7 minute read

Polymer gives 3D-printed sand super strength

from IM2021EN

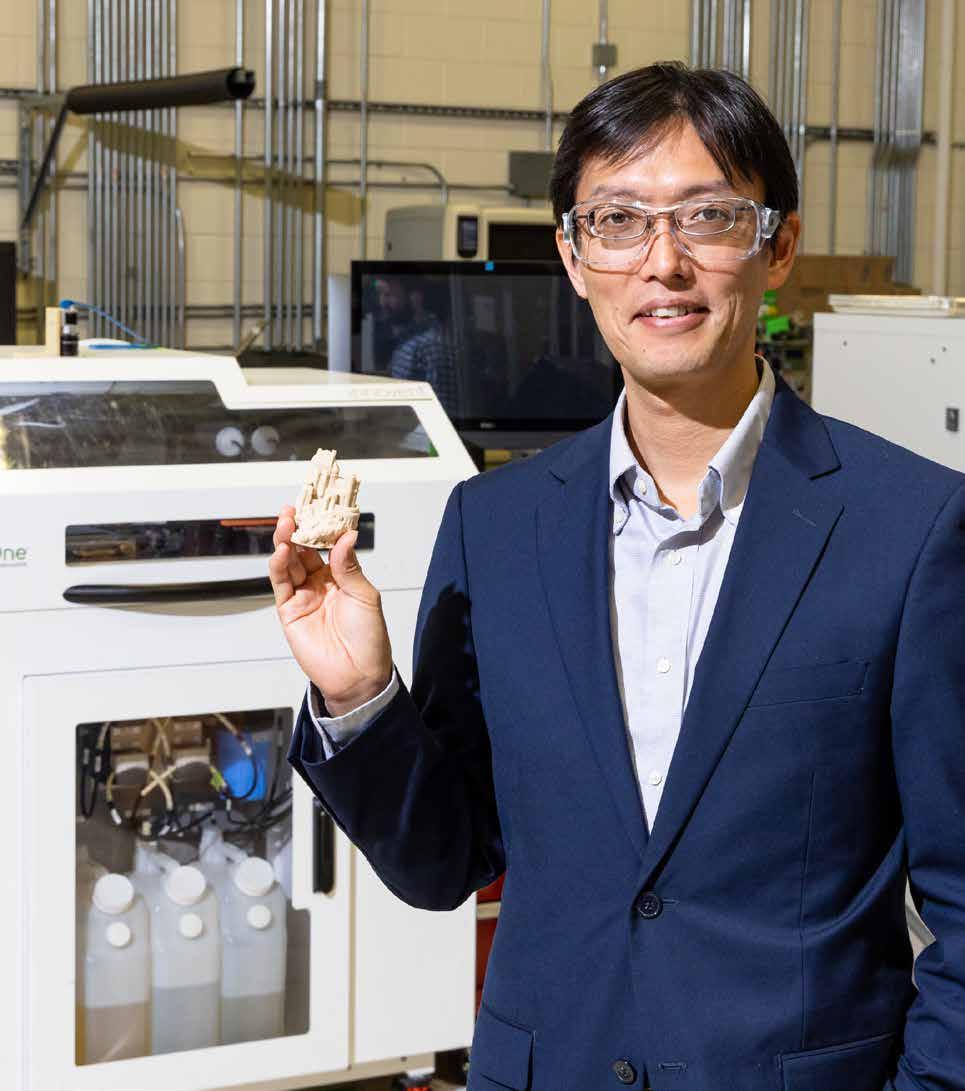

Researchers at Oak Ridge National Laboratory's (ORNL) Department of Energy have developed a new polymer to bind and reinforce 3D-printed silica sand. The polymer is added in binder jetting, a 3D printing method, such as used in the manufacturing industry. The study demonstrates a 3D printed sand bridge that at 6.5 centimeters can hold 300 times its own weight.

Binder jetting is a 3D printing technique in which powder particles are bonded together with a liquid binder. The binder, not the powder comes from the inkjet printhead. The powder cover is replenished after each layer. The binding polymer gives the printed sand its strength. The binder jet printing process is said to be cheaper and faster than many other industrial 3D printing methods.

Advertisement

Parts printed via binder jetting are initially porous when removed from the print bed. They can be strengthened by infiltrating the design with an additional super-glue material called cyanoacrylate that fills in the gaps. This second step provided an eight-fold strength increase on top of the first step, making a polymer sand composite stronger than any other and any known building materials, including masonry. Parts formed with conventional binders

are made denser with infiltrate materials, such as super glue, but the Oak Ridge team instead used a newly developed polyethyleneimine or PEI binder. This doubled the strength of the sand compared to conventional binders. The PEI binder’s impressive strength stems from the way the polymer reacts to bond with cyanoacrylate during curing.

Silica sand is a cheap, readily available material that has been gaining interest in automotive and aerospace sectors for creating composite parts with sand casting moulds. However, today's sand casting moulds and cores have limited industrial application because they are prone to failure. Stronger sand parts are needed to support manufacturing at a large scale and enable rapid part production. According to the ORNL researchers, the new high-strength polymer sand composite elevates the complexity of parts that can be made with binder jetting methods, enabling more intricate geometries, and widens applications for manufacturing and construction.

More at ORNL>

The research was published in Nature Communications in November titled ‘Additive manufacturing of strong silica sand structures enabled by polyethyleneimine binder.’ It is online>

Oak Ridge National Laboratory scientist Tomonori Saito shows a 3D-printed sandcastle at the DOE Manufacturing Demonstration Facility at ORNL (Credit: Carlos Jones/ORNL, U.S. Dept. of Energy)

5,6 & 7 April 2022 UTRECHT (WERKSPOORKATHEDRAAL)

The dates and location of MaterialDistrict 2022 are known. The event will move from March to April 5, 6 & 7 and from Rotterdam to Utrecht (Werkspoorkathedraal).

MaterialDistrict Utrecht (formerly Material Xperience) is the only annual event in the Netherlands that brings together material manufacturers and specifiers of materials in all sectors of spatial design (interior, architecture, garden & landscape, leisure, furniture & interior construction and exhibition, stage & decor). .

Click here for more information>

In-situ nanoscopic observations of local corrosion in aerospace aluminium alloys

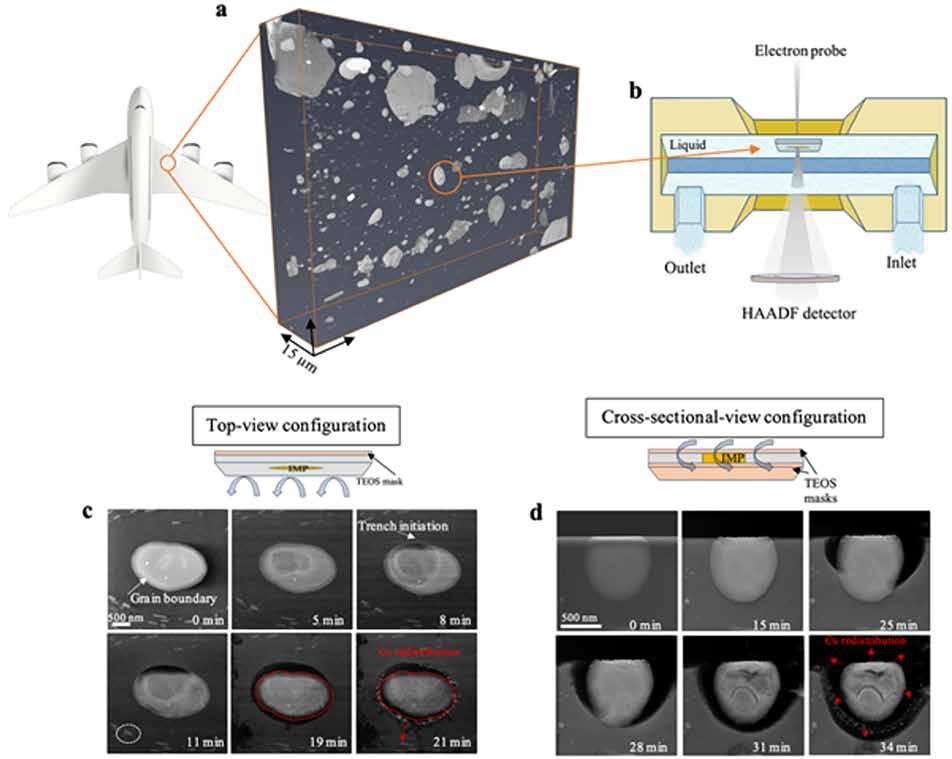

For many decades, local corrosion of high-strength aluminium alloys has been studied indirectly and through traditional and separately performed electrochemical, spectroscopic and microscopic techniques. The approaches employed to date commonly lack sufficient lateral and time resolution to unravel early-stage events. The corrosion events are controlled at the nanoscopic levels at which microstructural heterogeneities actually steer local and dynamic electrochemical activities. That is why theories of relevance are established through bridging and linking separately-obtained information and therefore are described in rather stochastic than deterministic terms. The detailed understanding of local corrosion mechanisms of engineered microstructures is of pivotal importance to developing reliable and active corrosion protection strategies.

Local corrosion in AA2024-T3, the most used aerospace aluminium alloy, is site-specific, with intricate local degradation events primarily occurring at surface intermetallic particles (IMPs) dispersed in the alloy matrix to improve mechanical properties. This can eventually lead to potentially catastrophic pitting and intergranular corrosion if left unattended and uninhibited in a timely manner. Dr. Ali Kosari applied liquid-phase transmission electron microscopy (LP-TEM) along with other analytical TEM techniques to study complicated degradation phenomena in AA2024-T3 in a project being led by Prof. Arjan Mol, Prof. Herman Terryn (Corrosion Technology and Electrochemistry, Department of Materials Science and Engineering, Delft

Figure: Liquid-phase scanning TEM for examining local corrosion degradation in aerospace aluminium alloys from surface initiation to in-depth propagation at the nano-scale. (a) Three-dimensional reconstruction of aerospace AA2024-T3 microstructure which leads to complicated corrosion. (b) Schematic of a liquid cell used for conducting liquid-phase TEM. The prepared TEM specimens are transferred to the home-made liquid cell using a focused ion beam (FIB)-based procedure. (c) Top-view scanning TEM observations are provided by masking one side of the TEM specimen using 25-nm-thick tetraethyl orthosilicate (TEOS). (d) Cross-sectional scanning TEM observations in which the TEM specimen is sandwiched between two 25-nm-thick layers of TEOS. The corrosive solution is 0.01 M NaCl.

University of Technology) and Dr. Frans Tichelaar and Prof. Henny Zandbergen (Quantum Nanoscience, Kavli Institute of Nanoscience, Delft University of Technology). Through a dedicated and intricate home-made experimental setup, they could, for the first time, directly evidence sequences of local corrosion initiation and propagation at different IMPs in real time and at the nanoscale. They showed that the intrinsic electrochemical stability of IMPs is a dominant factor governing the kinetics of local IMP-induced corrosion. Their research focuses on the early-stage self-corrosion (dealloying process) of various IMPs

and how this phenomenon affects the resulting local solution chemistry. As a result, detailed mechanisms explaining local corrosion of aerospace aluminium alloys are used to improve current techniques for active protection of this class of structural materials. On 6 October 2021, Ali Kosari received his PhD from Delft University of Technology (TU Delft) for the thesis entitled 'Corrosion and Corrosion Inhibition Studies of Aerospace Aluminium Alloys at the Nanoscale using TEM Approaches'.

The thesis can be found here>

Scientists explore method to produce composites with ‘shape memory’

Researchers from the Russian Skoltech Institute (Moscow) have investigated the shape memory behavior of a promising type of composite material: glass fiber reinforced epoxy-based flat laminates made by pultrusion. Pultrusion is a continuous shaping technique in which a fiber, provided with a resin, is drawn through a mould. The study was reported last November in Composites Part A: Applied Science and Manufacturing, titled ‘Investigation into the effects of inter-ply sliding during double diaphragm forming for multi-layered biaxial noncrimp fabrics.’ Shape memory polymers (SMP), are materials that can recover their initial shape under external stimuli such as temperature, light, moisture, acidity, electricity, or electromagnetic field. They are widely used in the aerospace, biomedical, and automotive industries, as well as in 4D printing, temperature sensors, and electronic devices. SMPs are often reinforced with carbon, basalt, or glass fibers, resulting in composite materials with superior properties. A number of techniques are used for SMP composite manufacturing, most of them fairly well-studied. Surprisingly, until now there have been no studies on the shape memory effect in composites produced by pultrusion - wich is, according to Skoltech - the most efficient composite manufacturing process available. It is a fast, versatile, and low-waste technology that could potentially yield new types of shape memory structural components with unique com-

Shape memory testing of cured resin and pultruded composite specimens: (a) deformed specimen of cured resin in the test fixture after heating; (b) cured resin specimens after shape fixing; (c) cured resin specimens after shape recovery; (d) deformed specimen of pultruded composite in the test fixture after heating; (e) geometry of pultruded composite specimen after shape fixing as compared to geometry of the test fixture; and (f) pultruded composite specimen after shape recovery (Credit: Roman Korotkov et al./Composites Part A: Applied Science and Manufacturing)

binations of geometries and mechanical properties, impossible to produce with other methods. The Skoltech scientists investigated the shape memory behavior and mechanical characteristics of epoxy-based pultruded flat laminates reinforced with unidirectional glass fibers. The analysis also encompassed the resin cure kinetics and the thermomechanical and thermophysical properties of the cured resin. The findings may be used for further numerical simulations and the optimization of the pultrusion process. Besides, the results demonstrate that pultruded SMPCs show significant promise for structural applications.