5 minute read

TELESCOPIC BOOM

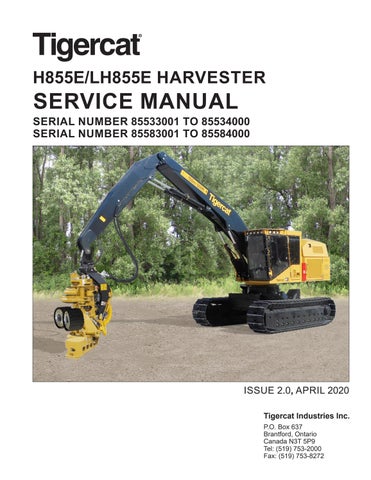

Tigercat H855E/LH855E Harvester

SAFETY HAZARDS–VITON SEALS

O-rings and other seals manufactured of Viton material (fluorine rubber) produce a highly corrosive acid (Hydrofluoric) when subjected to temperatures above 315°C (600°F). This contamination can have extreme consequences on human tissue since it is almost impossible to remove after contact.

The following procedures are recommended when inspecting equipment that has been subjected to high temperatures such as fire: • Visually inspect any seals or gaskets which have suffered from heat; they will appear black and sticky. • If these are found, do not Touch! • Determine the material composition of any seals or gaskets. If fluoro-elastomer seals (Viton, fluorel, or tecmoflon) have been used, the affected area must be decontaminated before undertaking further work. Natural rubber and nitrile materials are not hazardous.

• Disposable heavy duty gloves (neoprene) must be worn and the affected area decontaminated by washing thoroughly with limewater (Calcium

Hydroxide solution). • Any soiled rags and gloves must be safely discarded after use.

NOTE: Burning discarded items is not recommended except in an approved incineration process where the dangerous products are treated by alkaline scrubbing.

Safety

SAFETY HAZARDS–OPERATING

Maintain a charged fire extinguisher on the vehicle at all times and know how to use it.

Do not carry passengers either in the cab or anywhere else on the machine. The vehicle is provided and approved with seating for the operator only. Do not allow anyone to operate the machine who may not be physically fit or who may be under the influence of alcohol or drugs. When moving the machine, watch that enough clearance is available on both sides and above the machine or any of its attachments. Extra clearance may be required particularly where the ground is uneven. Approach with extreme caution any area where overhanging electrical power lines are present. Serious injury or death by electrocution can result if the machine or any of its attachments are not kept a safe distance from these lines.

Maintain a distance of 3 m (10 ft) between the machine or boom and any power line carrying up to 50,000 volts or less plus 10 mm (0.5 in) for each additional 1,000 volts above the 50,000 volt level. If State/Provincial, local or job site regulations require even greater safety distances than stated above, adhere strictly to these regulations for your own protection. If the machine must be transported, make sure that it is adequately secured to the transporting vehicle. Stopping the engine immediately after it has been working under load can result in overheating and premature wear of the engine components. Reduce engine speed and let run for approximately five minutes to allow gradual dissipation of heat and also to reduce turbo speed. This will also prevent loss of coolant by after boil and possible hot spot damage to the engine.

Safety Tigercat H855E/LH855E Harvester

Be aware when performing service and maintenance tasks that surfaces and grab handles in and around the engine and cooling system may become very hot when the engine has been running. Contact with hot surfaces may cause injury. Comply with instructions in this manual and also your company’s regulations for the operation of this machine. Read, understand and follow all general safety precautions specified by attachment manufacturer.

WARNING

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling. WARNING

Engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

If acid is accidentally splashed into your eyes, flush immediately with clean water and get medical attention. Do not attempt to charge a frozen battery; it can explode. When servicing the electrical system, turn off the battery disconnect switch before removing the battery compartment cover. Remove the battery cables from the batteries disconnecting the negative (–) cable first. Perform the service work, then attach the battery cables reconnecting the positive (+) cables first. Do not short out battery terminals for any reason. Serious burns or an explosion can result.

CAUTION

Lead-acid batteries contain sulphuric acid which can severely damage eyes or skin on contact. Wear a safety face shield, rubber gloves, and protective clothing to reduce risk of accidents. Lead-acid batteries produce flammable and explosive gases. Keep arcs, sparks, open flames, and lighted tobacco a safe distance from the batteries.

Tigercat H855E/LH855E Harvester

AVOID INJURY FROM BACKOVER ACCIDENTS

Before moving machine, be sure all persons are clear of the area.

Be alert for bystanders moving into the work area. Use horn to warn bystanders before moving the machine. When using a signal person, keep the person in view at all times. Ne sure the signal person is clear before backing up. To avoid backover accidents:

• Look around before you back up. Be sure that everyone is clear. • Keep motion warning alarm in working condition.

The motion warning alarm must sound when the machine is moving in forward or reverse. • Use a signal person when backing up if view is obstructed. Keep the signal person in view. • Learn the meaning of all flags, signs and markings on the job site and who is responsible for signalling. • Keep windows, mirrors and lights in good condition. • Dust, heavy rain, fog, snow etc. can reduce visibility.

As visibility decreases, reduce speed and use proper lighting. Turn off the engine when refuelling. Do not refuel the machine or work on the fuel system while smoking or near open flame or sparks.

Safety

Safety

OPERATING SAFETY PRECAUTIONS

Tigercat H855E/LH855E Harvester

FOR TIER 4F MACHINES ONLY:

D

Attach a grounding strap to an unpainted metal surface on the machine if the refuelling tank or nozzle is so equipped. Check that no other personnel have moved into a hazardous area before starting the machine. Sound the machine horn before starting the machine.

The operator’s seat is equipped with lap and shoulder harness belts. Use both of these restraint systems at all times when operating the machine. Start the engine according to the instructions in this manual. Refer to OPERATING THE MACHINE in SECTION 2.

WARNING

Never use a liquid starting aid to start an engine. This machine is equipped with a computer controlled heating element in the engine intake system. Starting fluids will explode on contact with the heating element.

41581AUNI R0

Diesel Exhaust Fluid (DEF) may irritate eyes or skin. Avoid eye and skin contact. First Aid treatment: DEF contains Urea. If swallowed call a Poison Control Center or doctor immediately. Do not induce vomiting. If in eyes rinse with water for 15 minutes. If on skin rinse well with water. If irritation persists seek medical treatment.