5 minute read

BOOM FUNCTIONS

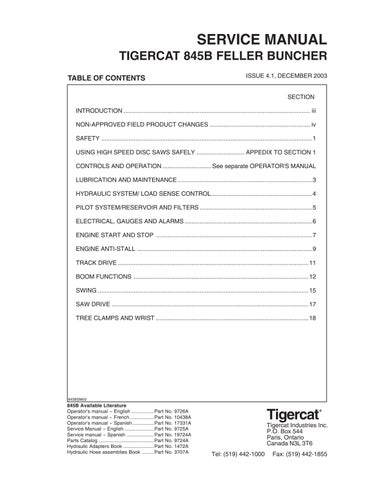

Tigercat 845B Feller Buncher Safety

OPERATING SAFETY PRECAUTIONS CONTINUED

If saw guard has been installed DO NOT remove until at the cutting site. Remove guard before starting engine. Do not turn on saw blade until machine is at cutting site. Never travel near co-workers or other pieces of equipment with saw blade turning. Do not allow people or other pieces of equipment near the felling operation. Use only prearranged and approved signalling practices. Operate the machine only from a seated position in the operator’s seat. Watch for ground hazards such as metal debris, wire fencing or rocks. When travelling position felling head and boom accordingly so as not to impair vision. If vision is limited by dust, smoke, fog, rain or snow, stop the machine until visibility is restored. When working on slopes, travel straight up or down the slope to prevent roll-over.

NEVER travel across a STEEP slope or side hill: • As logs are added to the accumulator pocket the handling and the stability of the machine will change. • To avoid tip over, keep the felling head as low as possible to maintain a low center of gravity. • Always be prepared to dump the load in case of an emergency. • Do not overload the machine as this can create an unstable condition and cause a rollover.

CAUTION

Do not open cab doors or window screens when machine is on a slope. The doors and screens are heavy and could swing out with considerable force.

FELLING TREES

Pieces of wood, debris from the ground and even teeth separating from the saw blade become potentially dangerous missiles when thrown from these machines. Inspect saw teeth, tooth retaining bolts, saw disc and felling head assembly. Ensure that all saw tooth retaining bolts are at correct torque value. Refer to attachment manual for correct values. Replace all worn saw teeth or rotate worn teeth to align unused cutting tips. Always replace saw tooth retaining bolts when replacing saw teeth. Inspect saw disc for stress cracks and that saw disc does not wobble due to worn saw shaft bearings. Never start the machine if the saw blade has missing teeth, teeth retaining bolts or a bent saw disc. Shut down machine immediately if vibration occurs during cutting. Check that the saw discharge area is clear and undamaged. When moving from tree to tree with the saw blade turning, take care not to make contact with other vegetation or debris. Do not over load felling head. Work within your operating skills, do not attempt to cut down a tree that is too large for the felling head. Operate so that the chip discharge area of the felling head is not directed at people, livestock, buildings or other machines. When making the cut, properly position felling head in front of tree and have saw blade running at full rpm. Always know and control the direction the tree will fall to prevent injury to co-workers or damage other vehicles. When backing away from a cut, watch out for obstacles in your path. Always travel with felling head as close to the ground as possible, never elevate the felling head unless necessary. Never use this machine to clear a logging deck on a new tract of timber when the rest of the equipment and operator's are also moving in. Pre-plan to clear decks in advance before other equipment arrives. Never work alone. Regularly inform other crew members of your intentions, location and length of time to perform duties. Stop the saw blade before leaving the cutting area. NOTE: The saw blade will continue to free wheel for several minutes after the saw switch has been turned OFF. To stop the blade from rotating, CAREFULLY lower the saw blade onto a stump. This should be done gently to prevent unnecessary loading of the saw blade, saw housing and bearings. Park machine at least 50 feet (15 meters) away from other equipment and in a cleared area. In the event of a fire, this distance will minimize the chance of the fire spreading to other equipment. Before leaving operator's cab, lower the felling attachment onto the ground. If out of the operator's cab for an extended period shut the machine off.

When parking the machine;

• Park on level ground only and engage the swing brake. • Do not park on a hillside or incline. • Lower felling attachment onto level ground. • Stop the engine. • Turn the master disconnect switch off if the vehicle is to be parked for an extended period of time (Example - overnight).

When transporting the machine watch that enough clearance is available on both sides and above the machine or any of its attachments to avoid contact with power or telephone lines, bridge structures, etc. Before transporting the machine check to ensure that all doors, panels and access covers are installed properly and secured. Improperly secured doors or panels pose a serious danger to pedestrians and other vehicles.

DISCONNECT THE MULTI-PIN PLUG FROM THE ENGINE ANTI-STALL CONTROLLER

Conduct maintenance inspections at least as frequently as recommended in section 3 of the OPERATOR'S MANUAL. When servicing or repairing equipment, shut the engine down. Turn Master Disconnect switch OFF. Install a “DO NOT START ENGINE” sign on the operator’s cab door and in the engine compartment when making repairs to the machine.

Before performing maintenance or repair work on any equipment, consult the manufacturer’s instruction manual and follow recommended procedures. The radiator and the engine cooling system should be cleaned and serviced daily to maintain moderate engine temperatures. Prior to welding on any part of the machine, it should be cleaned and a fire extinguisher should be made available at the welding location. Care must be taken in attaching the welding machine grounding clamp so current does not pass through bearings, especially the swing bearing. Also, disconnect the negative (-) battery cable from both batteries. This machine is equipped with an electronic horsepower limiting control. Prior to welding, disconnect the multi-pin plug from the engine antistall controller located on the rear inside wall of the cab. Never use your bare hand to check for fluid leaks.

Fluid leaks under pressure may not be visible. When searching for leaks, wear work gloves and use a wrench or piece of wood to move hydraulic hoses. Do not grab hold of hydraulic hoses. Wear safety goggles for eye protection.

870B-01