4 minute read

PRE-OPERATING PROCEDURES

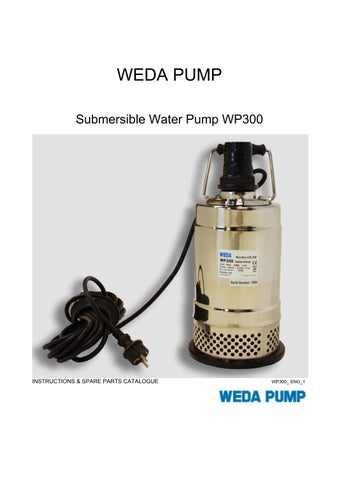

from Dynapac WEDA LINE Submersible Pumps WEDA 50 INSTRUCTIONS & SPARE PARTS CATALOGUE Manual 470W367055

Before attempting to operate the WP300 Submersible Pump, please perform the following procedures for the personal and property safety of the operator and jobsite.

1. Ensure that the pump is structurally and mechanically safe by checking the following: a. Does the pump start when plugged into socket? Does the pump function without excessive noise and/or unusual odour? Test as follows: a. Set up pump as instructed in "Setting up the WP300" section. b. Plug electrical cable into socket. c. Run pump for no longer than 2-3 seconds to check for noise and odour. b. Check the entire length of the electrical cable, impeller, and connector fittings are not worn, fouled or in any other conditions that would prevent the pump from safe operation.

NEVER RUN THE PUMP DRY!

This pump DOES NOT have an on/off switch!

Clear impeller of any debris and sand before operating pump.

DO NOT USE IF ELECTRICAL CABLE IS FRAYED OR DAMAGED IN ANY MANNER.

If any of the above checks fail, please take necessary steps to repair the unit before operating it in any environment.

2. Before using the pump on proposed jobsite, perform the following environmental checks: a. Check that available electrical socket conforms to local codes. b. Inspect the entire work area for unexpected buried hazards, such as rocks, pins, nails and other obstructions that can be sucked into the pump. The pump can malfunction as a result, and electrical shocks, leakage and other accidents can occur. c. Make sure that the pump is not being placed on a loose or soft platform where the unit can sink or suck up material excessively, blocking water flow to the impeller. d. Make sure that the pump will be running in water. e. DO NOT SUBMERGE PUMP DEEPER THAN 26' (8m) or the length of the supplied electrical cable, whichever is SHORTER. f. Ascertain that the discharge end of the discharge hose will be located above the water surface. If this end is submerged, water may backflow into the pump when power is discontinued. The end should be free from any obstructions that can prevent smooth discharge of water. g. Ensure that the temperature of the water that the pump is to work in does not exceed 110ºF, or approximately 40ºC.

NEVER RUN PUMP DRY. Doing so may result in damage to the pump, electrical short and/or damage to seal and will void manufacturer's warranty.

If any of the above checks fail, please DO NOT operate the pump.

Operation Procedures

1. Place the pump assembly (pump & discharge hose) in an upright position.

Always ensure that the pump will be operating in an upright position

2. Slowly lower pump into jobsite, using a rope, chain, or other implements attached to the handle.

NEVER USE ELECTRICAL CABLE TO CARRY, LIFT OR OTHERWISE MOVE PUMP. This will damage the cable, which can cause electrical shocks, shortage, pump failure, personal injury and other accidents.

DO NOT DROP PUMP. This will damage the pump and cause malfunctions that can lead to personal and jobsite damage.

NEVER REST PUMP ON SOFT OR LOOSE BOTTOM. Using the pump on a non-solid foundation can lead to the pump sinking into mud or other substances that WILL interfere with the performance of the pump. This can lead to severe damage to the unit, which can result in electrical shock, shortages and other hazards to personal and jobsite safety.

To prevent the pump from operating on a non-solid foundation, suspend pump with wire, rope or other implements attached to handle. TAKE CARE TO RESTRICT TWISTING ON WIRE, ROPE, OR IMPLEMENT USED IN SUSPENDING PUMP DURING START-UP.

3. Plug grounded electrical plug into a grounded socket:

MAKE SURE THAT CABLE, PLUG AND SOCKET ARE ALL DRY AND CLEAN. DO NOT MIX. WATER AND ELECTRICITY

DO NOT USE PUMP IF ELECTRICAL CABLE SHOWS ANY OF THE FOLLOWING SIGNS:

1. Electrical cable is frayed or shows signs of wear, such as ripped cord casing, acute bends in cord, etc, or if electrical plug is not securely connected to the cable. This can result in electrical shock or leakage.

2. Electrical cable is looped or placed on a gas pipe, water pipe, lightning arrestor, telephone wire or any other utility lines.

3. Electrical cable is overextendedvby attempting to lower pump farther than the length of the factory supplied cable or 8 m (26' feet), whichever is shorter.

4. Electrical wire is cut, twisted or damaged in any way. This may result in electrical shock and leakage which can cause injury to the operator, jobsite and/or the pump.

DO NOT use pump if there are no grounded electrical sockets on jobsite OR if the ground connection on electrical plug has been damaged in any way or removed.

DO NOT use pump if strain relief is not securely attached.

4. When operating pump, ensure that stops and starts of pump do not exceed 6 times per hour.

Do not attempt to run the pump dry, as permanent damage to the mechanical seal will result.

Maintenance Procedures

Regular scheduled maintenance procedures will help to maintain your pump's life and performance. Before performing any maintenance, disconnect the pump from power source. MAKE SURE THAT CABLE, PLUG AND SOCKET ARE ALL DRY AND CLEAN. DO NOT MIX WATER AND ELECTRICITY.

Standard Maintenance Procedures

1. Oil Change

a. Remove base, filter, pump cover, impeller and seal from the bottom of the pump.

b. Remove oil seal in the centre of the oil cover.

c. Unscrew oil cover from base of pump.

d. Refill pump with 50 ml of new transmission oil. The chamber should be approximately 80% full when done. DO NOT OVERFILL OIL CHAMBER.

Shell Tellus T or higher is the recommended oil grade.

e. Cover oil chamber with new mechanical seal.

f. Replace all parts that were removed in their reversed order. Consult "Machine Overview" for placement and order.

2. Mechanical Seal Inspection

a. Follow all the steps outlined above in 'Oil Change' up to step 'C'.

b. Tilt pump at slight angle so that some oil is drained from oil chamber.

c. Check oil for particles, water or any other impurities. If there are impurities in the oil, or if oil appears to be 'milkish' in appearance, remove mechanical seal and drain pump of all remaining oil.

d. Refill pump with 50 ml of new transmission oil. The chamber should be approximately 80% full when done. DO NOT OVERFILL OIL CHAMBER.

Shell Tellus T or higher is the recommended oil grade.

e. Replace mechanical seals if worn, or if drained oil has been contaminated.

f. Replace all parts that were removed in their reversed order. Consult "Machine Overview" for placement and order.