2 minute read

Spiral Water’s Filtration Products and Systems: Game-Changers in High Solids Separation and Concentration

Spiral Water Technologies’ advanced automatic, self-cleaning filtration products and systems are game changers when it comes to high solids separation and concentration. Our products offer a global solution for multiple markets and applications – from industrial wastewater treatment to biogas production, food processing and beverage production, biopharma, farm waste conversion, and more.

Our self-cleaning automatic filters are capable of processing considerable amounts of variable TSS and high solids loading. Compared to conventional selfcleaning filters that can only manage TSS up to 300 ppm, our products can manage TSS above 5,000 ppm and automatically manage upset conditions without operator intervention. This is because of our patented internal mechanical cleaning mechanism that keeps filters online and functioning, whereas other filters would overload and fail. In multifiltration processes, our advanced filter technology and control systems provide a top-of-the-line defense to give our customers peace of mind.

Not only are our filters setting new standards of performance – they are also significantly reducing Total Lifecycle Cost. They can filter water and other process fluids with up to 50 times higher solids than can be handled using traditional backwash filtration and separation technologies, while requiring just one pass and delivering 99% water recovery. In addition, their smaller footprint and lower weight contribute to reducing costs.

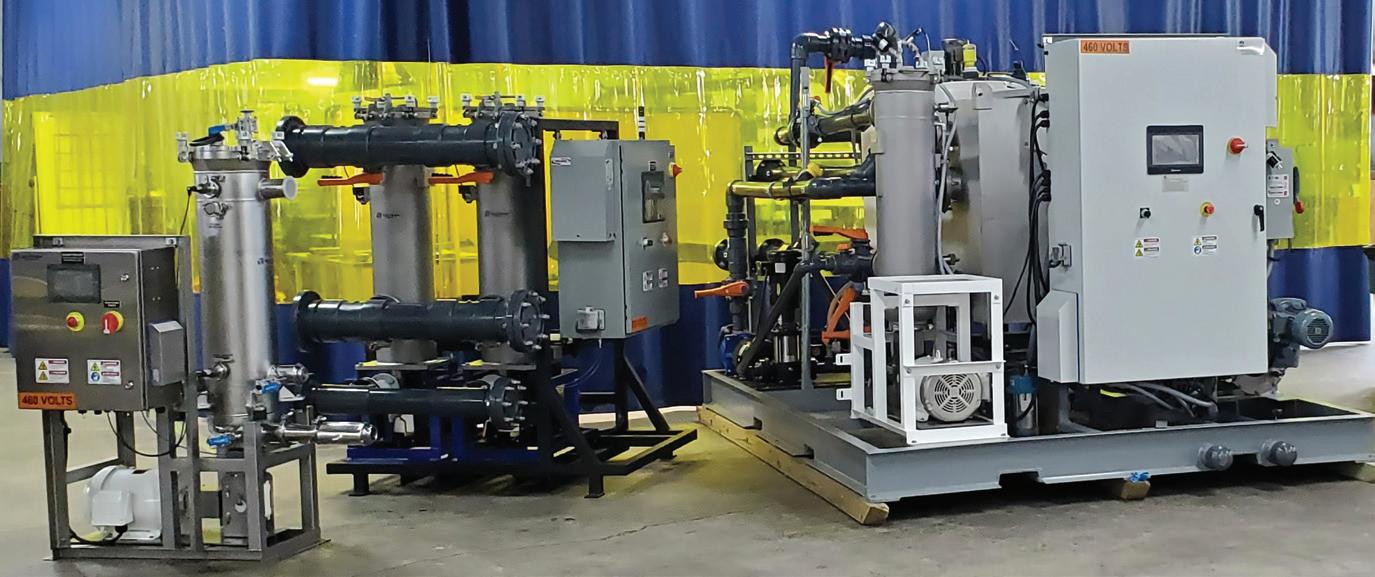

At Spiral Water, we don’t just sell our patented systems – we’ll work with you to tailor our products to fit your particular needs or facility. In doing so, we can create unique system solutions that align with your specific filtration requirements, whether you need a standalone product or require a complete custom integrated system.

Our filters are specially designed for seamless incorporation into customers’ existing filtration systems, allowing for enhanced efficiency without extensive modifications. Alternatively, we can design and engineer new water filtration systems that incorporate our filters. For example, our High Solids Water Recovery (HSWR) System – equipped with our Series 1000 self-cleaning filters–can manage high solids loaded process water with TSS greater than 15,000 ppm. And our Pre R/O System uses our automatic self-cleaning filters capable of handling upset conditions up to 2,000 ppm without operator assistance. We can also customize control systems to meet customers’ specific needs based on an existing control matrix.

Filtration Solutions in Action:

Biogas Production

Biogas/RNG production is increasingly important, and the biogas/RNG production process involves turning off-gassing products and decomposing material into a useful energy product. Enter Spiral Water. We design and develop water filtration systems that provide powerful solutions that help harness the full power of renewable natural gas.

Successful uses of Spiral Water technology include:

Digestate Processing: After the gas cycle is complete, sludge and digestate are removed. Our automatic self-cleaning filters remove inorganic non-digestible solids from the digestate stream while also increasing the efficiency of downstream water recovery and protecting process equipment.

Gas Scrubbing: Highly effective at removing a wide range of impurities from gas streams, water gas scrubbers play a key role in the efficient production of clean biogas and green hydrogen. Our T1000 systems allow water recovery and reuse of scrubbing water, reducing water waste.

Pressurized Dewatering of AD Sludge: When used in a closed loop, pressurized side stream dewatering helps minimize gas losses and reduces the risk of contamination and odors. Additionally, reusing digester water can significantly reduce water hauling charges. Rather than hauling water at $0.50 per gallon, Spiral Water allows for the reuse of AD, making real economic sense.

Feedstock Conditioning: Spiral Water’s systems are placed before anaerobic digesters to condition feedstock and remove as much contaminant as possible before it enters the anerobic digester, helping to increase gas production while preventing non-digestible solids from entering the digester.

To learn more about our products, systems, and specific applications, contact Spiral Water at info@spiralwater.com. www.spiralwater.com