4 minute read

Planting Biomass in Nonwoven Materials

Roswell Textiles core value is a commitment to support health, wellness and quality of life, while being eco-conscious and reducing environmental impacts. Their new ECOFUSE™ materials are the nonwoven textile solution to meet this mandate of using plant-based materials that can be composted and allow for substantial reduction in carbon emissions. It is manufactured from biopolymers, intended to replace conventional high carbon footprint synthetic plastics.

Formed in 2020, Roswell Textiles developed, commercialized, and scaled Canada’s first domestic supply of synthetic meltblown during the COVID-19 pandemic in response to a call to action from the Canadian Federal Government. At that time, the pandemic made it obvious for the need to create a supply of Canadianproduced melt blown filter media for PPE manufacturing, non-existent in the country. To pursue this, the company received some funding from the National Research Council Canada (NRC) for their efforts.

The Journey

Then known as Roswell Downhole Technologies – a manufacturer of tubing encapsulated cable for downhole sensor systems for oil and gas – the new Roswell Textiles transitioned away from that sector and put their expertise in manufacturing and machinery to work to develop sustainable materials for melt blown media. The team of mechanical engineers were able to move quickly from concept to application, scaling production quickly and efficiently by engineering and manufacturing its own nonwoven production equipment in-house and making its first commercial sale of Canadian produced melt blown material in just two months.

Roswell Textiles’ President Kyle Fiolka says, “We’re a smaller producer. We are focused on technology innovation and more niche, higher performing areas. Filtration is obviously very challenging, especially in the PPE space when you’re dealing with low DPs and medically certified devices. We have partnered with the PADM Group of Companies in Winnipeg to move it forward faster by providing converter capabilities, and they are now our parent company and strategic partner.”

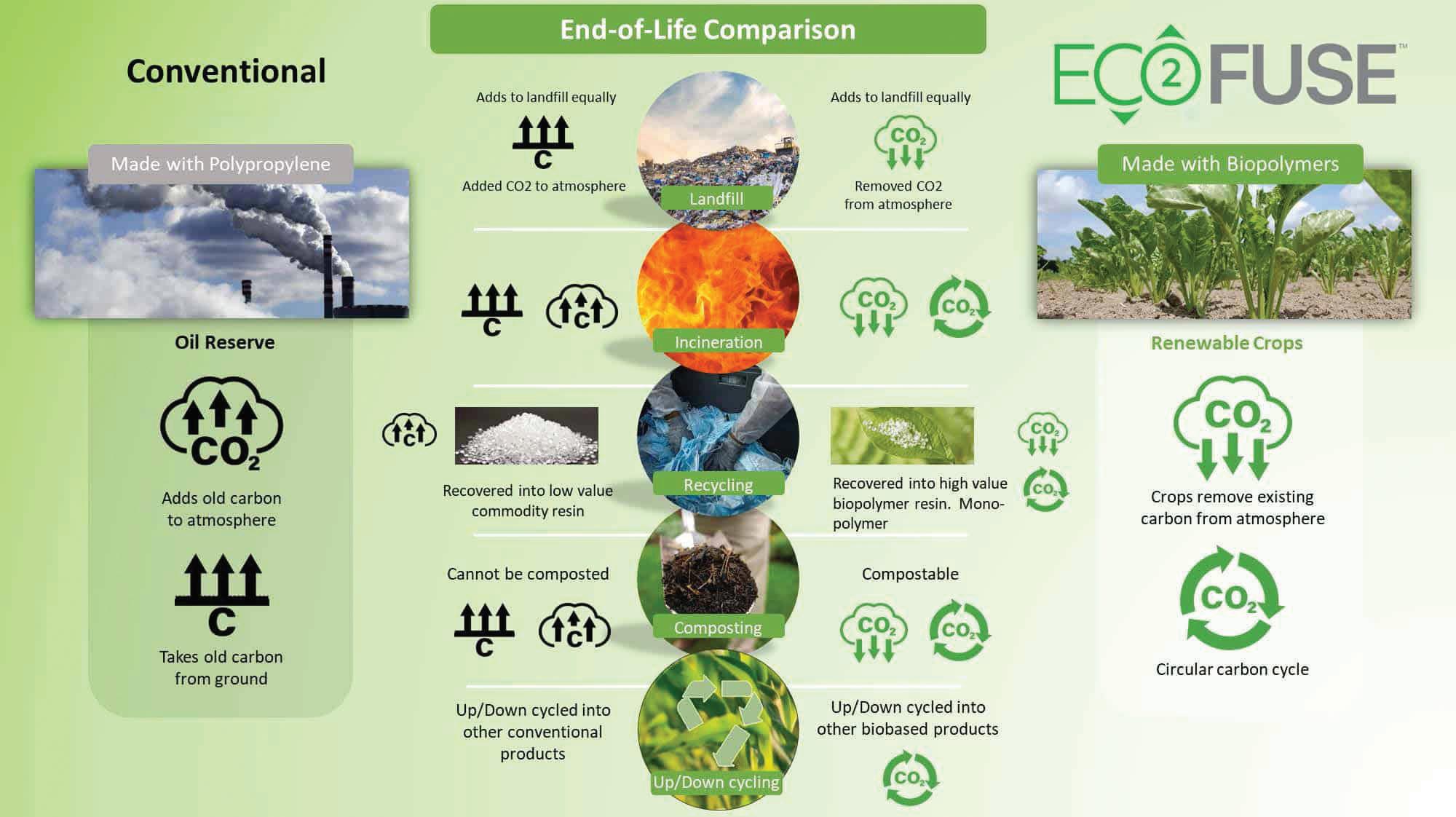

Roswell Textiles has now positioned itself as an innovative nonwoven manufacturer and OEM of biopolymer nonwoven equipment. They recently announced the next generation of high performance and technical nonwoven materials under the brand name of ECOFUSE™. These highly engineered materials possess simi- lar technical specifications as synthetic, polypropylene materials but with a 65% net carbon reduction. As a result of their plant-based start of life, they contribute to a more sustainable and circular economy.

Product Expansion

ECOFUSE™ materials are already commercial in medical, water and residential filtration applications with additional commercialization processes underway in hygiene, food and beverage packaging and construction materials.

“We’ve been working through the certifications of our PPE device (ECOFUSE™ is 82% of the raw material in PADM Medical’s PRECISION ECO™ procedural mask) and our big news is that as of March 8th, we received an FDA 510(k) Clearance on the product,” says Fiolka. (Kyle also serves as PADM Group’s Chief Innovation Officer). “That is extremely difficult. To our knowledge, we are the first PPE that the FDA has approved as a non-synthetic based procedural mask, so it is a big p ECOFUSE™ is 82% of the raw material in PADM Medical’s PRECISION ECO™ procedural mask. achievement.” The ECOFUSE™ biopolymer material is also a USDA Certified Biobased Product (100%) and tested to conform with ASTM D6400 and ASTM F2100 for finished product certification.

The Bio-Story

ECOFUSE™ is derived from crop feedstocks which offer a carbon footprint reduction when compared to hydrocarbon derived polymers. The product breaks down at end of life in an industrial composting process. “The feedstock used in ECOFUSE™ technology are regionally specific. Crops like corn, sugar cane, sugar beets are used to produce the biopoly- mers” says Fiolka. “Since we developed the proprietary machinery and process conditions to suit, it is a modified nonwoven process.”

The product does not leave residuals or toxins in the soil as it decomposes. “We validate that with life cycle analysis,” says Fiolka. “We also encourage our clients to know the total impact of their finished product to the end of life. Even in incineration, biobased materials have a better footprint when it comes to emissions compared to polypropylene, for example.

Users of ECOFUSE™ can pursue an ISO accreditation or apply for carbon offset or carbon credit programs. We’re familiar with analyzing materials in that way because it’s how we’ve ensured that we’re doing something that’s truly better from an environmental impact perspective.”

The company’s focus is on commercializing biopolymer and low carbon footprint materials that can replace conventional nonwovens for use in filtration applications and other industrial products. “We have a vision of leading mass adoption of plant-derived nonwovens to help the world transition to more sustainable products. We feel that ECOFUSE™ can help drive this adoption by breaking down technical barriers for regulated products requiring high performance filtration properties. We came at this challenge from purely an engineering and theoretical perspective, and maybe that’s why we were able to do what we did. We didn’t have limitations in the possibilities and outcomes,” says Fiolka.

The challenges to overcome in PPE development included using nonconventional materials to produce microfibers that can effectively filter particles while maintaining high breathability. Also, the requirement to have a suitable shelf life for the product was critical. The requirement to provide a fluid jet barrier for the product had to be overcome to achieve the appropriate ASTM performance, as well.

Current applications for ECOFUSE™ are procedural/surgical masks and respirators, industrial and commercial air handling filters, and liquid filtration (water).

“In hindsight, we began in a very challenging nonwoven sector, looking at it from a regulatory perspective,” says Fiolka. “Yet, we were able to achieve success, so now other commercial applications are much simpler to adopt. We are receiving more inquiries for different applications. As equipment manufacturers, we have the ability and advantage to work with clients and deliver complete solutions at scale quickly and economically.”

Innovations like ECOFUSE™ help close technological gaps to allow consumers and producers the option to choose sustainable materials.