11 minute read

TEAMWORK A HOME RUN TEAMWORK

WHAT GOES INTO AN AWARD-WINNING PUBLICATION? A CHILDREN’S BOOK, A CARDBOARD MOCKUP, AND DRONE SHOTS OF A 5.5-ACRE RETRACTABLE ROOF, TO START.

Late in 2019, we had the exciting opportunity to work with Manhattan Construction Group to create a commemorative publication for their latest Texas project – Globe Life Field, home to the Texas Rangers. We knew this publication needed to be special, incorporating some sophisticated printing effects to best present the impressive construction feats taking place at the stadium. A huge plus to a printed medium is that it provides a tangible experience for the reader, allowing them to physically interact with the content. There are lots of options to make that experience fun and flashy, but we really wanted it to be meaningful as well.

First, we assessed the most unique aspects of the project that deserved to be highlighted in the publication. We considered features such as the 100-foot-tall brick archways, the 1.8-million-square-foot HVAC system, the use of the largest crane in North America, and perhaps most notably, the 5.5-acre retractable roof. How could we draw attention to this impressive, mobile feature of the ballpark? Designer Molly Dixon had an idea.

What if the magazine opened the way that the roof does? Could the pages retract? We started to consider something like a foldout poster, but wanted to replicate the way that the roof actually operated as closely as possible. The roof is the largest single-panel operable roof in the world and slides open laterally on a track. We started brainstorming how the page could pull out to emulate this.

Inspiration comes in many forms One source of inspiration was none other than a children’s book belonging to designer Catherine Meany’s young daughter. The pages of Picture Magic Farm have tabs that pull out to the side to reveal color versions of the illustrations on each page. While not exactly the solution we needed, mechanically the idea was very similar and proved to be a helpful visualization tool (pictured at right).

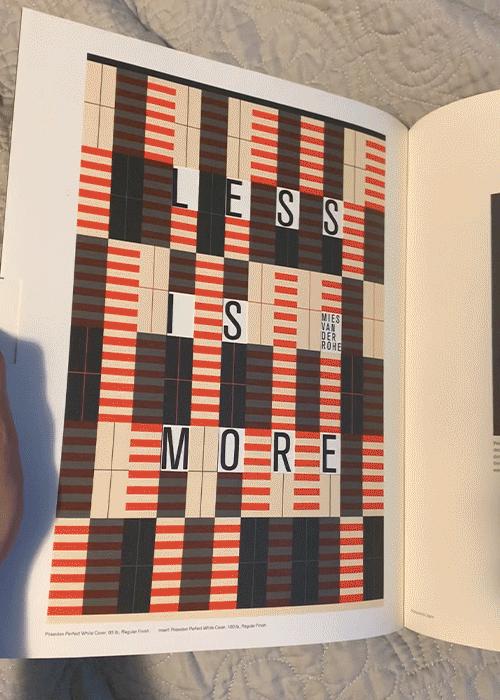

Another reference source was a coffee table book about art that Molly had seen. This book used similar pull-tab features to illustrate interactive artwork and design concepts. This further demonstrated the potential for something like that to work for our content (pictured at right).

A team effort

Next, we pitched the idea to the communications team at Manhattan Construction Group. It all hinged on getting two identical photos from directly above the stadium, one with the roof closed, and one with the roof open, to make this work. The construction team was already using drones to capture images of the construction progress along the way, and they agreed to take these images for us. They even arranged a test shot for us to work with and request adjustments to during production.

With the Manhattan Construction Group team on board and a loose concept of how this could operate, we met with our local printer Welch Printing Company to see if it was even feasible. Coincidentally, they had just finished another job printing invitations that had a similar pullout tab. We pitched the details of our idea, and they came back to us with a cardstock mockup to demonstrate how it could work. This would turn out to be a vital reference point for us as we put those pages together!

By design

For the rest of the publication, we pulled inspiration from both the sport of baseball as well as the Rangers’ branding to create recurring design elements. For example, we used a double chevron near each introductory paragraph and pull quote to subtly represent the stitches on a baseball. We also used a baseball diamond as the symbol to signify the end of each story, and a pennant shape as a page label.

For each section intro, we took an illustration of baseball stitches and placed it across two pages to give the illusion of a rounded shape. To make these pages stand out even more, the graphic was printed using UV-coating only on the illustration, which creates a gloss effect on the page (pictured below).

The Rangers organization was gracious enough to share the font graphics used for their team jerseys and other branding materials. We used this typography for the page numbers on the table of contents, for the by-the-numbers sidebars, as well as for the drop caps.

Curveballs

The construction of the stadium and the production of the magazine were occurring simultaneously. We knew many of the images were going to get to us at the last minute, including these crucial shots of the roof. Opening day for major league baseball 2020 was quickly approaching, which meant our deadline for press was approaching even faster. The goal was to hand out the magazines at the Rangers home opener, and we had to allow time for printing, including the hand labor to create this pullout page, and shipping. As a result, we were unable to get a photo of the finished roof and stadium in time for use in the publication.

Little did we know what 2020 would have in store. Covid-19 did not delay our print production, but it did delay the start of MLB and the public reveal of the brand-new stadium. Had the timing been a little different, maybe we could have gotten those finished project photos of the roof!

In the end, we were very excited to see this come to life. We couldn’t have done it without Manhattan Construction Group’s team, the Rangers and Welch Printing Company being so cooperative and wonderful to work with. All around, this project was an impressive display of TEAMWORK.

Globe Life Field would go on to win Associated General Contractor of America’s Build America award. As construction manager for the project, Manhattan Construction Company received the 2021 Construction Risk Partners Build America Award for Construction Management New or Renovation ($100 million or more). TEAMWORK would go on to win two 2020 Maggie Awards for Best Overall Trade Publication and Best Annual, Semi, Three-time, Quarterly/Trade Winner.

Catherine Meany is the design manager at Innovative Publishing. Reach her at catherine@innovativepublishing.com.

The page labels were made in a pennant shape

Full Swing

plate was dug up at Globe Life Park, which had been the home of the Rangers since 1994, and then ceremoniously placed in the Rangers’ new ballpark, Globe Life Field. That home plate has seen more than 2,000 regular season games in front of thousands of Rangers fans, and its journey from one ballpark to the other demonstrates the importance of honoring a legacy and continuing traditions, even when they continue in a new place.

That nod to the past can also be felt in some of the architectural features at Globe Life Field, most notably the brick arches that run along the ballpark’s north façade. These arches are reminiscent of the exterior of Globe Life Park, which consists almost entirely of brick arches that face outward from the ballpark.

“Brick itself can lend a feeling of history to an otherwise modern structure, as masonry is a time-tested building profession,” said Bill Van Meter, project manager at DMG Masonry.

“Even before there was steel, there was a guy back in cave days who put one rock on top of two rocks to create a wall. I live that. It’s what we do,” Van Meter said.

Of course, brick masonry has come a long way since cavepeople roamed the earth, and the arches at Globe Life Field are a testament to the potential of masonry.

Unlike the Rangers’ old ballpark, the 18 arches at Globe Life Field are built so that the openings line up and create a tunnel effect. DMG Masonry designed, built and erected the brick arches, which also included granite and limestone at the bottom of the columns supporting the arches. Both the main concourse and the upper concourse thread through the 100-foot-tall archways.

“They’re all lined up over your head, when you’re walking down the upper concourse on the north track,” Van Meter said. “It’s a stunning feature.”

At the Rangers’ old home, the brick arches were an exterior feature, but the arches at Globe Life Field are central to the ballpark’s design, both inside and outside, and intersect the 1,000-foot-long glass curtain wall on the north façade.

Even right beside a sleek, modern glass curtain wall, brick archways, which have been around for centuries, acknowledge a history. Certainly, Rangers fans will notice the connection and the continuity from the team’s old stadium. Despite being in a brand-new ballpark, Rangers fans will feel like they’re home at Globe Life Field.

“That’s the cool part to me,” said Andy Patteson, senior superintendent at Manhattan Construction. “They’re wanting to incorporate some of the old

The Rangers organization shared the font graphics used for their team jerseys and other branding materials for use in the bythe-numbers sidebars, as well as for the drop caps ballpark features into the new ballpark and trying to carry on a tradition.

“I’m out here day in and day out watching it go up, and I bring in a fresh set of eyes and show them, and they’re wowed by it,” Patteson said.

To create that look, the structural steel columns were erected first, followed by precast panels. Getting the precast panels into place was difficult, Van Meter said.

Each arch consists of about 42 pieces that weigh between 800 and 1,200 pounds, he noted. But there was nothing to work from except the steel structural. DMG Masonry had to figure out how to build the arches using the precast panels and how to access the hardto-reach areas in order to lay roughly 650,000 bricks.

“The floor of the upper concourse is not designed for the weight of a forklift that was capable of reaching that high,” Van Meter said. “I had to come up with a way that we could do it off of scaffolding that made it quite a bit more challenging and more labor-intensive.”

Even though the process would take more time, the masons were at the mercy of the other trades to finish their work before they could start the hand-laid brick on the arches.

“Everything had to be finished before we could get in there to do the hand-laid brick on the steel columns.

It was all framed — stud framing — with sheathing and water barrier, and you had to have all your water barrier intact and complete before we could start,” Van Meter recalled. “We’re the last of the process.”

DMG Masonry was also on-site in the earlier stages of construction, building some lower-level parts of the ballpark that most fans will never see.

Using about 533,000 concrete masonry units (CMUs) reinforced with rebar and grout, DMG Masonry worked with Manhattan and other subcontractors, including plumbers and electricians, to build elevator shafts and mechanical areas with piping, chillers and other equipment, Van Meter explained.

“We had to work hand in hand with everyone,” he said. That cooperative effort is precisely what made the Globe Life Field project a success despite its engineering challenges. That level of cooperation comes from having a good team, a team Manhattan carefully selected based on experience and trust.

“As subs, we know that Manhattan has got a track record with the kinds of projects they do, and they will get it done. They’re going to do everything they can to help, but every day’s a challenge. It’s a challenge that I look forward to, that we all look forward to. Even as challenging as it is, I enjoy working with Manhattan — or we wouldn’t do it,” Van Meter laughed.

DMG Masonry has been working with Manhattan for Van Meter’s entire career, which spans almost 30 years,

–BRYAN TRUBEY, PRINCIPAL AND EXECUTIVE VICE PRESIDENT, HKS and in that time Van Meter has come to appreciate Manhattan’s professionalism.

Working together, Manhattan, DMG Masonry and the rest of Manhattan’s subcontractors have accomplished some impressive architectural feats. Among them are Globe Life Field’s 100-foot-tall brick archways with a design that harkens back to the history of Rangers baseball. The arches are an iconic feature that’s sure to be appreciated by Rangers fans in Arlington and everywhere.

“When you pull up, what you’ll notice are those arches — those 18 brick arches in a row,” Van Meter said. “When you watch a baseball game on TV when they hit a home run, you’re going to see my arches in that shot because that’s [where] they’re hitting the ball.”

A double chevron near each introductory paragraph and pull quote was used to subtly represent the stitches on a baseball