1 minute read

Cylinder head gasket, measurement

Cylinder head removed

Special tools: 885819, 9989876, 9995192

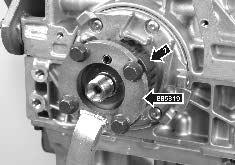

1. Install counterhold tool 885819 on the crankshaft toothed belt pulley (1) to rotate the crankshaft.

2. Make sure that the engine block gasket plane and piston crowns are thoroughly cleaned.

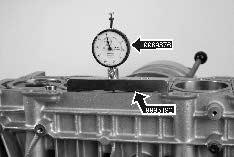

Put holder 9995192 with dial gauge 9989876 on the gasket plane. Zero the dial gauge against the gasket plane.

IMPORTANT! Be careful to avoid damage to the engine block gasket plane.

Distance between piston and gasket plane 0.26—0.47 mm 0.47—0.52 mm 0.52—0.57 mm 0.57—0.62 mm 0.62—0.74 mm No. of holes in cylinder head gasket

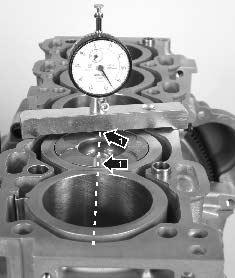

1 2 3 4 5 3. Crank the engine and measure the top dead center of each piston, on both sides (1) of each piston. Measurements must be done in line with the gudgeon pin, and as close to the cylinder walls as possible. NOTE! If a piston has different measurement values, the highest value must be used when calculating the gasket thickness. NOTE! Do not measure inside the valve cutouts in the piston crown.

4. Use the highest measured piston height and determine the correct gasket thickness with the aid of the table.