3 minute read

SIDE PLATE

5. Check for operation with reversed leads to the steering potentiometer and for steering in the wrong steering direction. Disconnect the battery connector. Temporarily move the wire from terminal 1 to terminal 3 and the wire from terminal 3 to terminal 1 (plug A).

6. Connect the battery. Check that the traction and steering systems do NOT operate. If the systems operate, the automatic shut–off circuit has damage. Replace the circuit board. If the systems do NOT operate, install the wires on the correct terminals.

Test Point Checks

The following voltage readings are taken at the three test points (TP) on the ECM board. Connect the negative (–) meter lead to TP9.

Connect the negative lead of the digital voltmeter to TP9 for all of these checks. Put the positive lead on the correct test point for each test. TP1 – The correct reading is 2.5 volts when the steer wheel is in the position for straight travel. When the steer wheel is fully toward a turn in the 9:00 clock direction, the correct reading is 0 volts. When the steer wheel is fully toward a turn in the 3:00 clock direction, the correct reading is 5 volts.

TP2 – The correct reading is 2.5 volts when the steer wheel is in the position for straight travel. When the steer wheel is 16° toward a turn in the 9:00 clock direction, the correct reading is 0 volts. When the steer wheel is 16° toward a turn in the 3:00 clock direction, the correct reading is 5 volts.

TP3 – The voltage reading times 10 is the steering motor current.

TP4 – The correct reading is 2.5 volts for no steering action. When turning the steering wheel quickly in one direction, the correct reading is 0 volts. When turning the steering wheel quickly in the other direction, the correct reading is 5 volts.

REPAIR

WARNING To help prevent injury, never have any metal on your fingers, arms or neck when using these repair procedures.

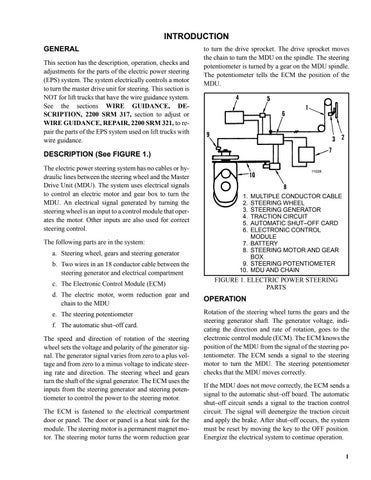

STEERING GENERATOR (See FIGURE 12.)

1. Disconnect the battery connector so that it is completely free. Remove the cover at the operator platform for an access to the terminal strip at the instrument panel.

2. Disconnect the two wires from the steering generator at the terminal strip. NOTE: Earlier units have a steering wheel held to a tapered shaft with a key and nut. It can be necessary to use a steering wheel puller on these units.

3. Use a wrench on the flats of the shaft and turn the steering wheel counterclockwise to remove the steering wheel. Remove the four capscrews, washers and nuts that fasten the steering generator assembly to the instrument panel. Remove the assembly.

4. Remove the screw and intermediate gear from the hub plate.

5. Remove the three screws and washers that fasten the generator to the hub plate. Remove the generator. Install the replacement generator on the hub plate.

6. Install a thin coating of Loctite 290 or equivalent on the threads of the screw for the intermediate gear. Install the intermediate gear and screw on the hub plate. Tighten the screw to 2.3 N.m (20 lbf in) torque.

7. Install the assembly on the instrument panel. Connect the generator wires to the terminal strip. If necessary, see the section DIAGRAMS, 8000 SRM 238. NOTE: On earlier units, install the steering wheel using the key, washer and nut.

8. Install a thin coating of Loctite 290 or equivalent on the threads of the shaft for the steering wheel. Hold the shaft and install the steering wheel.