5 minute read

Neat Nanofibers

As COVID Shut Down the World, Invenio Founders Used the Circumstances to Create a Compostable Surgical Mask from Cotton

By Caryn Smith, IFN Chief Content Officer

Simona Pellegri, CEO & Founder of Invenio, spent the year of the global pandemic researching and testing the idea to make air filtration media sustainable. Her background in agricultural sciences, and research in sustainable yarns, fed her desire to find innovative solutions to increasingly ambitious projects. Co-founder Annalisa Gaimarri has a medical biotechnology degree, and is a PhD in Pharmacology, Chemotherapy and Medical Toxicology. Between the two, their skillset was the perfect combination to tackle the vision for their innovation – a fully compostable face mask. Their mission now is to take the concept of compostability and sustainability to industrial filtration media.

Based near Milan, Italy, the founders of Invenio – with corporate tagline of New Innovation Dreams – are busy building the infrastructure to support companies on their path to environmentally sustainable growth, considering three parallel guidelines, all equally important: high material performance, environmental protection and process improvement.

We interviewed Simona Pellegri to find out how this innovation came about, and where it is headed.

International Filtration News: Give us some background information on the company, and how your invention came about?

Simona Pellegri: In 2017, I had the dream, if you want to call it that, of a compostable surgical mask when I was still studying at the university. Because of the 2020 pandemic and time on my hands,

Simona Pellegri

CEO & Founder of Invenio (at right) With ANNALISA GAIMARRI Co-Founder of Invenio

cally the filtration in masks to try to mitigate the spreading of the disease. That’s how it started. It was a very unhappy time, but it gave us this spark to do something about it.

We combined our two different fields of expertise – my knowledge of agrotechnology, and my partner’s research in medical biotechnology. I’ve always been very keen on the environmental side of things, having worked with agricultural products, as well as legal sciences. Having the knowledge of the current legislation has enabled me to fully understand what the requirements are for any sort of medical filtration product. Also, my colleague’s extensive research capability compelled us forward and after two years of research, we came up with our Neatess® filtering membrane.

IFN: What is Neatess® and what is its function?

Pellegri: The interesting thing is that it starts from simple cotton. We modified it through a special process and came up with this filtering membrane. It is currently only for face mask use, but we do see extended uses for the product in the future.

I decided it was the right time to pursue the idea. I began to aggressively research this idea. I felt I had to do something positive to come out of this pandemic storm.

I consulted with my friend, Annalisa Gaimarri, who is now the co-founder and Invenio chief R&D manager, and we developed the idea of how to improve basi-

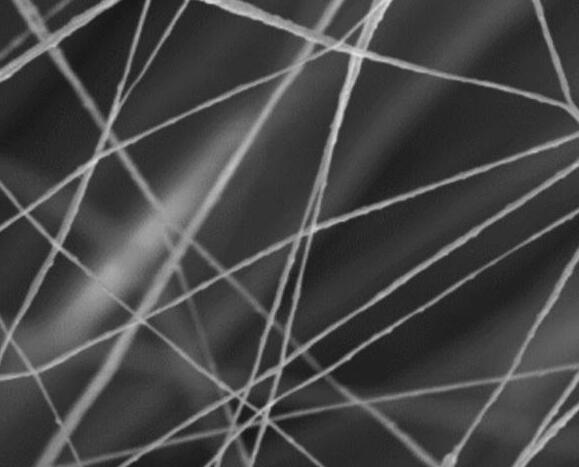

Neatess® is created through a special production process with a low environmental impact. Starting from nature, we can develop a new extremely highperforming, sustainable technical textile, thanks to their combination with nanofibers.

Neatess® is a cotton-based filter membrane that combines the natural characteristics of cotton with excellent filtering efficiency and high breathability.

It is currently intended for air filtration in personal protective equipment. Thin and very light, Neatess® provides high protection of the upper respiratory tract as a Type II surgical mask.

It filters 98.7% of bacteria (tested for determination of bacterial filtration efficiency for face masks for medical use, BFE, according to standard UNI EN 14683).

Due to the unique combination of materials, Neatess® provides excellent comfort and ease of breathing for many hours, unlike protective devices made of synthetic materials. The pressure difference deltaP (Pa/cm2) of Neatess® is 16.7. The acceptance criteria according to UNI EN 14683 is deltaP< 40. The thickness of Neatess® filtering material is 500 microns or 0.5 mm.

Accredited by a third-party lab, the most unique aspect of this material is the composability and effectiveness. It is 98% fully compostable and has a filtering capacity of 98.7%.

This is the first product of its kind, and now we are looking to expand it into air filtration products that filter rooms, factories, environments like that. Through our company, Invenio, Neatess® is patentpending.

IFN: How is Neatess® constructed?

Pellegri: We use a variety of carefully selected raw materials for the production of our high-performance eco-innovative electrospun materials, all of which are characterized by respect for the environment and people and a business philosophy that is concretely oriented toward sustainability.

The first element are biopolymers, which are highly biodegradable molecules with characteristics similar to conventional plastics. Also used are natural polymers, macromolecules spontaneously synthesized by living organisms. These can include proteins such as keratin found in hair and wool, and fibroin in silk; polysaccharides such as cellulose, starch, chitin and hyaluronic acid; nucleic acids such as DNA and RNA. Polysaccharides are considered among the most interesting natural polymers for use.

Finally, the electrospinning technique allows two ways to operate with regard to the layering of the final material where the fibers are formed by evaporating the solvent while the solution is passing through a high electric field.

By controlling processing times or performing repeated passes, it is possible to generate self-standing membranes, con- sisting only of the nanofibers of the polymer in use. They are structures that have physical characteristics that depend on the polymer chosen. t Neatess® is a filtering material. It can be used to create a surgical mask but also as replaceable filter in reusable masks. At left are replaceable filters made with Neatess®

Alternatively, nanofibers can be deposited on substrates of different nature. In this case, the substrate is mounted on the collector and the nanofibers are deposited directly on the chosen material.

Invenio

Neatess® is a composite material that combines the physical characteristics of the nanofibers with those of the substrate. The Neatess® filter membrane currently uses cotton as the substrate for the nanofibers and process it with electrospinning to the obtain the end result filtering membrane.

IFN: Where are you with product development?

Pellegri: We are currently working through how to apply this technology to an industrial scale product. We are applying for government contributions to further the research, and ideally, we would like to have machinery in our own factory producing the outcomes. But, of course, if it comes to it, we will look for partners to expand.

We are beginning to have some interests from multinational firms for creating different new innovative filtering media for environmental filtration. In just three years, my partner and I are proud that we have built market interest for the masks; and now we are looking to expand into larger scale production and filtration opportunities.

It is a slow and steady process since we started on this whole concept from scratch.

IFN: Do you see this process working with other fibers beyond cotton?

Pellegri: We are looking into to using other natural fibers, for instance bamboo-based pulp, which will also be compostable. The masks are obviously a disposable product, which makes it better that it is compostable. Yet, more work needs to be done about using other fibers at this time.

IFN: Is there anything else you would like to share about the company?

Pellegri: We won the “America Innovazione Award” in 2023, presented to the best Italian Innovative Startups. We were also invited to NanoInnovation Conference and Exhibition 2023, held in September in Rome, as a presenter sharing on, “Production from electrospinning of innovative, highly performing and ecofriendly electrospun materials.”