3 minute read

LASER PERFORATION Disrupts the Filter Industry

Compared to Traditional E-beam Processes, Laser Drilling Produces High-quality Filter Parts Far More Cost Effectively Than Traditional Manufacturing Methods

By Luca Longoni

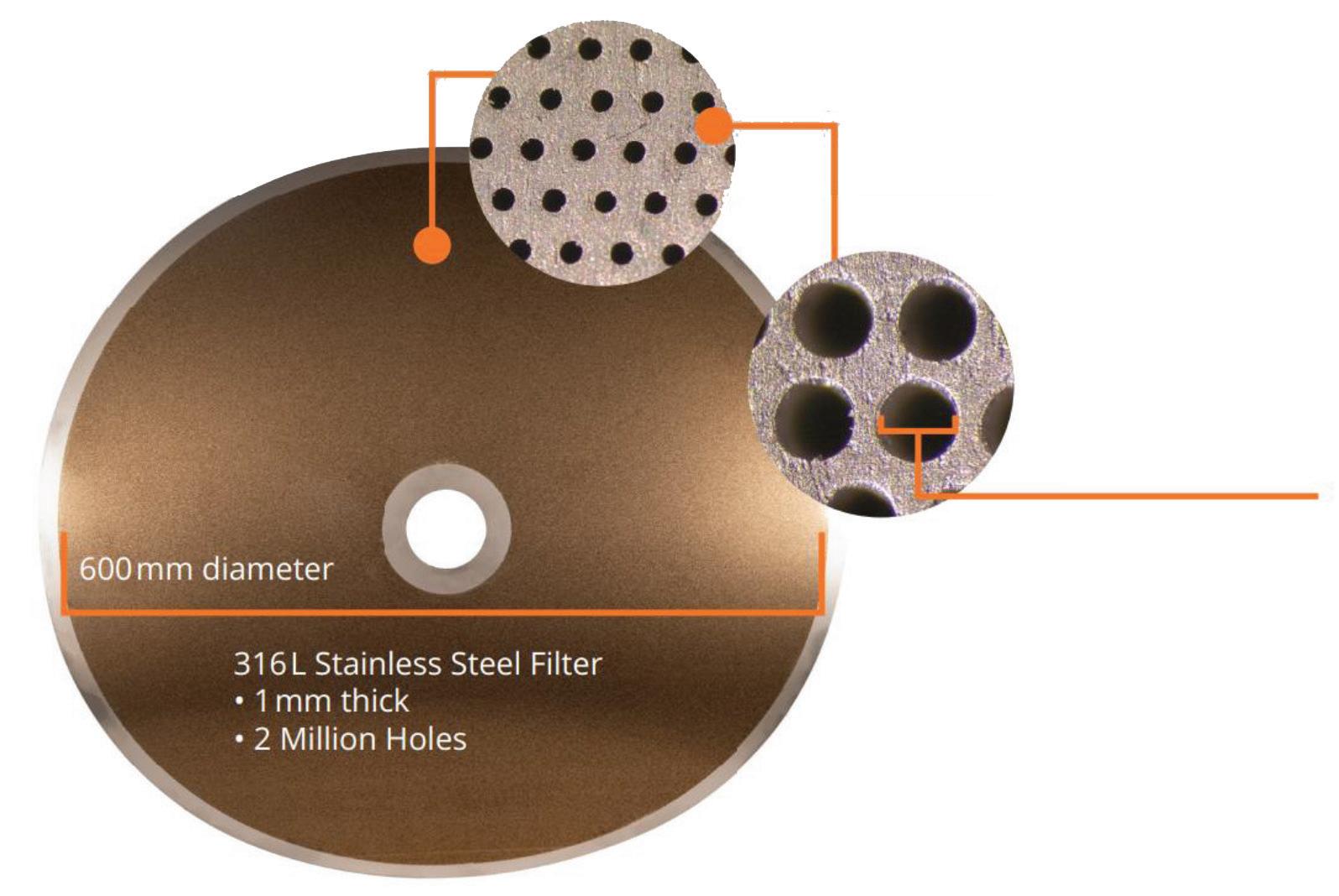

Fiber lasers are the tool of choice for precision metal work. For metal cutting applications, fiber lasers dominate due to their combination of speed, flexibility and precision. The advent of handheld welding solutions promises to quickly grow laser’s share over traditional techniques due to similar advantages. Years ago, the aerospace industry adopted laser drilling for perforating high performance metal parts to improve thermal performance. Now, advances in the productivity and precision of fiber laser drilling have begun to disrupt the industrial filter industry (Figure 1).

Filters are porous devices which remove impurities as material passes through. The quality of the filtered product relies on the uniformity and cleanliness of the filter holes. Lasers are a non-contact drilling technique which has no mechanical wear associated with tooling, so excellent hole uniformity is maintained over a lengthy fabrication process covering a large surface. In many cases, the smaller the holes, the better the filtering. Lasers are particularly suited to drilling holes < 100 µm diameter, which are challenging dimensions for traditional alternatives like chemical etching or mechanical punching (Figure 2).

Sustainability policies create new, demanding applications for high performance filters which laser drilling is uniquely able to fulfil. Plastic recycling plants melt incoming garbage, then pass the liquid through a sequence of filters, before re-solidifying the filtered material into recycled plastic pellet feedstock. Products made of recycled plastic, for example PET water bottles, must meet the high standards of the food and beverage industry. Laser-drilled filters featuring hole diameters in the 60-80 µm range are a field proven solution meeting these high standards.

Laser Drilling Materials

Drilling of common materials like stainless steel is accomplished by focusing an intense fiber laser beam to a spot diameter as small as 40µm. The intense laser melts and vaporizes the metal at a high rate with excellent consistency. High pressure nozzles direct gas which efficiently remove liquid and gaseous metal enabling the laser to drill deeper. In a short amount of time, usually just a few tens of microseconds, the laser punctures the backside, and the hole is complete. The laser is turned off, quickly repositioned, and the process repeats. In this manner, filters numbering millions of holes are fabricated at great speed with outstanding precision and uniformity. An excellent feature of laser drilled holes is the natural taper, meaning the exit diameter on the backside is smaller than the input side. This creates a useful funneling effect, while resisting harmful backflow through the filter.

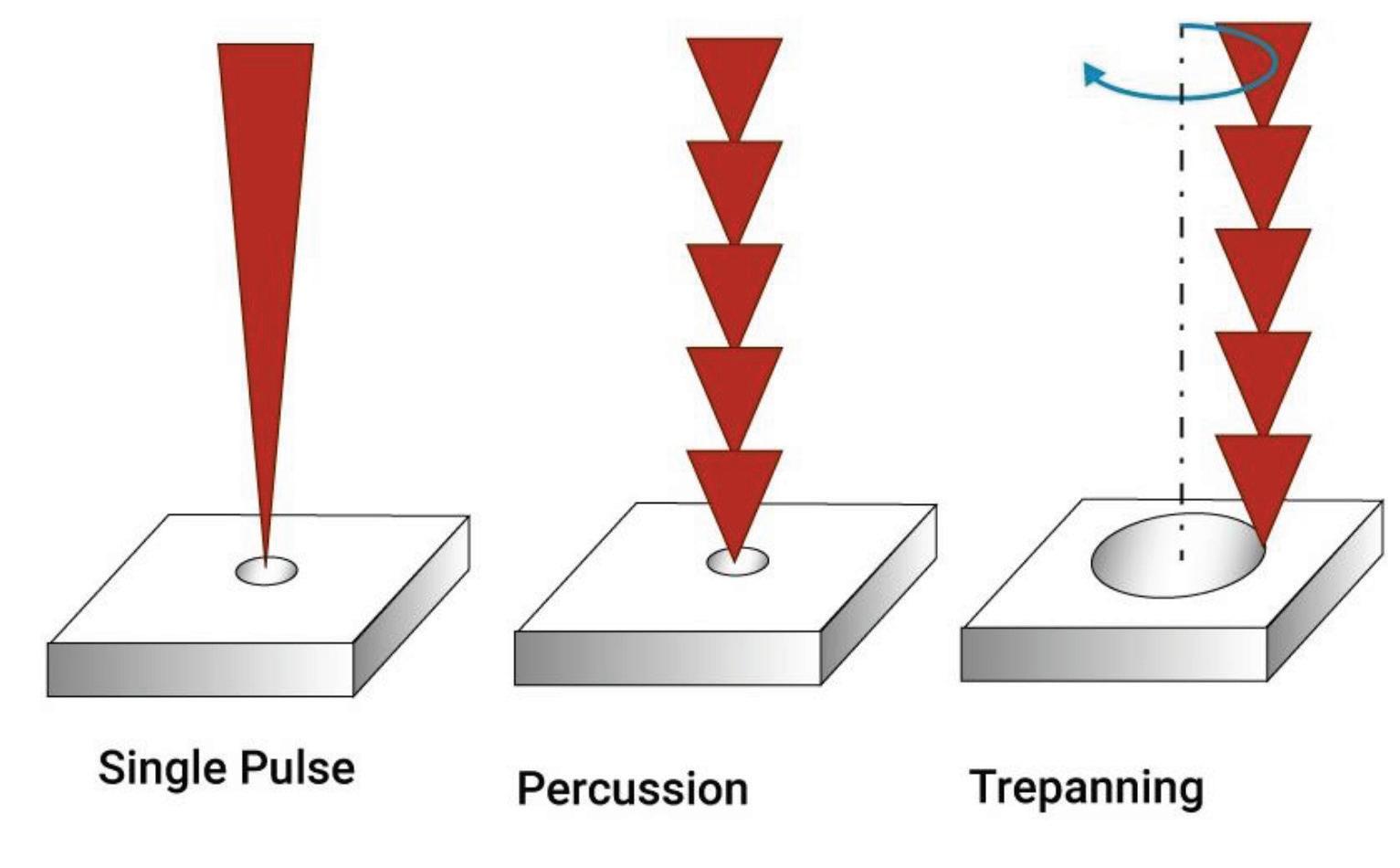

Laser drilling is a flexible technique able to employ multiple methods to optimize hole quality and throughput. The simplest is single shot drilling in which a single burst of energy penetrates the entire sample thickness. Single shot is the highest throughput technique, enabling a modulated laser to produce hundreds of holes per second.

Multi-shot, or percussion drilling, utilizes multiple laser bursts to minimize the overall thermal impact of the energy required to puncture the substrate. Percussion drilling is often accomplished

80 Micron Diameter Holes

Laser drilling easily penetrates stainless steel with high surface hardnesses.

Laser drilling creates highly tapered holes, minimizing back-pressure and risk of hole blind.

in concert with a galvanometric scanner and pulsed lasers which provide tens or hundreds of thousands of shots per second. This technique is most popular for microfabrication, where precision and quality requirements trump throughput. By repeatedly scanning the laser over multiple spots, high quality holes are created with minimal heat affected zone. The throughput challenges of multi-shot drilling are somewhat offset by its ability to create many holes in parallel (Figure 3).

Three Laser Drilling Techniques

A third technique called trepanning moves the laser energy in a spiral trajectory around the perimeter, resulting in a hole which is cut, rather than drilled. Trepanning is desirable for larger holes, because no energy needs to be expended to remove center material from the cut-out area. When trepanning, the laser spot may be moved either using mechanical or optical means. Large diameter holes of excellent quality are realized, but generally at a slower rate than is achieved by single shot or percussion drilling methods.

Throughput is maximized when “on the fly” techniques are employed, but precise timing is required (Figure 4). On the fly continuously moves the drilling head optic over the sample, without stopping to drill each position. By avoiding the inertia loss of stops and starts, on the fly maximizes laser utilization and drilling rate.

Filter fabrication is normally accomplished using parallel rows drilled by rastering the laser beam across the substrate in continuous motion. To ensure precision spacing and hole quality across the entire filter, heat input from the laser must be managed, else the substrate’s thermal expansion may bow upwards. The outer regions of the substrate are clamped to