2 minute read

MECHANICAL SHELL

The last stage of the project was to create a shell that will satisfy the needs of connections, becomings and rhizomatic. Also the understanding of both; static and dynamic configurations simultaneously.

Advertisement

**Constraints: a. The modules should included a min. of 6 Modules b. The modules have to be designed digitally c. The modules have to be parametrically d. Each module should be different e. Each module should include articulation (mobility) f. Each module’s exterior face needs to be partially or totally separated from the rest of the modules’s exterior faces

1. The final outer skin should result in a hard shell surface.

2. The shell should include the previous group project inside and should hold it in place in all dimensions without letting it fall out.

3. The shell should cover/wrap a minimum of 75% of the previous project.

4. The outside layer of the new shell can’t directly touch the previoys project. It should be three dimensional, and have filaments, thickening mass, or a double shell system to separate itself from the previoys proposal.

5. The shell should be modular.

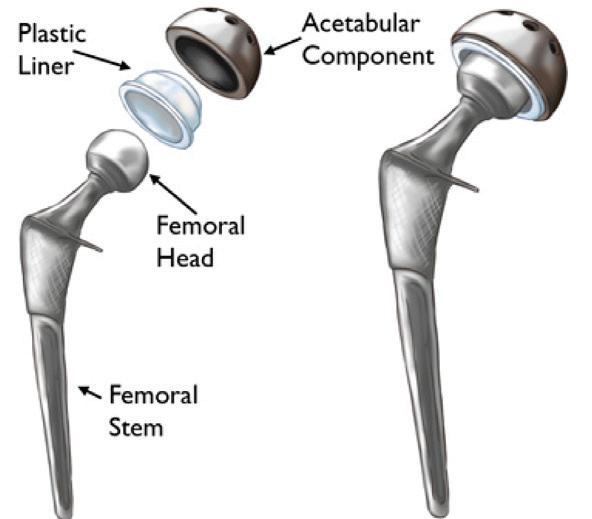

Armaball

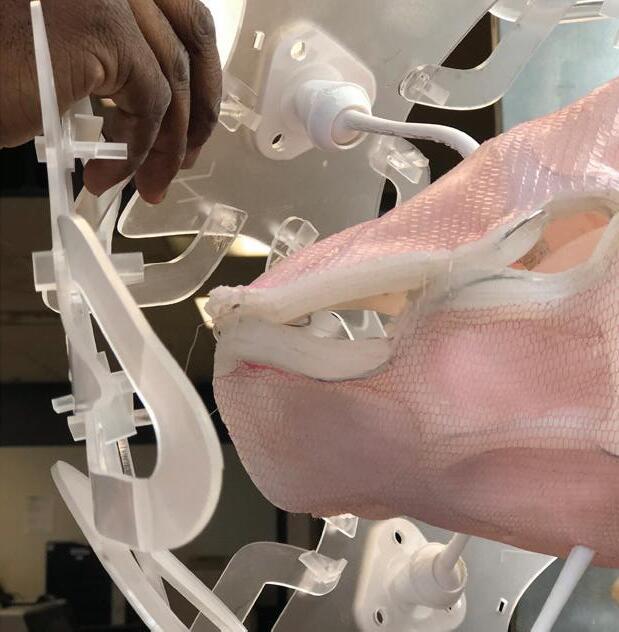

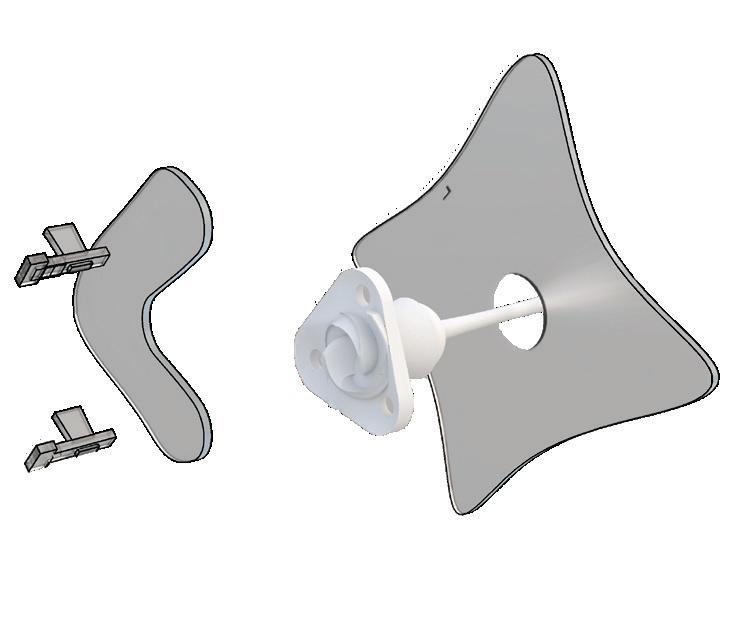

The concept for the shell was the Armadillo’s Shell, and for mechanical movement the Modular Dual Mobile. The shell will be broken down and each one of them will interlock with each other. Every module will have a Modular Dual Connection (Ball Joint Connection), which it will be sticked into the skin. This will help us to proceed without any constraint because the skin won’t touch the module, and at the same time the ball joint will be able to make the module move.

On my right, we have a fast Overall Proposed Shape of how the Final Model will look. Every module will be unique and form a curvature for the overall design. To achieve this, we 3D mold one of the forms to obtain the desire curvature and we CNC the mold. Later, we laser cut the form with Acrylic. Having the two pieces, we heat up the acrylic on top of the mold to get an accurate representation of the curvature. The module was broken down into five different individual pieces. This allowed us to to connect one “ear” to another making every module to interlock. The circle in the middle is the opening for the ball joint to fit in, connecting the module with the skin, and allowing us for mobility in the mechanical shape.

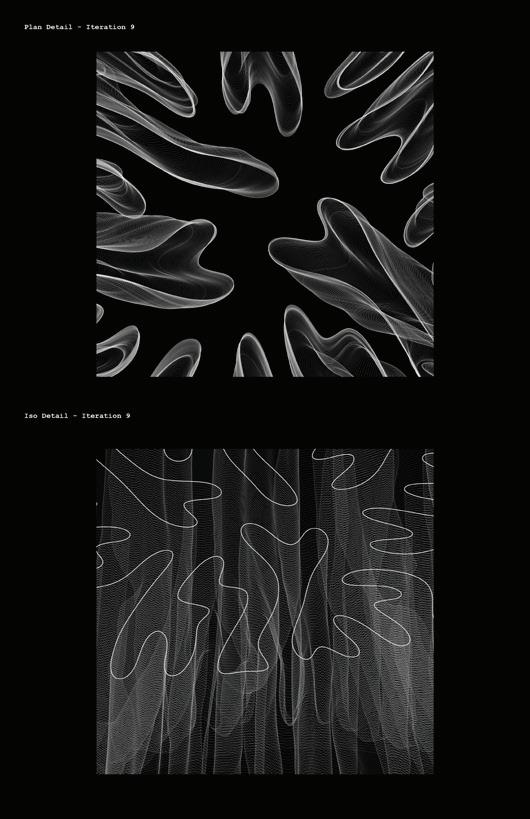

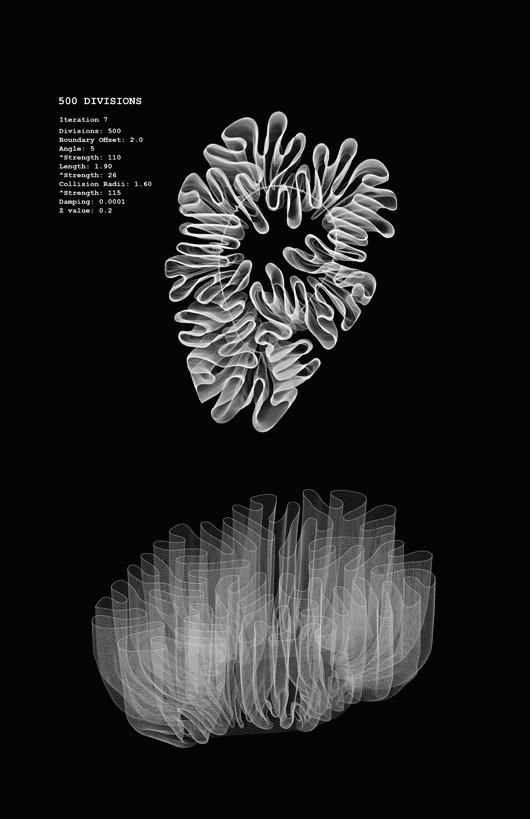

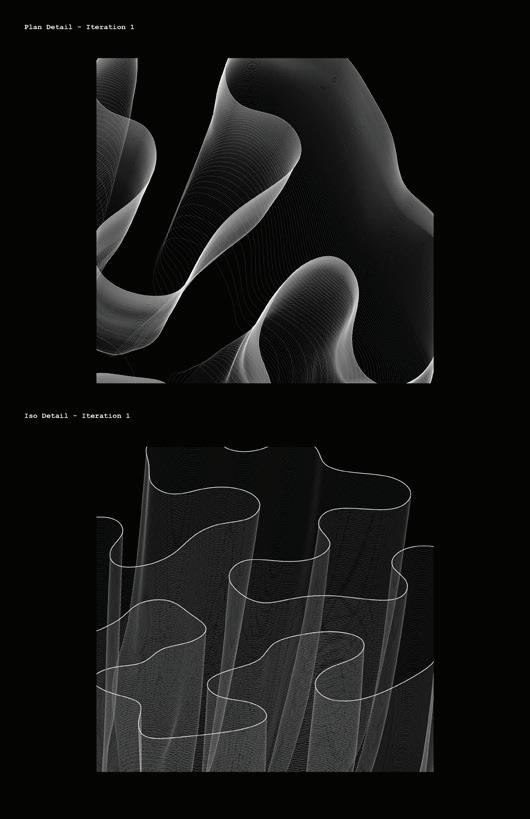

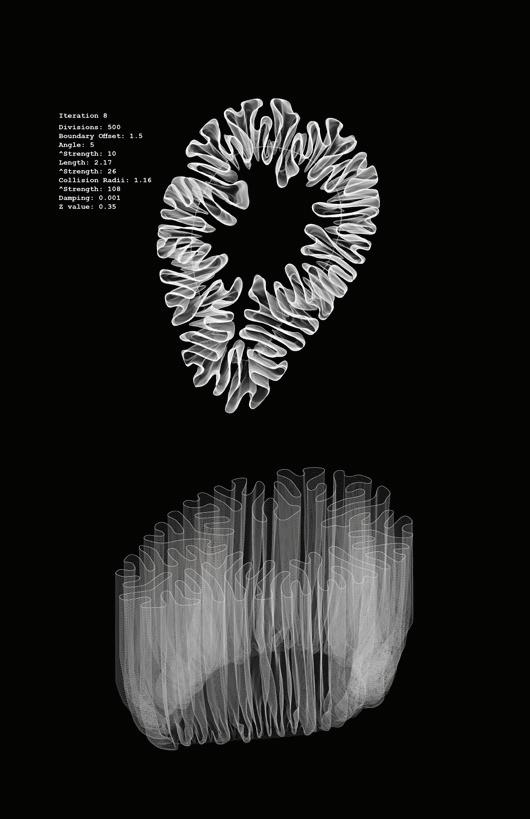

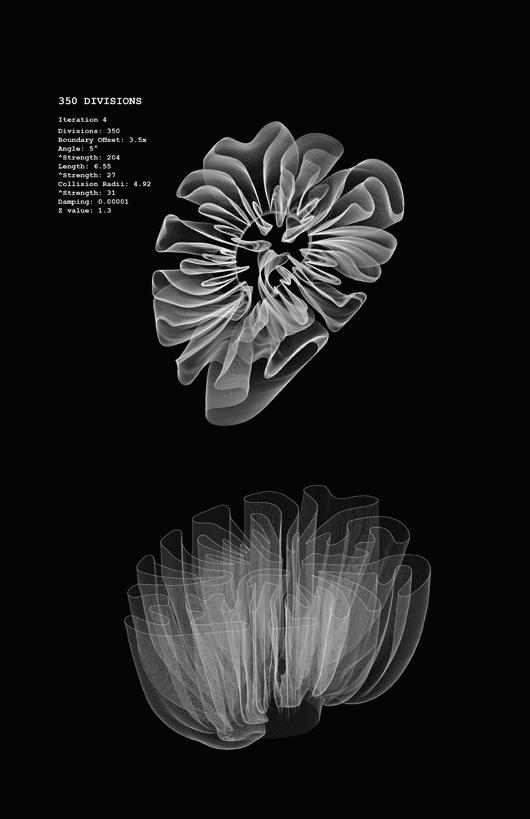

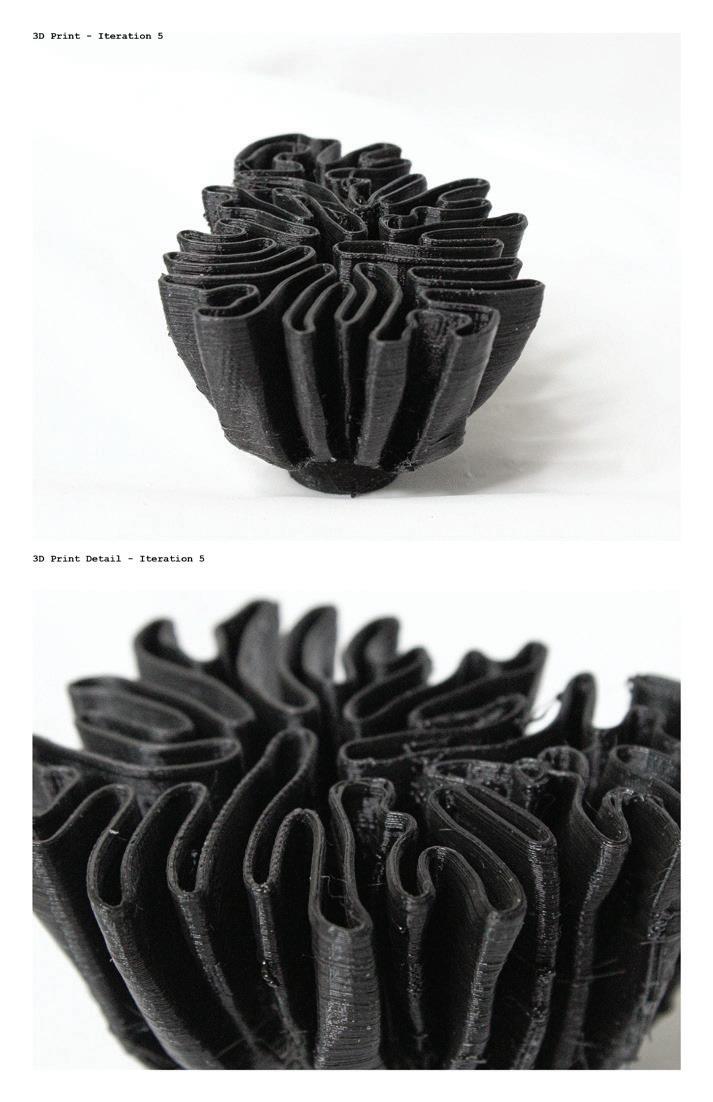

Differential Growth

As an organism, differential growth features cells, allowing organs to contruct themselves in endless array of shapes and forms. In our nature we have examples such as meandering rivers, rippled surface textures of fruits, snakes, intestines etc. that simulates differential growth. We certainly don’t know how these organisms are made, but we can simulate the beauty of these forms through digital technology.

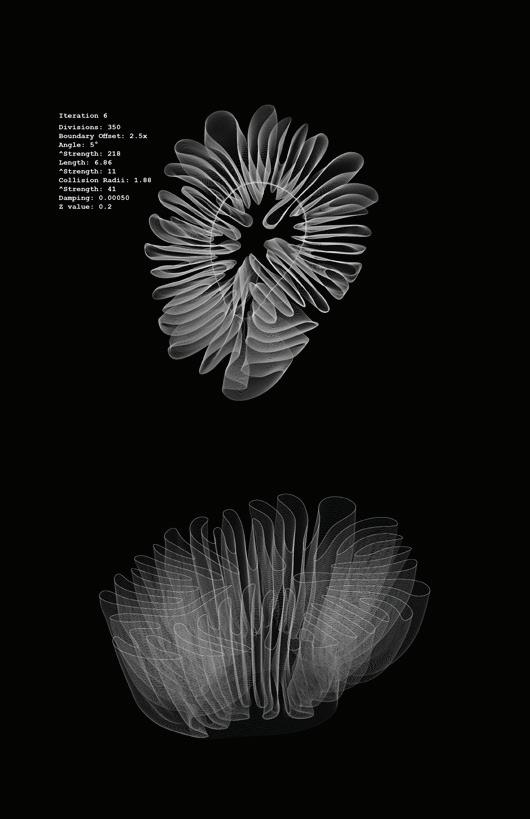

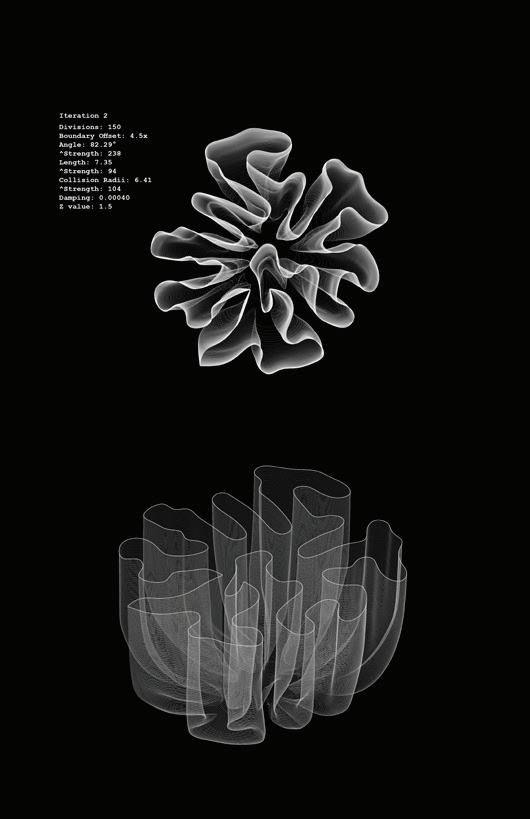

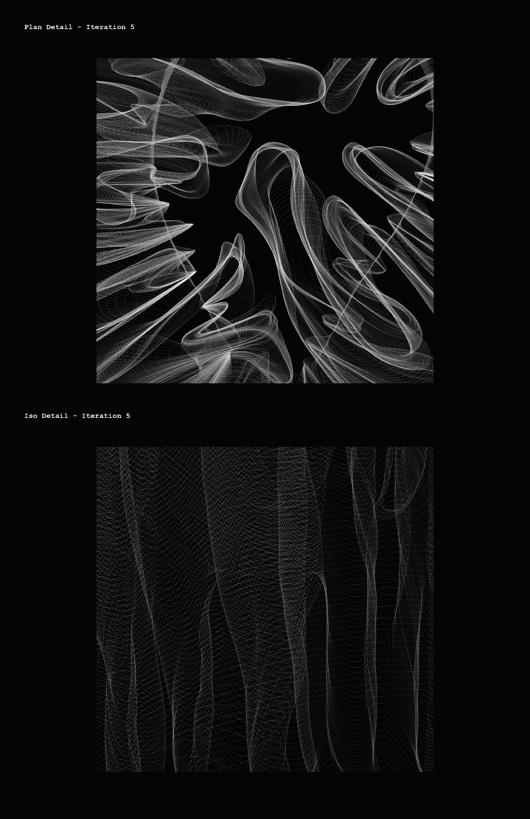

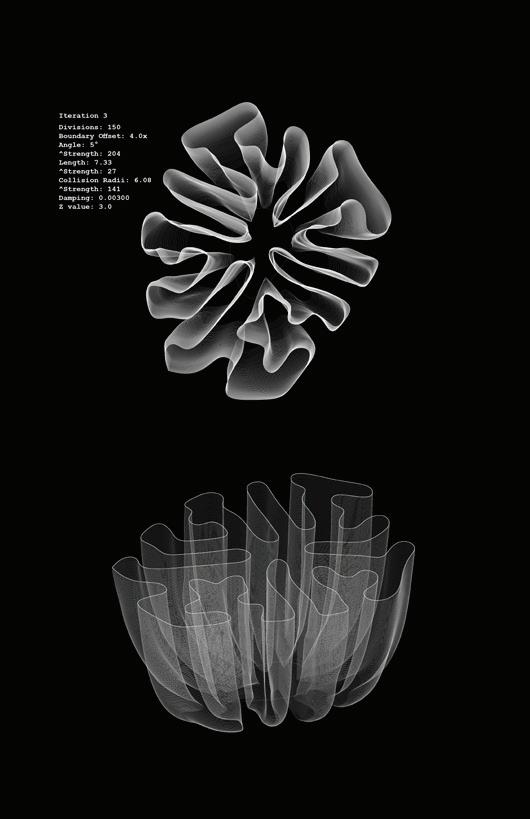

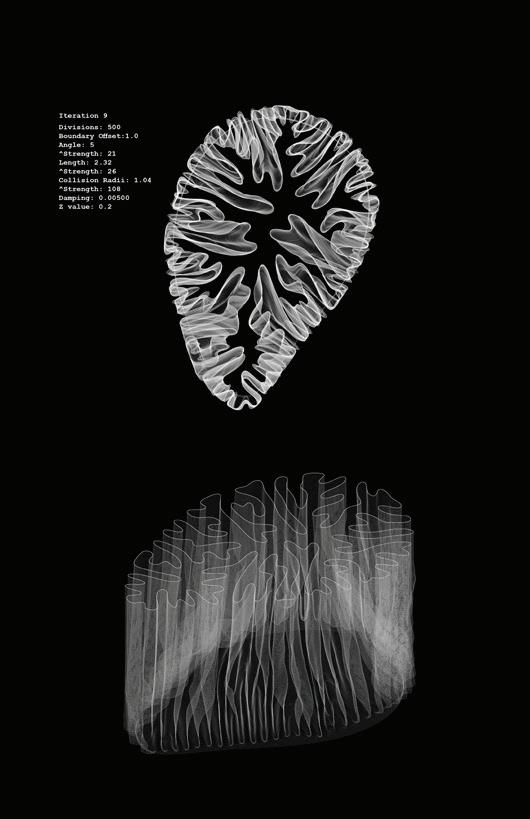

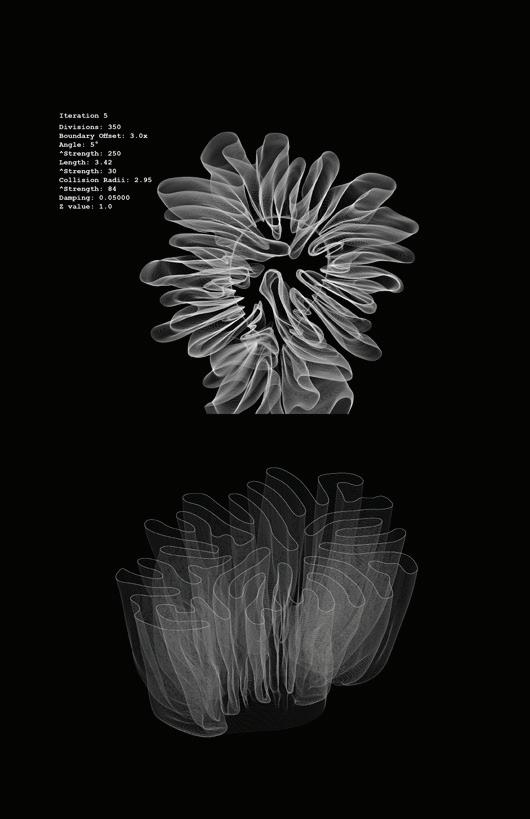

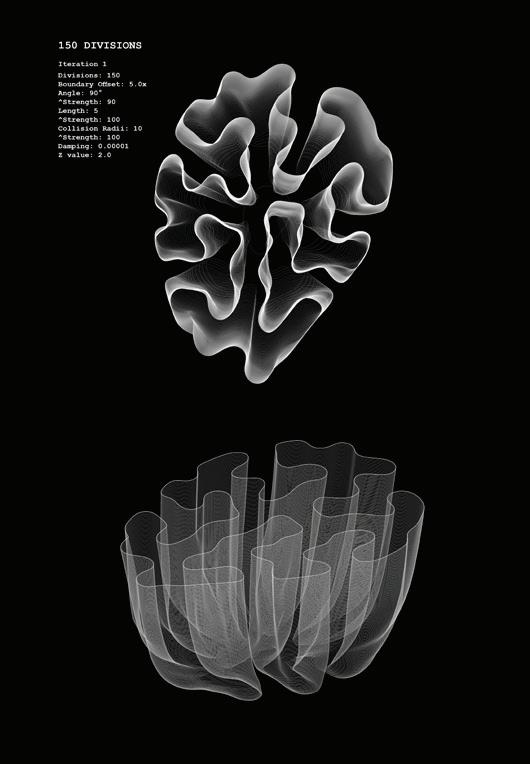

In the following examples, we used an invisble curve as a boundary and simulate the reaction of growth inside of this boundary. We tested different parameters, which altering a single number, can change the shape and form of the outcome.

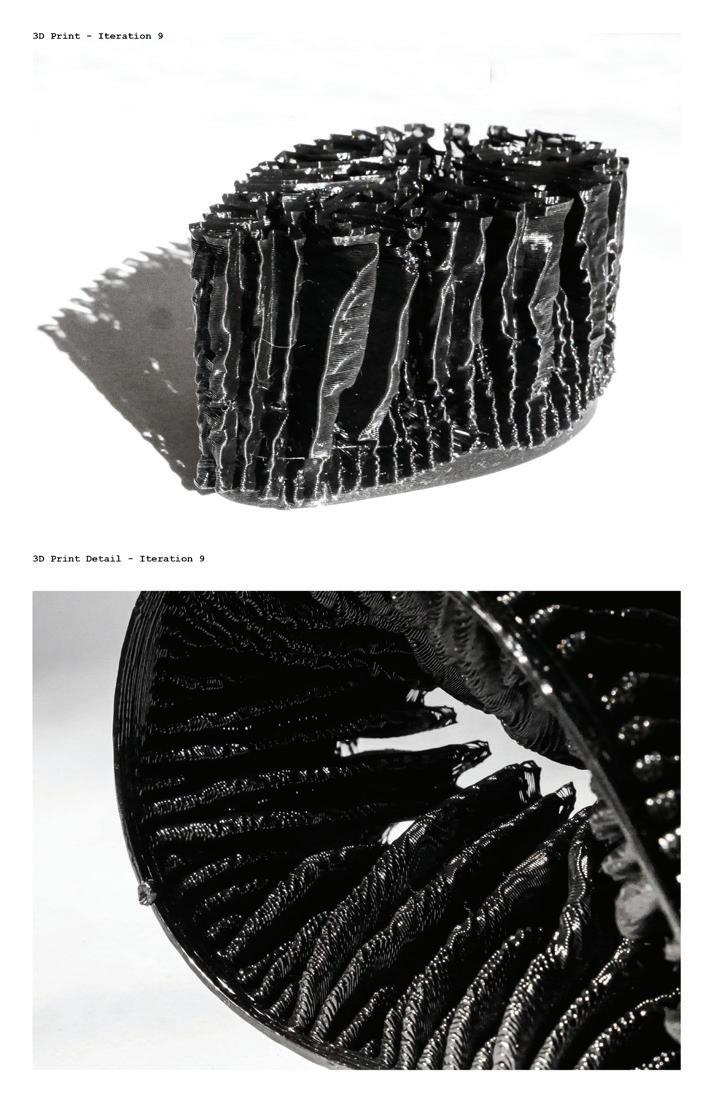

3D Printed Pieces- As a team, we had to create our own gcode. to print these forms. By manipulating the gcode. we have more accessibility to increase the amount the distance of the Z-Axis, giving us an amazing effect for Iteration 9

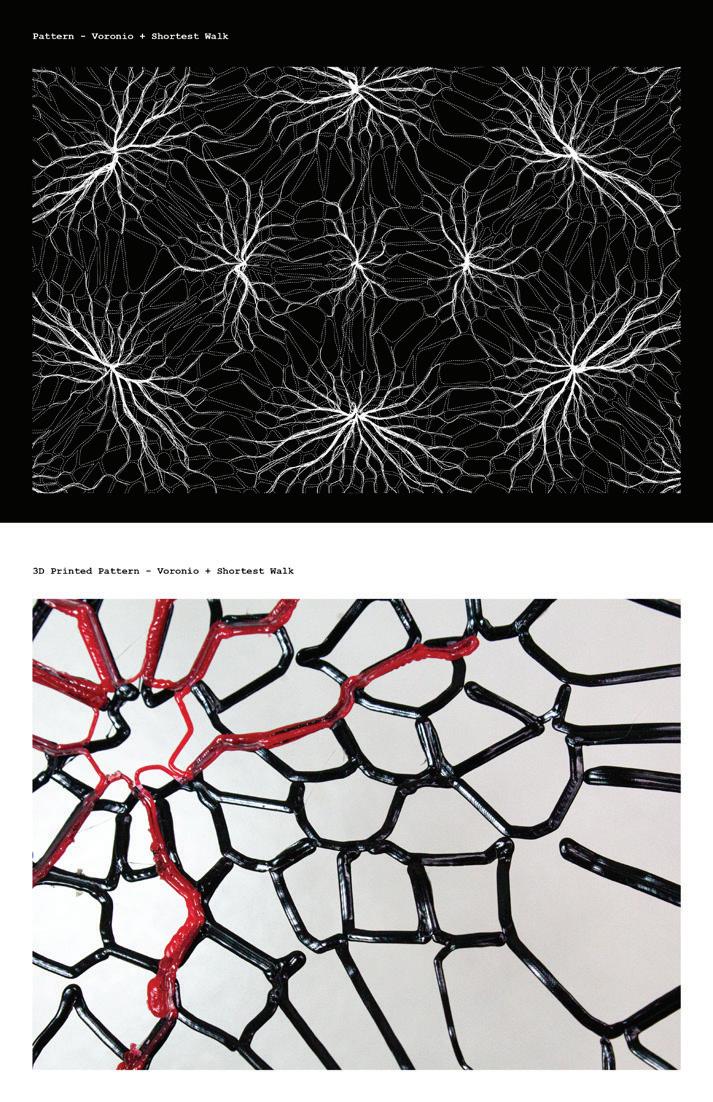

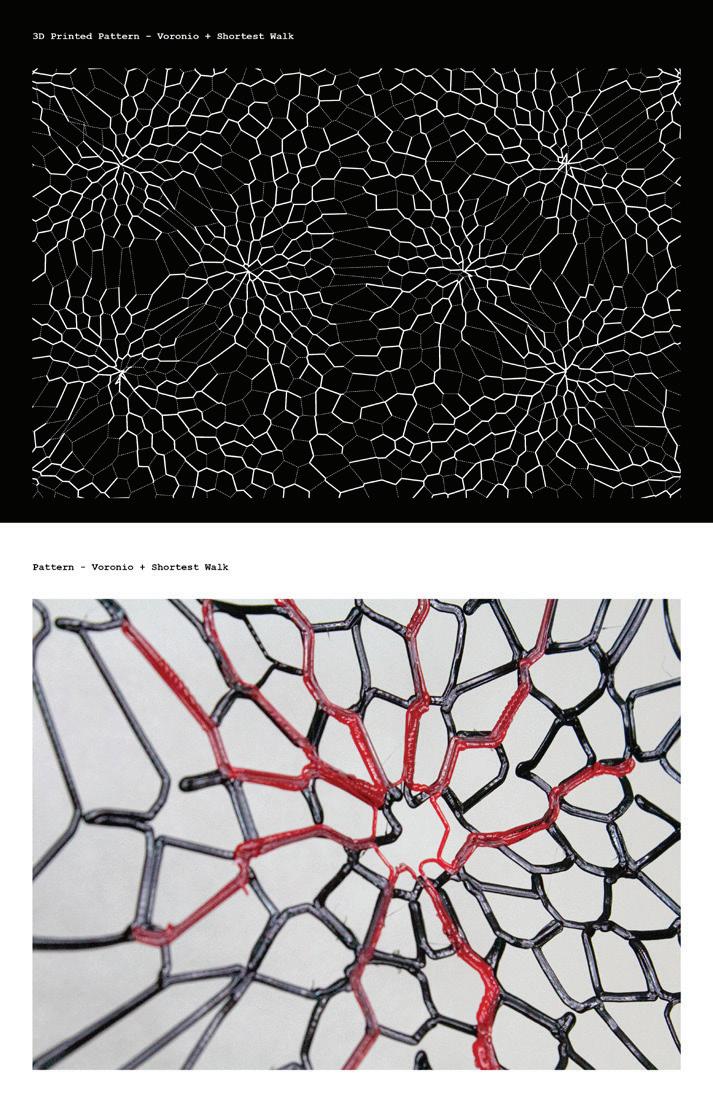

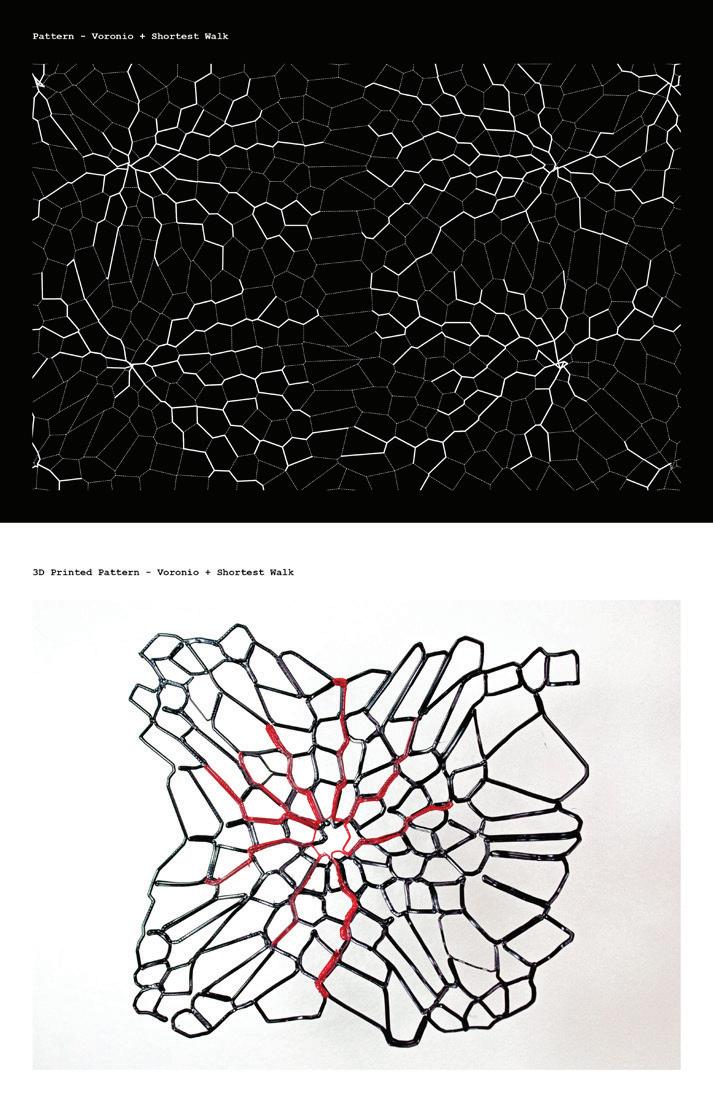

Shortest Walk- Another simulation we consider was Shortest Walk. By generating a script, we created a pattern based on curves and we calculated the shortest route from a line start point to line ends points in a network.