11 minute read

Test Your Skills

10.00 FLUID POWER SYSTEMS

Task 10.60: Describe the operation and application of electric flow control devices.

Outcome 10.60.1: Given the fluid power application; describes the operation and appli-flow at a throttling point adjusts the flow to optimize the system performance. This flow at a throttling point may cation of hydraulic electric flow control devices. be calculated dependent on the type of orifice, pressure drop, and the type of fluid. The electronic proportional flow control is similar to standard two-port flow controls except the main control orifice is adjusted electronically. The

Flow control valves influence actuator speeds in a fluid power system. Increasing or decreasing the opening to control orifice has been modified to work in conjunction with a force-controlled solenoid. If the position of the spool flow at a throttling point adjusts the flow to optimize the system performance. This flow at a throttling point is monitored with a feedback device such as a linear variable displacement transformer (LVDT), then a strokemay be calculated dependent on the type of orifice, pressure drop and the type of fluid. The electronic controlled solenoid is used to control the valve opening. proportional flow control is similar to standard two port flow controls except the main control orifice is adjusted electronically. The control orifice has been modified to work in conjunction with a force controlled solenoid. If the position of the spool is monitored with a feedback

Specifically, a two-port proportional pressure compensated flow condevice such as an LVDT (linear variable displacement trol valve has an electrically adjustable control orifice connected in series with a hydrostat (essentially a pressure-reducing valve), as shown transformer) then a stroke controlled solenoid is used to control the valve opening. A2 in the illustration. The hydrostat is located upstream of the main control orifice and Specifically, a two port proportional pressure compensated flow control valve has an electrically adjustable control A P1 is held open by a light spring. When the input signal to the solenoid is zero, the light spring force holds the main control orifice closed. When orifice connected in series with a hydrostat (essentially a pressure reducing valve). See Fig. 10.24. P2 P3 B the solenoid is energized, the control orifice opens. When the solenoid is open, the control orifice opens in proportion to the control signal and The hydrostat is located upstream of the main control orifice and is held open by a light spring. When the input allows the oil to flow from port A to port B.signal to the solenoid is zero, the light spring force holds Hydrostat

At the same time, the LVDT, if so equipped, provides the necessary the main control orifice closed. When the solenoid is 10.00 FLUID POWER SYSTEMS feedback to hold position. In this case, the LVDT provides feedback to maintain a very accurate orifice setting. Outcome 10.60.2: Given the fluid power application; describes the operation and cation of pneumatic electric flow control devices. energized, the control orifice opens. When the solenoid is open the control orifice opens in proportion to the control A3 appli

The control signal provides time-controlled opening and closing of signal and allows the oil to flow from port A to B. C the orifice. For reverse free flow, a check valve may be built into the An electropneumatic proportional valve is an open loop flow control valve that controls the flow rate in accordance with current through the coil. However, the system can incorporate a feedback loop as shown in At the same time, the LVDT, if so equipped, provides the valve. Proportional flow control valves are available with either linear or progressive flow characteristics. The input signal range is the same the example of a circuit controlling the rpm of an air motor, Fig. 10.25.necessary feedback to hold position. In this case, the LVDT provides feedback to maintain a very accurate Fig. 10.24 Proportional Pressure Compensated Flow Control Proportional pressure-compensated flow control for both. However, the progressive flow characteristic gives finer control orifice setting. at the beginning of orifice adjustment. In case of electrical power or feedback failure, the solenoid force drops to zero, and the force exerted by the spring closes the orifice. Typically, when feedback wiring is conPower amplifier (feedback circuit built-in type) control circuitnumber of rotations The control signal provides time-controlled opening and closing of the orifice. For reverse free flow, a check valve may be built into the valve. Proportional flow control valves are available with either linear or progressive flow characteristics. The input signal range is the same for both. However, the progressive flow characteristic nected incorrectly or damaged, the system uses an LED to indicate the feedback gives finer control at the beginning of orifice adjustment. In case of electrical power or feedback failure, the malfunction on the amplifier card.solenoid force drops to zero and the force exerted by the spring closes the orifice. Typically, when feedback Some flow control valves consist of a proportional-force solenoid and a pilot controller. Because this valve is relatively unaffected by changes tachometer wiring is connected incorrectly or damaged, the system has an LED (light emitting diode) indicating the malfunction on the amplifier card. in system pressure, it can open and close the orifice in the same length of time. This maximum time can be changed on the amplifier card by adjusting a built-in ramp generator. An electropneumatic proportional valve is an open loop flow control electro-pneumatic proportional valve air motor Some flow control valves consist of a proportional force solenoid and a pilot controller. Because this valve is relatively unaffected by changes in system pressure, it can open and close the orifice in the same length of time. This maximum time can be changed on the amplifier card by adjusting a built-in ramp generator.electropneumatic proportional valve valve that controls the flow rate in accordance with current through the (flow type, two port) (flow type, two port) coil. However, the system can incorporate a feedback loop as shown in the illustration of a circuit controlling the rpm of an air motor.

Controlling rotation of air motor

Fig. 10.25 Controlling Rotation of Air Motor

Under normal conditions, what directly controls the output rpm of the air motor?

a. Supply pressure to the electropneumatic c. Dither level to the solenoid. proportional valve. d. Restrictions in the muffler. b. Flow rate through the electropneumatic e. None of the above.

proportional valve. See page 31 for the solution.

COMPONENT SHOWCASE

Clippard continues to be an industry leader in providing innovative products, application engineering and cost saving solutions for a wide range of applications. Visit www.clippard.com. Proudly made in the USA.

CLIPPARD ECLIPSE PROPORTIONAL ISOLATION VALVES

Utilizing the industry’s most robust and powerful miniature linear actuator, the patent pending stepper-controlled Eclipse proportional isolation valve leads the industry in performance and durability. This valve is ideal in critical applications for liquid and gas delivery, medical, analytical and industrial automation requiring ultra fine resolution and excellent repeatability. In addition, the unique design allows for custom flow profiles.

Leak free (<0.05 sccm) Excellent linearity (<4% of full-scale) Fast response (<2 ms reaction time) Cycle life of typically >1 million Repeatability <0.5% of full travel

Clippard manufactures a full range of miniature pneumatic control devices and components including pressure controls, electronic valves, analytical and oxygen clean valves, proportional and proportional isolation valves, pinch and isolation valves, precision regulators, fittings, tubing and more.

FROM THE MAKERS OF THE WORLD’S LEADING O-RING GRIPPER FROM THE MAKERS OF THE WORLD’S LEADING O-RING GRIPPER FROM THE MAKERS OF THE WORLD’S LEADING O-RING GRIPPER FROM THE MAKERS OF THE WORLD’S LEADING O-RING GRIPPER FROM THE MAKERS OF THE WORLD’S LEADING O-RING GRIPPER

The AGW Long Stroke Gripper features a rigid wide bearing design ideal for The AGW Long Stroke Gripper features a rigid wide bearing design ideal The AGW Long Stroke Gripper features a rigid wide bearing design ideal for handling large, bulky parts. Offered in eight stroke sizes, available in synchronous or non-synchronized jaw versions. handling large, bulky parts. Offered in eight stroke sizes, available in synchronous or non-synchronized jaw versions. The AGW Long Stroke Gripper features a rigid wide bearing design ideal for handling large, bulky parts. Offered in eight stroke sizes, available in synchronous or non-synchronized jaw versions. for handling large, bulky parts. Offered in eight stroke sizes, available in synchronous or non-synchronized jaw versions. The AGW Long Stroke Gripper features a rigid wide bearing design ideal for handling large, bulky parts. Offered in eight stroke sizes, available in synchronous or non-synchronized jaw versions.

AGI’s line of Rotaries have the full advantage for high loading capacity and AGI’s line of Rotaries have the full advantage for high loading capacity AGI’s line of Rotaries have the full advantage for high loading capacity and ultra high torque to weight ratio for faster cycle times. Compact body design to fit into tight space applications. ultra high torque to weight ratio for faster cycle times. Compact body design to fit into tight space applications. AGI’s line of Rotaries have the full advantage for high loading capacity and ultra high torque to weight ratio for faster cycle times. Compact body design to fit into tight space applications. and ultra high torque to weight ratio for faster cycle times. Compact body design to fit into tight space applications. AGI’s line of Rotaries have the full advantage for high loading capacity and ultra high torque to weight ratio for faster cycle times. Compact body design to fit into tight space applications. AGI designs and manufactures a complete AGI designs and manufactures AGI designs and manufactures a complete range of innovative, patented, pneumatic robotic assembly line components. Our products serve all markets including assembly, automation, robotics, packaging, pharmaceuticals, material handling and automotive applications. range of innovative, patented, pneumatic robotic assembly line components. Our products serve all markets including assembly, automation, robotics, packaging, pharmaceuticals, material handling and automotive applications. AGI designs and manufactures a complete range of innovative, patented, pneumatic robotic assembly line components. Our products serve all markets including assembly, automation, robotics, packaging, pharmaceuticals, material handling and automotive applications. a complete range of innovative, patented, pneumatic robotic assembly line components. Our products serve all markets including assembly, automation, robotics, packaging, pharmaceuticals, material handling and automotive applications. AGI designs and manufactures a complete range of innovative, patented, pneumatic robotic assembly line components. Our products serve all markets including assembly, automation, robotics, packaging, pharmaceuticals, material handling and automotive applications.

American Grippers Inc. 203.459.8345 or info@agi-automation.com www.agi-automation.com/product-category/o-ring-assembly/ American Grippers Inc. 203.459.8345 or info@agi-automation.com www.agi-automation.com/product-category/o-ring-assembly American Grippers Inc. 203.459.8345 or info@agi-automation.com www.agi-automation.com/product-category/o-ring-assembly/ American Grippers Inc. 203.459.8345 or info@agi-automation.com www.agi-automation.com/product-category/o-ring-assembly/ American Grippers Inc. 203.459.8345 or info@agi-automation.com www.agi-automation.com/product-category/o-ring-assembly/

COMPONENT SHOWCASE

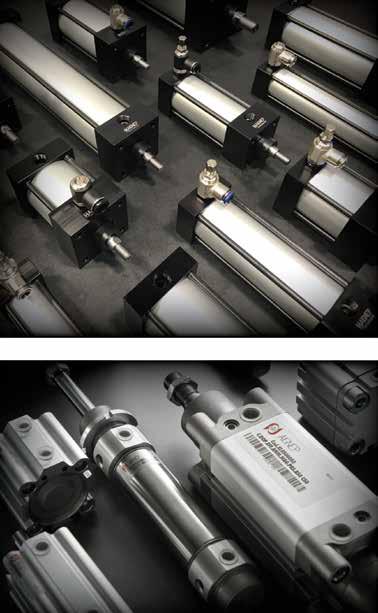

WHEN YOU NEED CYLINDERS, AIGNEP USA IS YOUR SOURCE.

We offer NFPA and ISO Cylinders. Our NFPA Aluminum cylinders are ideally suited for a wide variety of industries and applications. They are strong, light weight, affordable and are dimensionally interchangeable with other NFPA cylinders. Additional stroke lengths, steel, stainless steel, non-rotating and dual rod options are available.

Aignep USA manufactures a comprehensive range of NFPA and ISO cylinder styles in our state of the art manufacturing facility just outside of Nashville, TN, covering a wide variety of bores, strokes, materials and mounting accessories. We stock standard stroke cylinders in-house and ship within 24 hours, as well as produce non-standard units in a matter of days, not weeks. Call today to get a quote and enjoy same day shipping!

Don’t forget to also check out our fantastic line of fittings and accessories designed to make connections easy with the SWIFTFIT Universal Thread.

7121 Loblolly Pine Blvd. Fairview, TN 37062 USA 615-771-6650 www.aignepusa.com

PNEUMATIC ASSEMBLIES ACHIEVE PRECISION PRESSURE CONTROL WITH HIGH FLOW REQUIREMENTS

While products that combine high pressure requirements with high flows exist – like our QB3 and QB4 products - sometimes a standalone pressure regulator does not offer enough flow for a customer’s application.

One solution to achieve the required flow while still getting precision pneumatic control is to pair an electronic pressure regulator with a volume booster, or an air-piloted regulator. This combination offers an increase in both forward and reverse flow while providing accurate pressure control.

Three distinct components often compose these assemblies – an electropneumatic pressure regulator, like our popular QB2; an air volume booster; and a pressure transducer. The electronic pressure regulator provides an air pilot signal to the dome of the air volume booster. The transducer measures output pressure of the volume booster and provides this feedback signal to the QB2. The QB2 adjusts dome pressure (based on this feedback) to achieve the commanded pressure in the process.

Nearly any combination of these parts can be assembled to meet a customer’s needs. Low pressure, high pressure, vacuum, process control and even assemblies for hazardous media can be configured.

Contact our Applications Team to learn more about custom solutions for precision pressure control when flow requirements are high.