2 minute read

NOTES TECH

PURE Bioscience Unveils Membrane Treatment Solution for Dairy, Beverage Industry

PURE Bioscience, Inc., creator of the patented non-toxic silver dihydrogen citrate (SDC) antimicrobial, announced an innovative application method for membrane treatment in the dairy and beverage industry using their flagship product, PURE ® Hard Surface. This groundbreaking solution addresses common membrane fouling and sanitization challenges, delivering outstanding results that enable operators to restore throughput and sanitize the membrane without damage or oxidation.

Tom Myers, EVP of Technology & Development at PURE Bioscience, stated, “The introduction of PURE Hard Surface to the Dairy and Beverage industry represents a significant advancement in membrane treatment technology. This product delivers unmatched efficiency and enhances filtration operation and longevity.”

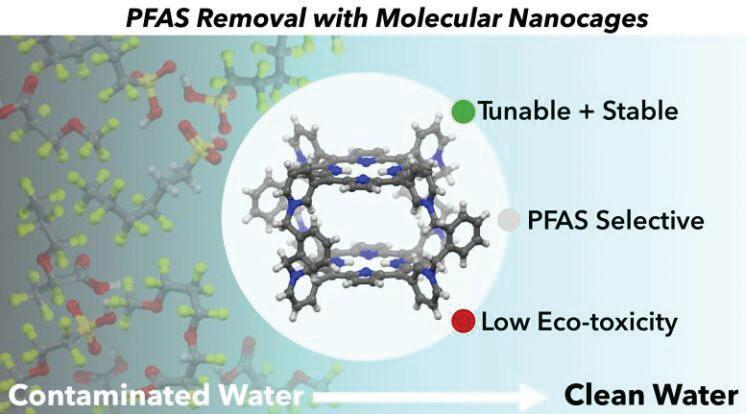

Molecular Nanocages Remove 80-90% of PFAS From Water

Researchers funded by the U.S. National Science Foundation have created a molecular nanocage that captures the bulk of per- and polyfluoroalkyl substances, or PFAS, found in water – and it works better than traditional filtering techniques that use activated carbon. Made of organic nanoporous material designed to capture only PFAS, this tiny chemical-based filtration system removed 80 to 90% of PFAS from sewage and groundwater during the study, respectively, while showing very low adverse environmental effects.

The study was led by scientists at the University at Buffalo and published in American Chemical Society ES&T Engineering.

Molecular nanocages have been previously suggested as candidates for pollutant removal, including for PFAS. Their sturdy structures provide capabilities to capture, remove and chemically deactivate hazardous substances like PFAS and many others. They could also potentially filter out noxious gases from the air, the study authors say.

The researchers synthesized the nanocages from a group of organic chemicals called porphyrins. Previous studies have shown success with porphyrin nanocages in removing dyes, antibiotics, insecticides and chemicals that disrupt human hormone production from water.

The researchers then tested their nanocages’ ability to absorb 38 different types of PFAS, including GenX, a type of PFAS commonly used in nonstick cookware and other materials. The results showed the nanocages removed 90% of PFAS from groundwater and 80% from unprocessed or “influent” sewage.

The organic molecular nanocages also outperformed the PFAS-filtering abilities of activated carbon, particularly in unprocessed sewage.

p Pure hard surface disinfectant.

Key Attributes of PURE Hard Surface for Membrane Treatment:

• One Treatment

• Complete Penetration in Minutes

• Environmentally Safe

• Cost-Effective Solution

“Our SDC technology is redefining what’s possible in the food industry – and PURE Hard Surface is at the forefront,” said Tim Steffensmeier, Vice President of Sales. “This modern membrane application brings a smarter, more efficient approach to streamlining operation, delivering a measurable cost savings, and empowers manufacturers to uphold the highest quality standards in the industry, without the negative tradeoffs of traditional chemistry.” www.purebio.com p An illustration of porphyrin-based molecular nanocages that are engineered for selectivity, water stability and fast sorption. These nanocages achieve on average 90% removal of 38 PFAS compounds from mixed water solutions. The material shows promise for more efficient, safer and sustainable water remediation.

Karla Sanchez Lievanos/Research and Education in Energy, Environment and Water Institute (RENEW), University at Buffalo

Activated carbon and other purification or filtration methods, such as ion exchange resins and reverse osmosis, tend to interact weakly with PFAS, the researchers note. They are also costly, high-maintenance and energy-intensive in comparison to nanocages.

“Porphyrin-based nanocages offer a potentially practical solution to the challenges of PFAS removal,” said Samy El-Shall, a program director in the NSF Division of Chemistry. “The material can also be mass-produced at scale, and the cages are modifiable to remove PFAS only while leaving other water contents alone.” www.nsf.gov