3 minute read

ENGINE START AND STOP

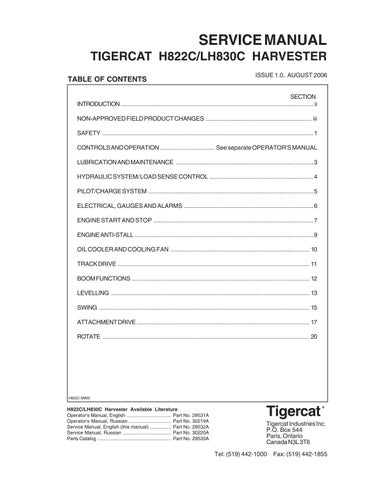

Tigercat H822C/LH830C Harvester Safety

GENERAL SAFETY PRECAUTIONS KEEP BACK 500 FEET

IMPORTANT

24 VOLT

ELECTRICAL SYSTEM

Remember that safety is a prime responsibility of all. To minimize the risks and promote safety at all times, this section of the operator’s manual details a number of safety rules which should always be followed and obeyed. Always read the operator's manual before operating the machine. Pay close attention to WARNINGS and HAZARD identifications

Follow all instructions from safety inspector and supervisors. You must be fully trained to operate this piece of equipment. Know the capabilities and the limitations of the equipment. Learn the most efficient operating techniques. Do not let untrained persons operate the machine.

Use recommended protective clothing and safety devices such as gloves, safety boots, safety hat, goggles, and ear protection when necessary. These safety rules highlight both general and specific measures that the operator should be familiar with and adhere to. More specific measures are illustrated with pictograms which may also be attached to the machine in locations pertinent to their respective message. Keep safety labels in good condition. Repair or replace damaged labels.

500 FEET 500 FEET

500 FEET 500 FEET

LH830-02

HAZARD ZONE

DANGER

ROTATING SAW

The safety of persons outside the cab is the responsibility of the machine operator

When approaching an operating machine on foot, stay at least 500 feet (150M) away until the operator recognizes your presence. Make sure that all harvesting equipment is shut down before advancing to the machine.

NOTE: Opening the cab front door will stop machine functions. Opening the cab side door will NOT stop machine functions.

The following diagram illustrates the HAZARD ZONE. All personnel should be kept clear of this zone while the harvesting head is operating. The HAZARD ZONE should be considered off limits to all individuals.

Tigercat H822C/LH830C Harvester Safety

GENERAL SAFETY PRECAUTIONS continued

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against noise. Prolonged exposure to loud noise can cause impairment or loss of hearing. This machine exceeds 70dB(A) in the cab and exceeds 85dB(A) when servicing machine engine. Use the handrails and steps provided when mounting and dismounting from the machine. Do not jump off the machine at any time. Do not try to climb onto or off of a moving machine. Do not use the seat armrest or joystick as handle when entering or leaving the cab. Do not use the machine foot controls as steps.

When mounting or dismounting the machine always use the 3 point technique; use one hand with 2 feet or 2 hands with 1 foot. Avoid mounting or dismounting the machine in areas with slippery surfaces. If this is not possible, clean up or cover slippery surfaces with a non-slip material. To reduce risk of fire, machines should be completely cleaned of debris at least daily, particularly around the engine exhaust components. Hydraulic oil leaks, excess grease, fuel and oil accumulation (including spillage) should be eliminated immediately, always shut off engine before cleaning machine. Maintain a clean cab interior, clear away trash or debris. Machine should be washed completely at every major service. Inspect the machine daily for signs of damage or unusual wear, to structures. Check for fluid leaks, or faulty operation. Repair or replace malfunctioning parts and systems immediately. Check windows and door guards for damage. Check protective windows for cracks, a damaged window has reduced strength to stop flying objects. All damaged windows must be replaced with original equipment. Check windows for scratching, crazing and cloudiness that could impair clear visibility all around the machine. Do not operate the machine with any defective or inoperable components. Check all fluid levels. Do not operate the machine with any of the exhaust system, safety covers, oil shields, or other devices removed.