2 minute read

WHE ELS

Volume: 08 Issue: 07 | July 2021 www.irjet.net p-ISSN: 2395-0072

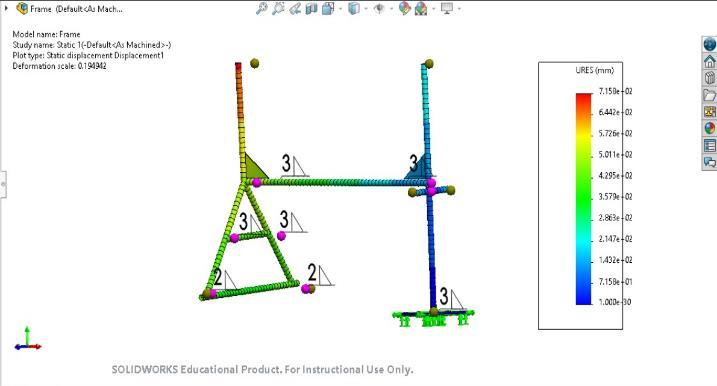

2.3 Analysis of Main Frame –

Advertisement

Figure 17 Main frame

Maximum Deformation Observed = 7mm

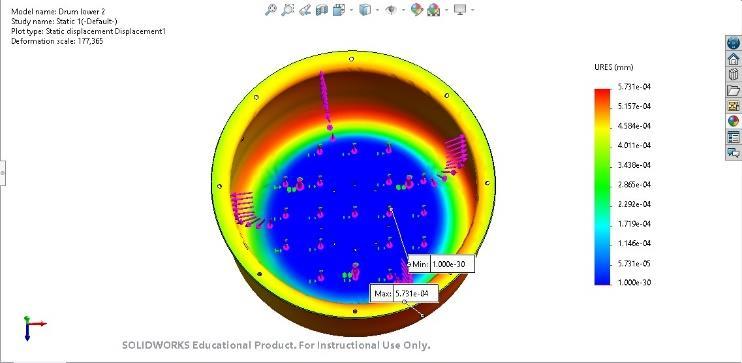

2.4 Analysis of Drum –

Figure 18 Drum

Maximum Deformation Observed = 5mm

3. CONCLUSIONS

Concrete has a continuously growing demand especially in developing countries. There is a constant requirement of concrete no matter how big or small the construction project is. To fulfil this demand in the fastpaced world we are living in, mechanization of the process is required. After considering all the calculations, a portable concrete mixer was designed to fulfil the requirement of forming the M10 grade concrete. The design is completely safe as the deformations in the parts observed were within the limits and because of which the assembly would not fail. Mixing is a complicated process because of which we have to take into consideration factors like duration, loading method and energy of mixing. As a result, stainless steel was selected as the material for blade with which the design overcomes factorssuch as strength or corrosion.

ACKNOWLEDGEMENT

The objective of this project is to provide clear understanding of the process with which a portable concrete mixer can be designed. To achieve this objective, the group members by no means have worked alone as these ideas have been shaped by comments, suggestions and acceptance given by Prof. Moreshwar Khodke, Department of mechanical Engineering. We are thankful to Prof. Moreshwar Khodke his guidance, support and inputs in this course project without which it would not have been a success. We are thankful to Prof. (Dr.) M.B. Chaudhari Head of Department of Mechanical Engineering for his support and for the addition of such kind projects in our curriculum. We express our sincere thanks to the management of Vishwakarma Institute of Technology, Pune for allowing us to carry out such educational projects. We express our feelings and respect towards our parents, without their blessings, help and motivation this project could not be completed and would have been just a dream for us. We are thankful to all those whom we might have inadvertently failed to mention here but have a positive contribution in successful completion of this project.

REFERENCES

[1] Pharmaceutical engineering and mixing by: - Dr.

Bhawan Bhatt. [2] Concrete Mixing Methods and Concrete Mixers: State of the Art Journal of Research of the National Institute of Standards and Technology. By Chiara F. Ferraris. [3] Artin Levon edition 1983 at chapter 8 of Molds and

Scaffolding. [4] Ristow G H 2000 Mixing and segregation in rotating drums, Proc. Symposium on Segregation in Granular

Flows, The Netherlands: Kluwer Academic publishers, 311–320. [5] Turbula T2C Heavy-Duty Shaker-Mixer 2004 www.artisanscientific.com/ 49853.asp accessed 12.06. 2007. [6] Ferraris, C.F., “Concrete Mixing Methods and Concrete

Mixers: State of the Art”, Journal of Research of the

National Institute of Standards and Technology, Vol. 106, No. 2, 391-399 (2001). [7] Thompson Aguheva, “Design and Fabrication of an

Industrial Mixer”, International Journal of Practices and Technologies, ISSN 1583-1078, Issue 20, January-

June 2012. [8] Siddhant Dange, Saket Sant, Anish Sali, Parthon

Pethodam, Sandeep Belgamwar., “Study of planetary concrete mixer”, International journal of latest research in engineering and technology, ISSN 24545031, Volume 2, Issue 4, April 2016. [9] Amruta K. Wankhede, Dr. A.R. Sahu Design,

“Modification and Analysis of Concrete Mixer

Machine”, International Journal on Recent and [10] Innovation Trends in Computing and Communication,

Volume:3 Issue: 12 6613 – 6616, ISSN: 2321-8169, 2015.