7 minute read

PFAS Removal from Drinking Water Strategies Using PAC, GAC,

Per- and polyfluoroalkyl substances (PFAS) are a large family of man-made chemicals characterized by the presence of strong carbonfluorine bonds. These compounds have been widely utilized since the 1940s in a variety of industrial and commercial applications, including non-stick cookware, waterproof textiles, food packaging, and especially firefighting foams (Rahman et al., 2014). Their chemical stability and resistance to degradation have led to their accumulation in water, soil, wildlife, and even the human body.

PFAS contamination in drinking water has become a global concern and a dominant topic of discussion across the media, policy and public health sphere. Due to their high mobility and persistence in the environment, PFAS are often detected in both surface and groundwater sources. As traditional water treatment processes – like coagulation, flocculation, and chlorination – are ineffective at removing PFAS, utilities and researchers have turned to more advanced technologies. Among the most prominent solutions are powdered activated carbon (PAC), granular activated carbon (GAC), ion exchange (IX) resins, and reverse osmosis (RO).

Ion Exchange Resins, and Reverse Osmosis

By Miles Menyhert

A growing body of scientific evidence links PFAS exposure to significant human health risks, including endocrine disruption, decreased fertility, immune suppression, developmental delays in children, liver damage, and increased risk of kidney and testicular cancers (EPA, 2024). These findings have led to increased scrutiny and regulatory action. In April 2024, the U.S. Environmental Protection Agency (EPA) proposed stringent national drinking water limits for six PFAS compounds, including PFOA and PFOS at 4 parts per trillion (ppt), a threshold lower than ever previously enforced (EPA, 2024). On March 14th of 2025, this regulation was narrowed to only include PFOS and PFOA by rescinding the maximum contamination limits and hazard index for the other four PFAS compounds (PFHxS, PFBS, PFNA, GenX).

The push for ultra-low detection and removal targets has intensified the need for effective and scalable treatment technologies. The following sections explore how PAC, GAC, IX, and RO compare in their ability to address PFAS contamination under real-world conditions.

Powdered Activated Carbon (PAC)

PAC is a fine carbon powder that can be dosed into water treatment systems to adsorb a wide range of organic contaminants. It is particularly effective for the removal of long-chain PFAS compounds, such as PFOA and PFOS, which are more hydrophobic and tend to adsorb readily to carbon surfaces. In municipal water treatment, PAC is typically added to the water during mixing and allowed to settle out with other solids before the clarified water proceeds through filtration.

PAC offers operational flexibility and low capital costs, making it a practical choice for emergency or temporary treatment scenarios. It can be introduced quickly into existing plants with minimal infrastructure changes. However, its effectiveness is diminished for short-chain carboxylic acid PFAS such as PFBA, which are less likely to adsorb due to their higher solubility and lower hydrophobicity.

To achieve meaningful PFAS reductions, PAC doses must often be much higher than those used for taste and odor control. Additionally, competition from natural organic matter (NOM) and other background organics can reduce the effectiveness of PAC, as these compounds compete for adsorption sites. Disposal of spent PAC, which contains concentrated

PFAS, poses additional handling and environmental concerns (Crone et al., 2019).

Granular Activated Carbon (GAC)

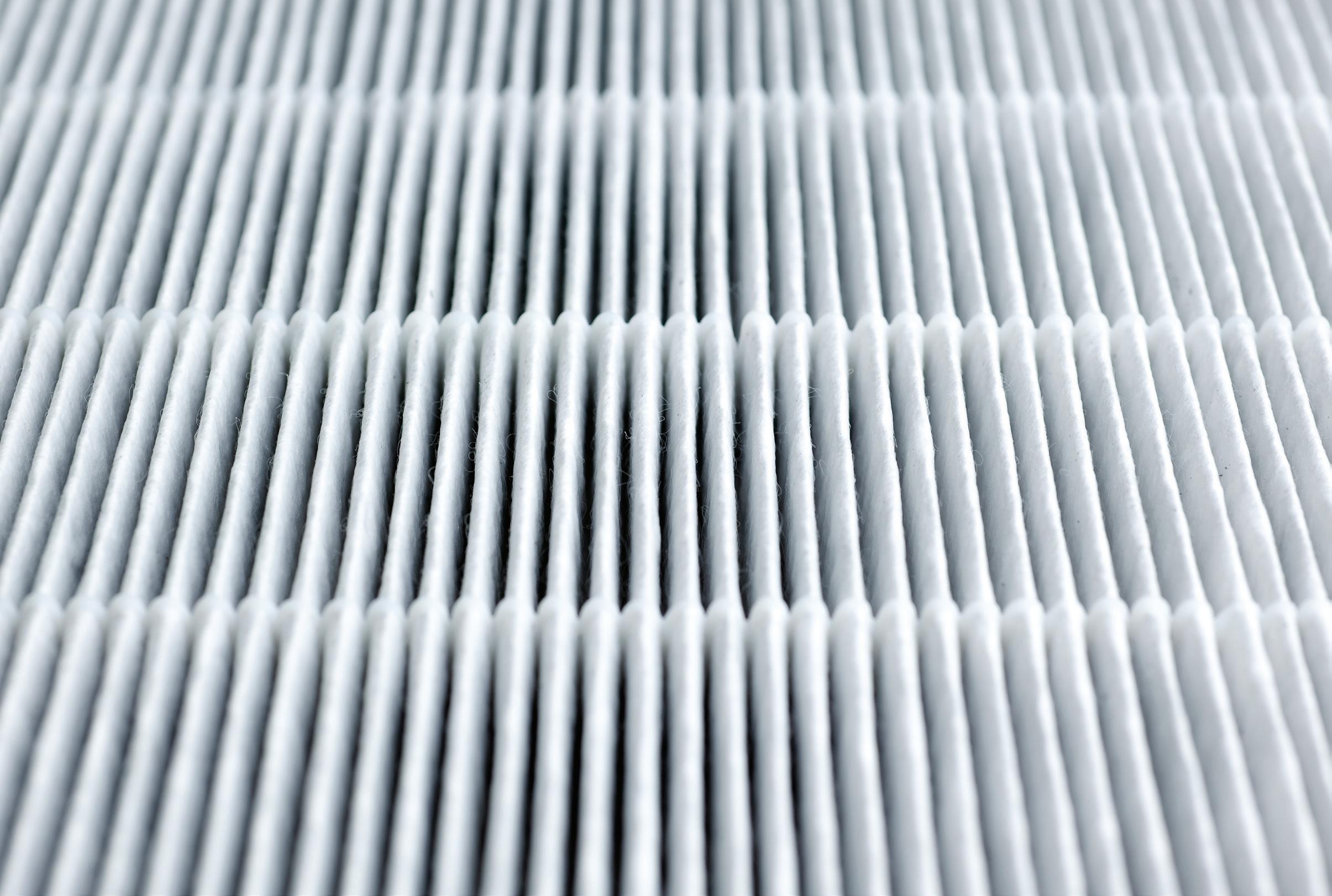

GAC is structurally similar to PAC but consists of larger granules and is used in fixed-bed adsorption systems. Water is passed through GAC filters, allowing PFAS compounds to adsorb onto the carbon surfaces over time. GAC is one of the most widely used technologies for PFAS removal and has been deployed in hundreds of municipal water systems across the United States.

GAC effectively removes long-chain PFAS compounds with empty bed contact times (EBCTs) of at least 10 minutes, though optimal performance may require longer contact times (20 minutes or more) and multiple beds in series. Over time, as adsorption sites become saturated, the media must be replaced or reactivated. Breakthrough monitoring is essential to prevent PFAS from re-entering the treated water supply.

Although GAC performs well for PFOA and PFOS, its performance for short-chain PFAS and new-generation substitutes like GenX is more limited. These smaller compounds tend to break through sooner due to their lower affinity for carbon. The effectiveness of GAC also depends on bed depth, flow rate, water temperature, and the presence of co-contaminants such as natural organic matter (NOM), which can clog pores and reduce adsorption capacity.

Nonetheless, GAC remains a trusted workhorse for PFAS treatment. It is relatively simple to operate, offers a moderate cost profile, and can be integrated into existing filtration systems. Some systems even employ GAC as a pre-treatment stage before IX or RO to extend the life of those more expensive technologies.

Ion Exchange Resins (IX)

Ion exchange resins are synthetic polymers designed to remove charged species from water. In the case of PFAS, strong base anion (SBA) resins are used, which can selectively remove PFAS molecules by exchanging them for benign anions such as chloride. These resins are engineered with functional groups and pore struc- tures that offer high affinity and selectivity for PFAS.

One of the key advantages of IX is its superior performance with short-chain PFAS and emerging replacement chemicals. Ion exchange resins also have fast kinetics, meaning PFAS is removed more quickly, thereby requiring less empty bed contact time.

However, IX systems are not without challenges. Their performance can be impacted by competing anions such as sulfate, nitrate, chloride, bicarbonate, and natural organics, which can interfere with PFAS binding. Additionally, once exhausted, resins require disposal as currently, regeneration is not widely used due to the chemical dosing requirements. IX technology is particularly effective when used in conjunction with other technologies in a treatment train approach.

Reverse Osmosis (RO)

Reverse osmosis is a pressure-driven membrane separation process capable of rejecting molecules as small as individual ions. RO membranes act as physical barriers that exclude PFAS compounds based on size and charge. Removal rates typically exceed 90% for both long-chain and short-chain PFAS, including challenging compounds for adsorbents like GenX and PFBS (EPA 2025).

Despite its effectiveness, RO has several limitations. It requires significant energy to maintain the high pressures necessary for operation. Membrane fouling from particulates or scaling from minerals can reduce performance and increase maintenance costs. Pretreatment steps, such as microfiltration or antiscalant dosing, are often needed to protect the membranes.

Another major challenge is the management of the brine waste, which contains a concentrated solution of PFAS and other contaminants. Disposal options include deep-well injection or treatment with destructive technologies, but these can be costly and logistically complex.

Nevertheless, RO remains the gold standard for high-purity water production and is increasingly being used as part of multi-barrier systems in municipal water treatment.

Integrated and Hybrid Approaches

Because no single technology perfectly addresses all PFAS species or operational constraints, utilities are increasingly turning to integrated treatment systems. These systems combine multiple processes to enhance overall performance and resilience.

For example, GAC is often used as a polishing step after IX or RO to remove residual PFAS or reduce organics prior to these systems that might interfere with resin or membrane performance. Hybrid approaches also allow utilities to balance cost, performance, and operational simplicity. While RO offers strong consistent removal across all chain lengths, its high costs and brine management needs may be offset by upstream treatment with GAC or IX. Similarly, using PAC as a pretreatment step can reduce the PFAS burden before reaching more sensitive or expensive technologies.

Operational Considerations

When designing a PFAS treatment system, several factors must be considered: influent PFAS concentration and speciation, target effluent levels, volume of water to be treated, and site-specific conditions such as source water quality and space constraints. Monitoring is essential for all PFAS treatment systems. Breakthrough curves for GAC and IX columns must be tracked to determine when media replacement is necessary.

For RO, membrane performance must be routinely evaluated for integrity and fouling. Cost is also a major consideration. While PAC is inexpensive on a per-dose basis, its ongoing operational demands may exceed those of GAC or IX over time and therefore PAC is recommended as a spot fix. RO has the highest capital and energy costs but offers unmatched removal capabilities in terms of consistency and broad PFAS removal.

Future Perspectives and Innovations

The future of PFAS treatment lies not only in separation but also in destruction. Technologies such as electrochemical oxidation, supercritical water oxidation, photocatalysis, and plasma treatment are being actively researched for their ability to break the carbon-fluorine bond and eliminate PFAS entirely. While these technologies show promise in lab settings, scalability and cost remain barriers to full implementation.

Material science also holds promise. New adsorbents based on metal-organic frameworks (MOFs), graphene oxide, or functionalized biochar are being tested for their PFAS selectivity and regenerative capacity (Rahman et al., 2014). These materials may offer lower cost, better performance, or easier disposal in future treatment systems.

Additionally, as regulatory limits tighten and the list of monitored PFAS expands, utilities will need to invest in adaptive systems that can evolve with changing standards. The development of analytical methods for real-time PFAS detection will also improve the responsiveness and efficiency of treatment operations.

Next Steps

PFAS contamination presents one of the most complex and persistent challenges in modern water treatment, and there is no “one solution fits all.” Technologies such as powdered activated carbon, granular activated carbon, ion exchange resins, and reverse osmosis each offer critical tools in the fight to protect drinking water supplies. While each has its strengths and limitations, their combined use in integrated treatment systems allows for flexible, effective, and scalable solutions.

As scientific understanding of PFAS continues to grow and regulatory pressure increases, innovation in treatment technologies will remain essential. Through continued research, pilot studies, and infrastructure investment, utilities can build resilient systems that ensure the long-term safety of drinking water for communities around the world.

References

Crone, B. C., Speth, T. F., Wahman, D. G., Smith, S. J., Abulikemu, G., Kleiner, E. J., ... & Schaefer, C. E. (2019). Occurrence of PFAS in source water and their treatment in drinking water. Critical Reviews in Environmental Science and Technology, 49(24), 2359–2396. https://www.tandfonline.com/doi/abs /10.1080/10643389.2019.1614848

Environmental Protection Agency (EPA). (2024). PFAS National Primary Drinking Water Regulation Rulemaking. U.S. Environmental Protection Agency; https://www.epa.gov/sdwa/and-polyfluoroalkylsubstances-pfas

Reducing PFAS in Drinking Water with Treatment Technologies | US EPA. (2025, February 26). US EPA. https://www.epa.gov/sciencematters/reducing-pfas-drinking-water-treatment-technologies Rahman, M. F., Peldszus, S., & Anderson, W. B. (2014). Behaviour and fate of PFAS in drinking water treatment: A review. Water Research, 50, 318–340. https://www.sciencedirect.com/science/ article/abs/pii/S0043135413008518

Miles Menyhert is an Applications Engineer specializing in drinking water treatment with Jacobi Carbons, Inc.

Resins’ high-quality epoxy and polyurethane solutions have solved complex filter manufacturing challenges for decades. Our experts partner with you, leveraging our experience to recommend products or formulate solutions designed for: