36 minute read

Family succession planning

from HRIA May 2021

Keeping it in the family:

by: Andrew Ash – Director, Business Advisory, Mann Judd and Tom Roberts – Director, Business Advisory, Mann Judd

Family businesses account for 70% of all businesses in Australia and employ half of the country’s workforce.

They form an integral part of the economy and many family business owners hope to pass their business onto the next generation.

Despite this, research shows that only 40% of established family businesses survive the transition to the second generation. Past that point, 13% will survive to a third generation and only 3% to a fourth generation and beyond. A lot of family business owners really do go from shirt sleeves to shirt sleeves in three generations.

Why is that the case?

It might surprise you to know that only one in four family businesses formally consider their approach to succession. It’s no wonder then that so many fail.

Why succession planning is difficult

Succession can be an emotionally charged topic that is difficult for families to discuss. While it can be an awkward topic to bring up, the reality is that succession is one of the biggest risks to the ongoing viability of a family business. The proof is in the pudding.

Whatever the vision that you have for your business and your family, it’s important to know and understand if this vision is shared with your successors.

So, what can be done about it?

Unfortunately, there is no silver bullet when it comes to succession. Every family is different, and every transition is unique. However, by going through due process and tackling these issues head on, you can drastically increase the chance of a successful transition. By putting things on the table ahead of time and creating transparency amongst the family, you can minimise potential conflict down the track. Once the issues are all out in the open, it can also help relieve a lot of the pressure that family members may be feeling. With that in mind, the best thing that can be done in terms of succession is actually getting started.

This article outlines some practical tips for you to consider in planning your succession.

Start with the end in mind

As a starting point you need to understand where you’re going.

What does success look like for your family and your business? What is your timeframe for getting there? Who do you want to be your successors? What do you want for your family and your business?

You may wish to transition the management and ownership to some or all your children over a specific period.

You may wish to transition the management of the business to your employees, separating the running of the business from its owners.

You may want to build some of your wealth outside your business for your family who is not involved in the running of the business.

You may want to secure the future of the business to support your employees.

Whatever the vision that you have for your business and your family, it’s important to know and understand if this vision is

practical tips for succession planning

shared with your successors.

Knowing exactly what you want can often be difficult and can take time, but the sooner you start thinking about it the clearer it will become.

Know where you are in the journey

The next step is to understand where you are in the journey and what obstacles and challenges you face.

Have you made any progress to date? Are you ready for succession? Do your children want to take over the business? Do your future successors have the right skills and leadership capabilities? Do your successors have authority, credibility and your endorsement to make the business a success?

To answer these questions, you need to understand the different perspectives and motivations of each individual that the succession impacts. The only way to gain this understanding is through communication. An advisor is a valuable resource in facilitating these discussions as they can look at your situation independently and taking the emotion out of the conversation. Advisors will help you get an understanding of where you, your business and your family stand so you can create alignment.

Work backwards

Once you understand the vision for the future, and where you and your family are on the journey, you can then start to design a plan.

The plan should address the challenges you are facing now those you potentially will face along the way. It should take care of the three subsystems that make up a family business – the family, the business and the owners. It should support the business and the family and it needs to set clear roles and responsibilities for how the plan should be executed.

Take action

At the end of the day, you create a succession plan to move forward and to take action. The plan should detail the actions you will take including the steps involved with both the management and ownership succession.

Importantly, businesses and families change over time, so a succession plan also needs to change. To support this, you will need to create a governance structure that ensures the plan is executed and evolves over time. These structures may include; • A family constitution (the rule book) • Regular and structured family meetings • Advisory boards • Strategic planning sessions for both the family and the business.

The process has many moving parts – many of which you will not know about or have the expertise in – and what you don’t know can hurt you. That’s why it’s important to get advice along the way.

A family business advisor can help you with the process and ensure you are engaging with the right advisors at the right time so your legal, tax, estate planning, training and development needs are taken care of.

The goal

At the end of the day, the goal should be to have a succession plan and a succession planning process that is transparent, understanding and creates alignment. It should create greater certainty for the future, collaboration and openness so that you can address issues or challenges before they arrive.

Remember, ‘succession is a process and not an event.’ It takes time, and the more time you invest, the better.

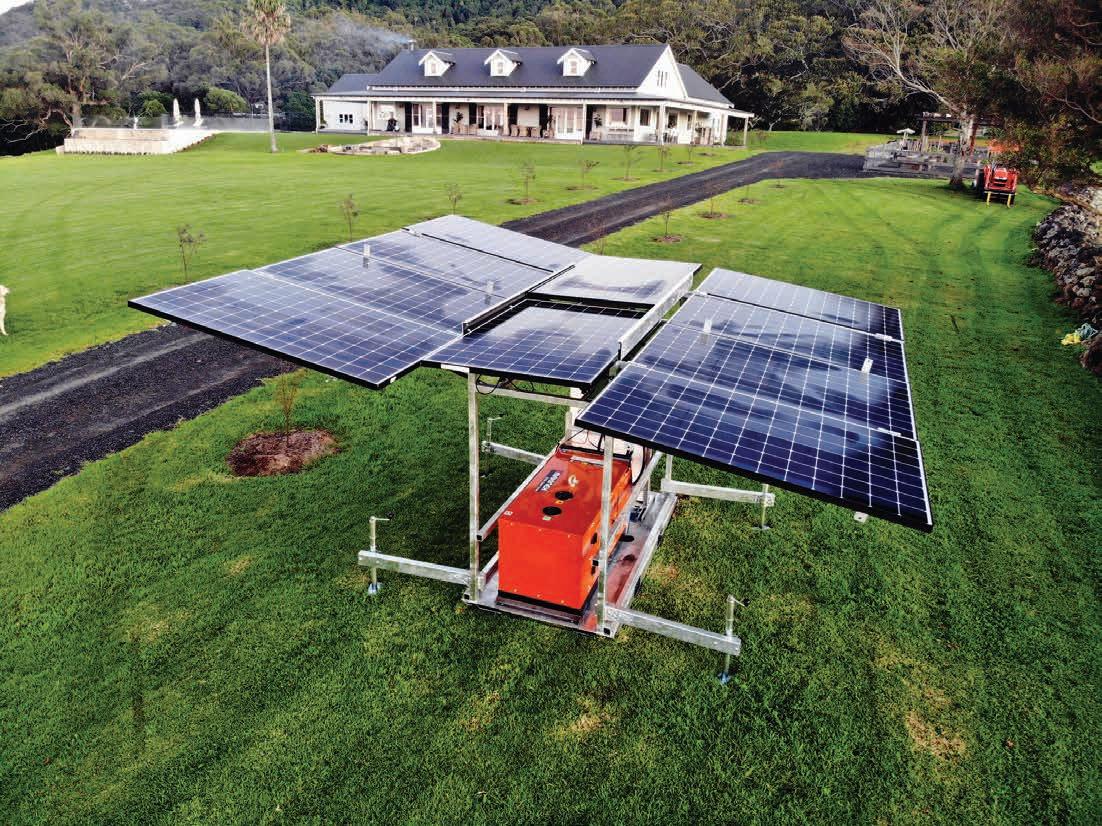

HYBRID POWER SYSTEM (HPS)

DESCRIPTION

Makinex Hybrid power system (HPS) is the most versatile and advanced o grid power system. Providing grid like electrici in areas where grid power is either unavailable or directly replacing expensive/ unreliable grid power. The system consists of solar panels, a ba ery bank to store energy, an integrated backup diesel generator and an inverter to act as an interface between the di erent inputs.

1300 795 953

sales@makinex.com.au Makinex.com.au

BENEFITS

Portable, easy to store & deploy vs traditional grid electrici Significant fuel and servicing savings. Reduced emissions and noise Lower vulnerabili to weather events such as bushfires

Reduces electrici outage times for customers & costs for network business Easy monitor and control the system locally or remotely

Visit Us At HIRE21

Don’t be casual in your approach

by James Sanders, Senior Associate, MST Lawyers

On 18 March 2021, Federal Parliament passed the Fair Work Amendment (Supporting Australia’s Jobs and Economic Recovery) Bill 2020 (the Bill) which introduces a number of changes to the Fair Work Act 2009.

The Bill received Royal Assent on 26 March 2021 which means that these changes have now taken effect as of 27 March 2021.

The first reading version of the Bill initially proposed significant reform of existing industrial relations law, including provisions relating to wage theft offences and enforcement, increased part-time flexibility, flexible work directions, changes to enterprise agreement making, sunsetting of pre-2010 workplace agreement, revised transfer of business rules, and the lifting of the small claims jurisdictional limit. These provisions were proposed on the basis of assisting Australia’s economic recovery from COVID-19, creating greater certainty and increased flexibility for both employers and employees.

After a passage of debates and amendments, all the abovementioned provisions were axed from the final version of the Bill as passed by Parliament, leaving only the amendments relating to casual employees. These new laws apply to both existing and new casual employees.

New statutory definition of casual employee

The Bill introduces a new section in the Fair Work Act which defines a person as a “casual employee” if an offer of employment was made and accepted on the basis that there is “no firm advance commitment to continuing and indefinite work according to an agreed pattern of work”.

This closes off the ability for courts to determine that a casual employee could be a permanent employee by the conduct of the employer and employee. A casual employee will retain their status as a casual until either they convert to full-time or part-time employment or accept an alternative offer of employment by the employer.

Casual conversion entitlement in the national employment standards

Employers who employ 15 or more employees now have a positive obligation to make an offer to convert a ‘regular casual employee’ to a permanent employee unless there are reasonable grounds not to do so.

A ‘regular casual employee’ is an employee who has been employed for a period of 12 months and has worked a regular pattern of hours on an ongoing basis for at least the last six months of that period.

Requirements of the offer and acceptance procedure are set out in the amended Fair Work Act. An employer must, within 21 days after the end of the employee’s 12 month anniversary, either make an offer to a ‘regular casual employee’ or provide written notice to

the employee explaining the reasons for not making an offer.

In some circumstances, casual employees also retain a residual right to request conversion to full-time or part-time employment.

If there are any existing casual employees employed as at 27 March 2021, employers are required to make an offer of permanent employment to the existing casual employees before 27 September 2021 or within 21 days after the casual employee’s 12 month anniversary, whichever is later, or provide written reasons for not making the offer.

Employers should note that this casual conversion entitlement operates in addition to any casual conversion clause under any industrial instrument.

Casual employment information statement

A casual employment information statement which contains information about casual employment and casual conversion has been prepared by the Fair Work Ombudsman. This statement can be found on the Fair Work Ombudsman website. Employers must provide all casual employees with a casual employment information statement before, or as soon as practicable after, the employee starts employment as a casual employee. Employers must also provide this statement to any existing Employers who employ casual employees by 27 September 2021.

make an offer to convert a The new laws ‘regular casual employee’ to now also require that a court sets-off a permanent employee unless an identified casual there are reasonable grounds loading amount paid to a casual not to do so. employee against any permanent employee entitlements claimed by that employee relating to paid annual leave; paid personal/carer’s leave; paid compassionate leave; payment for absence on a public holiday; payment in lieu of notice of termination; and/or redundancy pay. It is important that all current and future employers of casual employees understand the implications of the new laws on their employer obligations. Employers should look to updating their casual employment contract templates and implementing a standard casual conversion procedure which involves a suite of draft employee correspondence. If you have any questions in relation to this article or your obligations as an employer, please contact a lawyer at MST Lawyers on the HRNet Hotline on 1800 474 247 for free employment law advice.

NO004

OFFICIAL PUBLICATION OF THE ELEVATING WORK PLATFORM ASSOCIATION OF AUSTRALIA INC

www.ewpa.com.au

IN THIS ISSUE

A green solution to diesel generators – 38

Contents

ELEVATING WORK PLATFORM ASSOCIATION OF AUSTRALIA INC ABN 32 545 830 419 EWPA BOARD OF DIRECTORS President: Doug Rawlings Tel: 08 9350 5700 Vice President: Tim Nuttall Tel: 03 9547 7700 Past President: Rick Mustillo Tel: 02 9817 7610 Chief Executive Officer: James Oxenham Tel: 02 9998 2222 Operations Director: Nicolas Chiew Tel: 02 9998 2222 Director of Resources: Andrew Delahunt Tel: 02 9998 2222 NSW President: John Glover Tel: 0419 663 863 VIC President: Keith Clarke Tel: 0400 369 900 QLD President: Richard Gannon Tel: 0437 477 279 SA President: Jason Gaskin Tel: 08 8449 0500 WA President: Will Reilly Tel: 0408 474 261 TECHNICAL DIRECTOR – OPERATIONS Peter Davis, Tel: 02 8796 50551 TECHNICAL DIRECTOR – ENGINEERING Peter Wenn, Tel: 03 9568 7211 COMMITTEE Luke Schubert, Tel: 0458 770 002 Bob Mules, Tel: 0402 982 999 James Nightingale, Tel: 1800 457 145

TELESCOPIC HANDLER ASSOCIATION OF AUSTRALIA (TSHA)

PRESIDENT: Stuart Walker Tel: 0418 849 107 EWPA & TSHA PO Box 1304, Mona Vale NSW 1660 Tel: 02 9998 2222 Email: info@ewpa.com.au Web: www.ewpa.com.au Opinions published in Hire & Rental Magazine do not necessarily reflect the opinions of the association or the Editor. The HRIA accepts no responsibility for the accuracy of any information contained in this magazine and readers should rely upon their own enquiries in making decisions related to their own interest. All rights reserved. ISSN 1838-1197

36 New TeleFORKS extend your reach

MAY

2021

VOL22

NO004

OFFICIAL PUBLICATION OF THE ELEVATING WORK PLATFORM ASSOCIATION OF AUSTRALIA INC

www.ewpa.com.au

Hot topics

30 EWPA President Message

32 TSHA President Message

34 A world first for the hire industry

38 A green solution to diesel generators 40 Many hands make light work

42 Column: Accessing your needs

IN THIS ISSUE

A green solution to diesel generators – 38

30 A guide for good practice 32 Extend your fork reach, not your budget 34 World first for the hire industry 38 A green solution for diesel generators

On the cover

JLG’s TSL-2000

JLG’s Australian-designed and manufactured TSL-2000 Trailer was developed to transport JLG Scissor Lifts such as the ES1330L to the work site safely and efficiently. A fit-for-task design ensures easy loading and unloading and once on board, the lift is secured with a high quality restraining package that includes three load binders, connecting links and chains as standard. At the job site, the ES1330L comes into its own with a 3.80m platform height and generous 227kg platform capacity. The machine’s light 900kg weight, compact dimensions and quiet operation make it ideal for a range of applications including on sensitive indoor flooring. This lift and trailer is a perfect combination.

President’s message

Looking forward to a healthy future

From an operational perspective, members have been kept busy these last few months and we hope this continues through to the end of the financial year and beyond. If your business was affected by the floods in March, on behalf of the association, we hope that the recovery and clean-up operations went well and you are all back in business once more.

It has certainly been a challenging 18 months when we look back on the natural and man-made disasters - bush fires, floods, COVID-19 and now more floods. The Association offers support to members when times are hard and we hope that our resources and social connections have provided some level of assistance with the challenges faced.

The EWPA obviously has a strong safety focus and whilst most people’s thoughts go to operating machines, it is also important that we also keep the data we manage safe. It’s been said in the past, “It’s not a question of ‘if’ you will be the victim of a cyber-attack, but ‘when’.”

Cyber security is very important

The national office had an external expert perform a cyber audit and provide recommendations for handling data. Without giving away our various methods of protection, I can say that we go to great lengths to maintain the integrity of our IT systems. We also have in place a disaster management plan.

Cyber-security is a subject that is addressed during our IT update at each Board meeting. Finally, if the worst should happen, the Association has a comprehensive insurance policy in place. Remember, it’s not always the high profile corporates who are attacked, so be prepared and seek expert advice if you haven’t already done so.

Take care when transporting

problems. Load restraint is critical for scissors, booms and other MEWPs being transported from hire companies to their customers. The HRIA recognised the importance of this and applied for government funding to assist in getting the message out via face to face training courses.

At the end of 2020 and for six months of 2021, Chain of Responsibility courses have – and will be – held across the country. I would encourage anyone involved in the hire and transportation of MEWPs to take up this free option of NHVR funded training. This applies to the sub-contractors and transport companies you engage as the program is open to all. Please contact the national office for information on the last two months of courses.

See you at the Gold Coast

As we near the half way mark in 2021, it feels like the country is gaining the upper hand over the pandemic. Without tempting fate, I think it’s a positive sign to see more people travelling and meeting customers face to face once more. With increased confidence and a return to more normal levels of travel, I hope to see many of you at HIRE21 on the Gold Coast this month. The event has already grown in size with very strong support from exhibitors after a forced 24-month gap between conventions.

HIRE21 has an excellent line up of keynote speakers including Ben Crowe and Glenn McGrath and industry focussed workshops, plus a program on social events so that we can finally connect with each other in person.

On the Tuesday afternoon (prior to the exhibition opening) the EWPA is hosting its annual “Global Access Meeting” at the Gold Coast. This is a chance to hear industry experts and their thoughts on the future of the access industry. With more original equipment manufacturers joining the EWPA from overseas, our global connections and presence is going from strength to strength. The EWPA is also sponsoring its first ever “Access Night” and our keynote speaker is the very entertaining Mick Colliss – a evening not to be missed on Wednesday 12 May.

Training is essential

The access industry is booming and with low unemployment around the country this puts added pressure on our members to be resourced enough for the extra work load. I would encourage members to look at the training and funding that the EWPA has established a link to through our training partners Strategic Alignment Training and VERTO. Last year association members benefited through funding and subsidies to the tune of $1.8m. For more information on this please contact the national office.

Once again, I look forward to seeing many of you on the Gold Coast at HIRE21 for the EWPA’s Global Access meeting, our ‘Access Night’, a full program of events and a chance to connect in person.

Doug Rawlings National President, EWPA

President’s message

Safety always comes first

From an operational perspective, members have been kept busy these last few months and we hope this continues through to the end of the financial year and beyond. If your business was affected by the floods in March, on behalf of the association, we hope that the recovery and clean-up operations went well and you are all back in business once more.

It is important to always remember the safety element whenever you undertake a new project. Telescopic handlers are machines that require expertise in their operation and it is imperative that everyone abides to safety requirements at all times.

In conjunction with the EWPA, we supply an array of safety information relating to the operation and regulations regarding telescopic handlers, which is available through the TSHA Operator Licence Training Program – the TSHA Gold Card – as well as industry advice lines, online safety resources, guidance notes and specialised stationary.

The safety of everyone involved in telescopic handlers is non-negotiable and we can’t emphasis enough to abide by all regulations at all times.

Work is picking up

Every industry, besides supermarkets, suffered greatly from the 2020 pandemic. Even now as we see jobs return and people move about more freely, there is still the occasional COVID-19 scare that sees state governments close borders faster than a speeding bullet.

When this happens, it causes businesses to stop planning for the future and work halts in that particular state or territory.

Despite this, we are seeing an increase in the demand for telehandlers and we are hopeful that the second half of 2021 will continue to see our members busier than last year, while we are hopeful that 2022 will see business returning to pre-pandemic levels.

Members need to abide by all regulations...

Working in unity

In 2020 we worked closely with the Victorian Farmers Federation in lobbying the Victorian Government regarding telehandlers licence requirements.

In Victoria the rules are different to other states and we strive to achieve unity in conformity across Australia.

In Victoria, non-slewing telehandlers that are over three tonne rated capacity (3001kg or more) require a high risk work licence – CN Class. For the other states, competency/industry based training such as TSHA Gold Card or Statement of Attainment is acceptable.

The CN Class is the minimum HRW licence where applicable, but any mobile slewing crane class (C2/C6/C1/CO) is acceptable.

We are continuing to work closely with the Victorian Farmers Federation and talk with the Victorian Government to strive to attain consistency across the six states and two territories in Australia.

Time to get together

It just wasn’t the same last year holding the annual HIRE conference via zoom. No chance to mingle, swap stories and understand the challenges and complexities of each business.

The good news is that the preparation and organisation of HIRE21 is in full swing thanks to the efforts of the national office and it looks as though it is going to be bigger and better than ever.

I would encourage all members to attend and re-connect with each other. There is nothing better than meeting face-to-face as it takes away all unintended misperceptions that can occur through electronic participation.

The Gold Coast conference in May is shaping as the best HRIA event yet and you can be assured that everyone will be welcoming and full of energy to once again discuss business in person.

Gold Card reminder

From 1July 2021 you will no longer be able to order a replacement for Gold Cards issued prior to 31 January 2014 (with no photo ID or expiry date).

The TSHA operator training program or “Gold Card” was created as the result of the TSHA working with industry, helping them to comply with the WHS/OHS Acts and regulation. This Gold Card program was designed to ensure that the Gold Card holder is trained in the safe use and operation of telescopic handlers.

The overall intention of the Gold Card program is to assist operators, employers, equipment owners and manufacturers to more easily be able to comply with the WHS/ OHS regulation.

Current WHS/OHS regulations require that operators of plant equipment must undergo activity-based instruction and training. As a result, as of 1 July 2021 old Gold Cards will not be replaced/reissued by the TSHA, and the TSHA encourages holders of these old cards to update their Gold Card and receive current telescopic handler operator training.

Remember Gold Card training is based on assessing the operator’s competency in safely operating a telescopic handler. It includes a classroom component as well as practical assessment. The training includes any safety messages that may help operators avoid taking risks when working at height.

A guide for good practice is a world first

The Telescopic Handler Association (TSHA) is pleased to announce the release of its Good Practice Guide. The production of this document is a world-first and for Australian users of telescopic handlers, it provides one-stop online guidance that is easy to navigate and updated with the latest information on a regular basis.

“In making this freely available, by hosting the guide online at www.tsha. com.au, the TSHA hopes that owners, supervisors and operators will improve their knowledge and decision-making relating to the safe operation of these machines,” James Oxenham, HRIA CEO, said.

“Telescopic handlers are versatile pieces of equipment used across a number of industries, including construction, agriculture and mining and they can be used with a number of different attachments.

“Understanding load charts, load management systems, training and legislative requirements is a complex process. The TSHA Good Practice Guide brings together all the relevant information so that operators can make informed decisions prior to using telescopic handlers.”

One of the main contributors to the guide was Robbie Wilkinson, an engineer at Wenn Wilkinson.

“It is an important document to put together to assist in the safety and operation of telescopic handlers,” Wilkinson said.

“There was great input from may people, especially Andrew Delahunt, and I think what we have produced it is an excellent guide for those who need to use a telescopic handler.” The TSHA would like to thank Robbie Wilkinson and Andrew Delahunt for their input and its OEM members for their support of this project.

Zero emission scissor lift powering on lithium-ion batteries

Ahern have launched a new zero emission new Snorkel S2755RTE narrow rough terrain scissor lift, which is maintenance free and powered by lithium-ion batteries.

Designed for working in confined spaces, the S2755RTE can reach heights of up to 10.1m, yet measures just 1.45m wide, and weighs 2,750kg, meaning that it can be towed on a tandem trailer between jobs.

Based on the popular diesel-powered Snorkel S2755RT, this electric version simply replaces the diesel engine with two 5.75kWh lithium-ion battery systems, that deliver up to eight hours of normal driving and elevation usage on a single charge.

The S2755RTE has an on-board charger and can be fully recharged within five to eight hours. It can also be easily top-up charged throughout the day, such as between shifts or during break periods.

With higher torque and speeds, the S2755RTE retains powerful 4-wheel drive capabilities and has high grip non-marking tyres for indoor and outdoor use. When compared to the diesel equivalent, the S2755RTE delivers 100% reduction in emissions, a 62% noise reduction, and a 93% reduction in service costs.

Ahern Australia are also introducing a Snorkel SR626 compact rough terrain telehandler and a Ruthmann Bluelift SA18HB tracked spider lift.

The narrow Ruthmann Bluelift SA18HB tracked spider lift has a simple three-section boom design which delivers up to 17.8m working height, and up to a 9.3 metres lateral outreach (230kg platform capacity) yet has a stowed width of just 0.84 metres and a stowed height of less than 2 metres. This model is fitted with a BlueHybrid package, the first-ever full hybrid solution that meets industry needs for zero emission equipment. Three energy-efficient operating modes offer versatility by switching between battery power and combustion engine.

Designed to be simple and robust, the compact Snorkel SR626 telehandler is capable of lifting up to 2,600kg, with a maximum lift height of 5.79m and a maximum forward reach of 3.2m. At just 1.89m wide, compact dimensions make this model ideal for using in tight spaces, particularly on construction jobsites or in rental applications.

It is equipped with powerful four-wheel drive and a Yanmar diesel engine. This model is also now available as the Snorkel SR626E with lithium-ion batteries, providing a full electric zero emission alternative to diesel for indoor use or in areas with emissions regulations.

New TeleFORKS extend your fork reach, not your budget

The main challenges faced by warehouses today is availability of space to accommodate increased inventory flow and establishing affordable material handling solutions that increase productivity.

Acommon solution to optimise warehouse space is with double deep racking and storage. Due to the need for fewer aisles this system saves space but requires specialist forklift attachments to allow pallets to be stored two deep.

For many businesses, the cost of specialist fork trucks equipped with telescopic forks or a pantograph to can be inhibitive.

To make telescopic forks more affordable, leading forklift attachment and material handling equipment supplier East West Engineering has launched their new TeleFORKS.

“Our mission has always been to develop and supply cost effective material handling solutions for our customers,” Ron King, East West Engineering owner, said.

TeleFORKS hydraulically extend and retract for double deep stacking and one-sided loading/unloading. These forks therefore help reduce loading times and increase warehouse storage capacity.

One-sided loading/unloading eliminates the need to turn the vehicle or drive your forklift to the opposite side thereby making the operation safer. Double deep stacking can increase warehouse capacity by up to 30% compared to single deep warehouse operation.

“The specialised engineering processes required to manufacture telescopic forks mean the cost to purchase can deter warehouses who must carefully consider the return on investment,” King said. “Our TeleFORKS now make telescopic forks more affordable for warehouses across Australia and New Zealand to own.”

For product information contact East West Engineering on 1800 061 998 or visit https://www.eastwesteng.com.au/tf

A green solution for diesel generators

Makinex Hybrid Power System (HPS) delivers clean green power combining a solar panel system, a battery bank to store energy, an integrated backup diesel generator and an inverter to act as an interface between the different inputs. All elements of the power system are combined on a compact mobile solution that takes minutes to setup on site.

The Makinex HPS can replace a standard diesel generator when being used for providing power to events, construction site offices, pumps, remote powering of communities and disaster recovery power. The use of the batteries at times of low power consumption creates a huge advantage in protecting generator damage and waste in fuel.

Makinex HPS overcomes traditional power challenges including managing power supply without access to electricity grid in remote areas; high maintenance costs of poles/wires for electricity providers to supply power to remote areas.

It also means challenges where traditional long lengths of poles/wires are much more likely to get affected by bushfires and lightning strikes are no longer an issue. Major benefits of HPS means events and site users will have lower vulnerability to weather events and will ensure reliability issues are localized.

Makinex Hybrid Power System (HPS).

“HPS will reduce electricity outage rimes for customers and costs for network businesses,” Rory Kennard, Makinex CEO, said. “Plus, the status of the HPS can be easily monitored and controlled locally or remotely.”

Kennard describes the system as a steelframed, standalone power system with fold out solar panels with generator, batteries, and inverter in an all-in-one rapid deployment skid unit. The Makinex HPS model range consists of a 10, 20 and 45 kVA units, replacing the equivalent generator models.

“It takes about five minutes to deploy on site,” Kennard said. “The solar panels provide power for day use and at night, the generator kicks in to boost the batteries when needed. Once the batteries are charged, the generator turns off.”

HPS targets a reduction in fuel consumption between 80-95% while offering a reliable and more flexible power solution. The reduced costs of fuel, servicing and onsite truck movements pays for the extra upfront expense of the innovative Makinex HPS. The return of investment for this product ranges from between 36 months on a 10–15 year asset.

JLG delivers a booming versatile range

JLG’s Compact Crawler Boom range has expanded with the addition of the X13J Plus model, which joins the larger existing X17J Plus and X20J Plus variants.

The X13J Plus model’s narrow chassis, tracked wheel carriage (0.75 metres unretracted width) and light weight makes it easy to manoeuvre around work sites, through gates, yards and even through standard doorways. The non-marking rubber tracks also make it suitable for use on delicate surfaces, further increasing its appeal.

As well as being versatile and userfriendly, the X13J Plus still provides a generous platform height of 11.30 m (13.30 m working height), and a working reach of 7.08 m, while platform capacity extends to 230 kg, which should be sufficient for a twoperson work crew plus tools.

For added safety on the platform, the X13J Plus features SkyGuard as standard, while auto levelling outriggers with integrated lifting lugs increase stability and ease of setup, allowing the model to be safely operated on slopes of up to 16° and to climb grades of up to 28 per cent.

Further safety features include auto cut-out when the machine is out of level, emergency descent systems and envelope management load-sensing system.

Depending on operator preference or application requirements, the X13J Plus can be specified with a 11.7 kW petrol or 7.5 kW diesel engine; alternatively a Lithiumion option is also available. A further benefit of Lithium-ion power is its quite operation, meaning this machine is more suitable for use in noise sensitive areas.

“By adding the X13J Plus to the lineup, we can now offer platform heights from 11.30 to 18.05 metres and provide all the many benefits of the larger XJ Plus models in a smaller package,” Arron Cooper, JLG Industries product manager – ANZ, said.

“The X13J Plus lighter weight and compact dimensions – benefits that make it very convenient to manoeuvre on site – also make this model easy to transport, making it ideal for rental applications. Tipping the scales at around 2,185 kg, it may vary slightly depending on accessories fitted, means it is well within the braked towing capacity of utes and even some lighter vehicles.

“Like the larger models in the XJ Plus range, we expect the X13J Plus to also prove popular across a variety of industries from construction and maintenance through to use in parks and gardens, as well as for DIY work.

“While the Compact Crawler Boom range now stands at three variants, we’re aiming to expand our offering further later this year, providing even greater choice.”

The new X13J Plus is backed by JLG’s ‘one and five year/s’ warranty which provides a full year of coverage on the complete machine, plus five years’ coverage on all specified major structural components.

JLG’s X13J Plus compact crawler boom.

Many hands make light work

The moving of ladders and the set-up of scaffolds and platforms is also a time-consuming process which leads to loss of productivity. Toyota Material Handling Australia’s range of elevated stock pickers and work platforms solves both problems by maximising safety and helping to eliminate risk, allowing workers to be more efficient with less physical effort.

The Leonard HD Vertical Lift available from Toyota Material Handling Australia provides a solution for rental companies and contractors installing plaster board and ceiling panels in tight spaces and most construction and refurbishment applications. While complying with social distancing requirements and the strict site safety regulations on construction sites the Leonard HD is now an alternative to other larger and bulky scissor lifts and forms of manual scaffolding. The Leonard HD comes with all-steel chassis and canopies and integrated forklift pockets. It’s designed to be used in the harshest environments and features active pothole protection for an increased ground clearance, preferred in the contracting environment. Tailor-made to the operator’s

The Leonard HD Vertical Lift is perfect for installing plaster board and ceiling panels.

and contractor’s needs in the building industry, the Leonard HD eliminates the need for scaffolding, scissor lifts and normal push-around units. No more ladders, no outriggers, no hassles. One person can easily do a job safely, quickly and efficiently.

TMHA is pleased to introduce the Leonardo HD vertical lift together with the Solo-Gyps plaster board attachment which enables faster installations and less fuss. With zero turn, ultra-compact footprint and comfortable extendable dual decks the Leonard HD boasts exceptional manoeuvrability within a conjested site application. The addition of the Solo-Gyps simplifies the positioning of plaster board sheets saving manpower and labour allowing one operator to lift panels without assistance.

Exclusive to Toyota Material Handling, this quality range is built to exacting standards and comes fully backed by Toyota Material Handling, your guarantee of outstanding customer support.

For more information you can call Toyota Material Handling Australia on 1800 425 438 or visit www.toyotamaterialhandling.com.au

Big deck scissors join electric range

Haulotte has launched its latest PULSEO mobile elevating work platforms, revolutionising the aerial industry. The all-terrain scissor lifts HS15 E and HS18 E feature electric architecture which offers the same outstanding drive performance of an internal combustion diesel machine. This new generation of scissor lifts reinforces the direction taken by Haulotte in recent years towards versatility and environmentally friendly alternative energies.

The HS15 E and HS18 E scissors feature a remarkable load capacity to meet the most demanding applications: cladding, insulation, maintenance work. They can lift up to 750 kg of load and up to four people. The large work platform reaches 7.40 metres long when both extensions are deployed. To enhance your productivity, PULSEO scissor lifts move at height on even terrain: full height for HS15 E, up to 13 meters working height for HS18 E.

The HS15 E and HS18 E scissors are perfectly suited to work in all types of terrain: even the most rugged. They easily conquer all obstacles and climb slopes up to 45%. The oscillating axle matches the position of the front wheels to the uneven terrain to maintain optimal ground traction.

The 4-wheel drive axles deliver maximum torque and ensure excellent power distribution. In low grip situations, the manual differential wheel lock provides extra traction, getting the machine in and out of challenging terrain. The new PULSEO mobile elevating work platforms can be deployed on slopes up to five degrees with outriggers to guarantee safe elevation on uneven ground. High ground clearance protects machine components in all terrain conditions.

Proportional commands ensure precise movements and smooth operation on the way up to the work area, while ergonomic controls guarantee comfortable driving. The new PULSEO scissors incorporate the benefits of the ultra-high performance Haulotte Activ’Lighting System. Ten LED spotlights provide ideal illumination of the basket, controls, and the maneuvering area around the machine for safe loading/unloading operations in low visibility conditions. New on scissors, the renowned Haulotte Activ’Shield Bar system protects the driver from entrapment situations. The machine stops automatically as the operator is pushed towards the bar.

More and more cities and companies are taking steps to reduce their environmental footprint. With the 100% electric design, the HS15 E and HS18 E scissors operate with no harmful emissions. They offer a clean alternative suited to any situation, such as Low Emission Zones (LEZ), or green construction sites.

Available with non-marking tyres, they can also be used indoors on sensitive surfaces without leaving a trace. The latest PULSEO machines operate in silence (acoustic profile <60 dB in electric mode), they are perfect for work in low-noise areas or public places without bothering people nearby.

By expanding its successful PULSEO generation range, Haulotte strengthens its all-terrain and electric aerial platforms offer. Versatile, the HS15 E and HS18 E combine remarkable off-road performance, exceptional load capacity and eco-responsibility. The various charging possibilities, on mains power or via a range extender, allow you to adapt to the constraints of all work sites. Improved serviceability and on-board innovations reduce maintenance costs significantly.

The Haulotte Activ’Lighting System is comes as part of the recently released all terrain scissor lift range, designed to ensure the safety of the driver during loading and unloading operations.

OUTRIGGER PADS.

STABLE SUPPORT FOR LIFTING EQUIPMENT, MOBILE PLANT AND VEHICLES.

Our range of high quality outrigger pads and spreader plates provide maximum strength, durability and load distribution with load bearing capacities of up to 300 tonnes.

Engineered to withstand extreme pressure, our tough no-nonsense pads are waterproof and resistant to chemicals, and will adapt to the contours of uneven terrain whilst retaining their shape.

Outrigger pads off er stable support for:

Mobile cranes, crawler cranes, mobile elevating work platforms, truck mounted cranes, cherry pickers/bom lifts and many more. Scan QR code to view our brochure.

OUR RANGE IS CONSTANTLY BEING EXPANDED. PLEASE INQUIRE WITH OUR FRIENDLY STAFF FOR YOUR SPECIFIC NEEDS. ACCESS PARTS QUICK REFERENCE GUIDE. OUT NOW!

TVH AUSTRALIA PTY LTD • HEAD OFFICE BRISBANE

ABN 67 117 701 587 • 60 Bernoulli Street • Darra QLD 4076 • Australia T +61 7 3717 3222 • F +61 7 3275 3881 • info.au@tvh.com • www.tvh.com

BRISBANE

735 Boundary Road Richlands QLD 4077 T +61 7 3277 0877 F +61 7 3277 0026 brisbanesales@tvh.com ADELAIDE

96 South Terrace Wingfi eld SA 5013 T +61 8 8359 1155 F +61 8 8359 0600 adelaidesales@tvh.com MELBOURNE

7/66-74 Micro Circuit Dandenong South VIC 3175 T +61 3 9544 6622 F +61 3 9544 2617 melbournesales@tvh.com PERTH

2/15 Colin Jamieson Drive Welshpool WA 6106 T +61 8 9358 2200 F +61 8 9358 2822 perthsales@tvh.com SYDNEY

4/463 Victoria Street Wetherill Park NSW 2164 T +61 2 9756 6677 F +61 2 9756 3555 sydneysales@tvh.com