6 minute read

New Methane-Hydrogen Fuel Technology and its Potential Application in the Gas Industry

by IGU

By Oleg Aksyutin, Alexander Ishkov, Konstantin Romanov, Valery Khloptsov, Varazdat Kazaryan and Anatoly Stolyarevsky

x Figure 1. This article deals with highly efficient hydrogen energy carriers based on natural gas, their production technology and potential application in the gas industry. It formulates the innovative methods of natural gas conservation and environmental protection in the gas sector, providing for the creation of efficient methanehydrogen mixture (MHM) production technology, with hydrogen content of 40-48%, based on proven industrial processes and used catalyst agents.

The unique properties of hydrogen make it possible to increase the heat engine efficiency 1.5 to 1.7 times, with the actual cycle of a hydrogen-fired engine being much closer to the ideal cycle than with any hydrocarbon fuel. In addition, the emission toxicity falls dramatically (2 to 4 times), hydrocarbon fuel consumption decreases by 35-40%, while cost efficiency

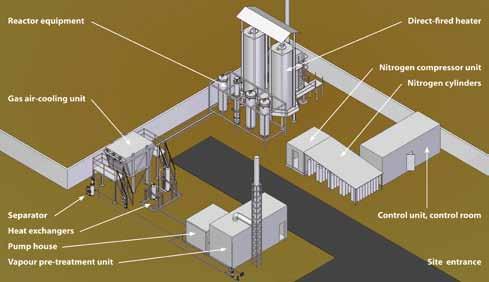

AMC process flow diagram.

grows by 20-25%.

Methane-hydrocarbon mixture (MHM) technology

There are several industrial technologies for hydrocarbon production. Steam methane reforming (SMR) is considered to be the most affordable and cheapest technology. However, a new technology, adiabatic methane conversion (AMC), developed in Russia, considerably facilitates the industrial process of MHM production. The benefits of the technique are that it does not require oxygen generation, it is carried out at lower temperatures (up to 680°C), does not need energy- and cost-consuming water electrolysis and is based on technological solutions, flow patterns and catalyst agents tried and tested in hightonnage chemistry.

Figure 1 illustrates the process flow diagram of AMC. A steam-gas mixture is fed into a high

temperature heat exchanger and then, having

been heated to 640-680°C, is delivered into a On-site MHM production through adiabatic

two-piece adiabatic reactor filled with a catamethane conversion will not only provide for

lyst. After the reactor, the methane-hydrogen involving hydrogen in the conventional energy

mixture together with water steam flows into sector, but will considerably save the necessity

a waste-heat exchanger for dehydration. At the of preliminary stripping and fractionating

waste-heat exchanger output we obtain a natural gas at sophisticated and costly facilities.

purified MHM. In some technical applications, It will also help establish small scale production

for example, in the Tandem model described of methanol.

below, MHM together with water steam is The transition to methane-hydrogen fuel

supplied to the gas turbine unit burner. will allow improving the performances of many

Gazprom has designed and is now testing a gas turbine drivers, which are currently less

pilot MHM production unit with the performance efficient than modern gas compressor facilities.

of 1,000 m³/hour for joint testing with a gas The testing of combustion chamber burners in

turbine drive (Figure 2). In the aforementioned different modes with different MHM

unit the heating temperature of a steam-gas compositions have shown that the use of MHM

mixture does not exceed 700°C, which allows will significantly improve the emission indices of

for obtaining a high-hydrogen MHM. gas turbine units making it possible to reach

The designed MHM production unit surpasses its global counterparts in all basic low NO x values (down to 10-12 mg/m³) with a simultaneous sharp decrease in CO emissions

properties (performance, hydrogen content in (down to 4-8 mg/m³) with the excessive air

the mixture, energy resource consumption,

emission by a burner at high values of α.

emissions rate). The new solution provides for The presence of hydrogen in the main burner

increasing the degree of methane conversion, circuit significantly extends the stable operating

reducing heat consumption and prolonging the range in terms of the air speed in the burner

lifetime of the adiabatic reactor catalyst agent. (approximately doubles), as well as in terms of

x Figure 2.

The fuel and energy complex is the most promising market for MHM. The use of MHM for gas industry-specific needs, with a view to increase the efficiency of both natural gas production and transportation, may boost the development of this business line.

At present, the application of MHM production technologies at fields may be considered, first of all, for treating raw gas and increasing the efficiency of on-site use of rich gases (stabilization gas, associated gas from marginal, remote or lowpressure fields), transportation of which is unprofitable.

General overview of Gazprom’s pilot MHM production unit.

utilization of gas with a relatively high water steam content.

When supplying modern gas turbine units powered by converted methane with waste heat recovery units at compressor stations or power plants, the efficiency and capacity of such turbine units may grow by 50%. Through adding heating load, the efficiency of gas use may be increased to 60-62%, with the NO x emissions reduced below 10 ppm.

The use of MHM for producing various gas chemicals can be potentially advantageous through the application of AMC technology and installation of relevant facilities for the production of synthesis gas as the basis of gas chemical processes. This approach is especially efficient when applied to creating centralized MHM transportation networks connected to sources with a low cost of power generation.

In the transportation sector the pilot operation of MHM-fired cars has proven the expediency of converting vehicles to MHM with a hydrogen content of 5-10% by weight (20-40% by volume). Besides, the emission toxicity declines more than 2 to 4 times as compared to natural gas, while the fuel consumption falls by 35-40%.

Summarizing the above, the basic concept of the future hydrogen-based energy sector may seem as follows: ◆ Use MHM produced from natural gas (which is considerably cheaper) as a fuel instead of pure hydrogen. ◆ Apply the AMC technology for MHM production. ◆ Introduce this technology at gas facilities. ◆ Supply gas turbine drives with compact unitwise plants producing a triple mixture: natural gas/hydrogen/water vapour to improve gas transmission efficiency.

It should be noted that MHM produced through AMC technology based on natural gas conversion looks more financially attractive than MHM produced through mixing natural gas and hydrogen (extracted from water by electrolysis using available excess electricity). This fact provides ample opportunities for developing MHM production based on AMC technology in the gas industry.

Conclusion

As of today, a partial substitution of widely-used hydrocarbons by MHM is an essential and strategic move towards hydrogen-based power generation and the hydrogen-based economy.

Russia has developed an AMC technology, which produces methane-hydrogen fuel containing up to 48% hydrogen. This technology makes it much easier to produce hydrogen on a commercial scale, because the process needs zero production of oxygen and occurs at lower temperatures (to 680°C).

Two integrated technologies – i.e. flue gas treatment recovery and low temperature AMC – will make it possible to design a new type of gas turbine drive featuring high energy and eco efficient properties (called the Tandem technology). In this case, the output of a gas turbine unit (compared to its standard version) may reach 70-80%, fuel consumption may go down by 35-40%, accompanied by a sharp decrease of NO x emissions (4-8 times) and CO emissions (approximately 10 times).

The application of MHM production technology and use of methane-hydrogen mixtures by compressor stations at gas fields and in gas chemistry, as well as sales of this hi-tech energy source abroad, provide a good option for diversification and serve as a means of enhancing natural gas efficiency.

Oleg Aksyutin is a Member of the Management Committee and Head of Department at Gazprom; Alexander Ishkov is Deputy Head of Department – Head of Directorate at Gazprom and Konstantin Romanov is Head of Division at Gazprom. Valery Khloptsov is Director general at Gazprom Geotech and Varazdat Kazaryan is Deputy Director General at Gazprom Geotech. Anatoly Stolyarevsky is Director of the CORTES Center.