3 minute read

Treatment of AFFF IMPACTED WATER

Application of Foam Fractionation Technology for Remediation of AFFF Wastewater

By Dr. Mirka Wilderer

In firefighting scenarios involving flammable liquid fires (i.e., jet fuel or petroleum fires), highly effective suppression methods are required. One such method has been the use of aqueous film-forming foams (AFFF), a specialty foam that spreads rapidly and forms a protective film, preventing the release of flammable vapors. Per- and polyfluoroalkyl substances (PFAS) have historically been a key component of AF; their surfactant properties allow the foam to spread quickly, and the strength of the carbon-fluorine bond ensures stability in extreme heat. AFFF has been in use since the 1960s to put out fires at military and civilian airports (see Figure 1), refineries and chemical plants, fire departments, and harbors and marinas.

Public health concerns have led to a gradual phase-out of AFFF in favor of fluorine-free foam (FFF), which does not contain PFAS.2 Despite their phaseout, thousands of sites across the United States continue to face groundwater contamination issues associated with historic AFFF use.3 Furthermore, millions of gallons of AFFF are stored in firefighting trucks, hangars, and suppression systems across thousands of locations. As AFFF is replaced, storage sites are rinsed and AFFF-rich wastewater is produced in the process. The designation of PFOA and PFOS as hazardous substances under CERCLA in April 2024 provides the legal framework required to kick-start the cleanup and treatment of impacted rinse water at these sites.

The Need for Innovative Treatment

The complexity of AFFF-impacted waste streams often creates challenges for traditional PFAS treatment technologies. Depending on the source (i.e., impacted tions, the lifetimes of granular activated carbon (GAC) and anion exchange (IX) resins decrease, thereby increasing the total operating cost of a remedial system. Furthermore, the presence of other nonPFAS surfactants and organic chemicals in AFFF-impacted waters may affect the effectiveness of adsorption and ionic exchange mechanisms. groundwater vs. AF rinse water), concentrations of PFAS can be in the parts per billion or parts per million range, whereas typical municipal drinking water applications tend to be in the lower parts per trillion range. At these higher concentra-

Due to these challenges, alternatives to GAC and IX are being explored. One such alternative is AqueoUS Vets’ FoamPro™ foam fractionation system. The patented FoamPro™ system creates micro-bubbles that facilitate the removal of PFAS by pressurizing the treatment reactor with a vacuum pump. Vacuum pressure also creates flow within the reactor, eliminating the need for mechanical pumping during conventional foam fractionation. Furthermore, the vacuum pressure facilitates one-step PFAS removal and foam dewatering, simplifying the overall treatment process compared to conventional foam fractionation.

Treatment Results

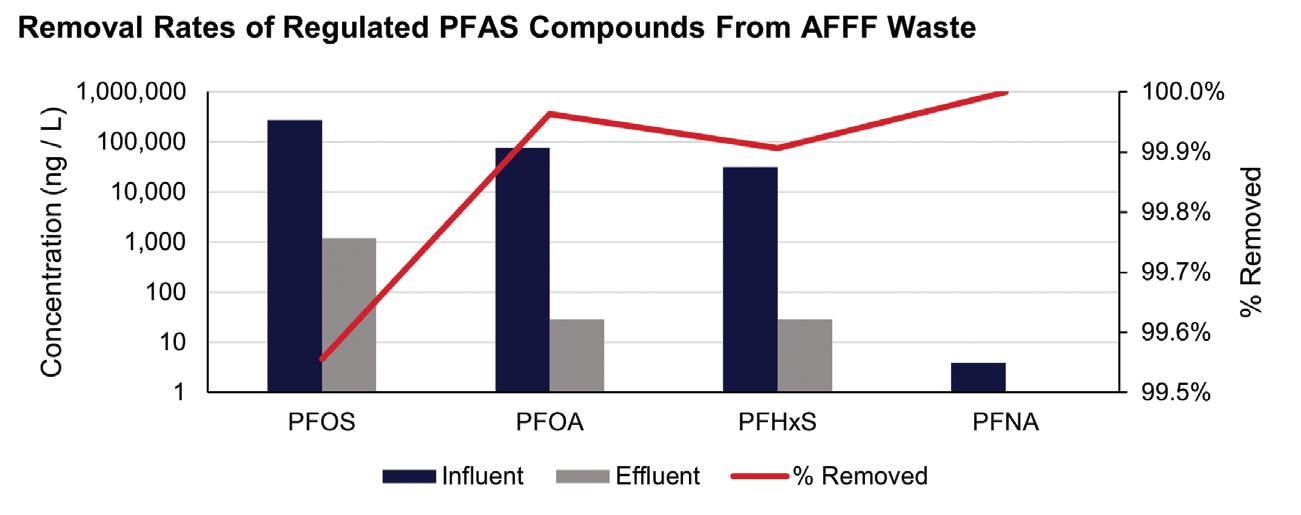

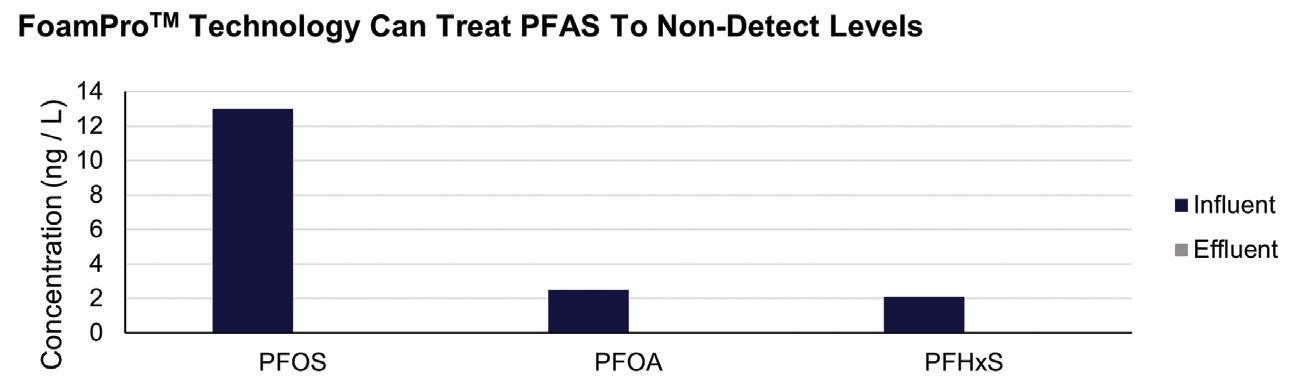

The FoamPro system was tested at the US EPA's Test and Evaluation Facility in Cincinnati, Ohio, on AFFFimpacted water. The treatment results for contaminants regulated by the US EPA’s maximum contaminant levels are shown in Figure 2. In this test, a co-foamer was used to enhance the adsorption capacity of short-chain PFAS, consistent with previous reports on conventional foam fractionation technology.4 The results in Figure 3 show the removal of PFAS compounds to nearly 100%. Depending on the treatment goals for a given application, retention time and the number of phases can be adjusted to achieve even the most stringent effluent limits. Figure 2 shows treatment of PFOA, PFOS, and PFHxS to non-detect levels from initial

References

1. Photograph: State Archives of Florida/ McDonald.

2. United States Government Accountability Office. “Firefighting Foam: DOD Is Working to Address Challenges to Transitioning to PFAS-Free Alternatives.” GAO24-107322, July 2024.

3. Salvatore, Derrick, et al. “Presump - concentrations in the part per trillion levels. These results indicate that the FoamPro™ system is a highly flexible solution amendable to a variety of different effluent types and deployment scenarios.

Benefits & Applications

Due to the capital and operating cost advantages this technology offers over conventional foam fractionation and media filtration technologies, FoamPro can play a significant role in treating traditionally challenging PFAS waste streams. With a small footprint – the size of a standard 275-gallon tote in which liquid wastes are typically stored – rapid portability, and low power requirements, this system is well suited to on-site and mobile treatment in emergency applications. The FoamPro™ can reduce waste volumes by 100-10,000 times and, in combination with one of the many available destruction technologies on the market, facilitates the cost-effective destruction of PFAS-laden waste.

Dr. Mirka Wilderer is recognized as one of the leading female executives in the water industry with deep experience in corporate strategies, business transformation, and cross-functional leadership in global organizations. Mirka is a seasoned executive with two decades of experience in the water industry. Prior to Aqueous Vets, Mirka was the CEO of De Nora Water Technologies. Mirka started her career at Siemens AG as strategy consultant and held management positions in Germany, China, Thailand, Indonesia, the United States and South Africa.

tive contamination: a new approach to PFAS contamination based on likely sources.” Environmental Science & Technology Letters 9.11 (2022): 983-990.

4. Buckley, Thomas, et al. “Effect of different co-foaming agents on PFAS removal from the environment by foam fractionation.” Water Research 230 (2023): 119532.

the Topics and Technologies that will Shape the Future of Filtration and Separation.

at www.filtnews.com/