2 minute read

XHL Technology for Extra High Loft Nonwovens

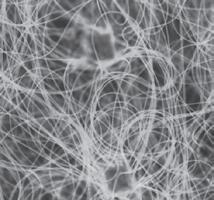

With the XHL (Extra High Loft) Technology Reifenhäuser Reicofil enables producers to easily combine superior softness with unseen drapability in nonwovens. The material is especially in demand among premium diaper manufacturers.

Manufacturers of baby diapers are looking for nonwovens that are particularly soft and adapt well to the baby’s body shape. Nonwovens producers, however, have only ever been able to satisfy one of these properties, and thus have not been able to make customers 100 percent happy. With Reicofil XHL technology, they can produce nonwovens that combine exceptional softness and super drapability in one material.

The Reicofil Technology Behind Extra High Loft Nonwovens

All that is needed to produce super-soft, drapable nonwovens is the proven Reicofil Bico spunbond process, which combines two polypropylene raw materials in one fiber. For Extra High Loft (XHL), Reicofil has developed a special recipe which – run as an eccentric core-sheath fiber – ensures optimum crimp with reduced fiber diameter.

Compared to common spunbond without crimped fibers, Extra High Loft technology enables 30 percent thicker material. At the same time, softness parameters such as drape and haptic are improved compared to processes that consolidate nonwovens using hot air. The result is a particularly soft feel combined with high abrasion resistance. By using a state-of-the-art Reicofil 5 line the fiber size is reduced to almost one denier in XHL mode, thus lowering raw material consumption. Because bonding does not require hot air, the process also saves energy costs. In addition, XHL enables the processing of polypropylene raw materials only, which are ideally suited for inline recycling processes, thus reducing production costs and conserving resources.

Visit https://reifenhauser.com/en/linescomponents/xhl-extra-high-loft

Thermore Introduces Freedom Stretch Insulation: Sustainable Performance for The Boldest of Movement

In March 20204, the Thermore group debuted its most dynamic stretch insulation in its five decades of innovation: Freedom. Made from 50% post-consumer recycled polyester, this unique and compelling insulation offers groundbreaking stretch while providing warmth across a multitude of uses including alpine sports, running, golf, commuter, fishing & hunting, cycling and a host of other active pursuits.

The new Freedom insulation adds a higher level of comfort and functionality than what was previously attainable in the stretch category. It reaffirms Thermore’s place in the textile industry as a true innovator that is deeply rooted in performance and sustainability.

Dynamometer testing shows that the insulation – which comes in four levels of warmth, ranging from 60-150 grams per square meter –has incredible elasticity and recovers to 100% of itspre-stretch size time after time. The ability to provide warmth while also allowing for a dynamic range of motion is what impels performance brands to utilize Thermore.

The Freedom insulation is GRS certified. It’s machine washable, can be dry cleaned and is easy-care for the consumer – and very design friendly for product developers with its high resistance to fiber migration. This represents another step forward in Thermore’s ongoing dedication to commit to a sustainable product line. Thermore pioneered the use of recycled fibers in the 1980’s and has mastered the technology ever since. Visit https://www. thermore.com/en/