4 minute read

Technical Detail

Integrative Systems / Design Conclusions

Skin

Advertisement

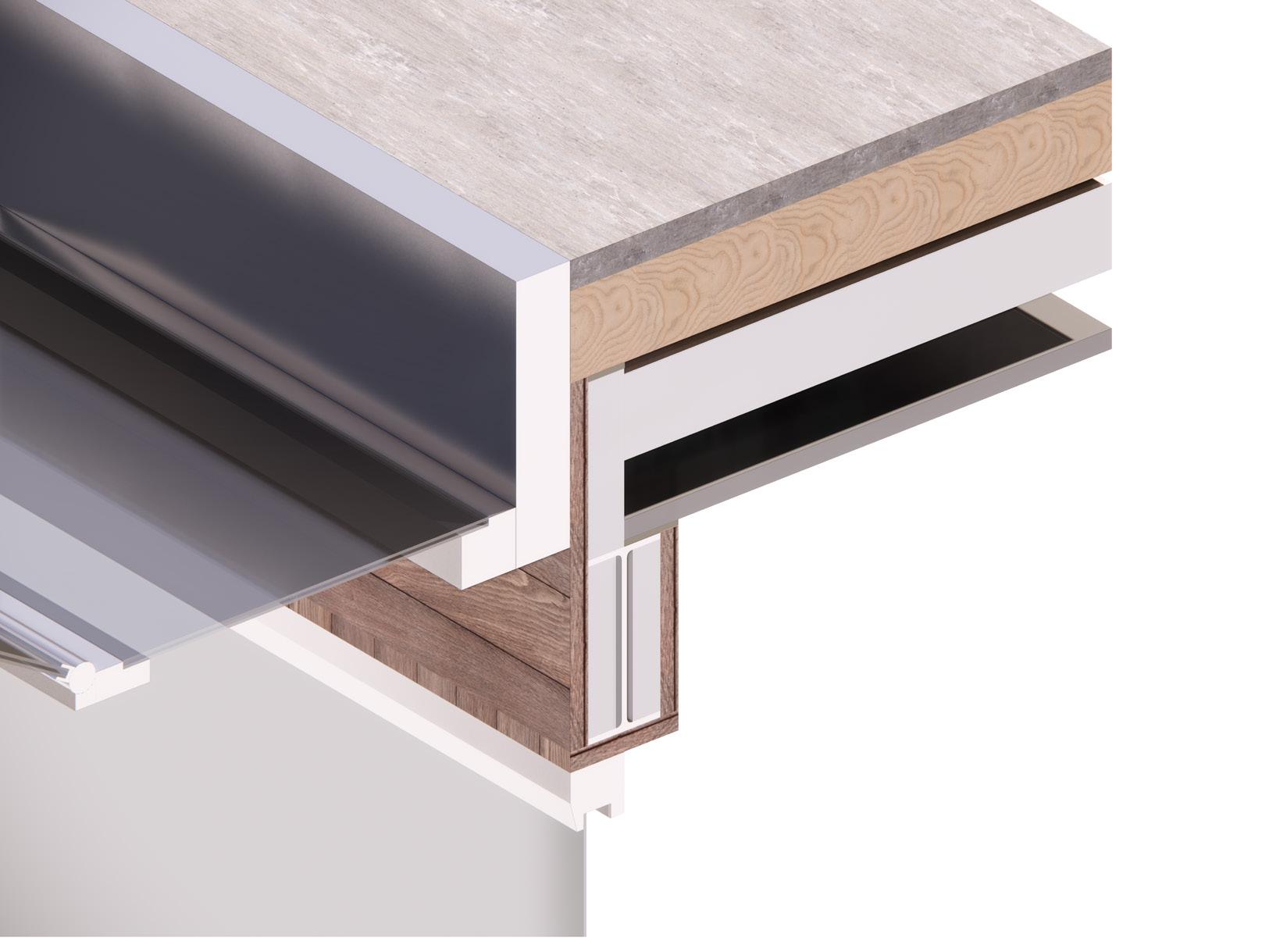

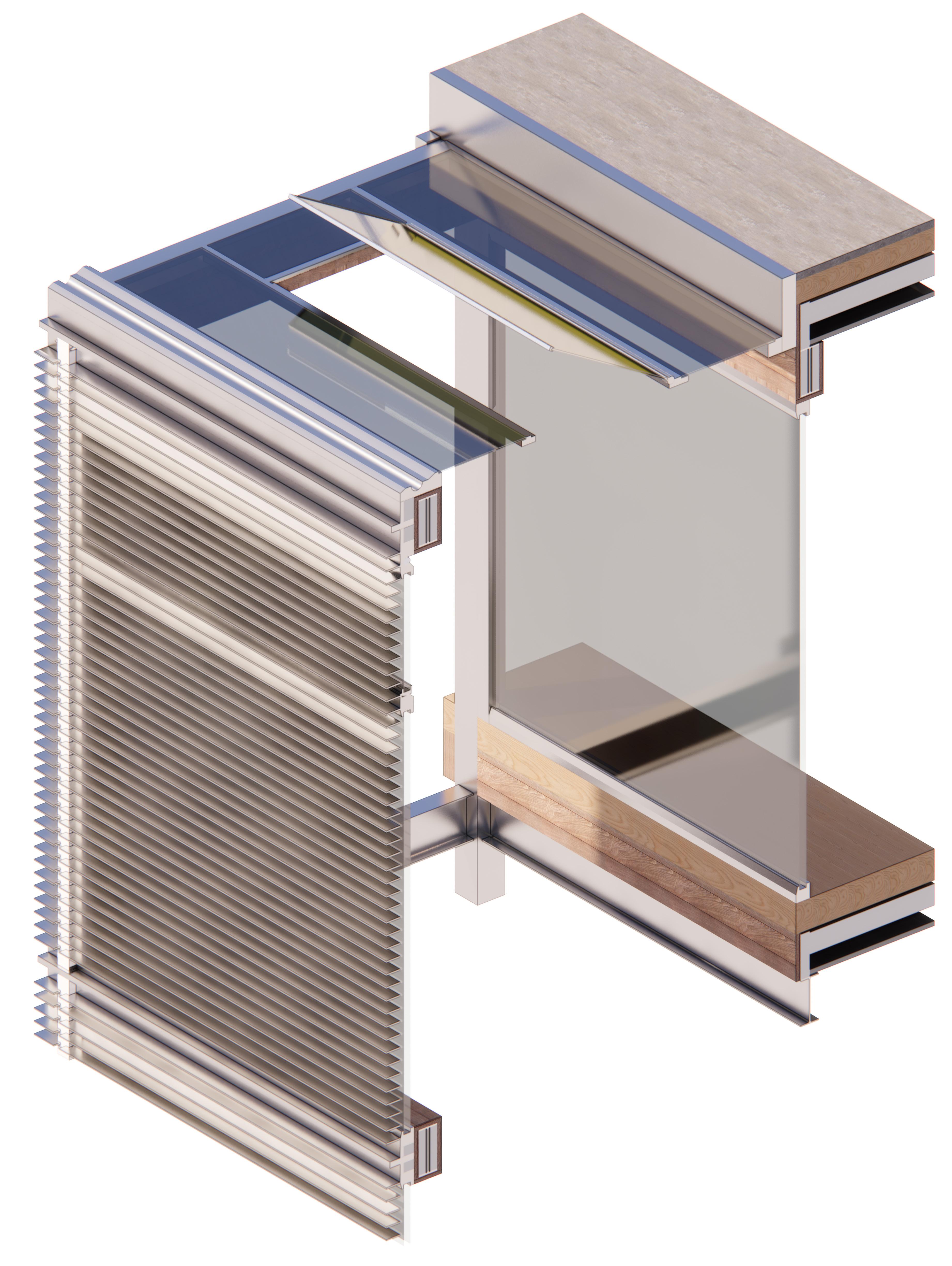

The floor slabs retained the CLT slab. As stated on page 1, the aim was to use environmentally beneficial materials where possible. The CLT slabs and wooden covers are the results.

Facade

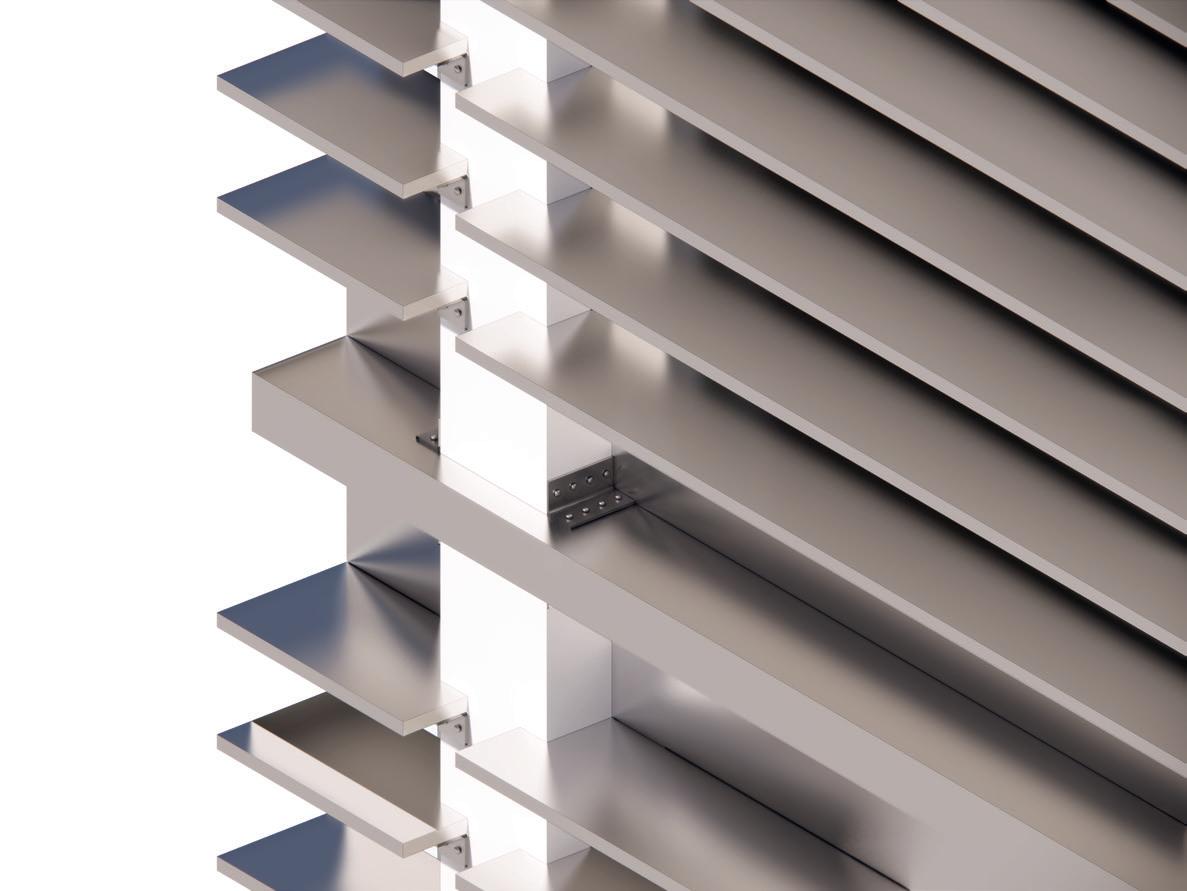

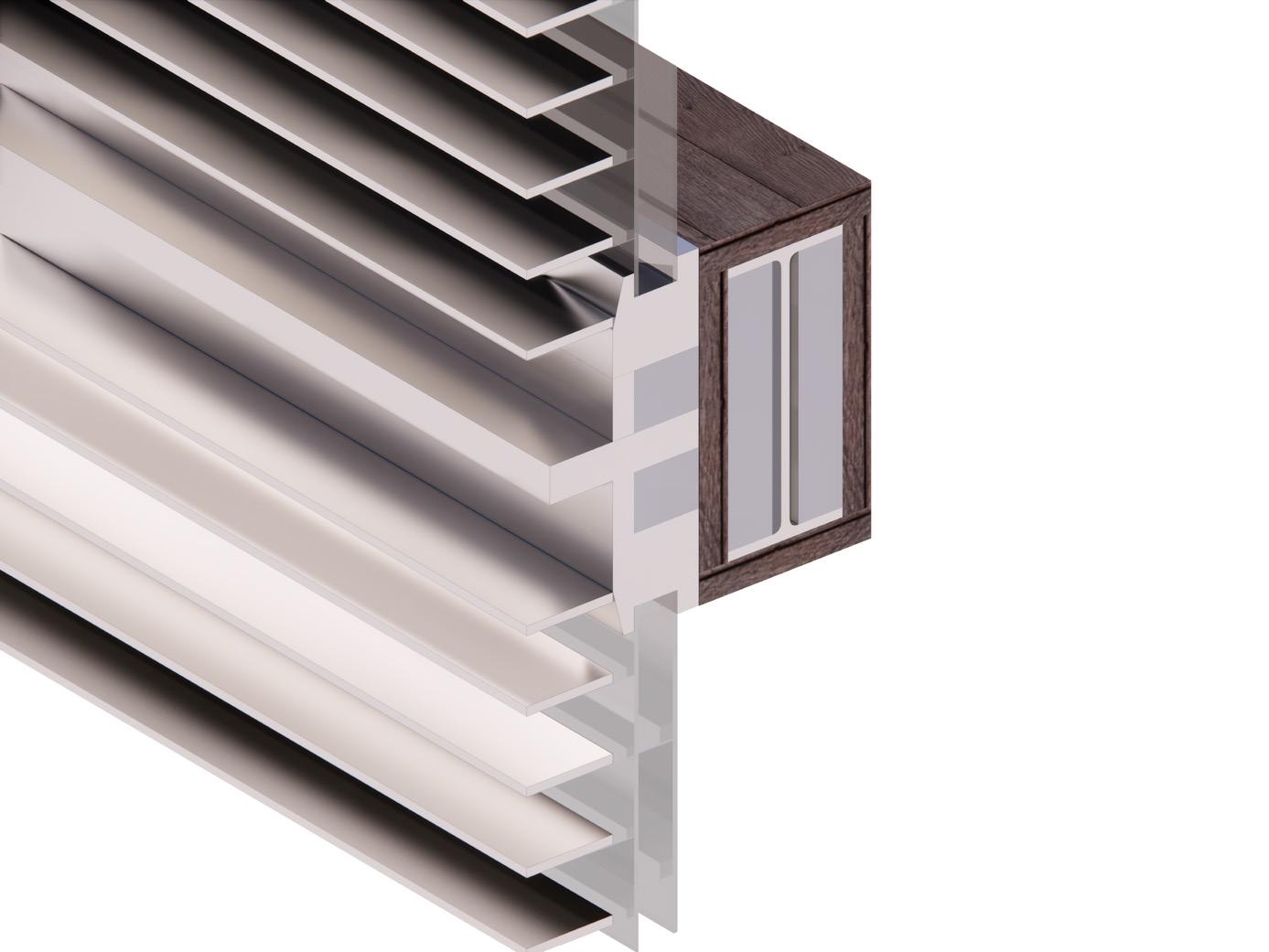

The final lovre system is iteration 1 with 100mm wide strips. To install these facade segments, a frame is inserted in between the window panels, so they are attached to the structure directly. the strips are partially inserted into the small cutouts in the vertical parts of the frame and partially screwed with the help of L-brackets. Thus the stability of the whole system is accomplished.

Inserting the frame and attaching it to the structure

Inserting strips into the frame

on the Technologies Position

As mentioned on the 1st page, the fragment responds to climate change via the choice of recyclable materials, using materials with low carbon footprint, e.g. CLT, where it is possible, and giving access to natural light

On the 2nd page, the iterations had strong connections to the climate response: In summer the energy costs are the highest for cooling, and with the prospect of the future warmer mean temperature a proper louvre system was needed to limit illuminance that, when considering a glazed and exposed to sun fragment, can lead to the excessive heat gain that can lead overreliance on mechanical solutions that increase operational carbon.

As stated on the 1st page, the fragments tackle the dilemma of building and life safety by choosing materials and elements, e.g. steel and CLT for structural reasons, and coating elements to decrease flammability. To tackle fire safety specifically, a shaft at the top of the gap was proposed that can be opened when smoke is detected

The louvre system itself enhances safety, especially life safety, by preventing excessive heat gains that can lead to thermal discomfort and even in extreme situations health risks.

The fragment, like the rest of the project, is intended to be constructed out of the commonly known and available in the economy. In the best possible option, they can be sourced locally from the C&D Recycling Facilities, thus lowering the costs and energy needed in the spheres of transport and production.

The louvre system was also intended to follow these strategies. The system is also easier to renovate, thanks to its simplicity. Additionally, Iterertion 3 has also an explicit cost advantage.

Net Zero Operational Carbon

Fine tune internal environment with efficient mechanical systems: An operable shaft automatically opens when smoke is detected. The operable panels can and, due to the gaps between them and the floor, have to be remotely operable.

• Provide responsive local controls: As mentioned above, smoke detectors open the shaft when smoke is detected. there is a possibility to install a system regulated by a thermostat or a more advanced system to regulate the air inflow through the operable panels.

Net Zero Embodied Carbon

• Prioritise ethical and responsible sourcing of all materials: materials can be sourced locally, which can result in a better understanding of the potential providers and if they produce their products ethically.

Minimise materials with high embodied energy impacts: The project was designed can be constructed fro the materials from providers so fo recyclable and reusable materials and elements.

Design building for disassembly and the circular economy: The assembly can be done with repurposed materials and elements as well as after disassembly the elements can be released back into the economy for future projects

Good Heath & Wellbeing

• Provide spaces with strong visual connection to outside: The constraint of maintaining the outside visible was determined by the desire to expose the viaduct and the space above the viaduct to the people inside.

Provide responsive local controls eg. opening windows, or local control: The fragment provides operable windows and the shaft that can be used for ventilation and in case of fire.

• Design spaces with good indoor air quality: The operable panels provide fresh air when needed.

• Design spaces to adaptive thermal comfort standards: The operable panels provide fresh air when needed louvre system and operable panels help in regulating thermal comfort.

Design spaces with good acoustic comfort: Aluminium as the material of choice for the facade louvre system is good in decreasing noise.

Design Insights

Before testing, I was most inclined towards the vertical option, and after choosing the horizontal system my intuition was leading me rather towards iteration 1. Iterating these prototypes allowed me to confront my mistaken perception of these options and by focusing on one specific parameter I could test and compare the iterations clearly and implications were varied, ranging from climate change, constructability, and building&life safty.

If there was more time, I would model a series of physical prototypes. More parameter could be tested to, e.g. the angle of the strips, the material they are made from. other types of facades, e,g, the vertical, could be tested rigorously. All of that could be explored in a potential further prototyping.

The state of change was important throughout the whole process: At the beginning, the fragment was designed in a way that promotes a circular economy and simple elements that can accelerate a state of change. The respect for the architectural artifacts on the side evinced through the visibility aspect. I tried to propose both a fragment on page 1 and a louver system on page 2 that provides visibility and acts as an architectural promenade.

Athough the fragemnt and ptrototyping has, in my opinion, succeded in the goal that put forward for myself, there a aspects of the fragment that could be critiqued: The choice of materials, ampunf glazing, the shape itself. The iterations as well could be criticised: The choice of louvre system, choice of the parameter a for testing, or the idea of glazing being covered by a louvre sytem could have some better alternative.