19 minute read

Protect your Employees from the Heat Safety Meeting

Prevent Heat Illness at Work

Outdoor and indoor heat exposure can be dangerous.

Advertisement

Ways to Protect Yourself and Others

Ease into Work. Nearly 3 out of 4 fatalities from heat illness happen during the first week of work.

20% 100%

MON TUE WED THU FRI

New and returning workers need to build tolerance to heat (acclimatize) and take frequent breaks. Follow the 20% Rule. On the first day, work no more than 20% of the shift’s duration at full intensity in the heat. Increase the duration of time at full intensity by no more than 20% a day until workers are used to working in the heat.

Drink Cool Water

Drink cool water even if you are not thirsty — at least 1 cup every 20 minutes.

Take Rest Breaks

Take enough time to recover from heat given the temperature, humidity, and conditions.

Dress for the Heat

Wear a hat and light-colored, loose-fitting, and breathable clothing if possible.

Find Shade or a Cool Area

Take breaks in a designated shady or cool location.

Watch Out for Each Other

Monitor yourself and others for signs of heat illness.

If Wearing a Face Covering

Change your face covering if it gets wet or soiled. Verbally check on others frequently.

First Aid for Heat Illness

The following are signs of a medical emergency! Abnormal thinking or behavior ? ? ? ? ? ? Slurred speech Seizures Loss of consciousness 1 CALL 911 IMMEDIATELY

9-1-1

2 COOL THE WORKER RIGHT AWAY WITH WATER OR ICE

3 STAY WITH THE WORKER UNTIL HELP ARRIVES

Watch for any other signs of heat illness and act quickly. When in doubt, call 911.

If a worker experiences:

Headache or nausea

Weakness or dizziness

Heavy sweating or hot, dry skin

Elevated body temperature

Thirst

Decreased urine output

Take these actions:

Give water to drink Remove unnecessary clothing Move to a cooler area Cool with water, ice, or a fan Do not leave alone Seek medical care if needed

For more information: 1-800-321-OSHA (6742) TTY 1-877-889-5627 www.osha.gov/heat

Federal law entitles you to a safe workplace. You have the right to speak up about hazards without fear of retaliation. See www.osha.gov/workers for information about how to file a confidential complaint with OSHA and ask for an inspection.

FactSheet

Protecting Workers from the Effects of Heat

At times, workers may be required to work in hot environments for long periods. When the human body is unable to maintain a normal temperature, heat illnesses can occur and may result in death. It is also important to consider that hot work environments may exist indoors. This fact sheet provides information to employers on measures they should take to prevent worker illnesses and death caused by heat stress.

What is Heat Illness?

The following are illnesses that may result from exposure to heat in the workplace.

Heat Stroke is the most serious heat-related health problem. Heat stroke occurs when the body’s temperature regulating system fails and body temperature rises to critical levels (greater than 104°F). This is a

medical emergency that may result in

death! The signs of heat stroke are confusion, loss of consciousness, and seizures. Workers experiencing heat stroke have a very high body temperature and may stop sweating. If a worker shows signs of possible heat stroke, get medical help immediately, and call 911. Until medical help arrives, move the worker to a shady, cool area and remove as much clothing as possible. Wet the worker with cool water and circulate the air to speed cooling. Place cold wet cloths, wet towels or ice all over the body or soak the worker’s clothing with cold water.

Heat Exhaustion is the next most serious heatrelated health problem. The signs and symptoms of heat exhaustion are headache, nausea, dizziness, weakness, irritability, confusion, thirst, heavy sweating and a body temperature greater than 100.4°F. Workers with heat exhaustion should be removed from the hot area and given liquids to drink. Cool the worker with cold compresses to the head, neck, and face or have the worker wash his or her head, face and neck with cold water. Encourage frequent sips of cool water. Workers with signs or symptoms of heat exhaustion should be taken to a clinic or emergency room for medical evaluation and treatment. Make sure that someone stays with the worker until help arrives. If symptoms worsen, call 911 and get help immediately.

Heat Cramps are muscle pains usually caused by the loss of body salts and fluid during sweating. Workers with heat cramps should replace fluid loss by drinking water and/or carbohydrate-electrolyte replacement liquids (e.g., sports drinks) every 15 to 20 minutes.

Heat Rash is the most common problem in hot work environments. Heat rash is caused by sweating and looks like a red cluster of pimples or small blisters. Heat rash may appear on the neck, upper chest, groin, under the breasts and elbow creases. The best treatment for heat rash is to provide a cooler, less humid work environment. The rash area should be kept dry. Powder may be applied to increase comfort. Ointments and creams should not be used on a heat rash. Anything that makes the skin warm or moist may make the rash worse.

Occupational Factors that May Contribute to Heat Illness

• High temperature and humidity • Low fluid consumption • Direct sun exposure (with no shade) or extreme heat • Limited air movement (no breeze or wind) • Physical exertion • Use of bulky protective clothing and equipment

Prevention Made Simple: Program Elements

Heat Illness Prevention Program key elements include:

• A Person Designated to Oversee the Heat Illness

Prevention Program • Hazard Identification • Water. Rest. Shade Message • Acclimatization • Modified Work Schedules • Training • Monitoring for Signs and Symptoms • Emergency Planning and Response

Water. Rest. Shade. The work can’t get done without them.

U.S. Department of Labor Occupational Safety and Health Administration www.osha.gov 1-800-321-6742 (OSHA) TTY 1-877-889-5627

OSHA 3431-05R 2021

Prevent Heat Illness at Work

Outdoor and indoor heat exposure can be dangerous.

Nearly 3 out of 4 heat illness fatalities happen during the first week of work. New and returning workers need to build tolerance to heat by taking frequent breaks and working shorter shifts in the heat to start.

Dangerous heat exposure can occur indoors or outdoors, in any season. Employers can keep workers safe by following these simple safety practices:

Follow the 20% Rule — on the 1st day, don’t allow employees to work more than 20% of a shift at full intensity in the heat. Increase their time by no more than 20% a day until they are used to working in the heat. Provide cool drinking water – encourage workers to drink at least one cup every 20 minutes, even if they are not thirsty. Rest breaks — allow workers time to recover from heat in a shady or cool location. Dress for the heat — have workers wear a hat and light-colored, loosefitting, breathable clothing if possible. Watch out for each other — encourage workers to monitor themselves and others for signs of heat illness. Look for any signs of heat illness, including fainting, dizziness, nausea, and muscle spasms, and act quickly — when in doubt, call 911. Offer training on the hazards of heat exposure and how to prevent illness. Develop an Emergency Action Plan on what to do if a worker shows signs of heat-related illness.

To learn more about heat illness prevention and first aid, visit www.osha.gov/heat.

OSHA alerts are issued on occasion to draw attention to worker safety and health issues and solutions.

• osha.gov/heat • 1-800-321-OSHA (6742) • @OSHA_DOL

0 7 R 2021 OSHA 397 5 -

In Texas, August is no joke. As the hottest month of the year, it is imperative that marketers are protecting employees who often find themselves working in the oppressive heat. PERC recently released a “Safety Minute” on propane.com detailing signs of heat exhaustion. They additionally sent out links to resources that all marketers should review. that covers working in hot environments. Nonetheless, under the OSH Act, employers have a duty to protect workers from recognized serious hazards in the workplace, including heat-related hazards. Visit OSHA at www.osha.gov and select the “Safety and Health Topics” tab for information.

It explains how to use the heat index to determine when extra precautions are needed at a worksite to protect workers from environmental contributions to heat-related illness. Workers performing strenuous activity, workers using heavy or non-breathable protective clothing, and workers who are new to an outdoor job need additional precautions beyond those warranted by heat index alone.

Workers new to outdoor jobs are generally most at risk for heat-related illnesses. For example, Cal/OSHA investigated 25 incidents of heat-related illness in 2005. In almost half of the cases, the worker in-

volved was on their first day of work and in 80% of the cases the worker involved had only been on the job for four or fewer days. That’s why it’s important to gradually increase the workload or allow more frequent breaks to help new workers and those returning to a job after time away build up a tolerance for hot conditions. Make sure that workers understand the risks and are “acclimatized”.

Heat-Related Illness

There are several levels of severity when you are talking about heat related illness. Of course, being aware and recognizing the less serious, earlier warning signs is best for everyone involved!

Heat rash, also known as prickly heat, is skin irritation caused by sweat that does not evaporate from the skin. Heat rash is the most common problem in hot work environments.

Heat cramps are caused by the loss of body salts and fluid during sweating. Low salt levels in muscles cause painful cramps. Tired muscles—those used for performing the work—are usually the ones most affected by cramps. Cramps may occur during or after working hours.

Heat exhaustion is the body›s response to loss of water and salt from heavy sweating. Signs include headache, nausea, dizziness, weakness, irritability, thirst, and heavy sweating.

Heat stroke, the most serious form of heat-related illness, happens when the body becomes unable to regulate its core temperature. Sweating stops and the body can no longer rid itself of excess heat. Signs include confusion, loss of consciousness, and seizures. Heat stroke is a medical emergency that may result in death! Call 911 immediately.

Safety Tips

Additional safety tips are offered by the Center for Disease Control and Prevention (www.cdc.gov) under the “Natural Disasters and Severe Weather” tab. Here a few to share and plan around with your employees who are working in the field. • Stay hydrated. Drink plenty of fluids; drink about 16 ounces before starting and 5 to 7 ounces every 15 or 20 minutes. • Avoid dehydrating liquids. Alcohol, coffee, tea and caffeinated soft drinks can hurt more than help.

• Wear protective clothing. Lightweight, light-colored and loose-fitting clothing helps protect against heat. Change clothing if it gets completely saturated. • Pace yourself. Slow down and work at an even pace. Know your own limits and ability to work safely in heat. • Schedule frequent breaks. Take time for rest periods and water breaks in a shaded or air conditioned area. • Use a damp rag. Wipe your face or put it around your neck. • Avoid getting sunburn. Use sunscreen and wear a hat if working outside.

• Be alert to signs of heat-related illness. Know what to look for and check on other workers that might be at high risk. • Avoid direct sun. Find shade or block out the sun if possible. • Eat smaller meals. Eat fruits high in fiber and natural juice. Avoid high protein foods.

OSHA has tons of educational materials that employers can download, print and even post including fact sheets, pamphlets, posters, and alerts. Go to www.osha.gov/publications/ bytopic/heat-illness-prevention.

Experts at delivering QUALITY every time.

Visit Us Online: www.propanetank.com

TRUSTED & BEST

Quality | Customer Service | Delivery | People Warranty | Distribution Network | Inventory

Quality is more than just our name. We strive each and every day to provide our valued customers with the absolute best products and services available. We are family owned and appreciate the relationship we have with our customers. When you want the best...choose QUALITY.

HOME OFFICE 2914 U.S. 61 Cleveland, MS 38732 800-345-2495

OHIO LOCATION 721 Graham Drive Fremont, OH 43420 419-334-2664

UTAH LOCATION 5601 Axel Park Rd. West Jordan, UT 84081 801-280-1133

Aboveground | Underground | Above/Underground Dispenser | Anhydrous Ammonia

People in Propane

Troy B . Allen, 76, passed away June 7, 2021. Troy had the distinction of being the first cadet to graduate from the Houston Police Academy at age 19. He later joined the Department of Public Safety. After that he decided to own his own business, B&S Propane, in New Waverly with his brother Wayne. Troy was also a truck-driver instructor for Lee College. Our thoughts and prayers go out to the family at this time.

William Roy “Willie” Meyer, 72, of Schulenburg, passed away June 12, 2021 after a short illness. William worked for Moulton Propane for 40 years. He was a hard worker and loved by many. He enjoyed visiting friends and drinking coffee at the Food Mark, and working in the yard. Our thoughts and prayers go out to the family at this time.

Andrew Russell “Rusty” Spurgeon, 57, passed away June 25, 2021. Rusty worked as a baker at Furr’s Cafeteria in Paris and later went to work for Cooper Propane 1988 as an A/C HVAC Technician and Mechanic and continued work there until his death. Our thoughts and prayers are with the family at this time.

Propane Chefs Debut New TV Show

Through a strategic partnership with PERC, Chefs Bryan and Michael Voltaggio have been cooking up recipes on the propane grill and posting on social media about the benefits of cooking with propane.

Their new show Battle of the Brothers launches in mid-August on discovery+.

Take advantage of their growing success and popularity by promoting their recipes all summer long.

Gas or Electric? What Energy Consumers Prefer

According to the National Association of Homebuilders (NAHB)’s What

SQTG Leak Check & Regulator Test Kits

The SQTG kits are ideal for bobtail drivers and service personnel that conduct leak check and

regulator pressure testing.

The SQTG kits contain four pressure gauges: a) 30 psi gauge for pressure tap valves in the outlet of a first-stage regulator, or intermediate pressure of an integral two-stage regulator b) 300 psi (with high pressure test block) for systems with no regulator pressure taps c) 5 psi gauge for testing set and lockup pressure in 2 psi regulators d) 35" WC gauge for use in second-stage regulator leak testing The hose assembly has an inlet swivel connection for attachment to the pressure tap valve. The outlet connection is a high pressure (300 psi) industrial quick disconnect coupling for attachment to any of the included gauges.

Perfect for Servicemen

SQTG4A & SQTG4B NEW MEMBERS Retail Marketer

HIPER GAS LPG, LLC El Paso, TX

Supplier

NAT-G Houston, TX

Returning Retail Marketers

AMIGO PROPANE Pharr, TX

ARANSAS PROPANE Aransas Pass, TX

Home Buyers Really Want, 2021 Edition, reports that “consumers generally prefer electricity (51%) to gas (33%) for their air heating and cooling systems, but prefer gas (51%) to electricity (39%) for cooking. In comparison, consumers were split on electricity (45%) versus gas (40%) for water heating systems, with 15% indicating no preference.”

However, according to the report, homebuyers preferences vary per geographic region.

Visit https://nahbnow.com/2021/07/ gas-vs-electricity-which-energy-sourcedo-consumers-prefer to see regional preferences.

Don’t forget there are appliance rebates available from the Propane Council of Texas (ProCOT). $300 for a propane water heater and $300 for propane furnace. $600 cap per household. Learn more about the Texas Propane Appliance Rebate Program at www.txsaveswithpropane.com.

How to Educate Your Propane Customers This Fall with Propane Living Newsletter

Last quarter, the Propane Council of Texas (ProCOT) sent out almost 100,000 newsletters to Texas propane

customers all over the state.

Was your customer one of them? Your customers can receive it, too.

ProCOT covers the postage! For 2021 participants are responsible for a $49 per company fulfillment fee per quarter plus less than 4 cents per newsletter.

The newsletter helps retain the flame by featuring home propane applications and reminds them why they fell in love with propane, promotes propane safety and includes a seasonal propane recipe.

Sign up for Fall 2021 or perpetually.

Register and upload your mailing lists to the form at at www.propanecounciloftexas.org or current perpetual subscribers email updated mailing lists to info@ propanecounciloftexas.org by September 3, 2021.

Apply to Attend LP Gas Growth Summit

LP Gas magazine is accepting applications for its LP Gas Growth Summit, set for Sept. 15-17 at Reunion Resort, outside Orlando, Florida.

The unique networking event brings together retail propane company decision-makers and propane industry partners for two days of one-on-one business meetings, educational opportunities and other networking and recreational events. The magazine aims to help propane marketers improve their business operations, grow gallons across markets and build lasting partnerships.

LP Gas covers two-nights lodging, food, drinks and golf at the resort. LP Gas also confirms it is working closely with the resort to implement event procedures and practices that focus on the safety and well-being of Summit participants. Space for eligible retail propane decision-makers is limited.

For more information or to apply, visit https://www.lpgasmagazine.com/lp-gasgrowth-summit/.

Q?’s Contact LP Gas Editor-in-Chief Brian Richesson at brichesson@northcoastmedia.net or 216-706-3748.

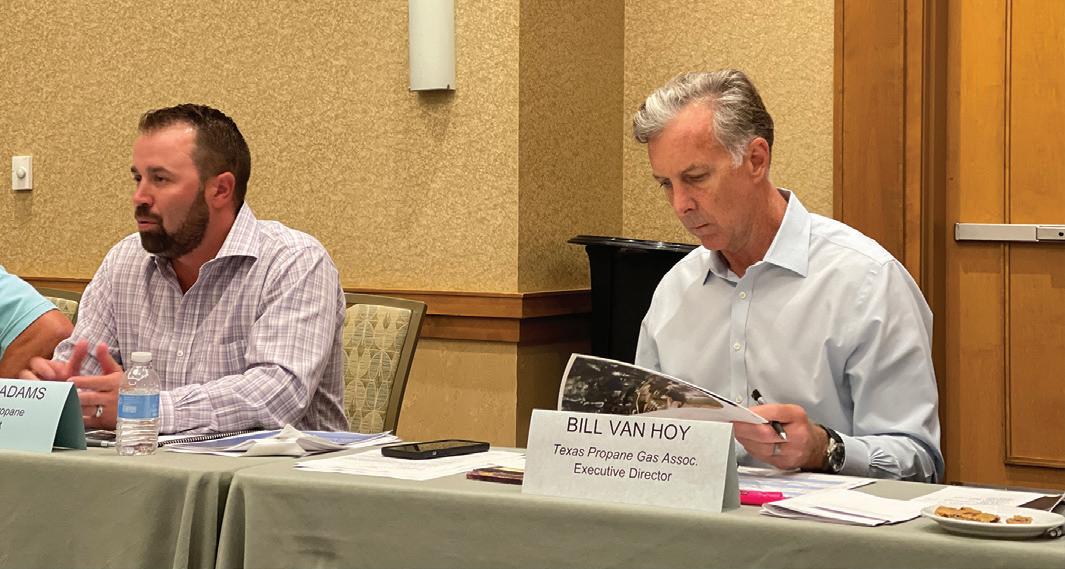

TPGA held its 2nd quarter board meeting in Austin on June 22, 2021 to get an end of Texas Legislative Regular Session recap, lawsuit update, and to discuss other propane industry matters.

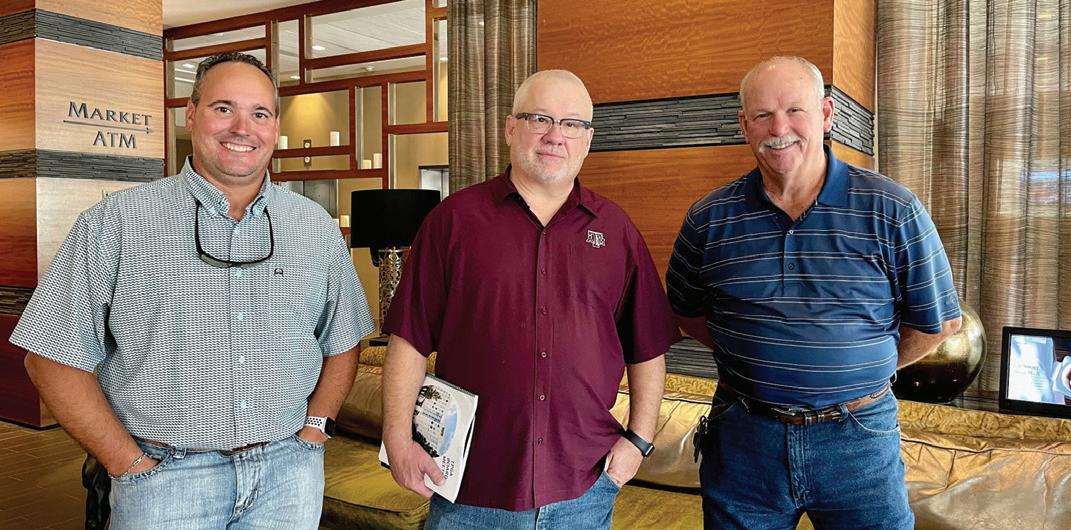

TPGA President Josh McAdams, McAdams Propane, and TPGA Executive Director Bill Van Hoy ready to kick off meetings and updates in Austin. TPGA District Director & Vice President Jeremy Gentile, Hill Butane; Jimmie Grant, Martin Midstream; and one of our Board Vice Presidents, Larry Baty, Cadenhead Servis Gas, all smiles after the end of the 2nd quarter meetings.

TPGA members Tod Garrett and Mark Garrison, Allstar Fuel / Fred Garrison Oil Company, traveled all the way from West Texas for the 2nd quarter TPGA board and committee meetings. TPGA District 9 Director Brad Quisenberry of Gene Harris Petroleum prepping for the meetings.

TPGA District 12 Director John Walter, Schneider Distributing, and TPGA member Ronnie Kelly, Meeder Equipment, catch up at the June TPGA Board Meeting. TPGA member Jim Fulton, 4JEnergy, and District 10 Director Josh Nowlin, McCraw Propane, travel to Austin for TPGA business and to catch up with fellow industry members.

TPGA Technical & Standards Chairman Lon Holloway, Northwest Propane, and TPGA District 4 Director Danny Meyers, Bellville Butane, catch up between association committee meetings. Brian, Diana, Joe and Garrett Green of Green’s Blue Flame of Houston at the 2nd TPGA Board & Committee Meetings in Austin. Joe Green serves as a Sr. Vice President on the TPGA Board of Directors.

TPGA District 11 Director Steve Adams of AAA Butane and Hardwick Propane; Mark Smith of Home Depot Pro; TPGA District 10 Director Josh Nowlin, McCraw Propane; and TPGA President-Elect Allen Wells, Baygas, at the 2nd quarter meetings in Austin.

TPGA District 2 Director Matt Brock, McAdams Propane, and TPGA District 1 Director David Collett, Gas & Supply, catch up on East Texas matters at TPGA 2nd quarter meetings in Austin this past June.

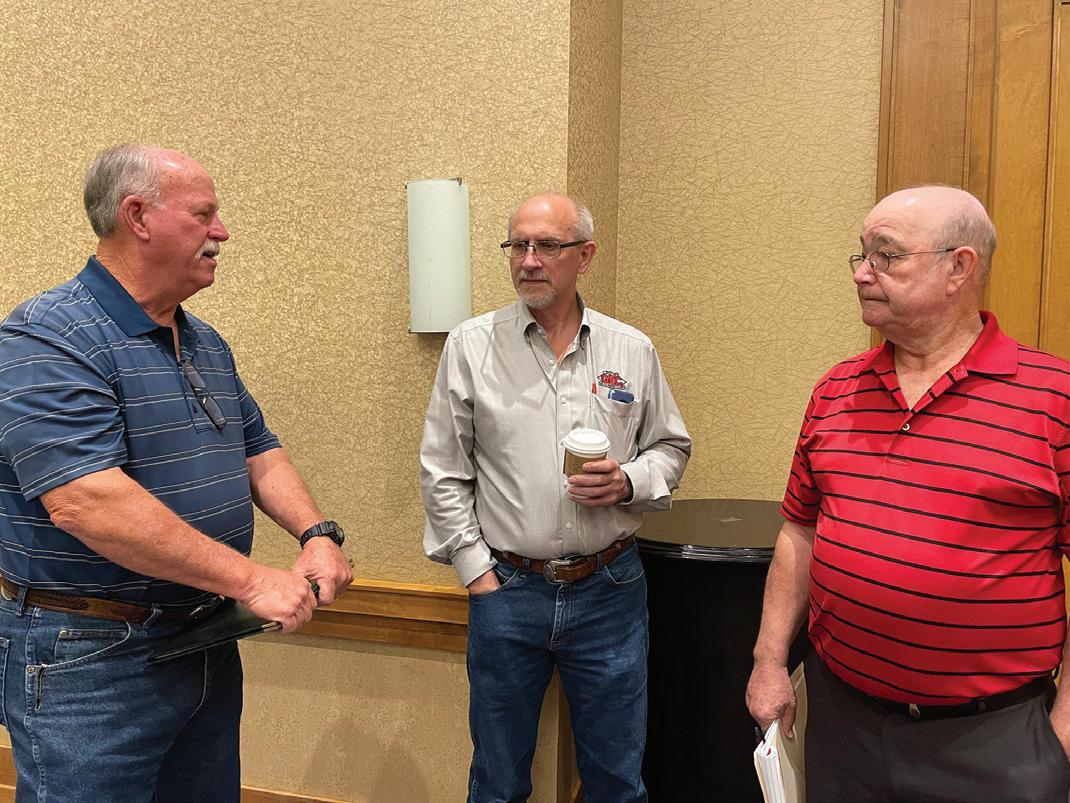

Board Vice President Larry Baty, Cadenhead Servis Gas; Chris Burchfield, Gas Equipment Company; and David Fulbright, White Distributors talk shop at the TPGA summer meetings in Austin, TX.

Garrett Insurance Agency, Inc Formerly, Southern Star Insurance Agency, Inc Cecil Joiner, Risk Manager cecil@garrettinsurance.com 936-756-2222 www.garrettinsurance.com

PetroStar Equipment Resources Purchase & Sale Pre-Owned Propane Tanks 5,000 gallons to 90,000 gallons

FOR SALE (2) 90,000 gallon, 250 psi, saddles, 2006 (2) 18,000 gallon, 250 psi, skidded, 2011

Contact: Jim Oliver 936-755-6108 petrostar@pdq.net For Sale

1996 GMC Bobtail 2600 Gallon Capacity Hydro still good until 2024. $12,000 O.B.O. 361-364-3274

WOULD YOU LIKE TO ADVERTISE IN TEXAS PROPANE MAGAZINE?

For Advertising, contact: Joanne Pantaze at 512-273-2639 or by email at jpantaze@pvco.net

CHERYL@LONGHORNPROPANE.COM or WENDY@LONGHORNPROPANE.COM, 830-964-2525

AUGUST

10 September ads due for Texas Propane magazine 12-14 2021 Crossroads TPGA Propane Expo & Conference

Corpus Christi, TX

SEPTEMBER

3 Fall Propane Living Subscriptions & Mailing Lists Due 6 TPGA & PSC office closed for Labor Day 10 October ads due for Texas Propane magazine 12-14 2021 NPGA Fall TS&S Committee Meeting

Colorado Springs, CO

12-18 National Truck Driver Appreciation Week

OCTOBER

5-6 PERC Advisory Meeting

Tampa, Fl

10 November ads due for Texas Propane magazine . 18-20 2021 NPGA Southeastern Convention & International Propane Expo

Atlanta, GA

20 NPGA Fall Meeting & Board of Directors Meeting

Atlanta, GA

Bergquist 24 BLT Tanks 17 Cunningham Gas Products 31 Enterprise Products 20 Fisk Tank Carrier Inc.

Outside Back Cover

Gas Equipment Company 31 Legacy Energy Consulting 18 Lone Star Energy Group 29 Longhorn Propane 28 Lumbermen’s Insurance Agency 9 Maquinado de Equiposy Tanques SA de CV 13 Marshall Excelsior 15 Marshall Young Insurance 21 Meeder Equipment Co. 5 Pinnacle Propane

Inside Front Cover

Propane Service Corporation 25 Quality Steel Corporation 23 Rural Computer Consultants 19 Westmor Industries 25 White River Distributors 12

FUEL YOUR PROFITS WITH LOWER WORKERS’ COMP PREMIUMS

Endorsed by:

*Dividends are not guaranteed and past dividends are not a guarantee of future dividends. The Texas Department of Insurance must approve all dividend plans Call your agent to get a quote or call Curtis Heptner, Master Agent H H (940) 397-2771 H H Curtis@certessentials.com