11 minute read

8 Hours / Daily service

1. General

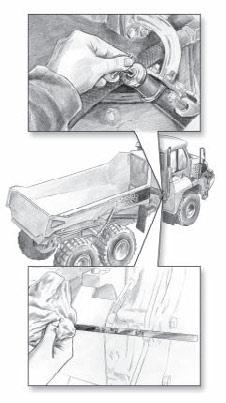

1.1. Walk around check, before start

• Check for leaks at the engine (see also item 2.1), transmission, differentials, reduction/tandem housings, tanks, hydraulic hoses and lubrication system. • General check for loose bolts on the driveline, specially on radiator, engine/transmission brackets and at the prop. shaft flanges. • Check for damage, wear and other abnormalities on the visible parts of frames, body, tyres, cylinders, etc. • Check lights. Replace burnt out bulbs. If leakages, loose bolts, damages or other abnormalities are observed, remedy if necessary (before operation). If necessary contact your local Moxy Dealer.

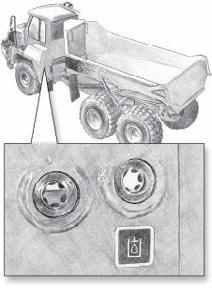

Breather, front differential

Breather, front differential

The breather for the front differential is located under the cab, on the right hand side of the transmission.

CAUTION

Donot fill any oil or other fluid into the breather reservoir!

1.2. Check driver's seat, before start

• Check function.

• Check all seat adjustments for easy operation. • Check function of the air valve.

• Check safety belt for proper lock functions. See chapter 3, seat adjustment, for more detailed information.

2. Engine

2.1. General condition check - look for leakages

Remedy as necessary

1.Start the engine. 2.Look for leakage of oil, coolant, fuel, air and exhaust. 3.Tighten or change leaking connections. Check the overflow holes (1) which show whether the O-rings between the cylinder liner and crankcase are leaking, see drawing. a. If coolant is leaking out, the two upper O-rings are leaking. b. If oil is leaking out, the lower O-ring is leaking. 4.A small amount of leakage from the overflow holes during the engine's running-in period is normal. (Seals and O-rings are lubricated with soap or oil when fitted). This leakage normally stops after a time. If there is a large amount of leakage - contact your Moxy Dealer.

2

2.2. Check oil level, before start 1*

• If the engine has been running: Let the engine remain stationary for at least 1 minute before checking the oil level. • The dipstick (1) is found on the left hand side of the engine. • The correct level shall be between upper and lower mark on the dip stick (1) (dump truck on level ground). • Fill up with oil (2) if level has dropped to the lower mark. See oil specification sheet, chapter 6 for correct oil type. • Check level correctness.

1

2.3. Check coolant level, before start 5*

• The level in the expansion tank shall be between minimum and maximum when the dump truck is on level ground. See marks. Refill with coolant of correct mixture if level is lower than minimum.

• If large quantities are required to correct the level, check and remedy the cause in such a case.

CAUTION

Be careful when removing the filler cap of a hot engine. Hot coolant and steam can spurt out! Never add large amounts of cold coolant when engine is hot. The temperature difference can cause cracks in the engine. Always top up with pre-mixed coolant.

1

2

2.4. Check fuel level, before start 13*

1.Turn on the starter switch key (to pos. 1) and check on the fuel gauge that there is enough fuel (1). 2.Fill up with fuel if necessary (2).

NOTE

Always make sure that there is enough fuel in the tank. NEVER run out of fuel.

2.5. Function check of the centrifugal cleaner, after operation 2*

The rotor rotates very fast, and will normally carry on rotating after the engine is stopped. 1.Stop the engine when it is hot. 2.Listen for spinning sound from rotor, or feel if cleaner housing vibrates. 3.The rotor normally rotates 30 - 60 seconds after the engine has stopped. 4.If not, dismantle and check the cleaner, see 500 hours service.

2.6. Drain air tanks, after operation 12*

• Two air tanks are located on the fire wall under the bonnet.

• From serial no 710353 - an additional air tank is located inside the fender, right hand side. • Pull the drain chain on the underside of the tanks sideways to release the air pressure. • If condensation is present in the escaping air, release system pressure completely and replace the air dryer, see 2000 hours service.

From serial no 710353 - an additional air tank is located inside the fender, right hand side.

3. Transmission

3.1. Check oil level, before operation 20*

1.The dump truck must be standing on level ground. 2.The gear selector shall be in neutral and confirm that the parking brake is ON. 3.Run the engine at low idle. 4.Turn the dip stick handle (behind the cab, right hand side) a few turns to the left to release the seal pressure. 5.Pull out the dip stick and clean it with a clean cloth. 6.Insert dip stick fully and remove it again (at least 2x) 7.Check level: Cold oil, 40 °C: lower mark Hot oil, 80 °C: upper mark 8.If necessary correct the level by adding oil according to the transmission oil list (chapter 6) through the dip stick tube.

9.Insert the dip stick again and turn handle clockwise to tighten the sealing.

CAUTION

Use gloves when checking the oil level or filling oil. The exhaust pipes and nearby area may be hot and fingers and hands could be burnt.

Do not overfill with oil! Both too high and too low level can cause serious internal damage!

4. Hydraulic system

4.1. Check oil level, before start 40*

1.Read the oil level in the oil level gauges (located on the back of the hydraulic tank). •The upper gauge shows max. level at warm oil •The lower gauge shows min. level at cold oil. 2.Fill up with oil (see oil specification sheet, chapter 6) if necessary. Oil filler located on the top of the hydraulic filter.

NOTE

The dump truck must be horizontal and dump body completely lowered!

5. Brake system

5.1. Check brake fluid levels, before start 60*

Two reservoirs on the fire wall under the bonnet.

• The reservoirs shall be min. 2/3 filled (see marks).

Fill up with correct brake fluid, if necessary. •If the reservoirs have to be filled up with brake fluid often (i.e. montly), check the brake system for leaks and/ or worn brake linings. Replace brake linings if necessary. • If the brake fluid level drops to minimum, the brake fluid warning light will illuminate. Check the brake linings and replace them if necessary (see 500 hours service).

Fill up the brake fluid reservoirs with correct brake fluid.

CAUTION

• When refilling, do not overfill! • Use only brake fluid as specified in the specification sheet, chapter 6!

6. Lubrication

Grease lubrication points until pure grease is forced out of the components. Wipe off.

59

59

50

Upper tip cylinder bearings

6.1. Articulation turning ring, 1 lubricator 50*

Lubricator located on the distribution block behind the hydraulic tank (left hand side). • By Manual lubrication: 6 pump strokes (1 stroke = 1-1 1/2 cm3)

6.2. Suspension legs, 2 lubricators 59*

The lubricators are located on the distribution block behind the hydraulic tank (left hand side). • By Manual lubrication: 1 pump stroke (1 stroke = 1-1 1/2 cm3)

54

54

54

54

55

53

53

55

6.3. Articulation bearings, 2 lubricators 53*

Lubricators are located on the distribution block besides the steering cylinder on left hand side. • By Manual lubrication: 3 pump strokes (1 stroke = 1-1 1/2 cm3)

6.4. Steering cylinder bearings, 4 lubricators 54*

Lubricators are located on the distribution block besides the steering cylinder on left hand side. • By Manual lubrication: 2 pump strokes (1 stroke = 1-1 1/2 cm3) Check the complete length of cylinder rods for scratches and other damage.

6.5. Tip cylinder bearings, 4 lubricators 55*

Lubricatos for the lower tip cylinder bearings are located on the distribution block besides the steering cylinder on left hand side.

• By Manual lubrication: 2 pump strokes (1 stroke = 1-1 1/2 cm3)

Lubricators for the upper tip cylinder bearings are located on the upper end of the tip cylinder. • By Manual lubrication: 2 pump strokes (1 stroke = 1-1 1/2 cm3) Raise the body to check all cylinder pistons for scratches and other damage.

6.6. Tailgate arm hinge (optional), 2 lubricators 56*

One lubricator on the inner side of each tailgate arm hinge. • By Manual lubrication: 1 pump stroke (1 stroke = 1-1 1/2 cm3)

6.7. Tip hinges, 2 lubricators 51*

One lubricator located on each tip hinge. • By Manual lubrication: 2 pump strokes (1 stroke = 1-1 1/2 cm3)

6.8. Tandem bearings, 2 lubricators 52*

Lubricators located on the distribution block between the tip hinges (on the rear frame). • By Manual lubrication: 6 pump strokes (1 stroke = 1-1 1/2 cm3)

52

6.9. Door and fender hatches, 8 lubricators 57*

There are 2 lubricators on the door, 2 lubricators on right hand side fender, 2 lubricators on left hand side fender and 2 lubricators on the cover upon the hydraulic tank (one per hinge) These lubricators must be manually greased, even if the automatic central lubrication is fitted.

6.10.Cab rear hinges, 2 lubricator 58 *

There is one lubricator on each side of the cab.

These lubricators must be manually greased, even if the automatic central lubrication is fitted.

7. Parking brake

7.1. Check braking (holding) capacity, before operation

1.Apply the parking brake (indicator light) and make sure that the system pressure is at normal operating pressure (i.e. no warning lights on). 2.Set the gear selector in 1st gear. 3.Increase the engine speed slowly. 4.The parking brake must be able to keep the dump truck stationary at engine speeds up to 1400 rpm. If not, check parking brake system and contact your Moxy Dealer.

8. Service brake (main brake)

8.1. Check braking (holding) capacity, before operation

1.Apply the parking brake (indicator light) and make sure that the system pressure is at normal operating pressure (i.e. no warning lights on). 2.Depress the brake pedal. 3.Release the parking brake. 4.Set the gear selector in 1st gear. 5.Increase the engine speed slowly. 6.The service brake must be able to keep the dump truck stationary at engine speed up to 1100 rpm. If not, check the brake system and contact your Moxy Dealer.

8.2. Check function, before operation

1.Apply the parking brake (indicator light) and make sure that the system pressure is at normal operating pressure (i.e. no warning lights on). 2.Stop the engine. 3.Depress brake pedal firmly and listen for leaks in the air system. 4.Also check that the brake fluid warning light and the brake system warning light (chapter 3) does not illuminate. 5.Check for brake fluid leakage at master cylinders, pipes and hoses.

6.Start the engine and release the parking brake. 7.Drive the dump truck slowly on firm, level ground and depress the brake pedal firmly. 8.Check that the braking effect is good and equal.

9. Steering

9.1. Check function, before operation

1.Drive slowly forwards (5-10 km/h) and check that the emergency steering light goes off. 2.Turn the steering wheel at an even speed until end stop, both sides.

10.Engine brake

10.1.Check function, before operation

1.Drive the dump truck forwards at approx 10-15 km/h with lock-up engaged. 2.Apply the engine brake by releasing the throttle pedal. 3.Check that the exhaust sound changes. 4.Check the indicator light for function and note the braking power. 5.Depress the throttle pedal again and note that the engine brake goes off (i.e no braking power, exhaust sound changes and the indicator light switches off).

11.Engine and retarder brake

11.1.Check function, before operation

1.Drive the dump truck forwards at approx 10-15 km/h with lock-up engaged. 2.Apply the retarder brake by depressing the retarder brake switch and release the throttle pedal. The engine brake will also then apply. 3.Check that the exhaust sound changes. 4.Check the indicator lights for function, both engine and retarder brake and note the braking power. 5.Depress the throttle pedal again and notify that both the engine and retarder brake goes off (i.e no braking power and the indicator lights switches off).