2 minute read

Converting Machinery:

Sustainability is Part of Our Innovation

In today’s rapidly evolving consumer landscape, sustainability has become a paramount concern across industries, including the wipes market. Heightened environmental awareness and a surge in consumer demand for eco-friendly products have posed significant challenges for companies. The pressure to innovate and offer sustainable solutions that meet both performance and environmental criteria has never been greater.

As businesses adapt to these changing consumer preferences, the importance of sustainability in the wipes market cannot be overstated. Companies are proactively embracing sustainable practices to differentiate themselves in a competitive market while also contributing to broader environmental goals.

Our Group is no exception. The Hygiene Division of BW Converting has developed the new VERTIS interfolder for wet wipes, which not only meets consumer expectations but also addresses environmental concerns head-on.

Market analysis reveals several key trends driving the wipes market. The increasing popularity of single-use wet wipes projects significant growth, but it also presents envi- ronmental and economic challenges. Consumers often flush wipes that are not compatible with municipal sewer systems, leading to poor environmental outcomes. Non-renewable plastics and materials that do not biodegrade under disposal conditions further exacerbate these challenges, prompting the need for tough regulations. Innovative solutions are required to address the main environmental and technical challenges associated with flushable and non-flushable wipes.

Consumers’ quality perception and requirements are enduring and demanding. Disposable single-use wipes present environmental, technical, and social challenges. In response, our company has developed cutting-edge technology to improve the quality and sustainability of wipes.

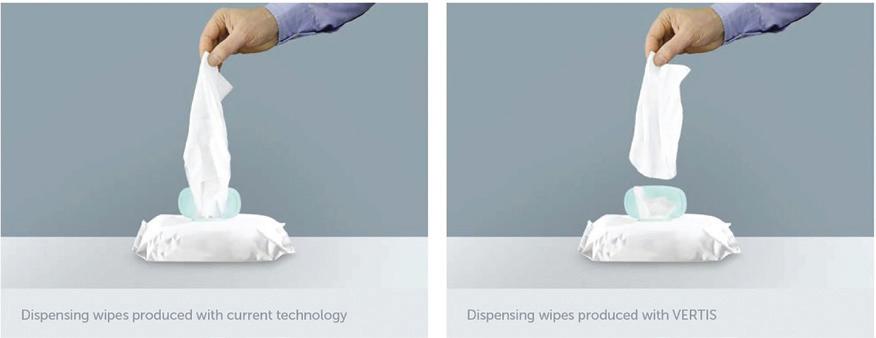

Our new converting technology VERTIS enhances the final product quality and consumer experience. With features such as a small footprint, zero-speed auto-splice system, and precise add-on lotion system, the VERTIS sets a new standard for hygienic and efficient wipes production.

The benefits of our technology are manifold. Its unique design results in a superior user dispensing experience, with better pop-up and folding capabilities. Simplified operation, small footprint, and Smart Touch© technology make it easy to use and maintain. Moreover, our VERTIS interfolder stand is compatible with biodegradable materials, reducing environmental impact. With its fully servo system, it ensures durability and flexibility, capable of recording data and settings for future machine learning and repeatability.

For more information about our innovative solution and how it can benefit your business, please contact us at nonwovens@bwconverting. com. We are committed to driving sustainability in the wipes market and invite you to join us in this journey towards a greener future.

Exposome Partners with Industry in Effective Waste Water Treatment & Industrial Air Pollution Abatement

Exposome Pvt. Ltd. is a material chemistry provider – enabling various industries achieve their sustainability and Net Zero goals. With our cost-effective and energy-conserving filtration solutions we are enabling industries in re-using and recycling their wastewater effectively and/or meeting stringent discharge norms.

Our air filtration molecular filters enable a safe, healthy and breathable environment for the people working in the heavily polluted industrial areas.

Regenerable Molecular Filters

We manufacture regenerable, hence re-usable effluent treatment media for waste water and air. Based on the principle of absorption, adsorption, and redox, our filtration media for waste water efficiently removes COD, recalcitrant COD, BOD, colour, odour, hardness, etc.

We also have specialised filtration media which can selectively remove aluminium, heavy metals (such as zinc, chromium, iron, cadmium and copper), cyanide, silica and total ammonical nitrogen from waste water. Our molecular filters for air are very efficient in removing commonly seen air pollutants across various industries: SOX, NOX, VOC, H2S, odour, humidity etc.

Why are our filtration solutions more sustainable than the rest?

• Because our molecular filters are regenerable on-site, operating costs are significantly low.

• As it requires a simple flow-through mode, electricity consumption is nil or negligible.

• With 60-90% reduction in COD and other parameters, industries are able to reuse the water in their facilities hence enabling zero liquid discharge plants.

• Our raw materials are natural in origin and biodegradable. Email us at info@exposome.in or visit www.exposome.in.