10 minute read

GEHLCOMPANY WARRANTY

GEHLCOMPANY,hereinafterreferredtoasGehl,warrantsnewGehlequipmenttothe OriginalRetailPurchasertobefreefromdefectsinmaterialandworkmanshipfora periodoftwelve(12)monthsfromtheWarrantyStartDate.

GEHLWARRANTYSERVICEINCLUDES:

GenuineGehlpartsandlaborcostsrequiredtorepairorreplaceequipmentatthe sellingdealer’sbusinesslocation.

GEHLMAKESNOREPRESENTATIONSORWARRANTIESOFANYKIND, EXPRESSORIMPLIED(INCLUDINGTHEIMPLIEDWARRANTIESOF MERCHANTABILITYANDFITNESSFORPARTICULARPURPOSE),EXCEPTAS EXPRESSLYSTATEDINTHISWARRANTYSTATEMENT.

ANYOFTHESELIMITATIONSEXCLUDEDBYLOCALLAWSHALLBEDEEMED DELETEDFROMTHISWARRANTY;ALLOTHERTERMSWILLCONTINUETO APPLY.

SOMESTATESDONOTPERMITTHEEXCLUSIONORLIMITATIONOFTHESE WARRANTIESANDYOUMAYHAVEGREATERRIGHTSUNDERYOURSTATE LAW.

GEHLWARRANTYDOESNOTINCLUDE:

1.Transportationtoselling dealer’sbusinesslocationor,attheoptionofthe OriginalRetailPurchaser,thecostofaservicecall.

2.Usedequipment.

3.Componentscoveredbytheirownnon-Gehlwarranties,suchastires,batteries, tradeaccessoriesandengines.

4.Normalmaintenanceserviceandexpendable,high-wearitems.

5.Repairsoradjustmentscausedby:improperuse;failuretofollowrecommended maintenanceprocedures;useofunauthorizedattachments;accidentorother casualty.

6.Liabilityforincidentalorconsequentialdamagesofanytype,including,butnot limitedtolostprofitsorexpensesofacquiringreplacementequipment.

Noagent,employeeorrepresentativeofGehlhasanyauthoritytobindGehltoany warrantyexceptasspecificallysetforthherein.

General information

Your decision to purchase this piece of Gehl equipment was a good one. We are sure that your decision was carefully considered and that you are looking forward to many years of reliable performance from this machine.

Gehl Company has invested much time and effort in developing its lines of equipment. The equipment you have purchased is built with a great deal of pride, and designed to provide long life, efficient operation, durability and dependability.

Modern machinery has become more sophisticated and, with that in mind, Gehl Company asks that you read and COMPLETELY understand the contents of this manual and become familiar with your new machine, BEFORE attempting to operate it.

This manual was developed specifically for the machine you have purchased. The information within is for your assistance in preparing, adjusting, maintaining and servicing your machine. More importantly, this manual provides an operating plan for safe and proper use of your machine. Major points of safe operation are detailed in the SAFETY chapter of this manual –see Safety instructions on page18. Refer to the Table of Contents for an outline (by chapters) of this manual. Use the Index, located at the back of this manual, for specific chapter and topic/page number references.

If this machine is resold, Gehl Company recommends that this manual be given to the new owner.

If this machine was purchased "used," or if the owner's address has changed, please provide your Gehl dealer or Gehl Company with the owner's name and current address, along with the machine model and serial number. This will allow the registered owner information to be updated, so that the owner can be notified directly in case of an important product issue, such as a safety update program.

“Right” and “left” are determined from the position of sitting in the operator’s seat, facing forward.

Gehl Company reserves the right to make changes or improvements in the design or construction of any part without incurring the obligation to install such changes on any unit previously delivered.

Throughout this manual information is provided that is introduced by the word NOTE or IMPORTANT. Be sure to read carefully and comply with the message or directive given. Following this information will improve your operating or maintenance efficiency, help you to avoid costly breakdowns or unnecessary damage and extend your machine's life.

Operational safety and readiness of the machine depend partially on maintenance and service of the machine. This is why regular maintenance and service work is absolutely necessary. Extensive maintenance and repair work must always be carried out by a qualified technician with appropriate training. Insist on using Gehl original service parts when carrying out maintenance and repair work. This ensures operational safety and readiness of your machine, and maintains its value.

Our wide dealership network stands ready to provide any assistance required, including genuine Gehl service parts. All parts should be obtained from or ordered through your Gehl dealer. Give complete information about the part as well as the model number and serial number of your machine. Record numbers, in the spaces provided, as a handy record for quick reference.

Purchased from:___________________________________

Date of Purchase: __________________________________

Model No.: _______________________________________

Serial No.:________________________________________

Serial number

The serial number is stamped onto the cab bearing A (on the right as seen in driving direction, behind the cab door lining), and is also located on the type decal.

The type decal is located on the frame on the right, next to the loader unit bulkhead (above the front axle).

Type decal information

Example: Model 580

Machine model:580

Version:343 00

Serial no.:343 01 0001

Model year:2005

Front gross axle weight rating:9370 lbs. (4250 kg)

Rear gross axle weight rating:9370 lbs. (4250 kg)

Gross weight rating:15,432 lbs. (7000 kg)

Output:75 hp (56 kW)

Other information –see Specifications on page138.

Cab number

The type decal (arrow) is located in the cab, on the top right frame member.

Designated uses and exemption from liability

• The machine is intended for:

• Moving earth, gravel, coarse gravel or ballast and rubble.

• Working with the attachments mentioned –see Fields of application, attachments on page9.

• Every other use and attachment is not designated for this machine. Gehl will not be liable for damage resulting from any other use or attachment. The user alone will bear the risk.

• Follow the instructions in the Operator’s Manual, Maintenance and Service chapters, accident prevention regulations, safety and occupational regulations, and machine and traffic regulations. Gehl is not liable for damage resulting from the failure to follow these regulations.

• You can damage the machine by modifying it with parts, equipment, attachments and optional equipment that is not checked or released by Gehl. Gehl is not liable for damage resulting from the failure to follow these requirements.

• Gehl is not liable for personal injury and/or damage to property caused by failure to properly:

• Operate.

• Transport.

• Service and perform maintenance.

• Repair the machine (in accordance with the Operator’s Manual).

• Read and understand the Operator’s Manual before starting, servicing, or repairing the machine. Follow the safety instructions.

• The machine may not be used for transport jobs on public roads.

• In applications with lifting gear, only use the machine according to its designated use.

Abbreviations/symbols

• This symbol stands for a list.

• Subdivision within lists or an activity. Follow the steps in the recommended sequence.

☞ This symbol requires you to carry out the activity described.

➥ This symbol marks the passages in the text describing the effects or results of an activity.

n. s. = not shown.

“Option” = optional equipment. Stated whenever controls or other components of the machine are installed as an option.

This symbol shows the driving direction – for better orientation in figures and graphics.

Identification of warnings and hazards

The following signal words are used throughout this manual and on decals on the machine to warn of potentially hazardous conditions.

DANGER!/WARNING!/CAUTION!

Failure to follow the instructions identified by this symbol may result in personal injury or death for the operator or other persons.

☞ Measures for avoiding the hazard.

IMPORTANT!

Failure to follow the instructions identified by this symbol may result in damage to the machine.

☞ Measures for avoiding damage to the machine.

NOTE:

Contains instructions to help use the machine more efficiently.

Environment!

Failure to follow the instructions identified by this symbol may result in damage to the environment. The environment can be damaged if hazardous material (e.g., waste oil) is not properly used or disposed.

Machine overview

Hydrostatic drive

Work hydraulics and hydrostatic fourwheel steering

The Model 680 is a versatile and powerful helper for moving earth, gravel and debris on construction sites and elsewhere –see Fields of application, attachments on page12. Equip the machine with the respective safety devices when using it as a lifting accessory –see Applications with lifting gear on page21. The main components of the machine are:

• ROPS certified cab, enclosed version (standard). •or ROPS tested cab, open version (option).

• Oil-cooled Deutz four-cylinder in-line diesel engine, 75 hp (56 kW)at2300 rpm.

• Exhaust emissions according to EC directive 97/68/EC.

• Sturdy steel sheet frame; rubber-mounted engine.

• Automotive drive, infinitely variable hydrostatic axial-piston gearbox; maximum speed 12 mph (20 km/h), there is also a 25 mph (40 km/h) option.

• Hydraulic four-wheel power steering with emergency steering feature. The emergency steering feature, located inside the hydraulic system, allows you to steer the machine if you lose hydraulic or motor power.

• Front and rear planetary axles, rear axle with oscillation.

• Service brake (hydraulic multi-disc brake), mechanical disc-type parking brake.

The diesel engine drives a hydraulic pump, whose oil flow is sent to a hydraulic motor flanged onto the rear axle. The force of the hydraulic motor is transmitted to the rear axle via the transfer gearbox. At the same time, the front axle is driven by the cardan shaft, ensuring full-time four-wheel drive.

The diesel engine also drives the joint gear pump for work hydraulics and hydrostatic fourwheel steering. The oil flow of this pump depends on the diesel engine speeds only. When the machine is in operation, the entire diesel engine output can be transmitted to the gear pump for work hydraulics and steering by using the inching valve. This valve responds as soon as the service brake is used, reducing or cutting off power input of the drive. Therefore, full engine output is available for the loader unit by pressing the accelerator pedal and the brake pedal at the same time.

Cooling system

A combined engine/hydraulic oil cooler (for the diesel engine and the hydraulic oil) is located at the rear of the machine. The indicators on the instrument panel of the machine allow you to constantly monitor the engine and hydraulic oil temperatures, and the coolant temperature and level.

Fields of applicat ion, attachments

The attachments determine how the machine is used.

IMPORTANT!

In order to avoid damage to the machine, only the attachments listed below are certified for attachment to the machine.

☞ See Use: attachment.

Use: attachment Possible attachment and material densities.

Description of attachment

Standard bucket – normal material 680810139 Loosening, picking up, transporting and loading loose or solid material (material density ≤ p=1.35 t/yd.³ [≤ p=1.8 t/m.³])

Standard bucket – lightweight material1 680810137 Picking up, transporting and loading lightweight material (material density ≤ p=0.98 t/yd.³ [≤ p=1.3 t/m.³])

Pallet forks 680810140 Picking up and transporting pallets

1.Only in connection with additional lights when driving on public roads

Serialnumberplatelocations

Serial number

The serial number is stamped in the cab bearing A (on the right as seen in driving direction, behind the cab door lining). It is also located on the type decal.

The type decal is located on the machine frame on the right, next to the loader unit bulkhead (on the right above the front axle).

Type decal information

Example: Model 580

Machine model:580

Version:343 00

Serial no.:343 01 0001

Model year:2005

Front gross axle weight rating:9370 lbs. (4250 kg)

Rear gross axle weight rating:9370 lbs. (4250 kg)

Gross weight rating:15,432 lbs. (7000 kg)

Output:75 hp (56 kW)

Other information –see Specifications on page138.

Cab number

The type decal (arrow) is located in the cab, on the top right frame member.

Engine number

The type decal (arrow) is located on the cylinder-head cover (engine).

Example:Deutz BF4M2011

Hydraulic pump number

The type decal (arrow) is located on the hydraulic pump housing (next to where the pump is attached to the diesel engine)

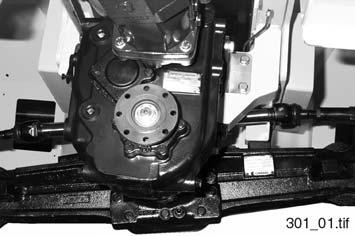

Hydraulic motor number

The type decal (arrow) is located above the cardan shaft, on the right of the hydraulic motor.

Rear axle number

The type decal (arrow) is located on the inside of the axle tube, on the left side (arrow).

Front axle number

The type decal (arrow) is located on the inside of the axle tube, on the right side (arrow).

Notes:

Safety d ecals

The following section explains signs and symbols that may not be easily understood.

IMPORTANT!

Safety decals must be replaced if they become unreadable.

Meaning

The eye hooks on the cab are for removing the cab only and may not be used for cranelifting the machine –see Moving the machine with a crane on page24.

Location

Cab roof (4x).

Meaning

Points for tieing down the machine. The eye hooks are used for tieing down the machine during loading and transport –see Tieing down the machine on page26.

Location

On the left and right of the machine frame above the front axle attachment, and on the towing facility at the rear.

Meaning

Sound levels produced by the machine. LWA = sound power level. Other information –see Sound levels on page146.

Location

Rear window.

Meaning

General indication of danger. This decal warns persons standing or working near the machine of existing hazards within the area of increased danger around the machine.

Location

Front left and right of machine frame, and at rear of machine.

Meaning

The CE mark means that the machine meets the requirements of the Machinery Directive and that the conformity procedure has been carried out. The machine meets all the health and safety requirements of the Machinery Directive.

Location

On the rear window.

Fig. 18:Prohibitory decal

Meaning

DO NOT open engine cover before engine is at a standstill. DO NOT touch any moving or turning parts.

Location

On the engine cover of the machine.

Safety instructions

Mandatorysafetyshutdown procedure

Before operating this equipment, read and study the following safety information. In addition, be sure that every individual who operates or works with this equipment is familiar with these safety precautions.

Before leaving the machine:

• Lower the working equipment to the ground and support it securely.

• Reduce throttle and turn off the engine.

• Lock out controls by raising right-hand control console.

• Remove the ignition key and take it with you.

Unauthorizedmodifications

Any machine modification made without authorization from Gehl could create a safety hazard, for which the machine owner would be responsible.

For safety reasons, use only genuine Gehl parts. For example, using incorrect fasteners could lead to a condition in which the safety of critical assemblies is dangerously compromised.

Attachmentprecautions

Operationalsafety

Optional kits are available through your dealer. Because Gehl cannot anticipate, identify and test all of the attachments that owners may wish to install on their machines, please contact Gehl for information on approval of attachments, and their compatibility with optional kits.

Control the machine cautiously and gradually until you are fully familiar with all the controls and handling.

Avoid high-voltage lines. Serious injury or death can result from contact or proximity to high-voltage electric lines. The bucket or boom does not have to make physical contact with power lines for current to be transmitted. Use a spotter and hand signals to keep away from power lines not clearly visible to the operator.

Depending upon the voltage in the line and atmospheric conditions, strong current shocks can occur if the boom or bucket is closer than 10’ (3 m) to the power line. Very high voltage and rainy weather can further increase the safe operating distance.

Before starting any type of operation near power lines (either above-ground or buried cable-type), always contact the power utility and establish a safety plan with them.

Before starting to dig, contact authorities. Contact Diggers Hotline One-Call Information at 1-888-258-0808.

Below-ground hazards also include natural gas lines, water mains, tunnels and buried foundations. Know what is underneath the work site before starting to dig.

Be aware of height obstacles. Any object in the vicinity of the boom could represent a potential hazard, or cause the operator to react suddenly and cause an accident. Use a spotter or signal person when working near bridges, phone lines, work site scaffolds, or other obstructions.

Use care on loose ground. Carrying heavy loads over loose, soft ground or uneven, broken terrain can cause dangerous side-load conditions and possible tipover and injury. Traveling with a suspended load or an unbalanced load can also be hazardous.

If temperatures are changing, be cautious of dark and wet patches when working or traveling over frozen ground. Stay away from ditches, overhangs and other weak support surfaces.

Never rely on jacks or other inadequate supports when maintenance work is being done. Use solid support blocking.