5 minute read

Operating Instructions GMK4080

Die Deutsche Grove GmbH hat die Krupp - Mobilkran - "KMK" - Typenreihe ubernommen und umbenannt in eine "GMK" - Typenreihe. In dieser Krandokumentation ist die alte Typenbezeichnung noch erhalten.

Deutsche Grove GmbH has taken over the Krupp - track crane - "KMK" - series and renamed it the "GMK" -series. The old series name has been kept in this crane documentation.

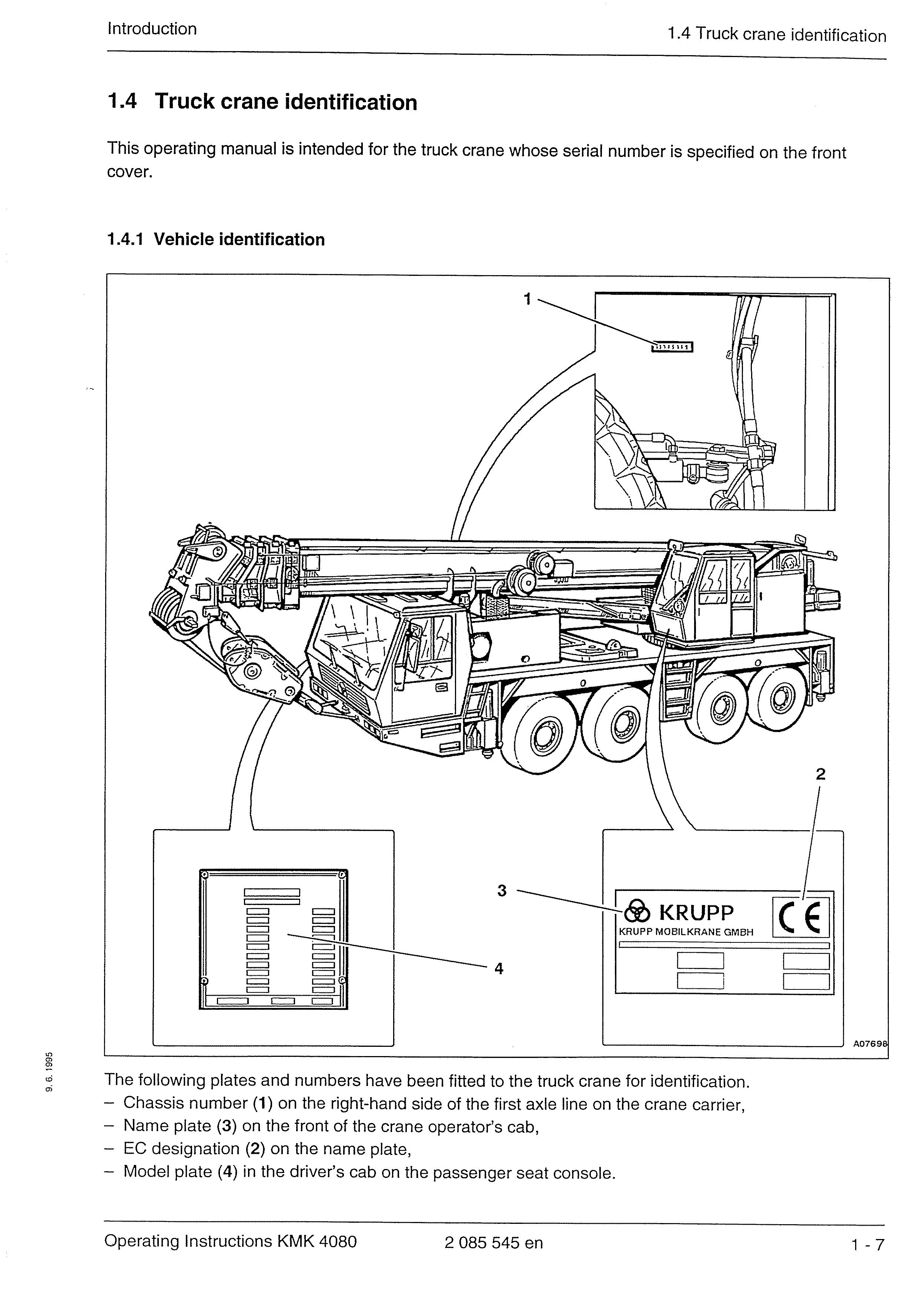

Vehicle - serial number: 9.6.1995

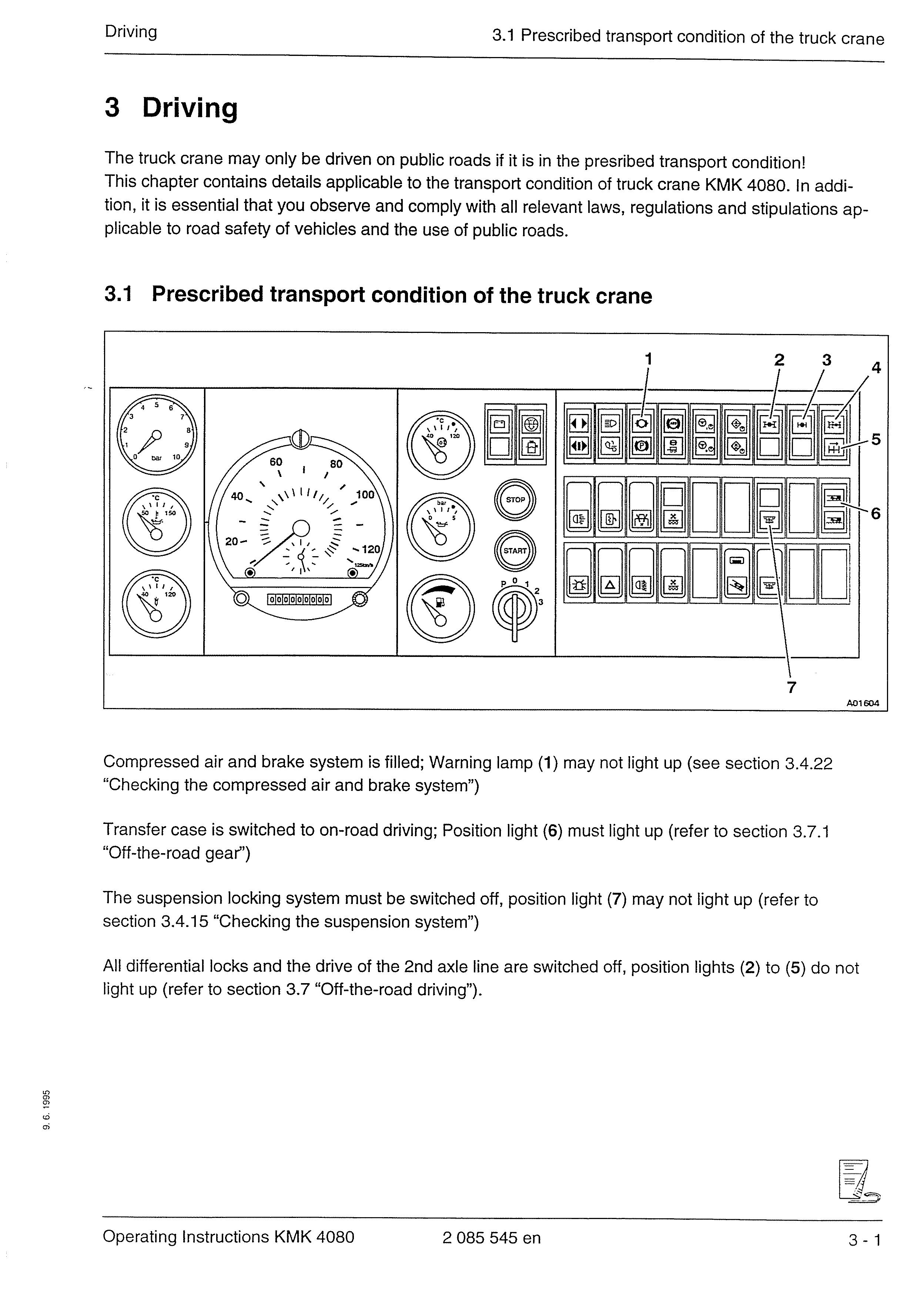

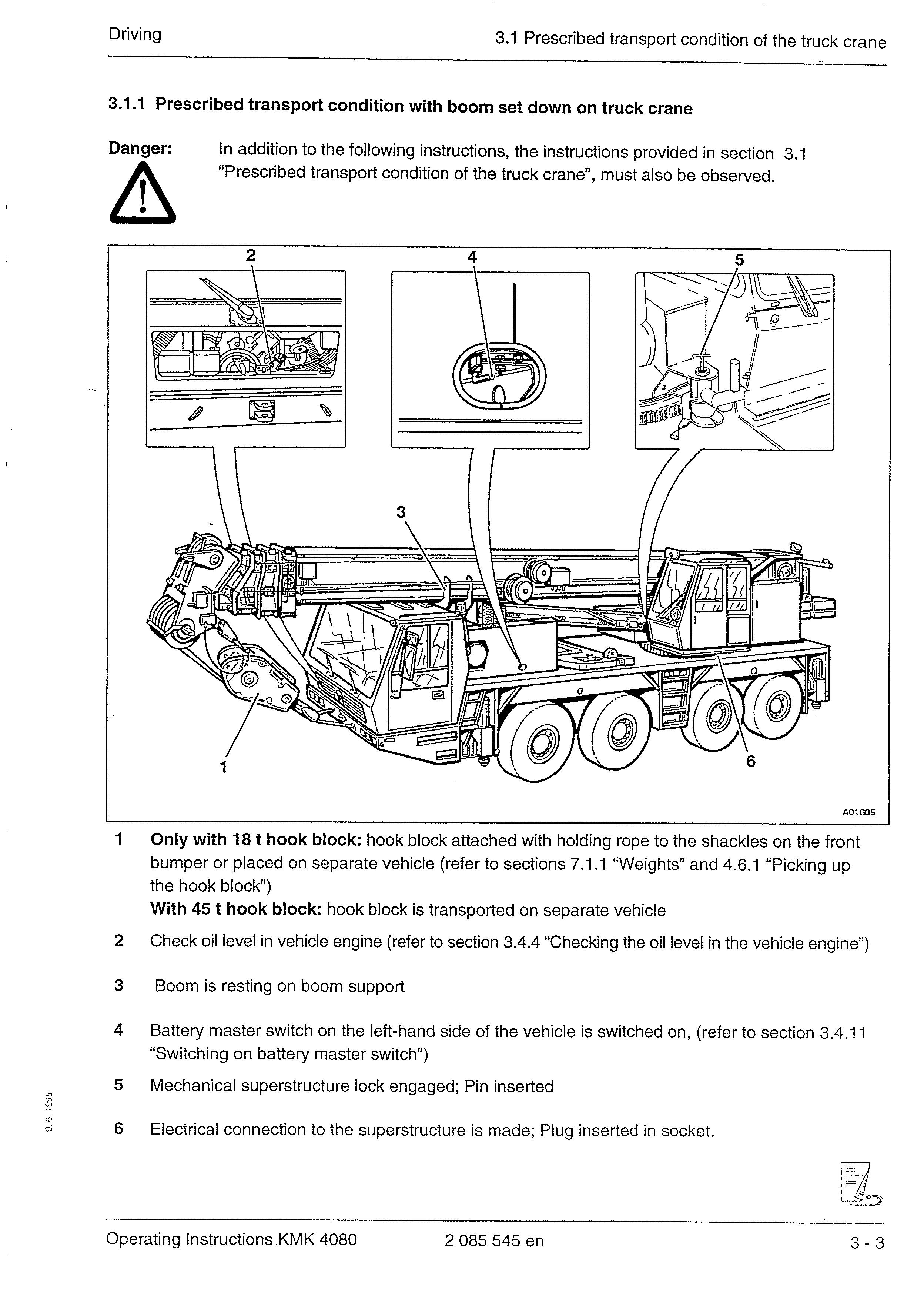

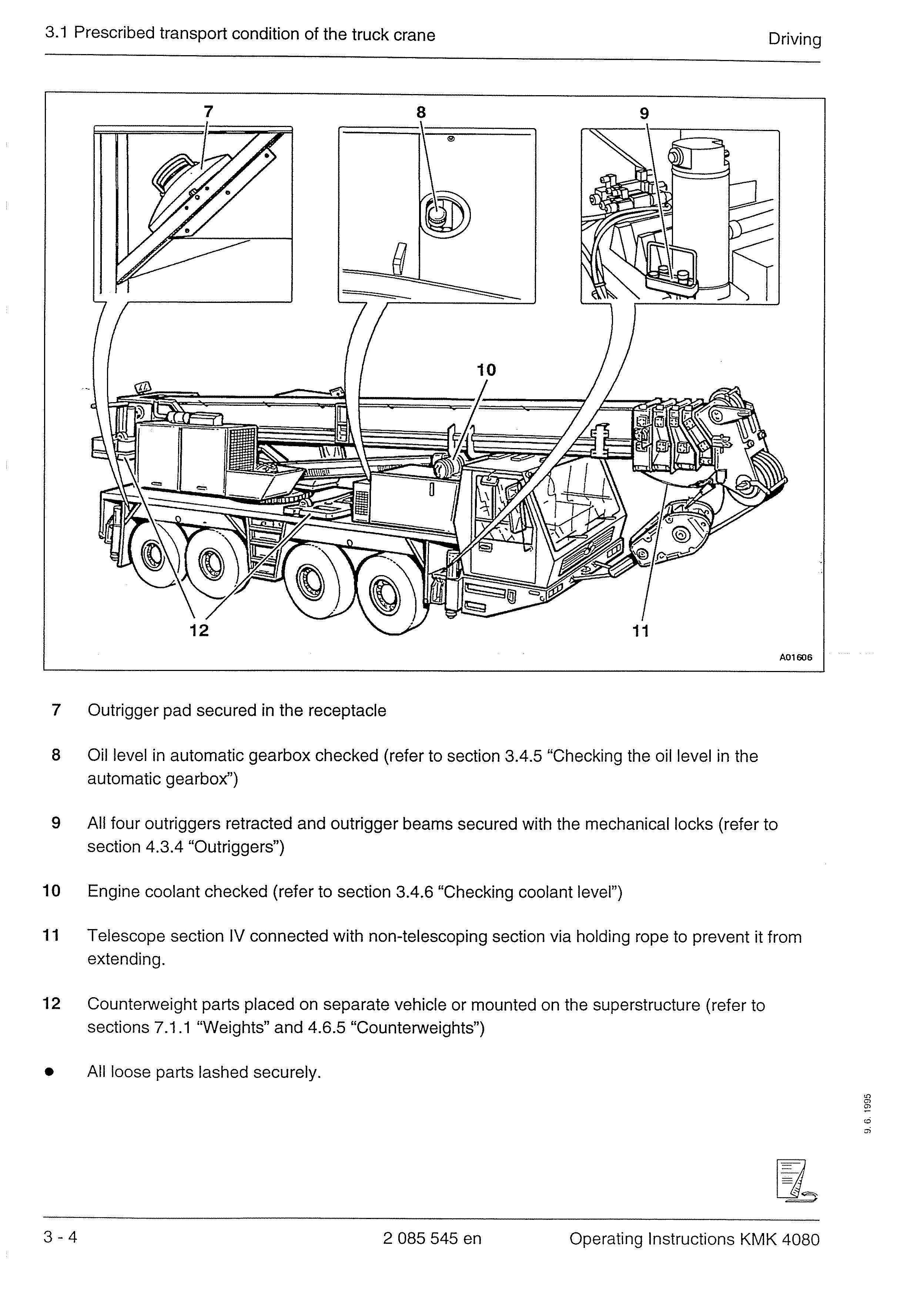

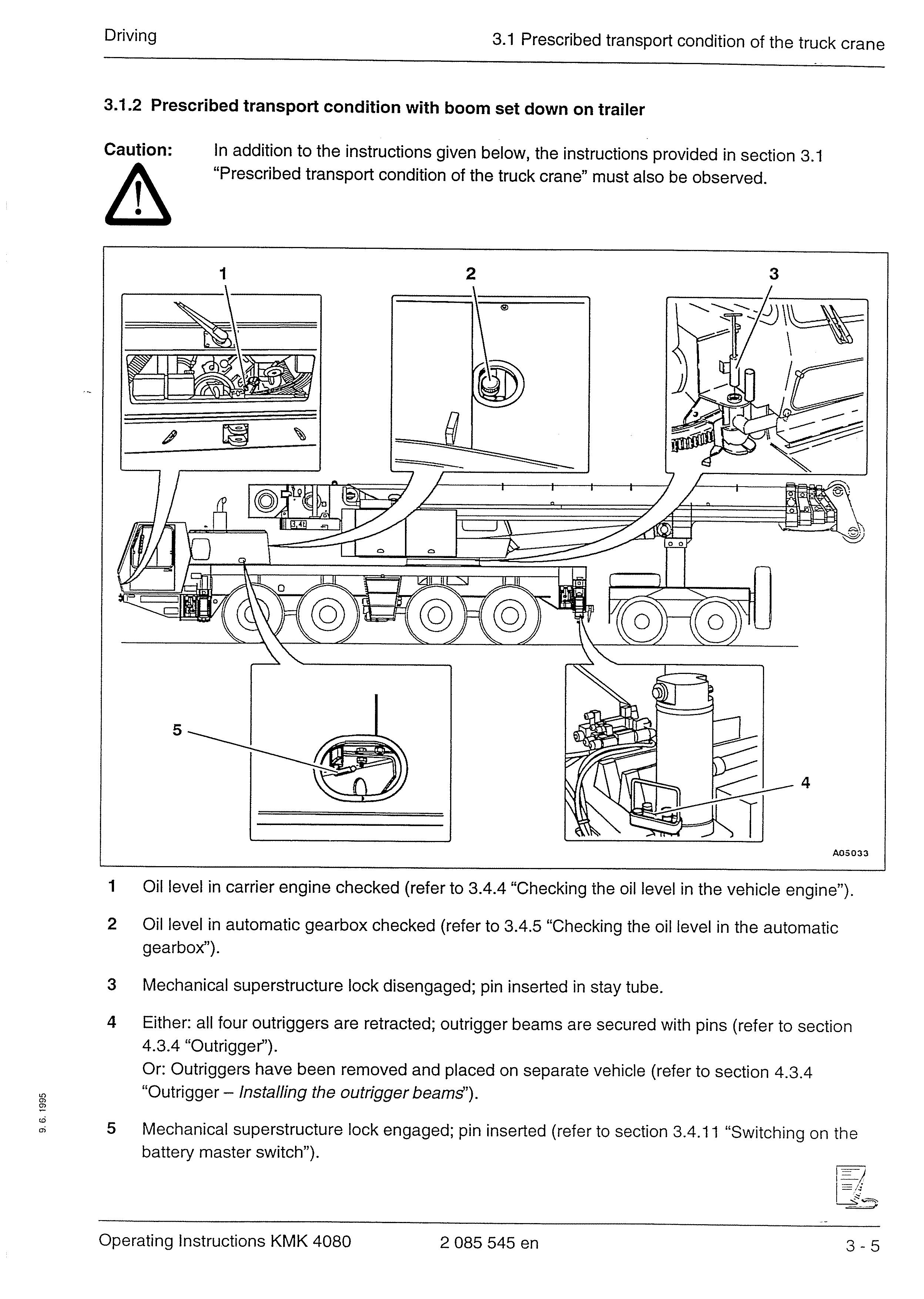

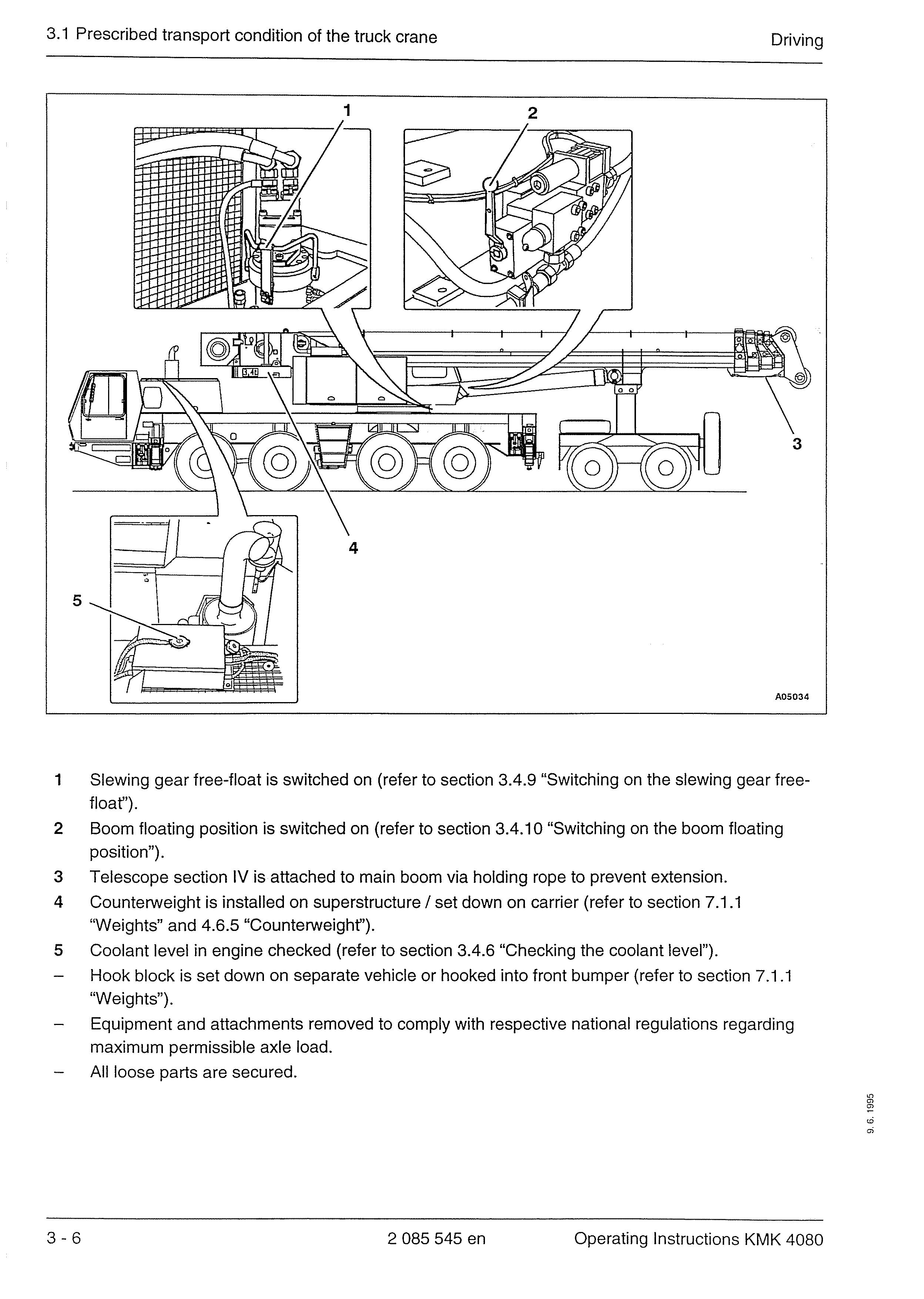

3.1 transport condition of the truck crane transport condition with boom set down on truck crane transport condition with boom set down on trailer

Driver's cab heating system

Heating the driver's cab .

Ventilating the driver's cab .

Fresh air blower (additional equipment)

Additional water heating system (additional equipment)

Establishing the proper transport condition During the winter . .

Visual inspection of the entire crane

Checkipg the oil level in the vehicle engine

Checking the oil level in the automatic gearbox

Checking the coolant level in the vehicle engine

Checking the tyres . . . . . . .

Checking the fluid level of the windscreen washing system

Switching on the slewing gear free-float (only for on-road driving with boom set down on trailer) . . . . . . . . . .

Switching on the boom floating position (only for on-road driving with boom set down on trailer) . . . . .

Switching on the battery master switch

Adjusting the driver's seat, steering column and mirrors

Inserting the 24-hour disc in the trip recorder

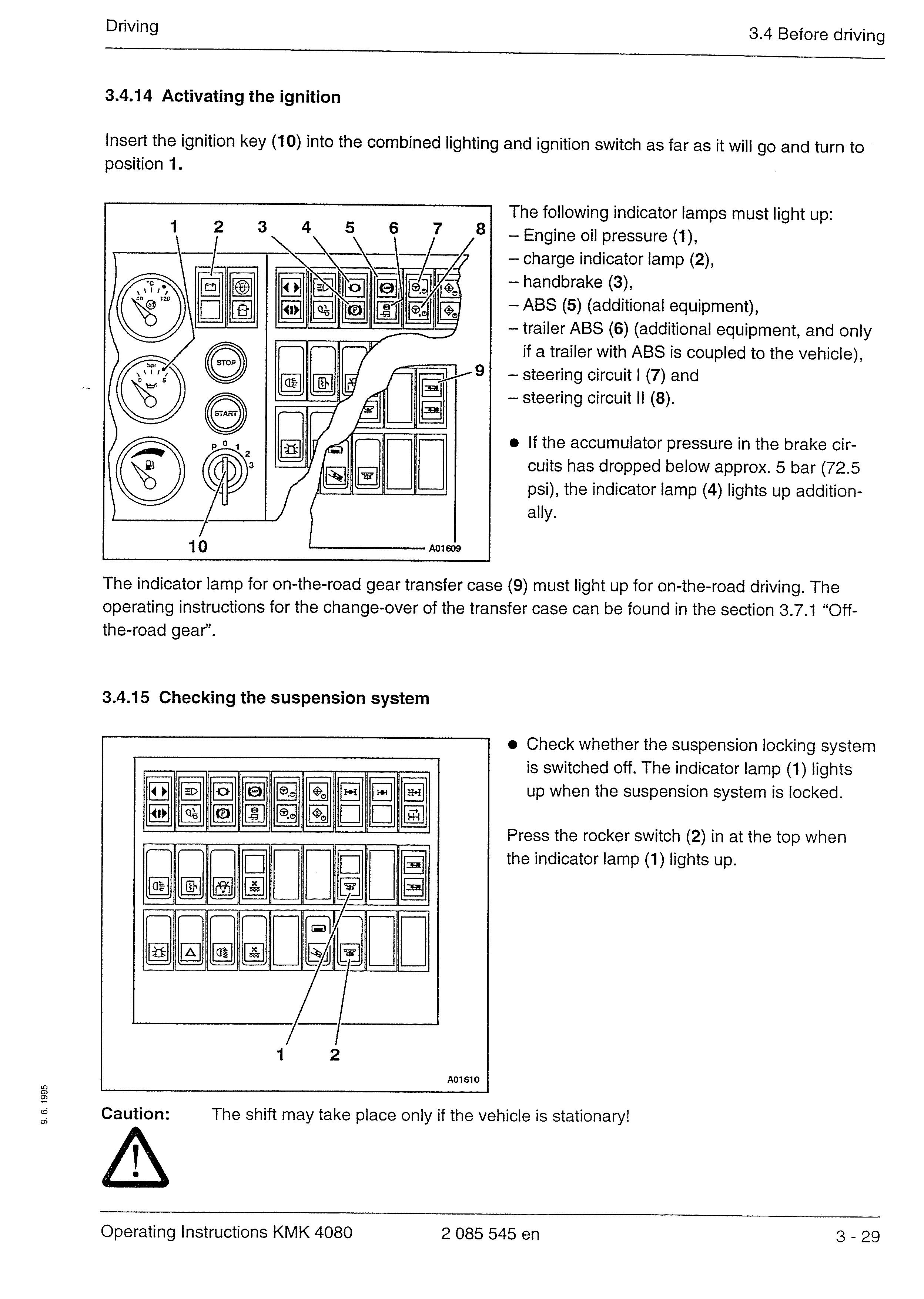

Activating the ignition . . .

Checking the suspension system

Checking the functions of the truck crane's electrical system

Checking the carrier level adjustment system for on-road driving

Checking the steering system for driving on roads (additional equipment)

Starting the vehicle engine . . .

Starting the vehicle engine with starter spray (additional equipment)

Vehicle engine running - check instruments

Checking the compressed air and brake system

Refuelling . . . . . .

While driving . . . . . . .

Testing the brake ...........

Driving ranges of the automatic gearbox

Automatic gearbox driving modes

Starting and stopping . . . . . . . .

Manual selection . . .

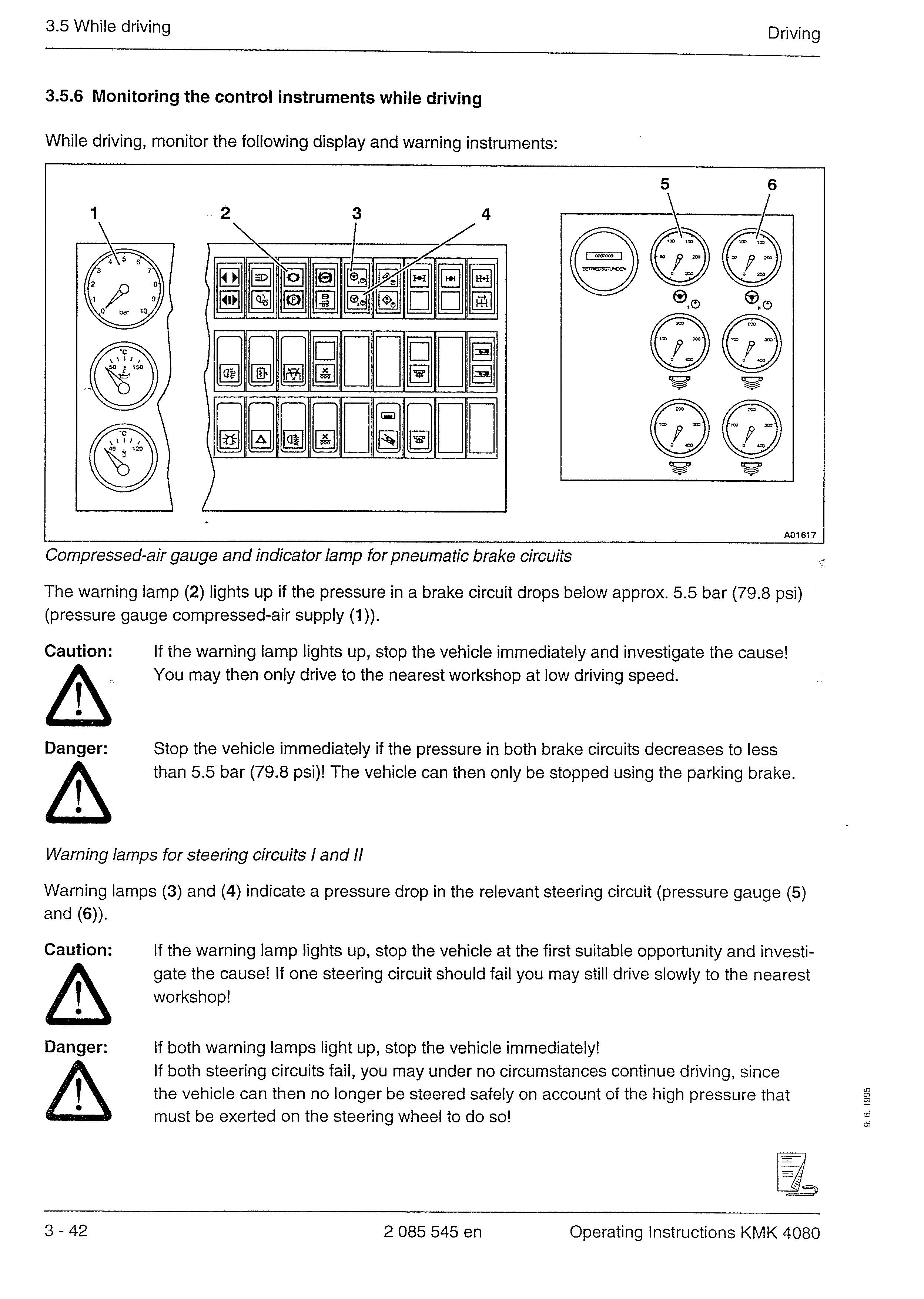

Monitoring the control instruments while driving

Driving on downhill slopes

Driving on uphill slopes .

After driving

Parking the vehicle . . .

Switch off the battery master switch if the truck crane is idle for a longer period of time

Off-road driving . . .

Off-the-road gear . . .

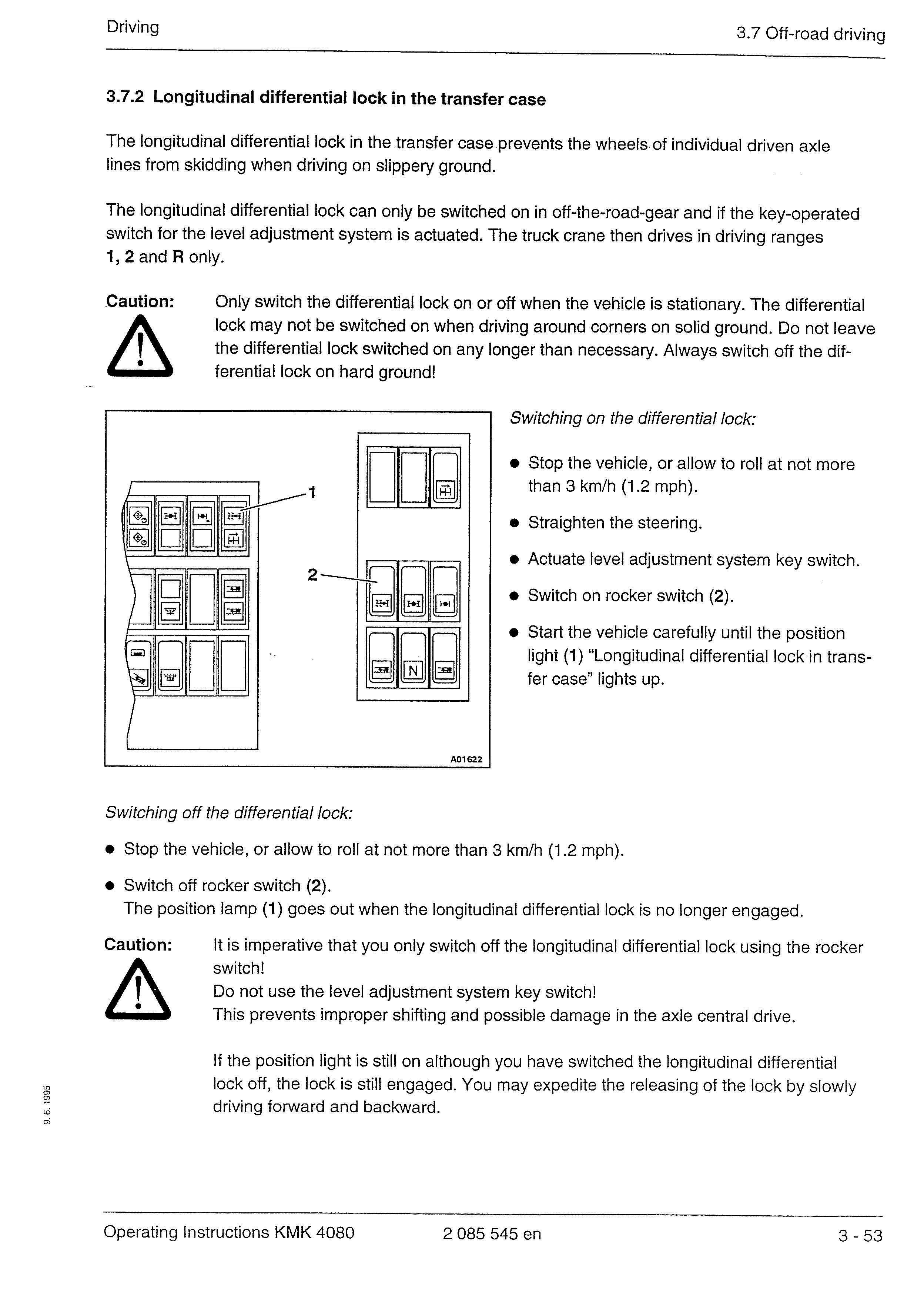

Longitudinal differential lock in the transfer case .

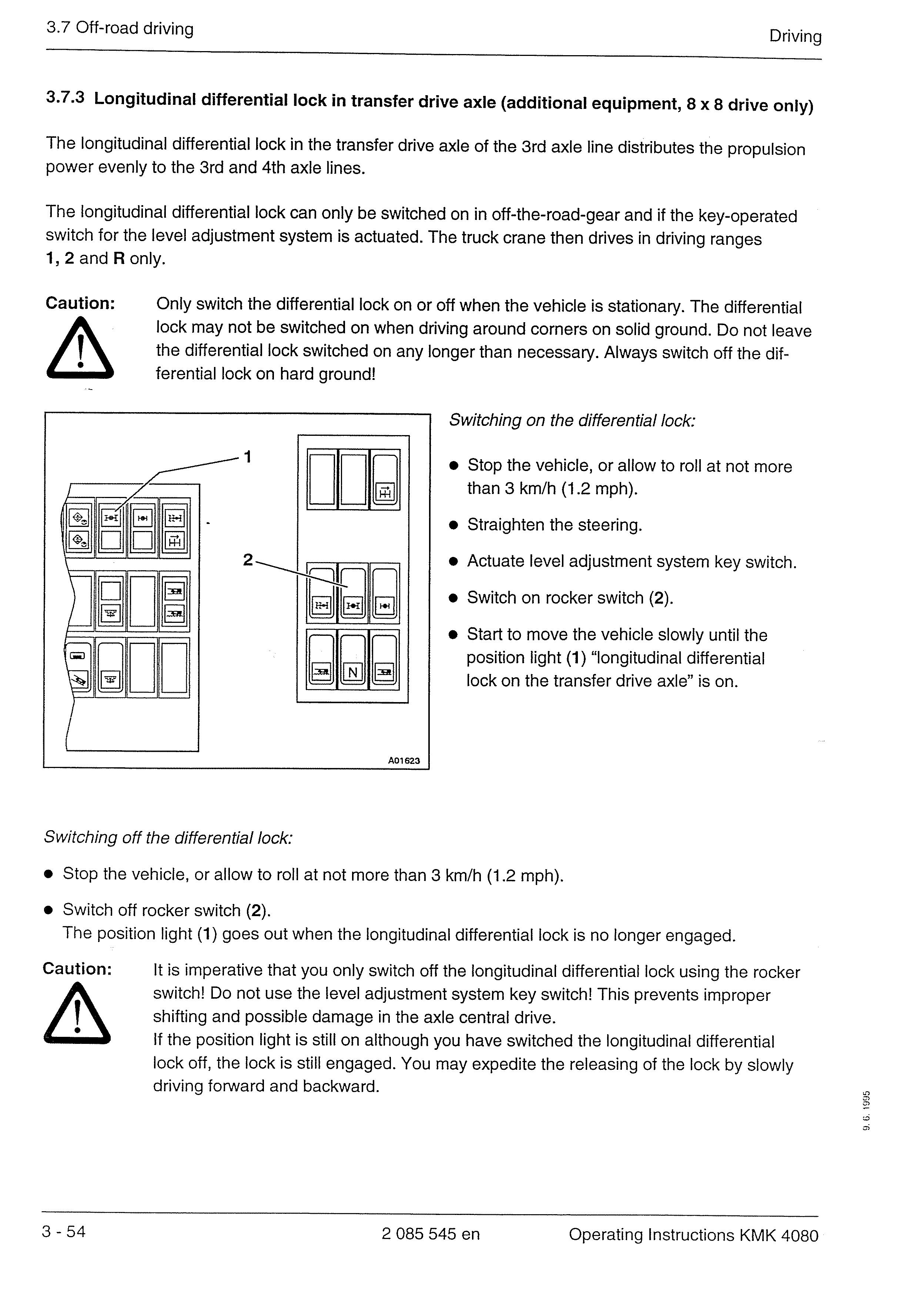

Longitudinal differential lock in transfer drive axle (additional equipment, _s x 8 drive only) ...............

Drive of the 2nd axle line

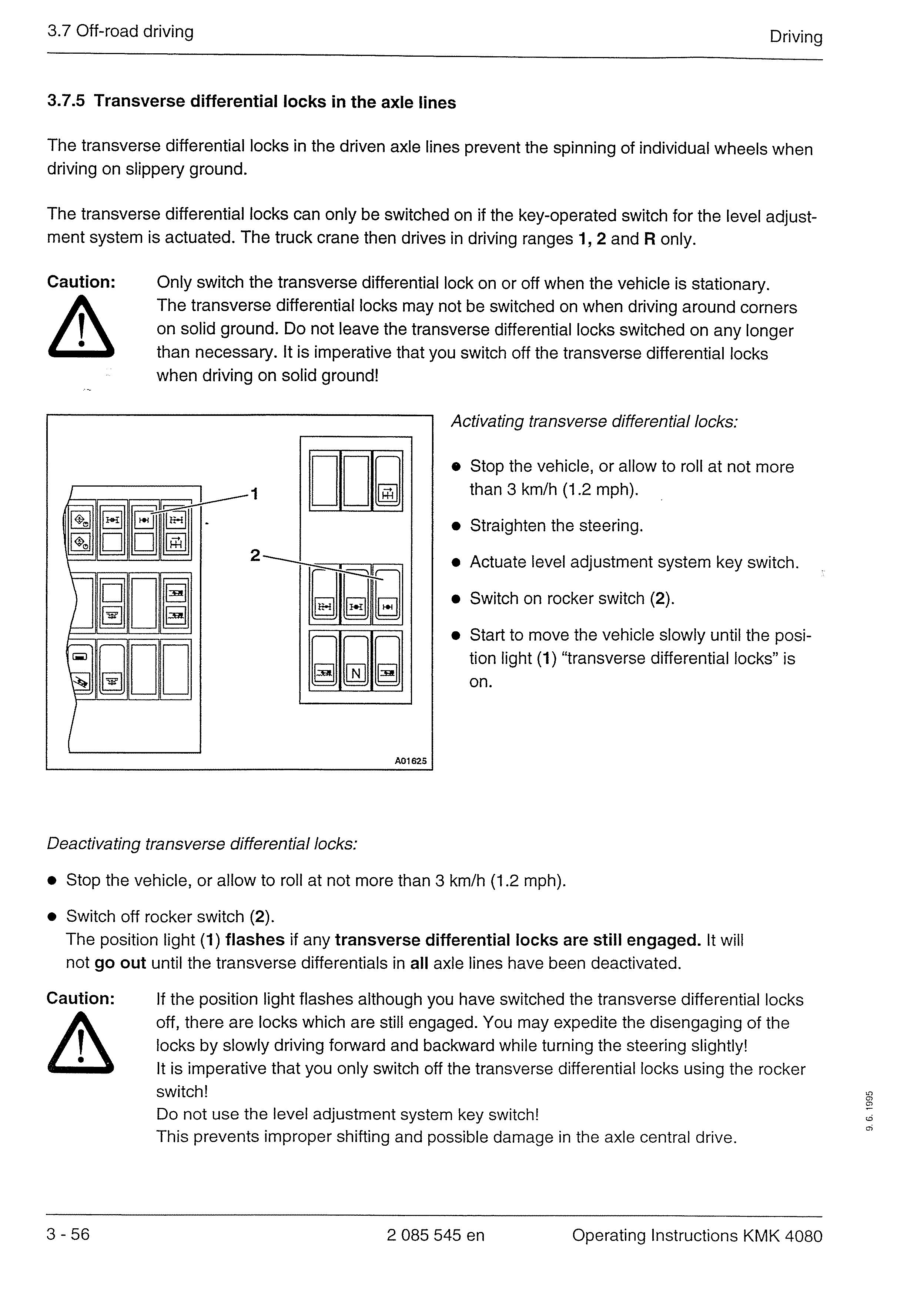

Transverse differential locks in the axle lines

Carrier level adjustment system

Freeing an immobilized vehicle

All-wheel steering, crab travel mode (additional equipment)

Switching the steering system to all-wheel steering, crab travel mode

Steering the 3rd and 4th axle lines . . . . . .

Setting the steering system to normal steering mode

Towing a trailer (additional equipment) Crane

Before crane work .

Switching off boom floating position (only for on-road driving with the boom resting on the trailer) .

Switching off slewing gear access (only for on-road driving with boom resting on the trailer) . .

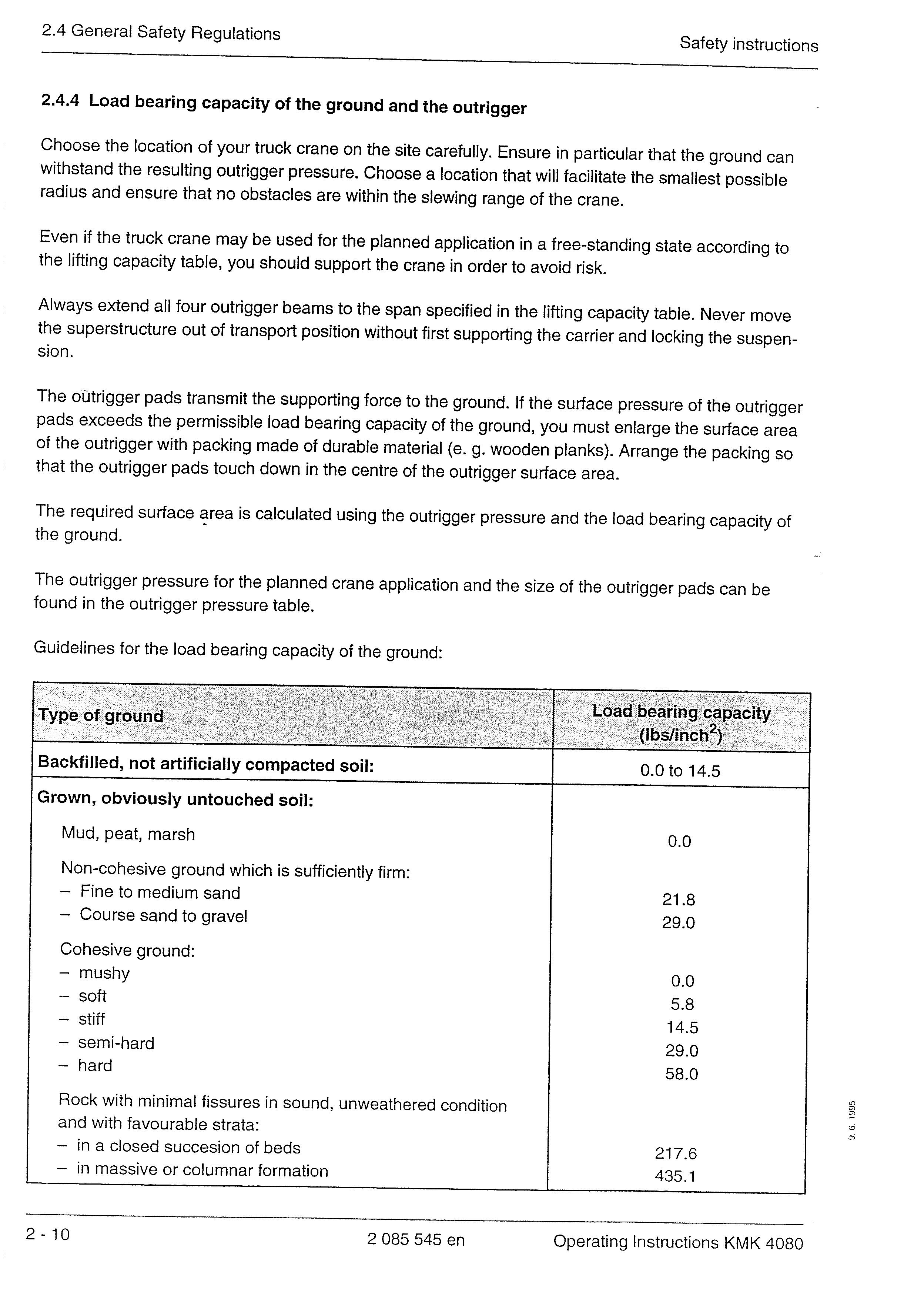

Condition of the ground on-site . . . .

Outrigger ..........................

Disconnecting the electrical connection to the superstructure

During the winter

Visual inspection of the entire crane

Checking the oil level in the crane engine

Checking the coolant level

Checking the fluid level of the windscreen washing system

Releasing the mechanical superstructure lock

Switching on the battery master switch

Adjusting the crane operator's seat

Activating the ignition . . . . . .

Starting the crane engine . . . . .

Starting the crane engine with the starter spray (additional equipment)

Engine running - check instruments

Refuelling

Working position . .

Working position "Supported on outriggers"

External influences during crane operation

Heating the hydraulic oil

Cooling the hydraulic oil

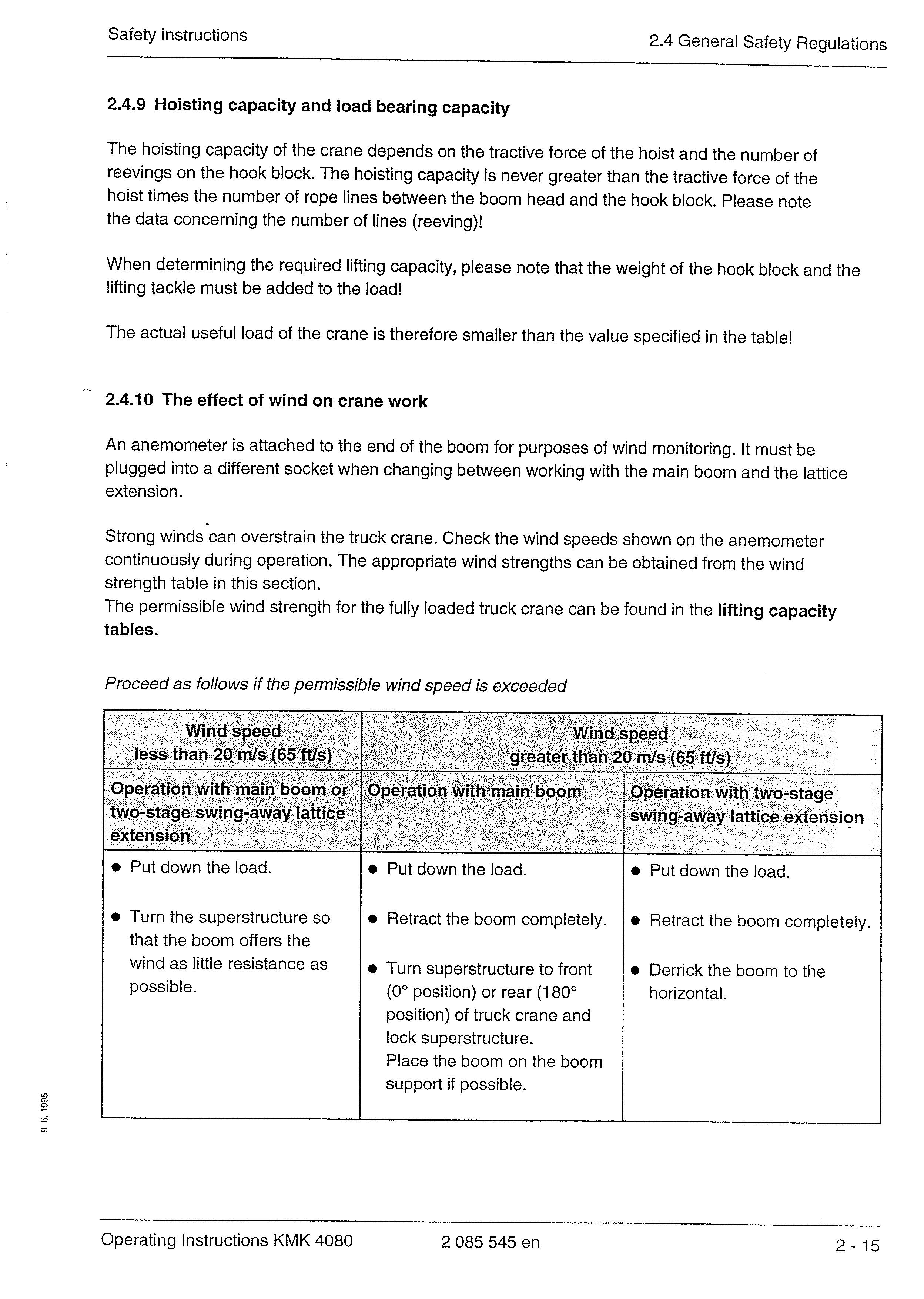

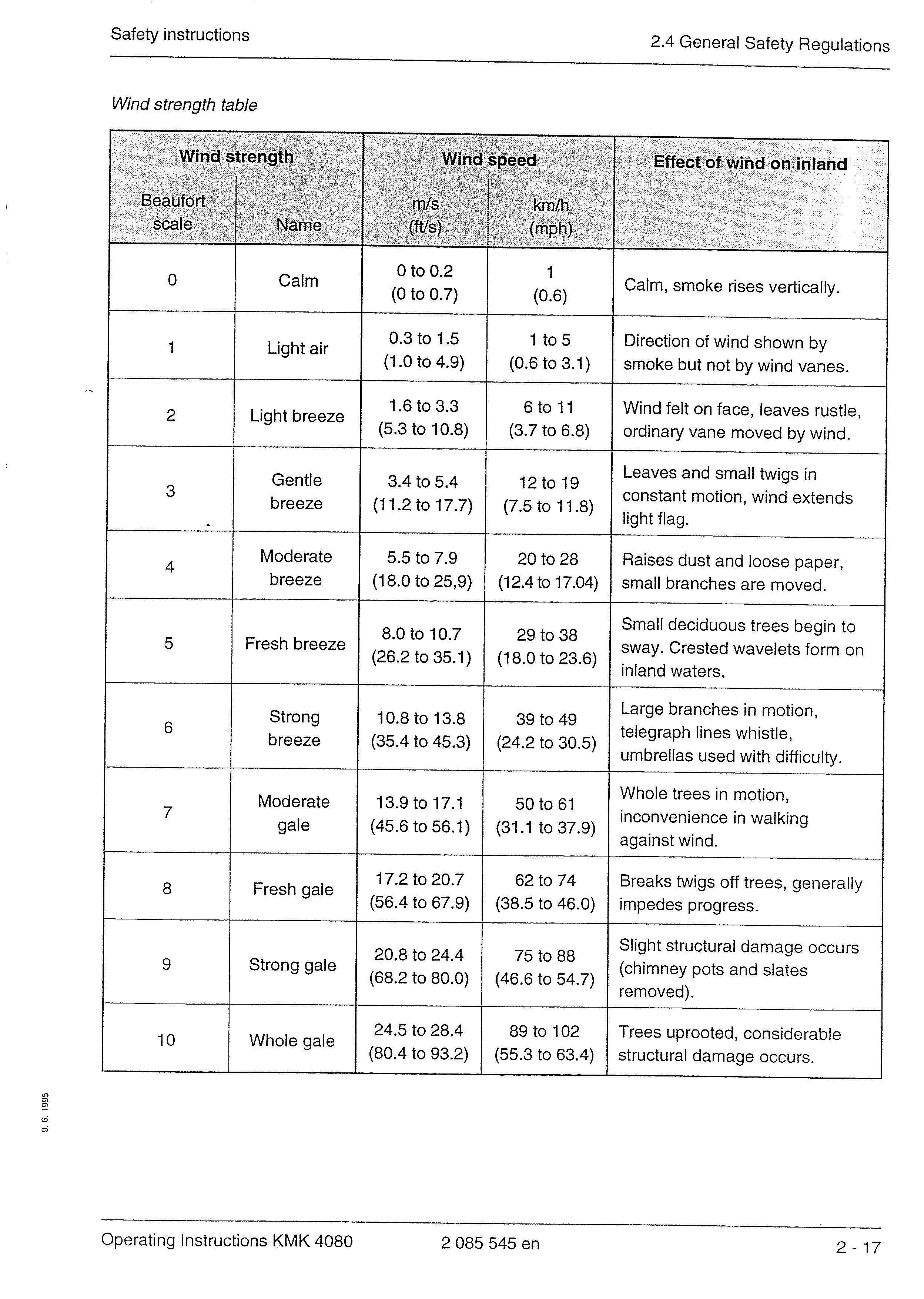

Effects of wind

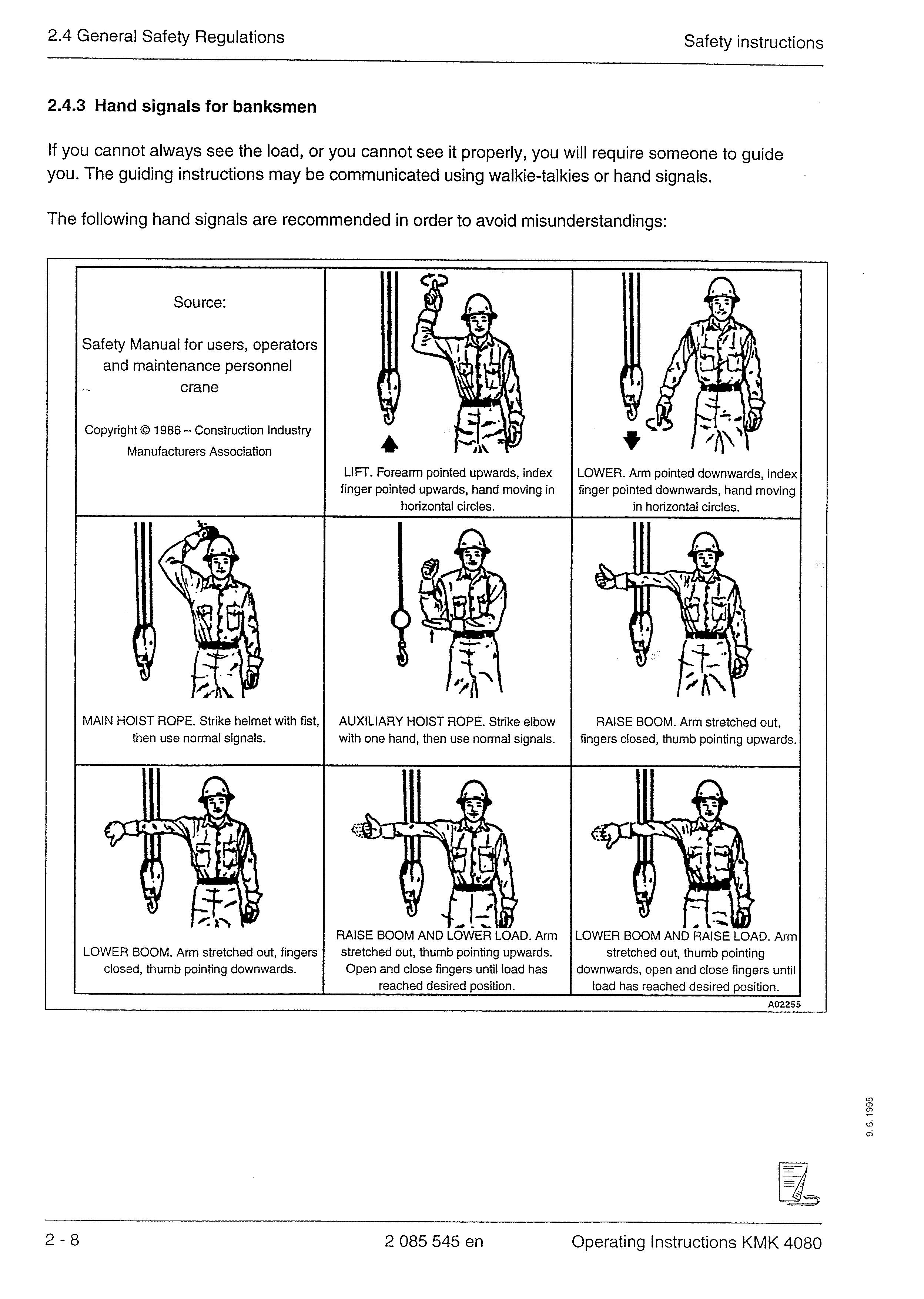

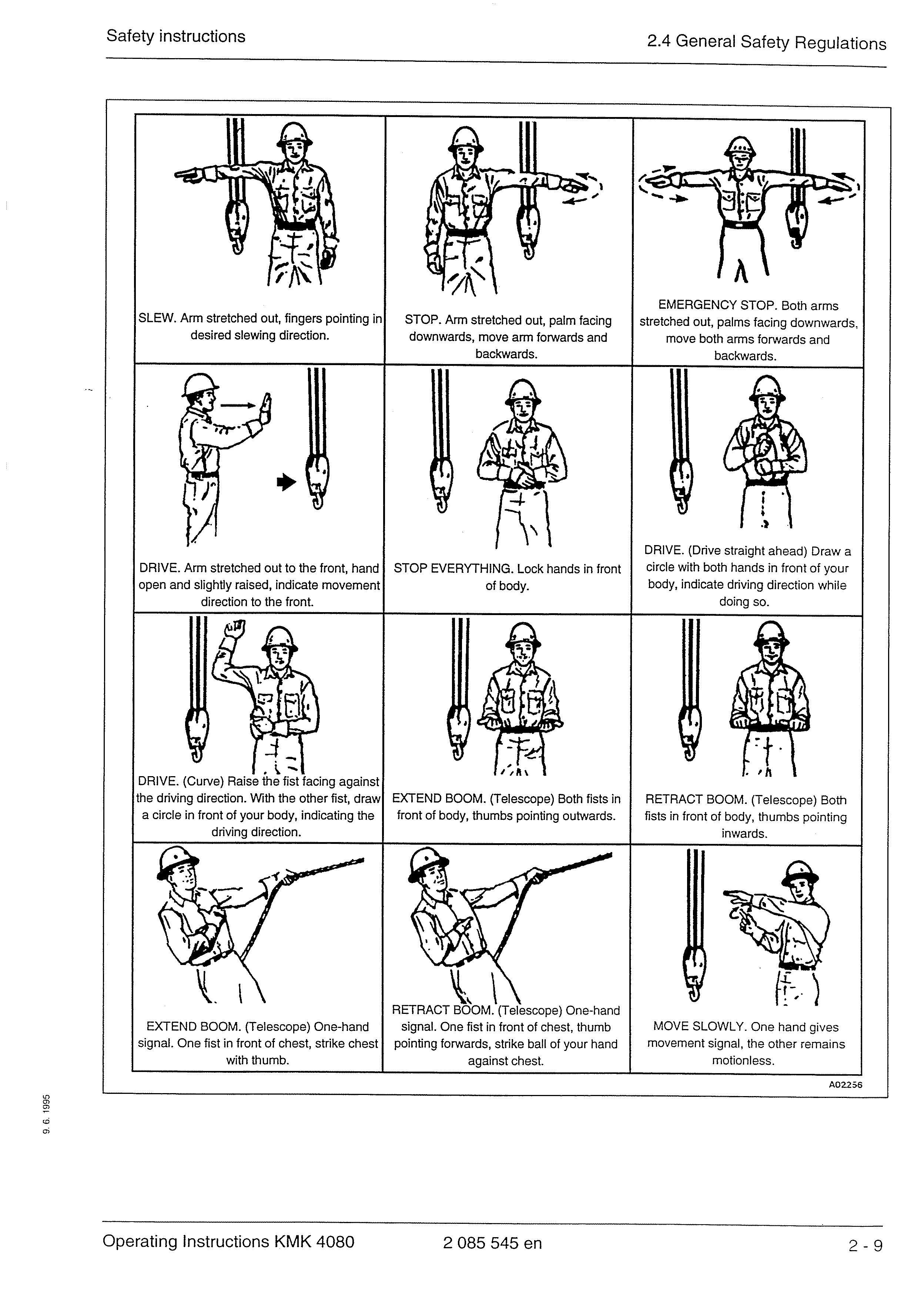

Hand signals

Crane operation . . . .

Picking up the hook block

Reeving the hoist rope .

Possible reeving methods

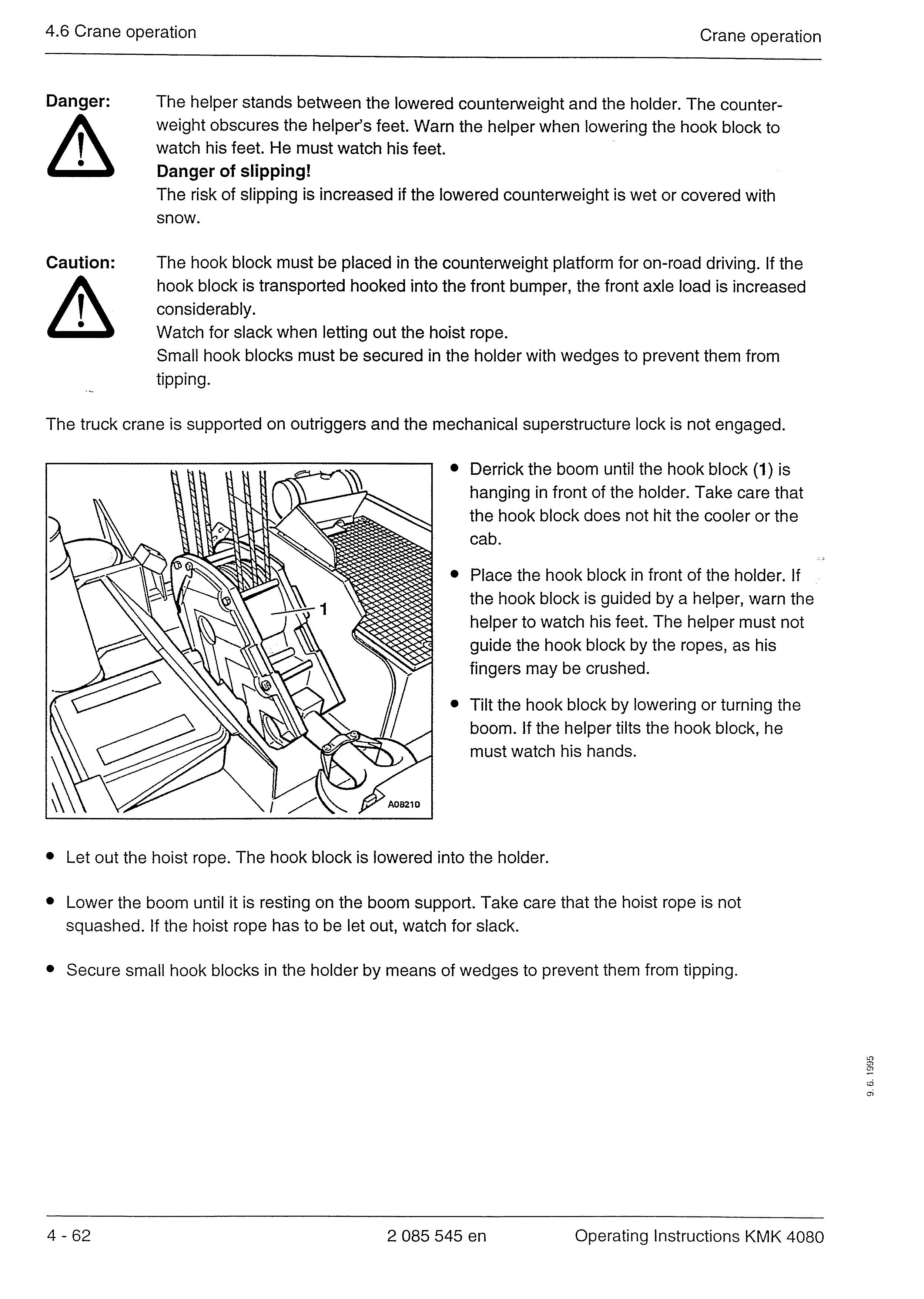

Setting down the hook block

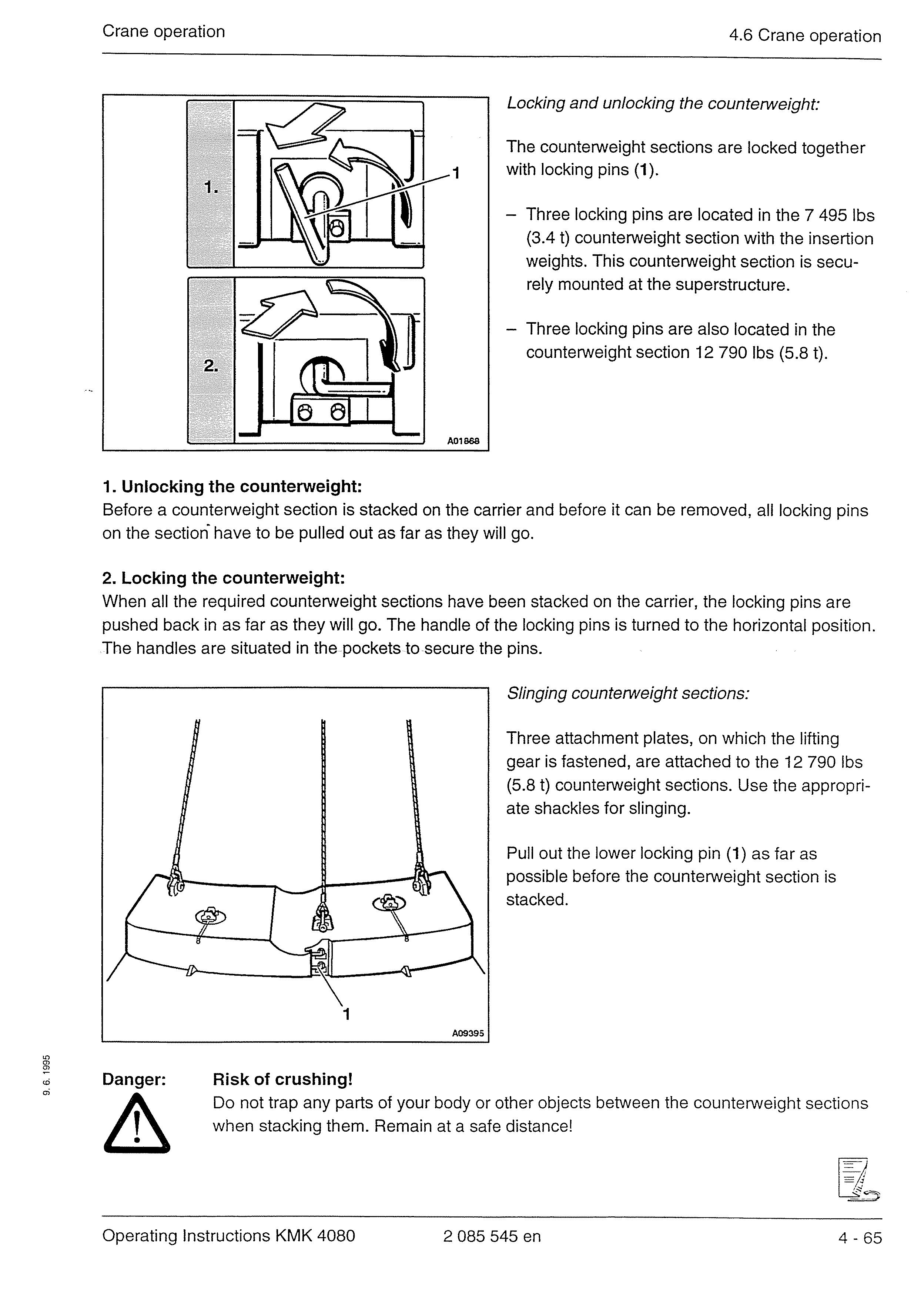

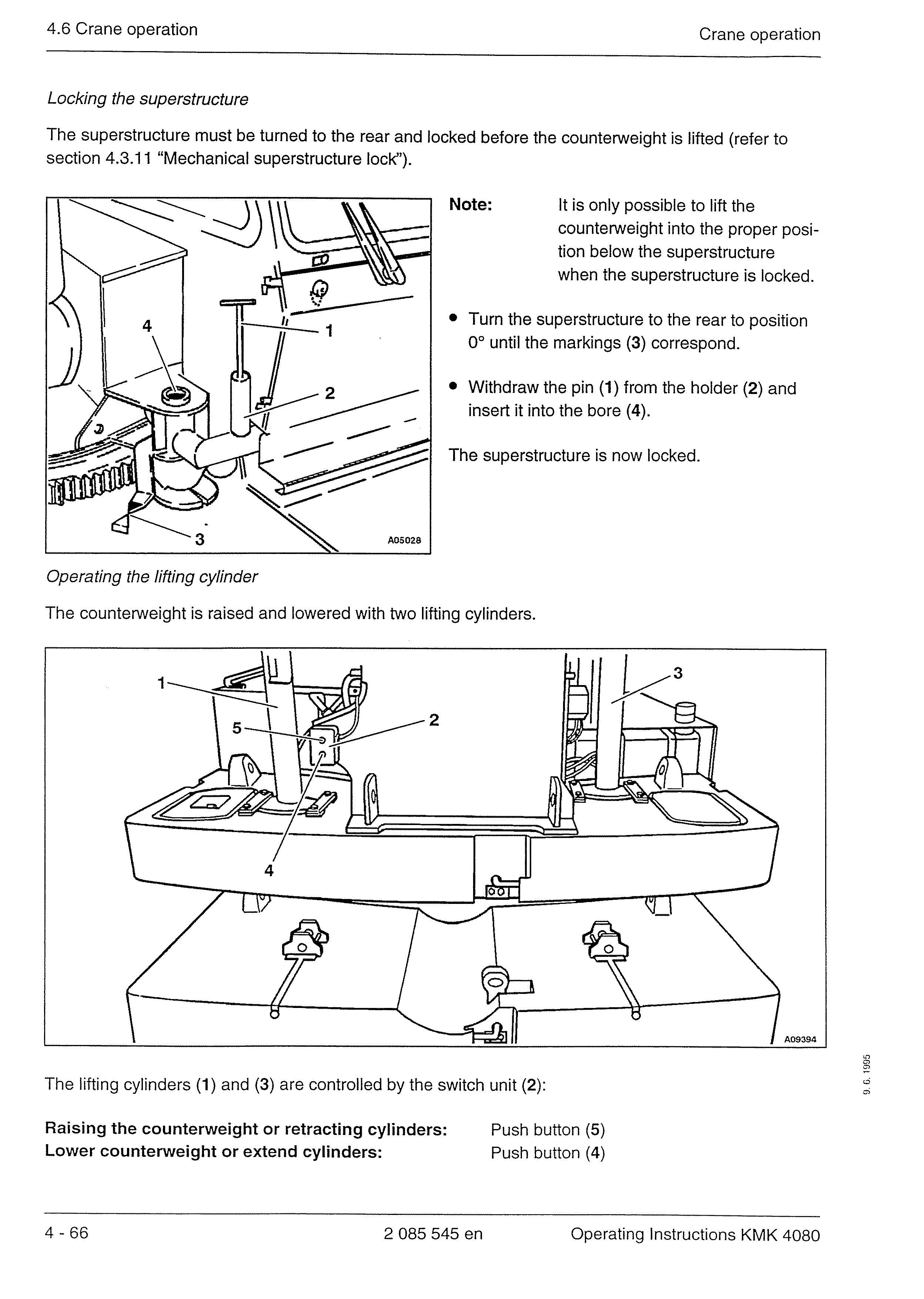

Counterweight

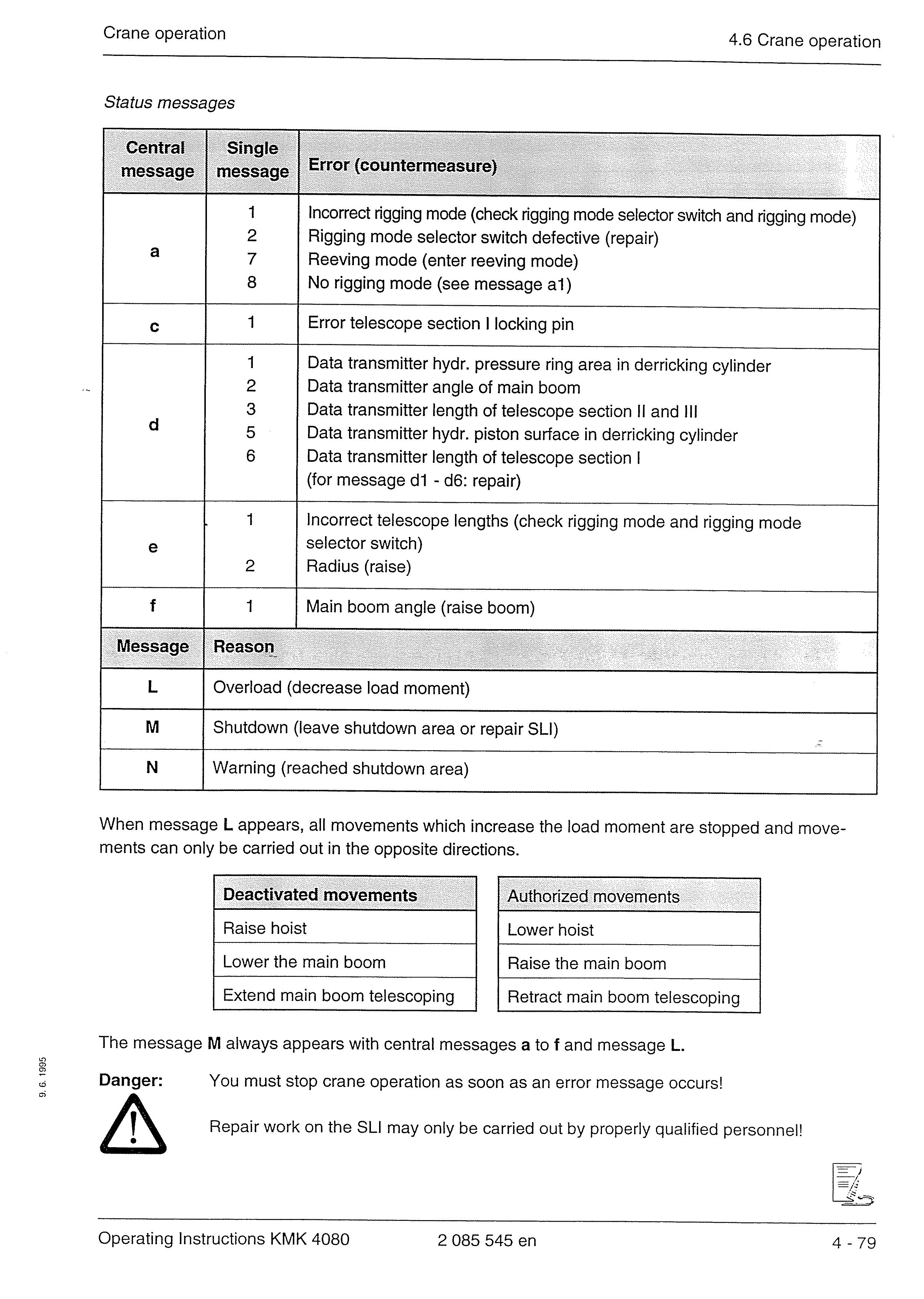

Safe load indicator (SU)

Limit switch

Spotlights

Dead man's switch

Main hoist

Auxiliary hoist (additional equipment)

Slewing gear

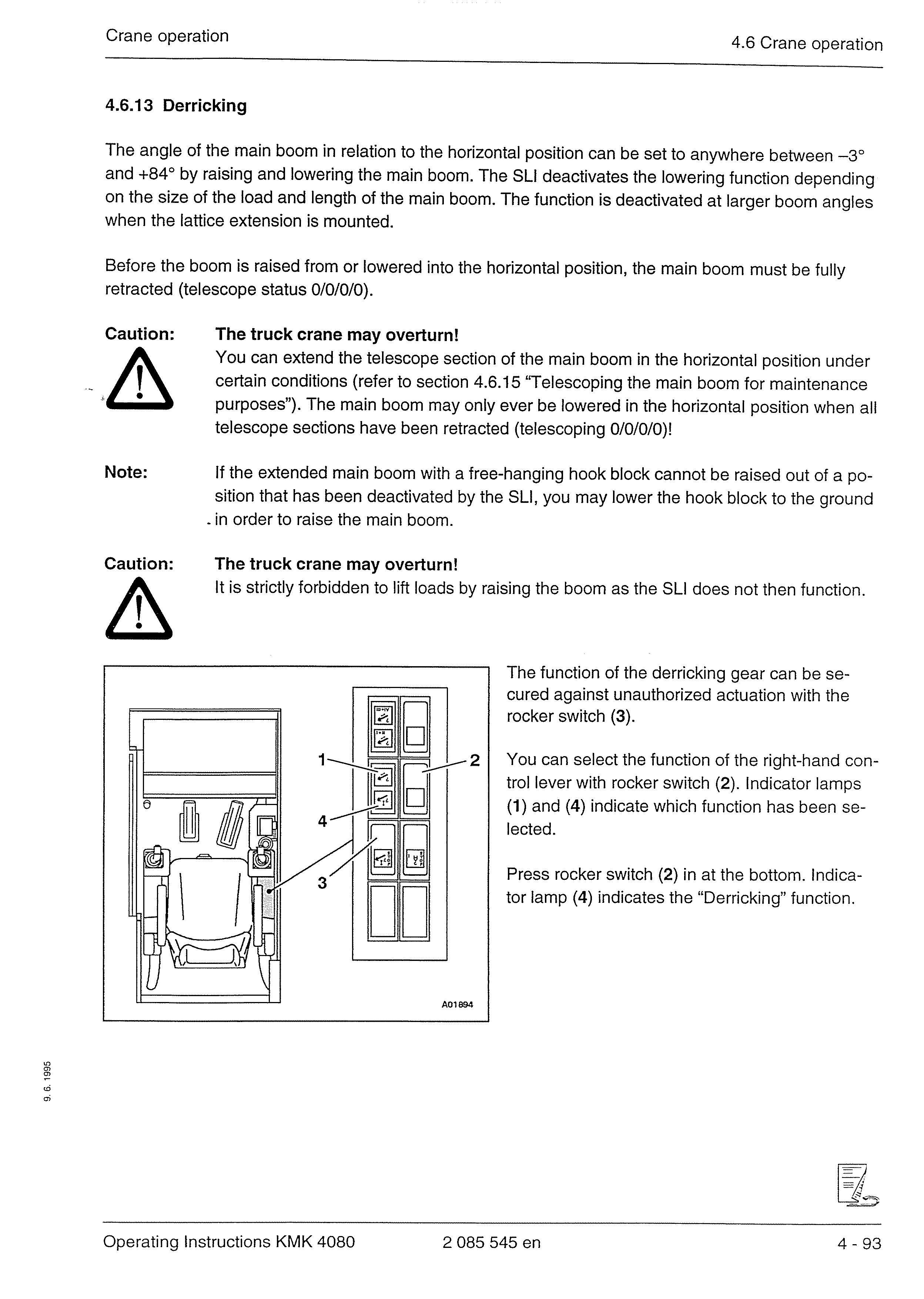

Derricking . . . . . .

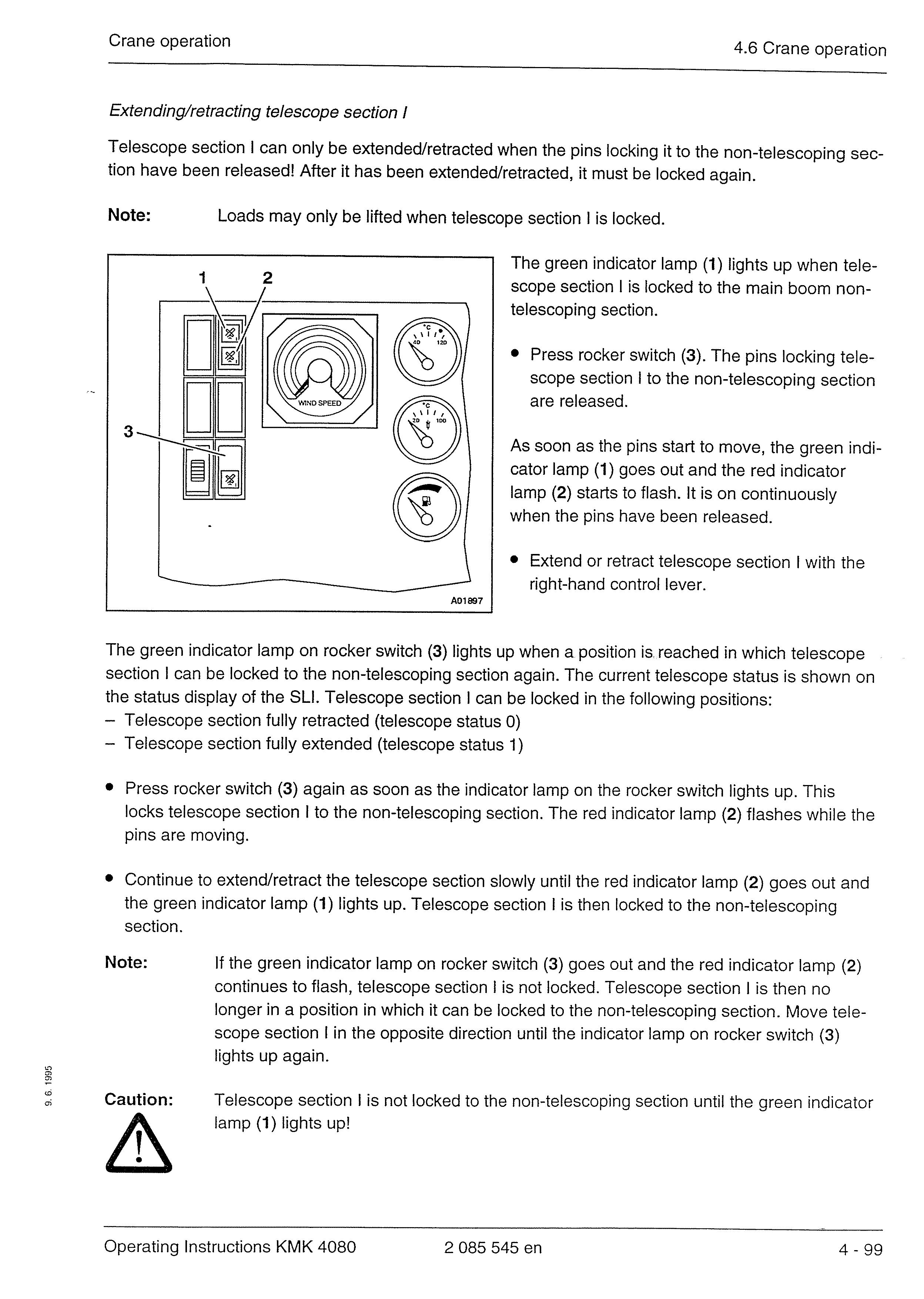

Telescoping

Telescoping the main boom for maintenance purposes

Movements which can be carried out simultaneously

Working with the lattice extension .....

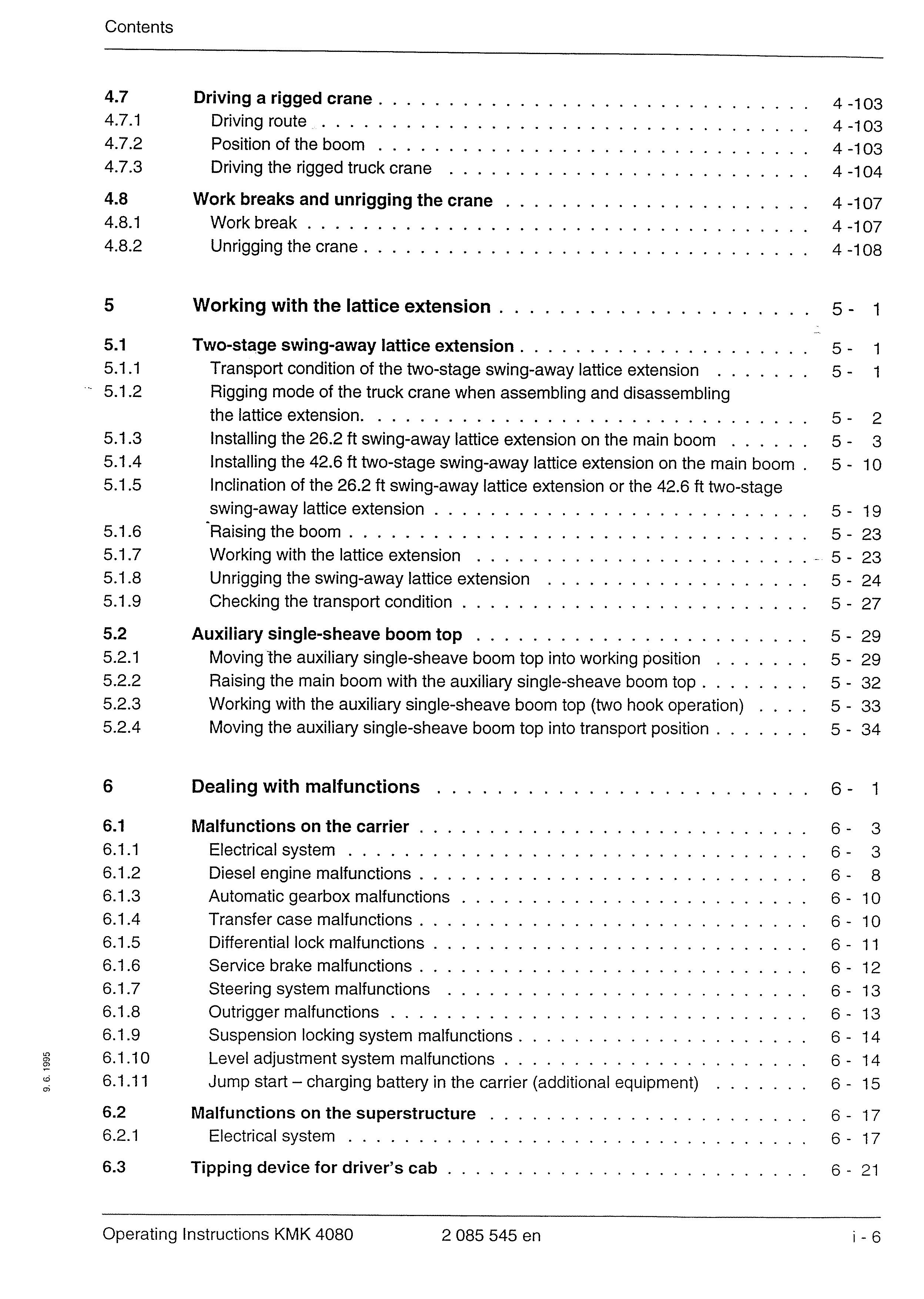

5.1 Two-stage swing-away lattice extension . . . .

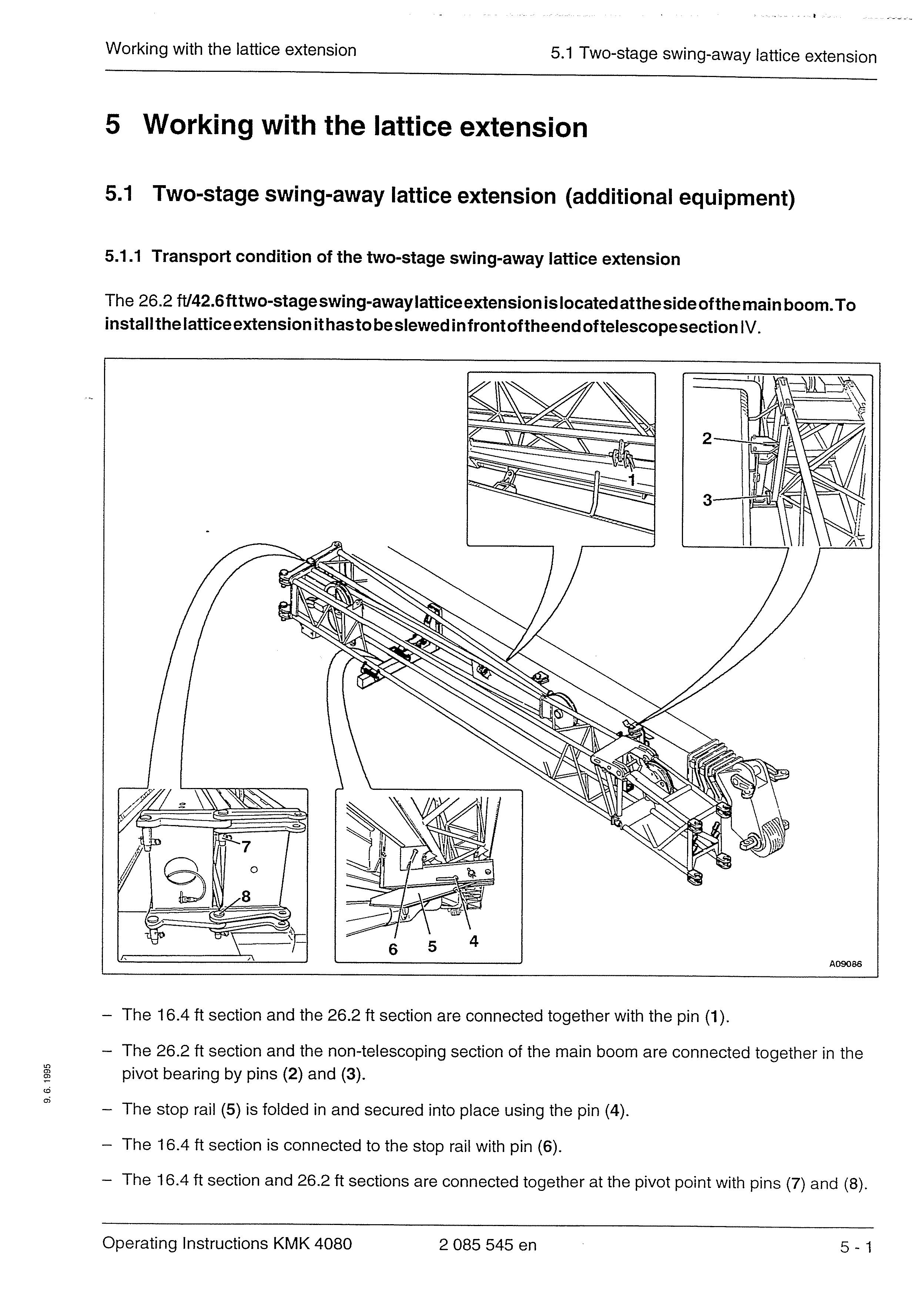

5.1.1 Transport condition of the two-stage swing-away lattice extension

5.1.2 Rigging mode of the truck crane when assembling and disassembling the lattice extension. . . . . . . .

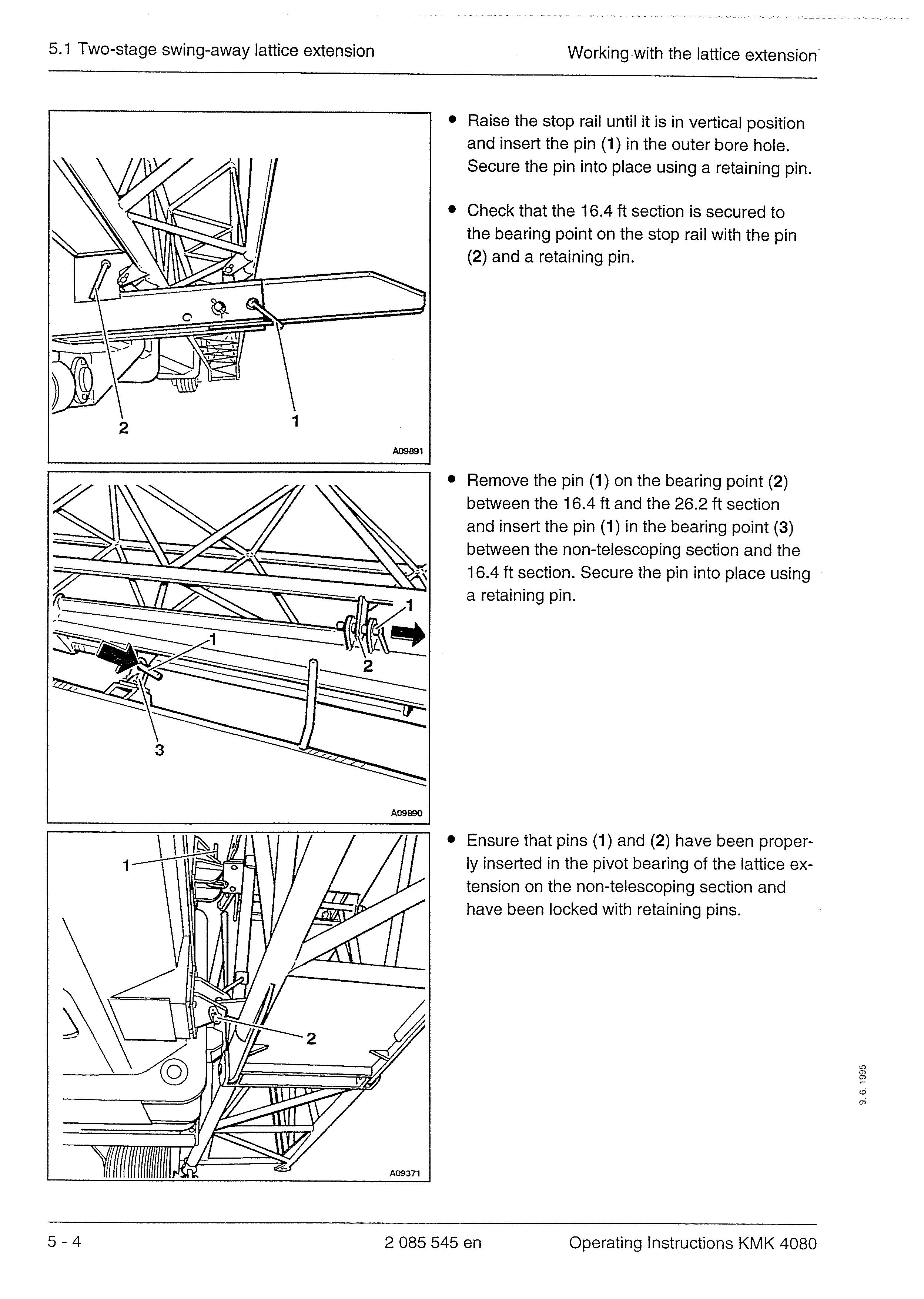

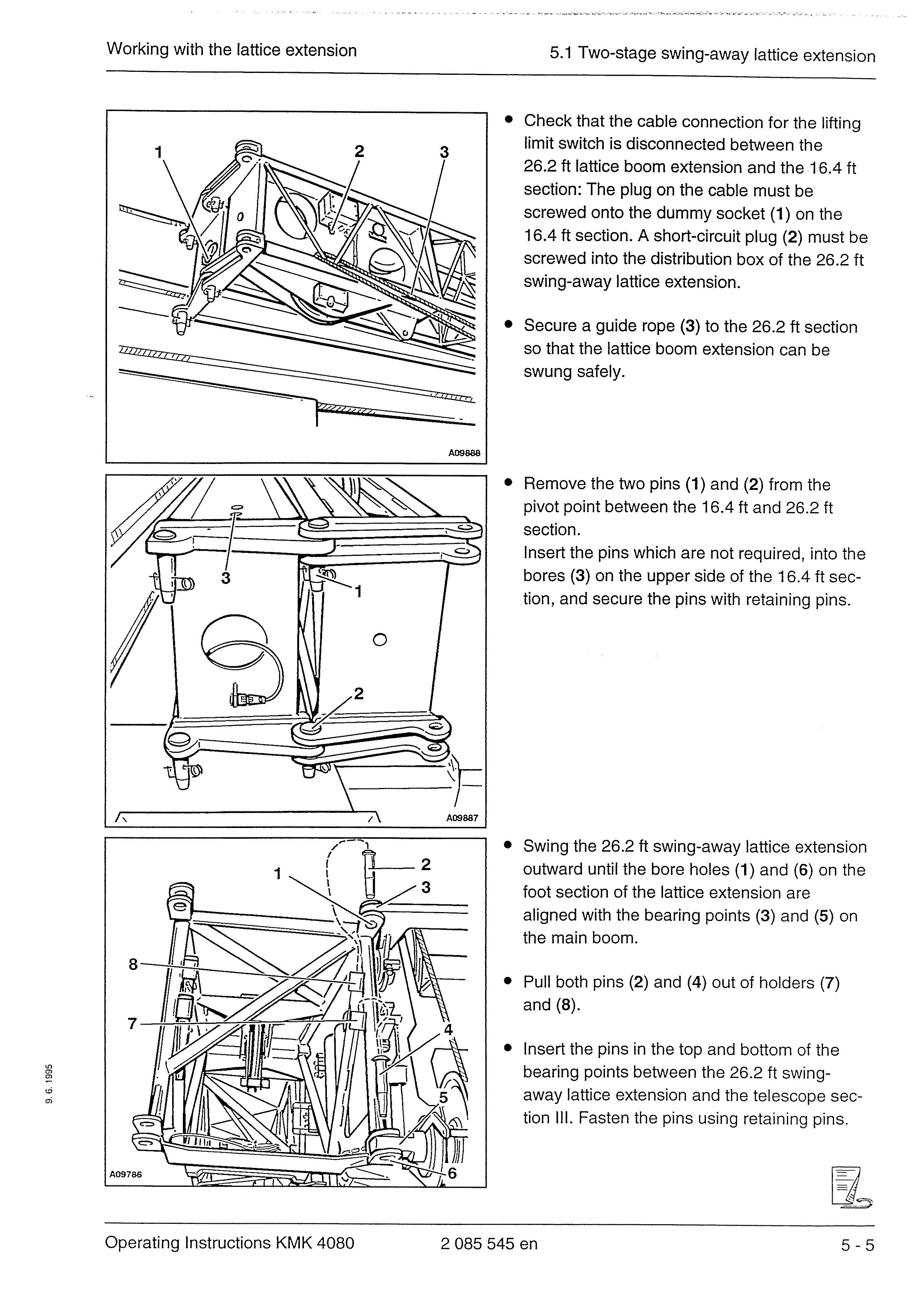

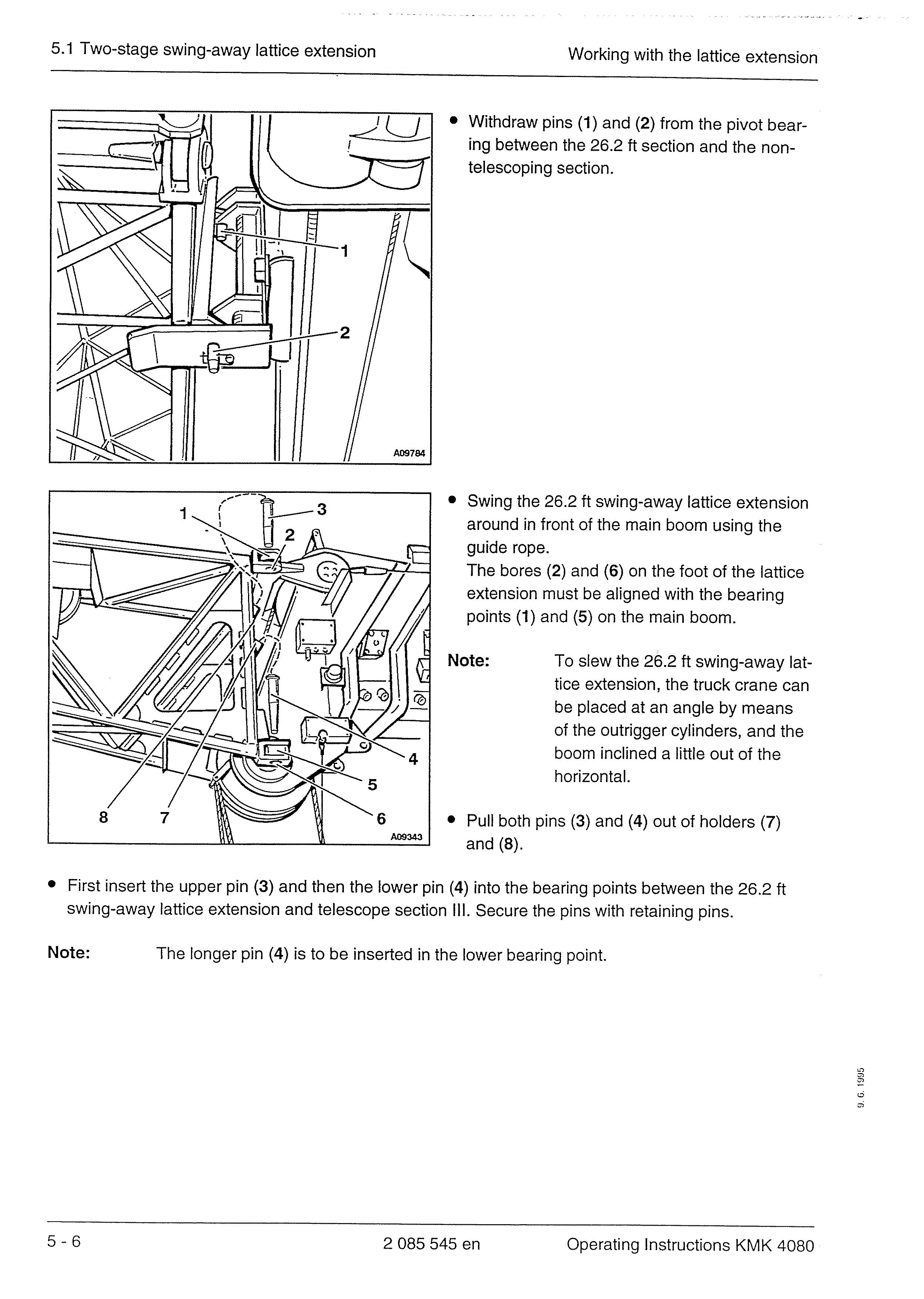

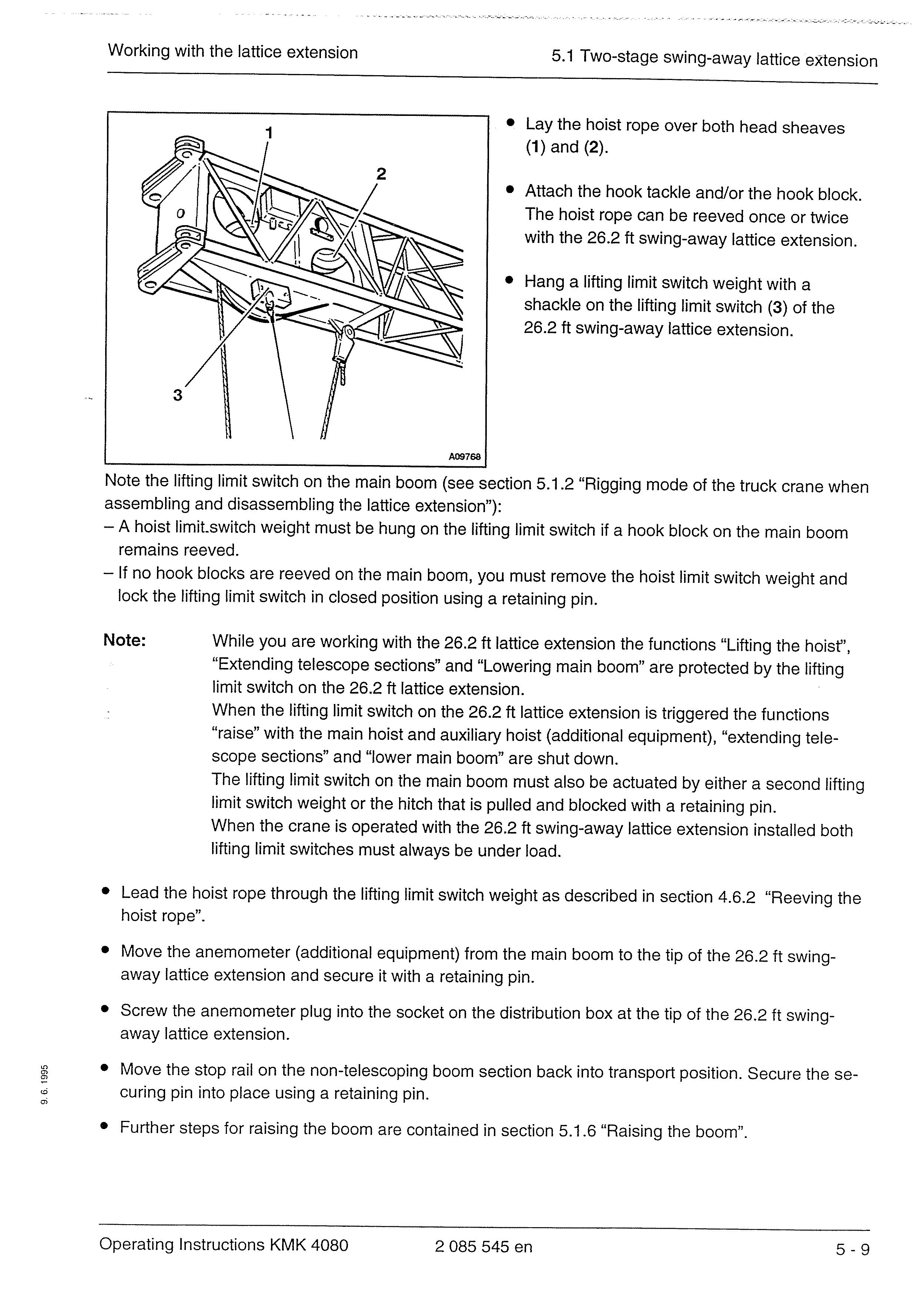

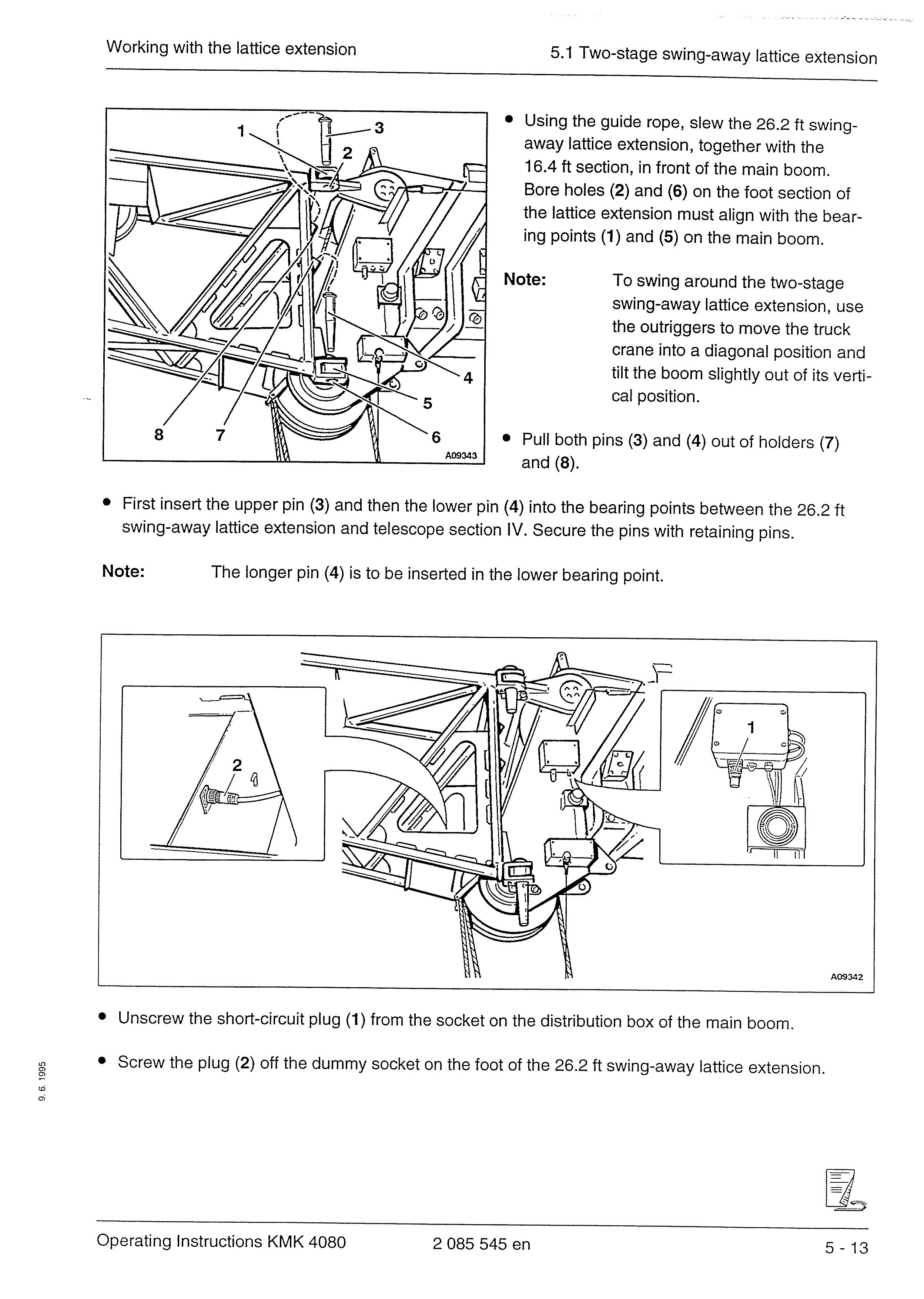

5.1.3 Installing the 26.2 ft swing-away lattice extension on the main boom

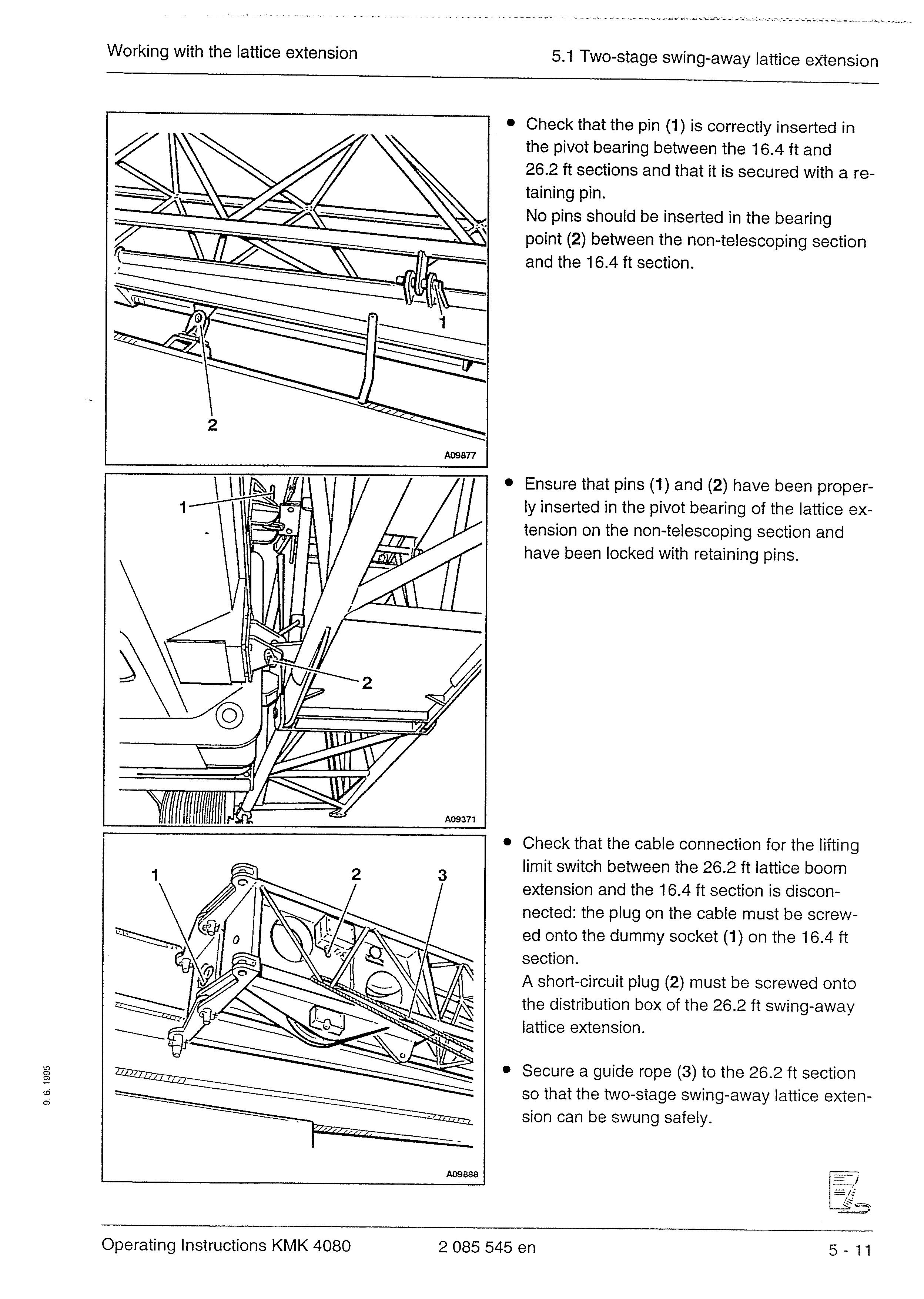

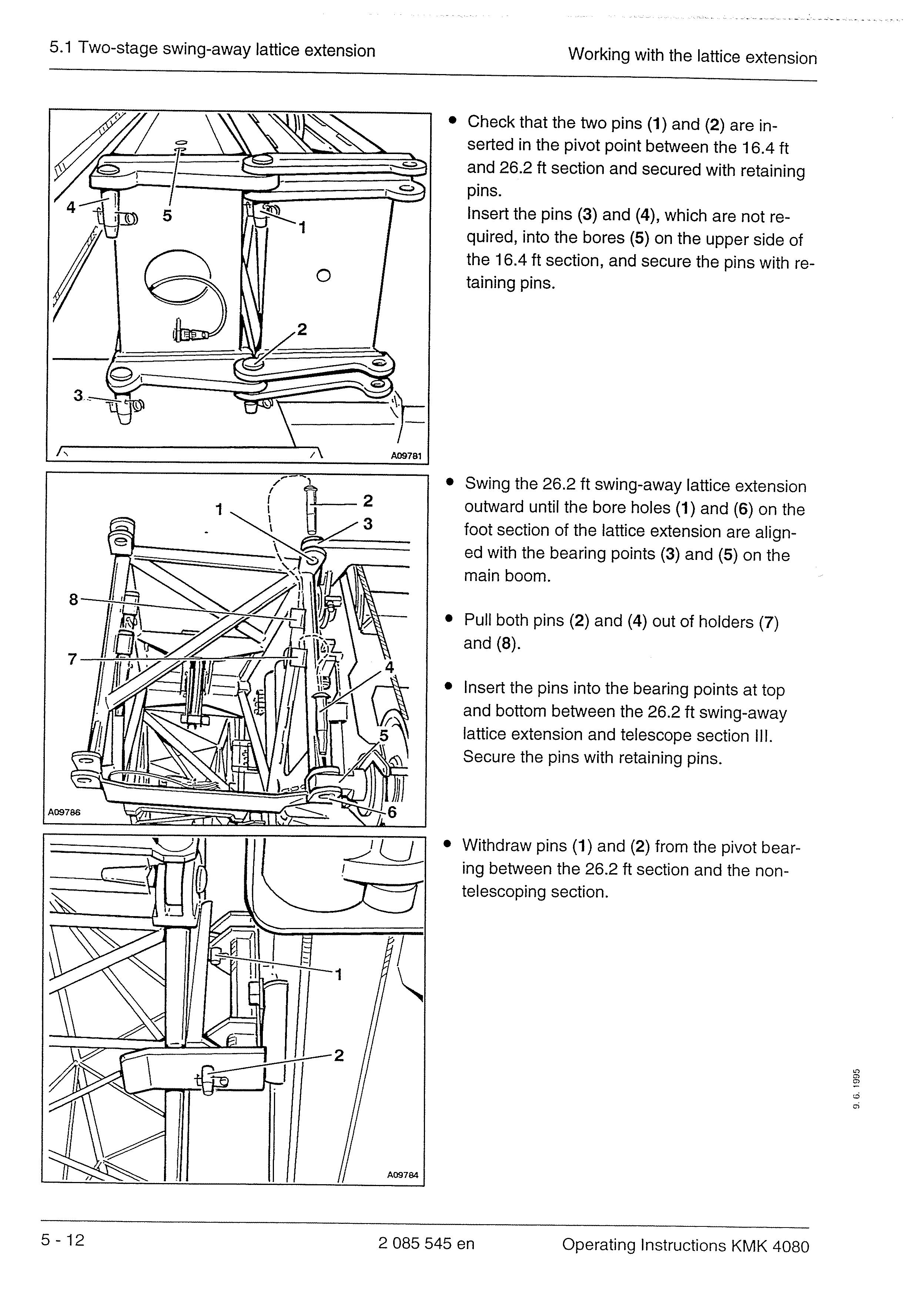

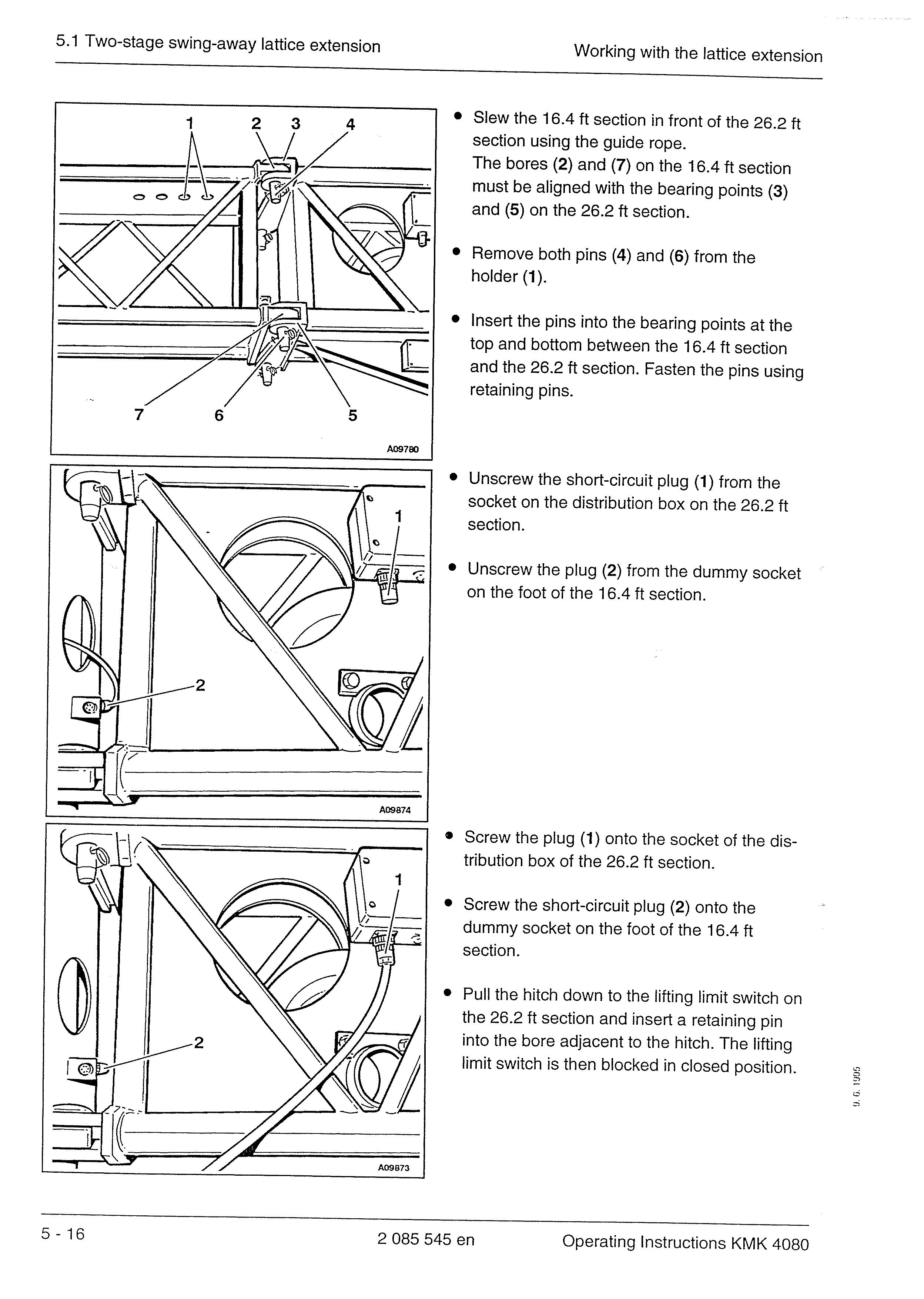

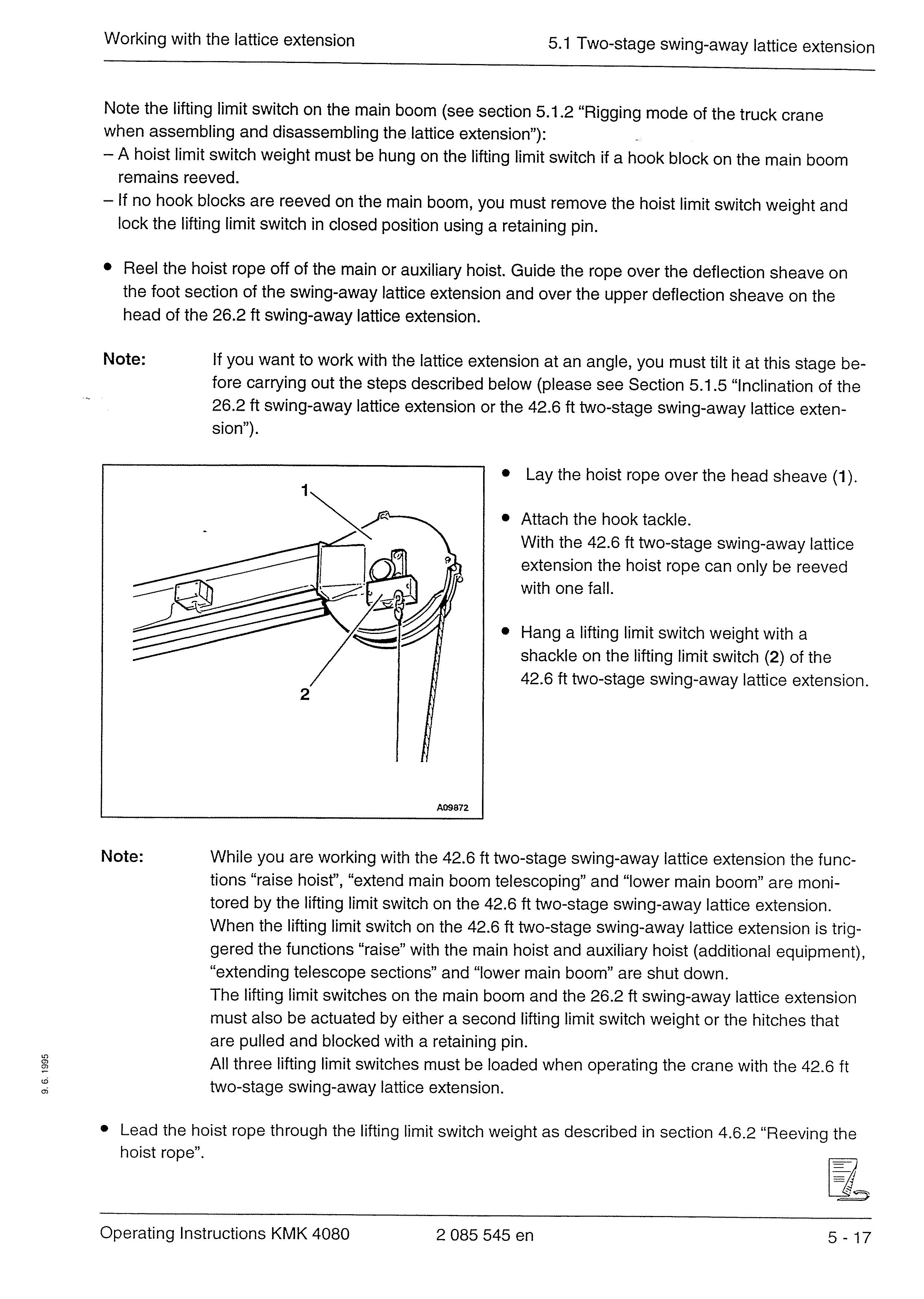

5.1.4 Installing the 42.6 ft two-stage swing-away lattice extension on the main boom

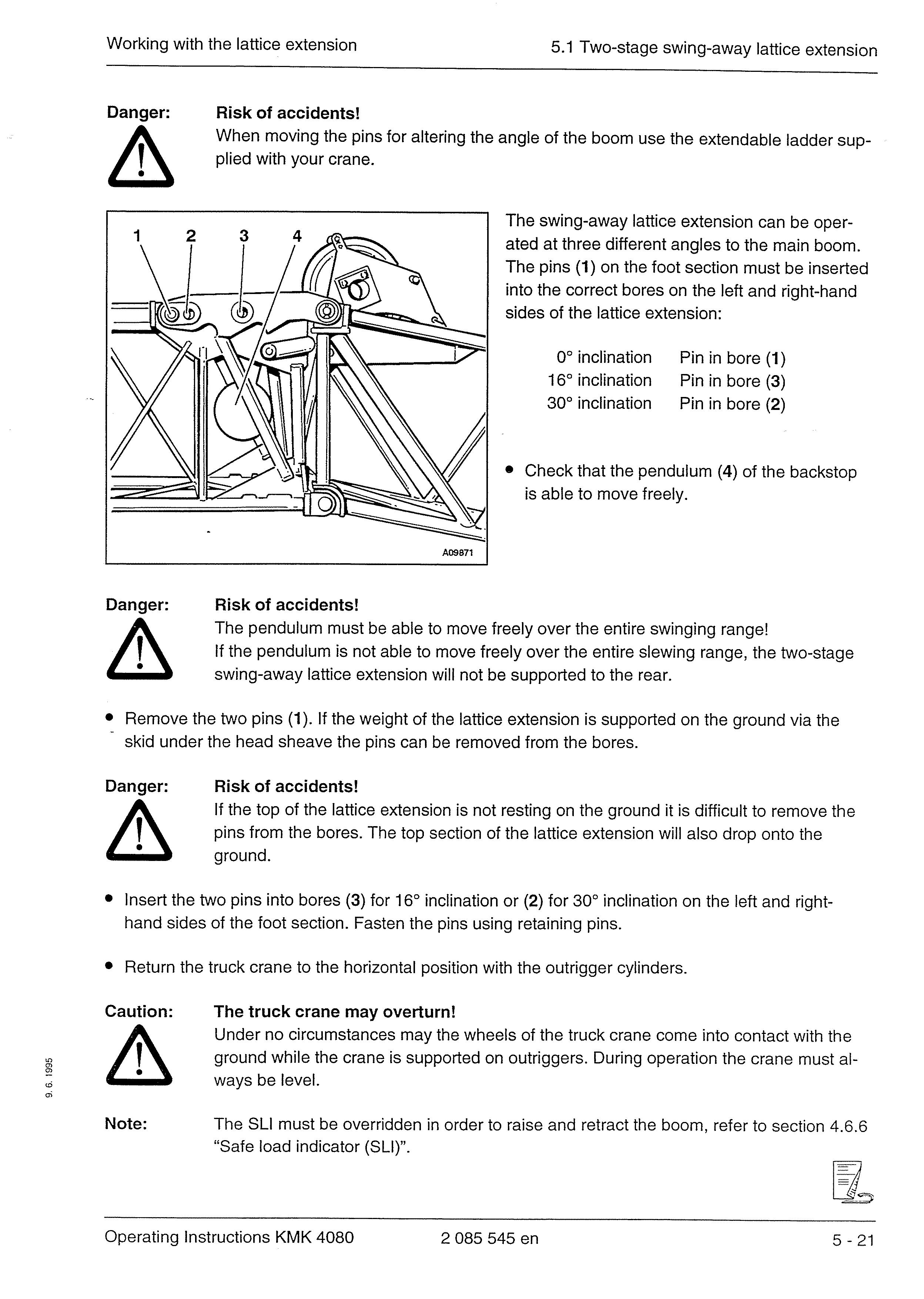

5.1.5 Inclination of the 26.2 ft swing-away lattice extension or the 42.6 ft two-stage swing-away lattice extension

5.1.6 ·Raising the boom . . . . . . . .

5.1. 7 Working with the lattice extension .

5.1.8 Unrigging the swing-away lattice extension

5.1.9 Checking the transport condition . . .

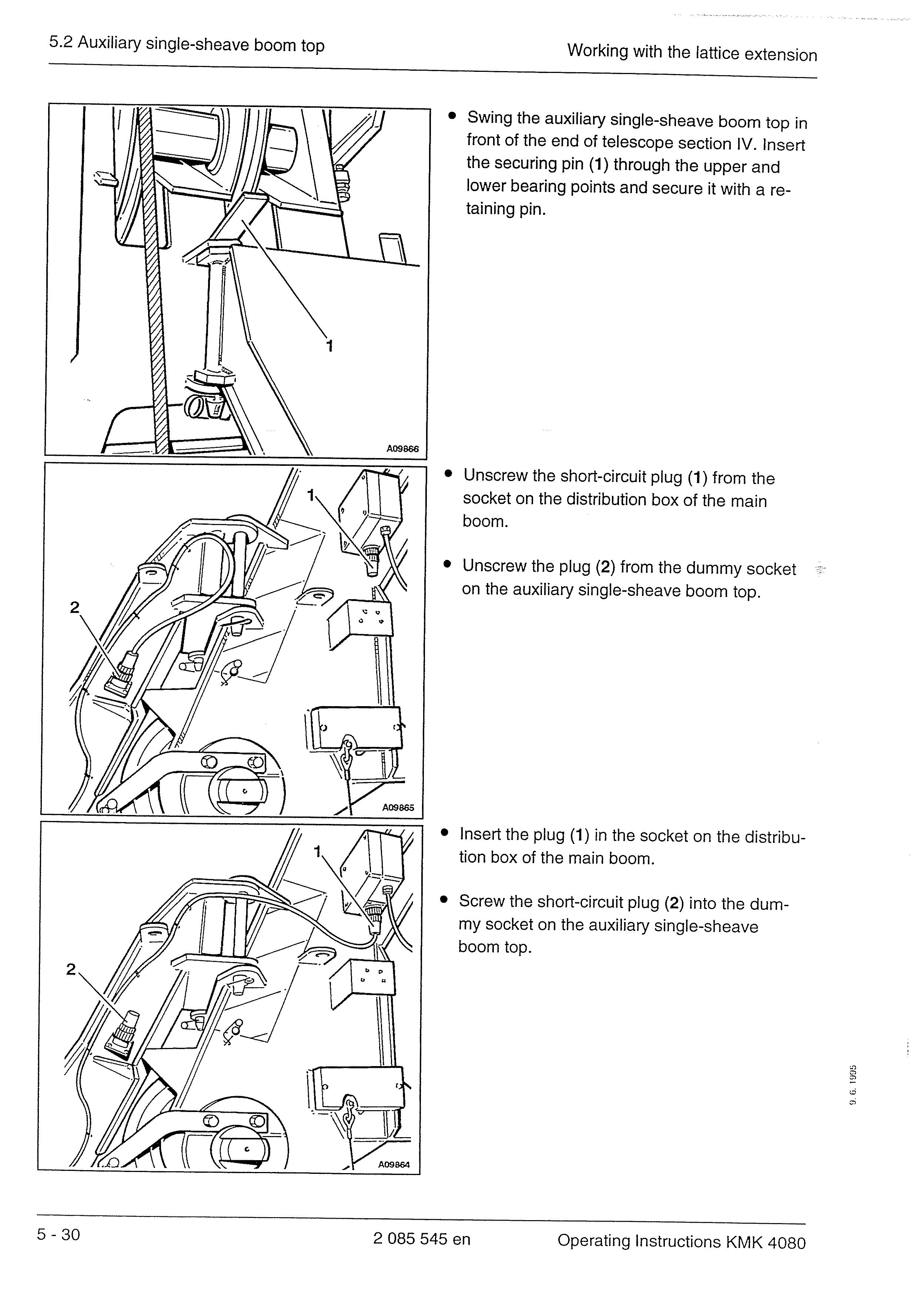

5.2 Auxiliary single-sheave boom top

5.2.1 Moving "the auxiliary single-sheave boom top into working position

5.2.2 Raising the main boom with the auxiliary single-sheave boom top

5.2.3 Working with the auxiliary single-sheave boom top (two hook operation)

5.2.4 Moving the auxiliary single-sheave boom top into transport position extension (two-stage swing-away lattice extension, additional equipment)

Foreword

Foreword

These Operating Instructions together with the lifting capacity table form part of the delivery package for truck crane KMK 4080. They are intended principally for crane operators and contain all necessary information regarding the permissible uses and safe operation of truck crane KMK 4080.

Other crane documentation includes an outrigger pressure table, a maintenance manual and a spare parts list.

This operating manual is not a training manual for prospective crane operators! All descriptions are written explicitly for crane operators who have been trained to operate truck cranes.

Plan each application carefully. Obtain all necessary information regarding the intended journey (dis- tance, route, overhead clearance, load bearing capacity of bridges, etc.). Ascertain the conditions for the job (load bearing capacity of the ground, weight and dimensions of the loads to be lifted, required lengths of stroke and radius, restrictions on movement caused by buildings etc.). Collect the necessary equipment (lifting tackle, counterweight, materials to place beneath outriggers, etc.). Organise transportation and obtain any necessary driving permits.

Poor planning leads to improvisation and improvisation is the cause of many accidents!

A general message to all crane operators:

As the driver of a truck crane, you appreciate your responsiblity for the crane and for all work carried out in conjunction with the crane.

For this reason, observe the following advice for your safety and the safety of others:

Familiarize yourself with the truck crane and all of its operational states before initial use. Read through these Operating Instructions and compare the diagrams with the crane itself. Carry out the actions described on your truck crane stage by stage.

Always carry this operating manual and the corresponding lifting capacity table with you on the vehicle.

Take particular care to familiarize yourself with the safety equipment in the crane itself. Check the functioning of this equipment on a regular basis. Be sure to shut down the crane operation in case of breakdown or malfunction of safety equipment.

When driving on the road and operating the crane, comply with all relevant laws and regulations, such as the Accident Prevention Regulations, which are not reproduced in this manual.

These Operating Instructions contain many notes intended to draw your attention to certain dangers. Pay close attention to these notes!

All measurements in these Operating Instructions are given in US units of measurement. Metric measurements are sometimes given.

Ensur'e the operational safety of your truck crane through careful servicing and maintenance.

Never postpone necessary repair work. Always have repairs carried out by qualified personnel.

Use only Original Krupp Replacement Parts. For ordering, use the spare parts list for truck crane KMK 4080.

The Krupp after-sales service is always at your disposal for repair work.

We will be pleased to advise you on points arising through routine operation.

We are always grateful for your comments and suggestions.