste were investigated by nuclear nations.[58] Which are;

• "Long term above ground storage", not implemented.

• "Disposal in outer space", not implemented.

• "Deep borehole disposal", not implemented.

• "Rock-melting", not implemented.

• "Disposal at subduction zones", not implemented.

• "Ocean disposal", done by USSR, UK, Switzerland, USA, Belgium, France, Netherland,

Japan, Sweden, Russia, Germany, Italy and South Korea. (1954–93) It's not permitted by international agreements.

• "Sub seabed disposal", not implemented, not permitted by international agreements.

• "Disposal in ice sheets", rejected in Antarctic Treaty

• "Direct injection", done by USSR and USA.

3.3.11 Initial treatment of waste

Vitrification:

Long-term storage of radioactive waste requires the stabilization of the waste into a form which will neither react nor degrade for extended periods of time. One way to do this is through vitrification.[59] Currently at Sellafield the high-level waste (PUREX first cycle raffinate) is mixed with sugar and then calcined. Calcination involves passing the waste through a heated, rotating tube. The purposes of calcination are to evaporate the water from the waste, and de-nitrate the fission products to assist the stability of the glass produced.[60] The 'calcine' generated is fed continuously into an induction heated furnace with fragmented glass.[61] The resulting glass is a new substance in which the waste products are bonded into the glass matrix when it solidifies. This product, as a melt, is poured into stainless steel cylindrical containers ("cylinders") in a batch process. When cooled, the fluid solidifies ("vitrifies") into the glass. Such glass, after being formed, is highly resistant to water.[62] After filling a cylinder, a seal is welded onto the cylinder. The cylinder is then washed. After being inspected for external contamination, the steel cylinder is stored, usually in an underground repository. In this form, the waste products are expected to be immobilized for a long period of time (many thousands of years).[63]

The glass inside a cylinder is usually a black glossy substance. All this work (in the United Kingdom) is done using hot cell systems. The sugar is added to control the ruthenium chemistry and to stop the formation of the volatile RuO4 containing radioactive ruthenium isotopes. In the west, the glass is normally a borosilicate glass (similar to Pyrex), while in the former Soviet bloc it is normal to use a phosphate glass.[64] The amount of fission products in the glass must be limited because some (palladium, the other Pt group metals, and tellurium) tend to form metallic phases which separate from the glass. Bulk vitrification uses electrodes to melt soil

and wastes, which are then buried underground.[65] In Germany a vitrification plant is in use; this is treating the waste from a small demonstration reprocessing plant which has since been closed down.[66] Fig 3.17: Virtification process

The glass inside a cylinder is usually a black glossy substance. All this work (in the United Kingdom) is done using hot cell systems. The sugar is added to control the ruthenium chemistry and to stop the formation of the volatile RuO4 containing radioactive ruthenium isotopes. In the west, the glass is normally a borosilicate glass (similar to Pyrex), while in the former Soviet bloc it is normal to use a phosphate glass.[67] The amount of fission products in the glass must be limited because some (palladium, the other Pt group metals, and tellurium) tend to form metallic phases which separate from the glass. Bulk vitrification uses electrodes to melt soil and wastes, which are then buried

underground.[25] In Germany a vitrification plant is in use; this is treating the waste from a small demonstration reprocessing plant which has since been closed down.[68]

Ion exchange:

It is common for medium active wastes in the nuclear industry to be treated with ion exchange or other means to concentrate the radioactivity into a small volume. The much less radioactive bulk (after treatment) is often then discharged. For instance, it is possible to use a ferric hydroxide floc to remove radioactive metals from aqueous mixtures.[69]

After the radioisotopes are absorbed onto the ferric hydroxide, the resulting sludge can be placed in a metal drum before being mixed with cement to form a solid waste form.[70] In order to get better long-term performance (mechanical stability) from such forms, they may be made from a mixture of fly ash, or blast furnace slag, and Portland cement, instead of normal concrete (made with Portland cement, gravel and sand).

Synroc:

The Australian Synroc (synthetic rock) is a more sophisticated way to immobilize such waste, and this process may eventually come into commercial use for civil wastes (it is currently being developed for US military wastes). Synroc was invented by the late Prof Ted Ringwood (a geochemist) at the Australian National University.[71] The Synroc contains pyrochlore and cryptomelane type minerals. The original form of Synroc (Synroc C) was designed for the liquid high level waste (PUREX raffinate) from a light water reactor. The main minerals in this Synroc are hollandite (BaAl2Ti6O16), zirconolite (CaZrTi2O7) and perovskite (CaTiO3). The zirconolite and perovskite arehosts for the actinides. The strontium and barium will be fixed in the perovskite. The caesium will be fixed in the hollandite.

Long term management of waste:

The time frame in question when dealing with radioactive waste ranges from 10,000 to 1,000,000 years,[72] according to studies based on the effect of estimated radiation doses.[31] Researchers suggest that forecasts of health detriment for such

periods should be examined critically] Practical studies only consider up to 100 years as far as effective planning[73] and cost evaluations[74] are concerned.

Long term behavior of radioactive wastes remains a subject for ongoing research projects in geoforecasting. Above-ground disposal Dry cask storage typically involves taking waste from a spent fuel pool and sealing it (along with an inert gas) in a steel cylinder, which is placed in a concrete cylinder which acts as a radiation shield. It is a relatively inexpensive method which can be done at a central facility or adjacent to the source reactor. The waste can be easily retrieved for reprocessing.

Geologic disposal:

The process of selecting appropriate deep final repositories for high level waste and spent fuel is now under way in several countries with the first expected to be commissioned some time after 2010. The basic concept is to locate a large, stable geologic formation and use mining technology to excavate a tunnel, or large-bore tunnel boring machines (similar to those used to drill the Channel Tunnel from England to France) to drill a shaft 500 meters (1,600 ft) to 1,000 meters (3,300 ft) below the surface where rooms or vaults can be excavated for disposal of high-level radioactive waste. The goal is to permanently isolate nuclear waste from the human environment. Many people remain uncomfortable with the immediate stewardship cessation of this disposal system, suggesting perpetual management and monitoring would be more prudent.

Because some radioactive species have half-lives longer than one million years, even very low container leakage and radionuclide migration rates must be taken into account.[75] Moreover, it may require more than one half-life until some nuclear materials lose enough radioactivity to cease being lethal to living things. A 1983 review of the Swedish radioactive waste disposal program by the National Academy of Sciences found that country’s estimate of several hundred thousand years—perhaps up to one million years—being necessary for waste isolation “fully justified.”[76] Aside from dilution, chemically toxic stable elements in some waste such as arsenic remain toxic for up to billions of years or indefinitely.[77] Sea-based options for disposal of radioactive waste[77] include burial beneath a stable abyssal plain, burial in a subduction zone that would slowly carry the waste downward into the Earth's mantle and burial beneath a 67

remote natural or human-made island. While these approaches all have merit and would facilitate an international solution to the problem of disposal of radioactive waste, they would require an amendment of the Law of the Sea.[78] Article 1 (Definitions), 7., of the 1996 Protocol to the Convention on the Prevention of Marine Pollution by Dumping of Wastes and Other Matter, (the London Dumping Convention) states: “Sea” means all

marine waters other than the internal waters of States, as well as the seabed and the subsoil thereof; it does not include sub-seabed repositories accessed only from land.” The

proposed land-based subductive waste disposal method disposes of nuclear waste in a subduction zone accessed from land,[79] and therefore is not prohibited by international agreement. This method has been described as the most viable means of disposing of radioactive waste,[80] and as the state-of-the-art as of 2001 in nuclear waste disposal technology.[81] Another approach termed Remix & Return would blend high-level waste with uranium mine and mill tailings down to the level of the original radioactivity of the uranium ore, then replace it in inactive uranium mines. This approach has the merits of providing jobs for miners who would double as disposal staff, and of facilitating a cradleto-grave cycle for radioactive materials, but would be inappropriate for spent reactor fuel in the absence of reprocessing, due to the presence in it of highly toxic radioactive elements such as plutonium. Deep borehole disposal is the concept of disposing of highlevel radioactive waste from nuclear reactors in extremely deep boreholes. Deep borehole disposal seeks to place the waste as much as 5 kilometers (3.1 mi) beneath the surface of the Earth and relies primarily on the immense natural geological barrier to confine the waste safely and permanently so that it should never pose a threat to the environment. The Earth's crust contains 120 trillion tons of thorium and 40 trillion tons of uranium

(primarily at relatively trace concentrations of parts per million each adding up over the crust's 3 * 1019 ton mass), among other natural radioisotopes. Since the fraction of nuclides decaying per unit of time is inversely proportional to an isotope's half-life, the relative radioactivity of the lesser amount of human-produced radioisotopes (thousands of tons instead of trillions of tons) would diminish once the isotopes with far shorter halflives than the bulk of natural radioisotopes decayed.

Fig 3.18: Yucca Mountain Nuclear Waste Repository of US

Transmutation:

There have been proposals for reactors that consume nuclear waste and transmute it to other, less-harmful nuclear waste. In particular, the Integral Fast Reactor was a proposed nuclear reactor with a nuclear fuel cycle that produced no transuranic waste and in fact, could consume transuranic waste. It proceeded as far as large-scale tests, but was then canceled by the US Government. Another approach, considered safer but requiring more development, is to dedicate subcritical reactors to the transmutation of the left-over transuranic elements.

An isotope that is found in nuclear waste and that represents a concern in terms of proliferation is Pu-239. The estimated world total of plutonium in the year 2000 was of 1,645 MT, of which 210 MT had been separated by reprocessing. The large stock of plutonium is a result of its production inside uranium-fueled reactors and of the reprocessing of weapons-grade plutonium during the weapons program. An option for getting rid of this plutonium is to use it as a fuel in a traditional Light Water Reactor (LWR). Several fuel types with differing plutonium destruction efficiencies are under study. Transmutation was banned in the US in April 1977 by President Carter due to the

danger of plutonium proliferation,[81] but President Reagan rescinded the ban in 1981.[53] Due to the economic losses and risks, construction of reprocessing plants during this time did not resume. Due to high energy demand, work on the method has continued in the EU. This has resulted in a practical nuclear research reactor called Myrrha in which transmutation is possible. Additionally, a new research program called ACTINET has been started in the EU to make transmutation possible on a large, industrial scale.

According to President Bush's Global Nuclear Energy Partnership (GNEP) of 2007, the US is now actively promoting research on transmutation technologies needed to markedly reduce the problem of nuclear waste treatment.[82]

There have also been theoretical studies involving the use of fusion reactors as so called "actinide burners" where a fusion reactor plasma such as in a Tokamak, could be "doped" with a small amount of the "minor" transuranic atoms which would be transmuted (meaning fissioned in the actinide case) to lighter elements upon their successive bombardment by the very high energy neutrons produced by the fusion of deuterium and tritium in the reactor. A study at MIT found that only 2 or 3 fusion reactors with parameters similar to that of the International Thermonuclear Experimental Reactor (ITER) could transmute the entire annual minor actinide production from all of the light water reactors presently operating in the United States fleet while simultaneously generating approximately 1 gigawatt of power from each reactor.[83] Re-use of waste Another option is to find applications for the isotopes in nuclear waste so as to re-use them.[56] Already, caesium-137, strontium-90 and a few other isotopes are extracted for certain industrial applications such as food irradiation and radioisotope thermoelectric generators. While re-use does not eliminate the need to manage radioisotopes, it reduces the quantity of waste produced.

The Nuclear Assisted Hydrocarbon Production Method,[84] Canadian patent application 2,659,302, is a method for the temporary or permanent storage of nuclear waste materials comprising the placing of waste materials into one or more repositories or boreholes constructed into an unconventional oil formation. The thermal flux of the

waste materials fracture the formation, alters the chemical and/or physical properties of

hydrocarbon material within the subterranean formation to allow removal of the altered material. A mixture of hydrocarbons, hydrogen, and/or other formation fluids are produced from the formation. The radioactivity of high-level radioactive waste affords proliferation resistance to plutonium placed in the periphery of the repository or the deepest portion of a borehole. Breeder reactors can run on U-238 and transuranic elements, which comprise the majority of spent fuel radioactivity in the 1000-100000 year time span.

Space disposal:

Space disposal is attractive because it permanently removes nuclear waste from the environment. It has significant disadvantages, such as the potential for catastrophic failure of a launch vehicle, which could spread radioactive material into the atmosphere and around the world. A high number of launches would be required because no individual rocket would be able to carry very much of the material relative to the total amount that needs to be disposed of. This makes the proposal impractical economically and it increases the risk of at least one or more launch failures.[86] To further complicate matters, international agreements on the regulation of such a program would need to be established.[85] Costs and inadequate reliability of modern rocket launch systems for space disposal has been one of the motives for interest in non-rocket space launch systems such as mass drivers, space elevators, and other proposals.

3.3.12 National management plans

Most countries are considerably ahead of the United States in developing plans for high-level radioactive waste disposal. Sweden and Finland are furthest along in committing to a particular disposal technology, while many others reprocess spent fuel or contract with France or Great Britain to do it, taking back the resulting plutonium and high-level waste. “An increasing backlog of plutonium from reprocessing is developing

in many countries... It is doubtful that reprocessing makes economic sense in the present environment of cheap uranium.”[86]

In many European countries (e.g., Britain, Finland, the Netherlands, Sweden and Switzerland) the risk or dose limit for a member of the public exposed to radiation from a future high-level nuclear waste facility is considerably more stringent than that suggested by the International Commission on Radiation Protection or proposed in the United States. European limits are often more stringent than the standard suggested in 1990 by the International Commission on Radiation Protection by a factor of 20, and more stringent by a factor of ten than the standard proposed by the US Environmental Protection Agency (EPA) for Yucca Mountain nuclear waste repository for the first 10,000 years after closure.[88]

The U.S. EPA’s proposed standard for greater than 10,000 years is 250 times more

permissive than the European limit.[89] The U.S. EPA proposed a legal limit of a maximum of 3.5 milli-Sieverts (350 millirem) each annually to local individuals after 10,000 years, which would be up to several percent of the exposure currently received by some populations in the highest natural background regions on Earth, though the U.S. DOE predicted that received dose would be much below that limit.[89] Over a timeframe of thousands of years, after the most active short half-life radioisotopes decayed, burying U.S. nuclear waste would increase the radioactivity in the top 2000 feet of rock and soil in the United States (10 million km2) by ≈ 1

part in 10 million over the cumulative amount of natural radioisotopes in such a volume, but the vicinity of the site would have a far higher concentration of artificial radioisotopes underground than such an average.[90]

3.3.13 Illegal dumping

Authorities in Italy are investigating a 'Ndrangheta mafia clan accused of trafficking and illegally dumping nuclear waste. According to a turncoat, a manager of the Italy’s state

energy research agency Enea paid the clan to get rid of 600 drums of toxic and radioactive waste from Italy, Switzerland, France, Germany, and the US, with Somalia as the destination, where the waste was buried after buying off local politicians. Former employees of Enea are suspected of paying the criminals to take waste off their hands in the 1980s and 1990s. Shipments to Somalia continued into the 1990s, while the 'Ndrangheta clan also blew up shiploads of waste, including radioactive hospital waste, and sending them to the sea bed off

the Calabrian coast. According to the environmental group Legambiente, former members of the 'Ndrangheta have said that they were paid to sink ships with radioactive material for the last 20 years.[91]

3.3.14 Accidents involving radioactive waste

A few incidents have occurred when radioactive material was disposed of improperly, shielding during transport was defective, or when it was simply abandoned or even stolen from a waste store.[92] In the Soviet Union, waste stored in Lake Karachay was blown over the area during a dust storm after the lake had partly dried out.[93] At Maxey Flat, a low-level radioactive waste facility located in Kentucky, containment trenches covered with dirt, instead of steel or cement, collapsed under heavy rainfall into the trenches and filled with water. The water that invaded the trenches became radioactive and had to be disposed of at the Maxey Flat facility itself. In other cases of radioactive waste accidents, lakes or ponds with radioactive waste accidentally overflowed into the rivers during exceptional storms. In Italy, several radioactive waste deposits let material flow into river water, thus contaminating water for domestic use.[94] In France, in the summer of 2008 numerous incidents happened;[95] in one, at the Areva plant in Tricastin, it was reported that during a draining operation, liquid containing untreated uranium overflowed out of a faulty tank and about 75 kg of the radioactive material seeped into the ground and, from there, into two rivers nearby;[96] in another case, over 100 staff were contaminated with low doses of radiation.[97]

Scavenging of abandoned radioactive material has been the cause of several other cases of radiation exposure, mostly in developing nations, which may have less regulation of dangerous substances (and sometimes less general education about radioactivity and its hazards) and a market for scavenged goods and scrap metal. The scavengers and those who buy the material are almost always unaware that the material is radioactive and it is selected for its aesthetics or scrap value.[98] Irresponsibility on the part of the radioactive material's owners, usually a hospital, university or military, and the absence of regulation concerning radioactive waste, or a lack of enforcement of such regulations, have been

significant factors in radiation exposures. For an example of an accident involving radioactive scrap originating from a hospital see the Goiania accident.[99]

Transportation accidents involving spent nuclear fuel from power plants are unlikely to have serious consequences due to the strength of the spent nuclear fuel shipping casks.[100] On 15 December 2011 top government spokesman Osamu Fujimura of the Japanese government admitted that nuclear substances were found in the waste of Japanese nuclear facilities. Although Japan did commit itself in 1977 to these inspections in the safeguard agreement with the IAEA, the reports were kept secret for the inspectors of the International Atomic Energy Agency. Japan did start discussions with the IAEA about the large quantities of enriched uranium and plutonium that were discovered in nuclear waste cleared away by Japanese nuclear operators.

At the press conference Fujimura said: "Based on investigations so far, most nuclear substances have been properly managed as waste, and from that perspective, there is no problem in safety management," But according to him, the matter was at that moment still being investigated.[101]

Chapter 4: Bangladesh Challenges

4.1. Estimated available energy

Bangladesh's per capita energy consumption is very low, the lowest within the Indian subcontinent. The 2008 energy consumption value stands at about 250 kgOE which is quite low compared to 550 kgOE for India, 515 kgOE for Pakistan, 430 kgOE for Sri Lanka, 475 kgOE (average) for South Asia and far below the world average of 1680 kgOE. Total primary energy consumption in 2008 was 33.50 MTOE and the energy consumption mix was estimated as: indigenous biomass 62%, indigenous natural gas 25%, imported oil 12% and imported coal and hydro combined about 1%. Two-thirds of the country's total population livel in rural areas, meeting most of their energy needs (domestic, commercial and industrial) from traditional biomass fuels. Various marketing companies under the Bangladesh Petroleum Corporation (BPC) distribute kerosene and diesel throughout the country at a uniform tariff rate set by the government. Around 32% have access to electricity, while in rural areas the availability of electricity is only 22%.

But the quality of service in rural areas is very poor: frequent outages, voltage fluctuations and unreliable and erratic supply. Only 34% of the households have natural gas connection for cooking purposes. Only about 23% households use kerosene for cooking and the rest (over 90%) depend on biomass. Contribution of biomass in total primary energy consumption of Bangladesh is around 60%. The major sources of traditional biomass are agricultural residues (45%), wood and wood wastes (35%) and animal dung (20%). Industrial and commercial use of biomass accounts for 14% of total energy consumption. 63% of energy required in the industrial sector comes from biomass fuel.

Primarily biomass and kerosene are used by a majority of households. Natural gas, liquefied petroleum gas (LPG), electricity, kerosene and biomass fuels are mainly used for cooking. In areas without natural gas and electricity, biomass is used to meet

household cooking needs. A good amount of bio energy is used for parboiling and space heating. A recent urban household survey estimated that consumption of biomass fuel is 319 kg per capita per year. Natural gas is currently the only indigenous non-renewable energy resource of the country and this has been continuously produced and consumed in significant quantities since 1970. Gas, the main source of commercial energy, plays a vital role in the economic growth of Bangladesh. The major consumers of gas are the power and fertiliser (using gas as feedstock) sectors, which account for 46.65% and 21.71% respectively.

The cumulative efforts for exploration of oil and gas resources in Bangladesh have resulted in the discovery of 22 gas fields of various sizes. According to the 2008 BP Statistical Energy Survey, Bangladesh had, in 2007, proven natural gas reserves of 0.39 trillion cubic meters (0.21% of the world total) with production for the year totalling 16.27 billion cubic meters (0.55% of the world total). Although the remaining recoverable gas reserve is enough for the time being, it is understood that there is significant field growth potential, as most of the state- owned gas fields have not yet been fully appraised.

Therefore, among the various renewable energy options, biomass energy might be the best choice for the electrification of rural Bangladesh.

4.1.1 Energy statistics

Average annual

growth rate (%) 2000 to

Energy consumption** 1980 1990 2000 2006 2008 2010 2010* - Total 0.17 0.33 0.5306 1.15 7 1.3724 1.5242 14.10 - Solids*** 0.007 0.01 0.015 0.01 0.168 0.171

- Liquids 0.07 70.08 0.173 6 0.19 - Gases 0.05 0.15 0.35 71 0.58 0.212 0.2186

0.633 0.762

- Nuclear 0.00 0.00 0.00 70.00 0.00 0.00

- Hydro+Wind 0.003 0.00 3

0.003 .003 - Other 0.00 0.00 0.00 3 0.35

Renewables 3 0.0034 0.0026

0.356 0.370

Energy production - Total 0.10 0.23 0.369 0.94 1.0338 1.1741

- Solids*** 0.00 0.00 0.00 30.00 0.0144 4 0.0395

- Liquids 0.00 0.00 0.00 0.00 0.00 40.00

- Gases 0.05 0.15 0.35 0.58 0.651 0.762

- Nuclear 0.00 0.00 0.00 70.00 0.00 0.00

- Hydro 0.01 0.01 0.003 .003 3 0.0034 0.0026 15.57

- Total * Year 2010 0.07 0.10 0.161 0.19 ** Energy consumption = Primary energy 0.1978 0.2431 5.28 consumption + Net import (Import TABLE 4.1 4 : ENERGY STATISTICS (All energy values are in Exa-Joule)

4.1.2 ENERGY POLICY

Presently, primary commercial energy resources include natural gas, oil, condensates, coal, peat and renewable energy resources. Biomass still plays an important role in the country’s energy consumption in the rural area. Government is actively

considering use of nuclear energy for electricity generation.

The appreciable commercial energy resources of the country are well-developed natural gas sector and undeveloped coal sector. Prevailing constraints in the indigenous commercial energy sources limit the scope of widening the range of possible long-term national energy supplies.

A long-term strategic plan is required for carrying out systematic exploration and proper appraisal of discoveries. Hydrocarbon resource assessment studies indicate good prospects for finding new hydrocarbon resources especially in the offshore and deep

sea areas.

In 2005-06 energy consumption was about 35 MTOE with biomass contributing 35% of the total energy. During 1999 – 2006, average annual increase of energy consumption was about 5%. In 2005-06 major commercial energy consumers were transport and household followed by agriculture, industry and commercial entities. During 1999 –2006 share of biomass in total energy consumption was decreasing although its quantity was increasing at an average rate of about 2% per annum. Consumption of LPG in households and coal in brickfields will be encouraged to reduce the use of biomass and thereby reducing deforestation.

Bangladesh is facing twin energy crises – an urban energy crisis characterized by power shortages and skyrocketing gas consumption and a rural energy crisis reflected in the increasing inability of the rural poor to have access even to low-valued traditional biomass. To overcome these crises, sector reforms and additional investments are urgently needed for accelerated development and thus improving basic livelihoods of urban and rural population.

Areas having prospects of finding uranium and thorium deposits are to be appraised and techno-economic feasibilities conducted at prospective sites.

An earlier energy planning effort led to the formulation of first National Energy Policy (NEP), 1996 which brought Government attention to the urgency of ensuring proper exploration, production, distribution and rational use of energy sources to meet the growing energy demand of the country. With the rapid changes in global as well as domestic conditions Energy & Mineral Resources Division (EMRD) has undertaken a comprehensive programme for updating the National Energy Policy. The proposed updated policy will describe the role that the energy sector must play in order to meet its obligations for sustainable development of the country. This policy will also focus on implementation mechanisms and procedures for tracking results to ensure that the policies are reflected in practice.

Priority will be given on diversification of available indigenous commercial energy resources with coal assuming a much expanded role in providing the country’s

future energy needs. The recoverable reserves of 4 (four) coalfields could range from 250 million to 900 million tons depending on the mining methods applied. Due attention will 78

be given for implementation of Nuclear Power Plant to cater to the future energy needs of the country. At the same time opportunity for regional energy trade will be explored to enhance energy security of the country.

The major issues causing slow development of the energy sector have been identified by Govt. and other agencies. Following remedial measures need to be taken to address those issues:

More emphasis needs to be given on hydrocarbon exploration and development by national companies as well as IOCs to meet the future demand of gas.

Dependence on natural gas is to be reduced by developing alternative sources of commercial energy. Gas and electricity consumption practices are to be improved by efficient management.

Transparent transaction of subsidies needs to be ensured through oversight regulatory body.

Massive investment is required to meet the growing energy demand.

Power supply shortages are to be addressed by establishing new power plants, and proper maintenance and rehabilitation of existing power plants.

Public-private partnership and/or joint ventures and private sector participation are to be further encouraged.

Institutional capacity is to be built through necessary legal and administrative reforms and intensive investment programmes.

Nuclear energy is to be introduced within the shortest possible time.

4.1.3 Strategic Goals

The overall goals of the energy sector are to:

Provide adequate and secure energy resources for all. Support socio-economic development.

Reduce poverty and ensure social equity. Provide sustainable energy mix. Promote rational use of energy. Improve sector management and performance. Increase private sector investment. Ensure balanced growth of east and west zone of the country. Promote regional energy markets.

4.1.4 Projected demand for electricity

In Bangladesh, the power supply has constantly remained strained in peak hours. Potential demands have not been met, and rotational outage has frequently occurred. The actual recorded maximum power has not included these potential demands. To estimate the maximum power that includes potential demands, PSMP 2006 adopts a method for calculating the generated power energy with which a compound daily load curve is produced by adding the evening peak demand for lighting, calculated from a daily load curve with no rotational outage on weekends and holidays in winter, to a daily load curve suppressed by rotational outage on weekdays in summer. By regressively analyzing the relation between the generated power energy calculated this way and the economic level indicated by the actual GDP and setting the load factor from a load curve that includes potential demands, PSMP 2006 estimates the maximum power energy. The following table shows the result of the forecast of power demands indicated in PSMP 2006.

In the first step of PSMP 2010, the power demand will be forecast using a similar method as that used in PSMP 2006. Since its independence in 1971, Bangladesh has striven to improve its socioeconomic conditions and grow its economy with support from domestic and international society. The average annual growth rate in the 14-year period from 1995 to 2008 was 5.6%. In the past three years, a high growth rate has been maintained since the stable and high growth of the mining and industrial sectors and the service sector has covered the low growth rate of the agricultural sector. The midterm macroeconomic framework of the Poverty Reduction Strategy Paper (PRSP), which the

government has formulated, set a goal of achieving a GDP growth rate of 6.8% in fiscal 2007 and 7.0% in fiscal 2008 and 2009. However, due to negative factors such as increased pressure for inflation, soaring international prices of crude oil, disasters caused by floods and cyclones, and serious power shortages, the real GDP growth rate in fiscal 2008 was only 6.2%.

Table 4.2: PSMP 2006 demand forecast scenarios

In the first step of PSMP 2010, the power demand will be forecast using a similar method as that used in PSMP 2006.

Since its independence in 1971, Bangladesh has striven to improve its socioeconomic conditions and grow its economy with support from domestic and international society. The average annual growth rate in the 14-year period from 1995 to 2008 was 5.6%. In the past three years, a high growth rate has been maintained since the stable and high growth of the mining and industrial sectors and the service sector has covered the low growth rate of the agricultural sector. The midterm macroeconomic framework of the Poverty Reduction Strategy Paper (PRSP), which the government has formulated, set a goal of achieving a GDP growth rate of 6.8% in fiscal 2007 and 7.0% in fiscal 2008 and 2009. However, due to negative factors such as increased pressure for inflation, soaring international prices of crude oil, disasters caused by floods and cyclones, and serious power shortages, the real GDP growth rate in fiscal 2008 was only 6.2%. The World Bank has drawn up a mid- to long-term growth scenario that by judging from circumstances, including the following facts: the country has assets required for growth, its economic fundamentals have improved and it has succeeded in first-stage reforms, its workforce is young, and corporate spirit and cultures have been established, the country will break away from its present status of being the poorest country and advance to become a medium-income country in approximately 10 years1.

Table 4.3: Economic Growth Scenarios

The adoption scenarios of the power demand forecast in this MP are as shown in the figure 2 below. The figure indicates three scenarios; (i) GDP 7% scenario and (ii) GDP 6% scenario, based on energy intensity method, and (iii) government policy scenario.

Figure 4.1: Three scenarios for power demand forecast

4.1.5 Perspective Energy Plan of Present Government

The Perspective Plan of the Planning Commission of the government of Bangladesh for the period 2010 – 2021 has recommended an energy mix to achieve the generation of 20,000 MW by 2021. Targets of electricity production by 2013 and 2015 are 7,000 MW and 8000 MW, respectively. According to the Perspective Plan, the energy mix for power generation is as follows.

Table 4.4: Energy mix of the Perspective Plan 2010 – 2025 for power generation

Energy Sources

Gas Coal Target Current Period 202 88 % 3.7 1 30 % 53 203 0 28% 38%

Oil % 6% % 3% 5%

Hydro 2.7 1% 4%

Nuclear % 0% 10

19 Renewable 0% % 3% % 6% Source: The Perspective Plan for Bangladesh 2010-2021.

4.1.6 Role of indigenous fuel in power generation

The total gas shortfall was about 800 mmcdf, in which about 500 mmcfd was unmet demand, i.e. the amount was not delivered to the existing gas customer, and about 300 mmcfd was potential demand, i.e. the amount was wanted from the potential customer who had already applied for a gas contract but it was not executed yet. This gas shortfall arose continuously from around 2005. In order to project the gas demand forecast, the shortfall amount as of June 2010 was incorporated into the forecast as unmet/potential demand, then extrapolated to 2005. The gas shortfall will be alleviated due to the Gas Evacuation Plan (2010-2015) including the introduction of LNG, and the Government incentive plan for switching from gas to other fuels to gas potential customers. Via these measures, the gas shortfall is expected to be dissolved by 2016.

Since the development of Chattak gas field, 23 gas fields have been discovered until now and currently (June 2009), 17 gas field are producing the gas. The gas fields are operated by three National companies and four IOC companies. The gas fields of Titas, Bakhrabad, Habiganj, Narsingdi, and Meghna are possessed by BGFCL, the gas fields of Sylhet, Kailasitila, Rashidpur, and Beanibazar are possessed by SGFL Company, and the gas fields of Salda, Fenchuganj, and Shahbazpur are possessed by BAPEX. The gas fields of Jalalabad, Moulavizar, Bibiyana (Chevron), Sangu (Cairn),

Bangura (Tullow) and Feni (Niko) are operated by IOCs with PSC. The average gas production volume is 1,791 mmcfd (2008/09) in all, and the production volume of IOC makes up 50%.

4.1.7 Energy Mix

Considering all the indigenous sources in Bangladesh, it can be concluded that the present primary energy sources cannot meet even the base case scenario (which is shown previously) let alone the high case scenario. Even considering high-case scenario, it is below those of the neighboring countries like India, Pakistan. In this context, the Government is formulating the “Five-Fuel strategy” in which the priorities are given

below.

1. Undertake immediate exploration of hydrocarbon and identify additional reserves that can meet the growing demand of gas by all consuming sectors

2. Develop alternative commercial energy supplies suitable for power generation, especially coal to ease the burden of fast-growing electricity demand on gas resources. Thus a two-fuel (gas and coal) strategy is required for both resource diversification and energy security.

3. Ensure efficient use of energy by using energy–saving appliances, plants and equipment in order to effectively increase the stock of available energy supplies. It can alleviate current capacity shortages, and create a more sustainable energy supply and demand balance. Mobilization of this “third fuel” will dampen unwanted demand

growth, reduce the need to add new peak power capacity, and insulate consumers from future price increases.

4. The resource potential of renewable energy is significantly larger than its present consumption and is a promising source of clean, convenient energy supply, especially in rural areas. With available and evolving technologies, renewable energy can be converted into modern energy like photovoltaic, biogas, bio-fuels, wind energy etc. making significant contributions to the total energy supply. This “fourth fuel” can help

in meeting the energy access throughout the country including the remote areas and thereby achieving poverty reduction goals.

5. Considering the limitation of fossil fuel supplies, nuclear fuel could be a potential energy option for the country, as it is a proven technology for economic, reliable and sustainable electricity generation. So, nuclear energy may be considered as the fifth fuel in the energy sector. Over the next decade, it could become a significant source of energy, thereby increasing diversity in the energy sector.

4.1.8 Options of fuel-mix for power generation

Fuels and Technologies

Considering the projected demand of power and the reserve bases of both gas and coal, it is high time to consider introduction of nuclear power as an alternative source of primary energy, and to explore the opportunity for regional energy trade. The option of the fuels and technologies for power generation is follows.

1. Considering the reserves and availability of resources, efforts are to be made to maximize the use of indigenous fuels, namely natural gas and coal.

2. A mix of fuel such as gas, coal and oil may be used for power generation and nuclear fuel should be considered to reduce reliance on any particular type of fuel for handling and transporting imported coal for power generation is to be developed.

4. Criteria for selection of technologies will include its proven, reliability, efficiency, maintainability and environmental compatibility.

5. Priority will be given to combine cycle technology for base load power plants using gas.

6. Preference will be given to nuclear energy for power generation.

7. Efforts will be made to standardize systems, sub-systems and components of energy equipment so as to minimize cost, improve reliability of the system and facilitate operation and maintenance

4.1.9. Structure of electric power sector

In the country Bangladesh MoPEMR Power Division manages the electricity business. Under its control, the power is generated by the BPDB, power plants which are departments and subsidiaries of BPDB, IPP, and private power generation companies. Power is supplied through PBCB’s power transmission facilities to customers in local

cities by BPDB, in the metropolitan area by DPDC and DESCO, and in rural areas by PBS. Note that distribution departments in local cities are being separated one by one. Fig. 3 shows the structure of the electric power sector in the country Bangladesh.

Generation: