5 minute read

General Information

Safety

General Information

123229-002

Of special importance

In order to prevent accidents, the information provided in this repair manual must be read and observed by all persons who use, maintain, repair, service or monitor the machine. Read the section on safety in particular.

123231-002

Identification of warning and danger signs

We have marked all points of this Repair Manual involving your safety and the safety of the front attachment or of the machine with the signs below. Please pass all safety precautions on to other users as well.

DANGER!

Nature and source of danger Consequences: death or serious injury –Countermeasures

WARNING!

Nature and source of danger Consequences: injuries –Countermeasures

CAUTION!

Nature and source of danger Consequences: material damage –Countermeasures

Note!

Nature and source of information Consequences: enhanced machine economy or easy assembly –Measures

Environment!

18-001

Nature and source of danger Consequences: damage to the environment –Countermeasures

The warning and information signs on the machine provide important information for hazard-free operation. Observing these warnings and information serves your safety!

123232-002

–In addition to this manual, the operator's manual for the machine must always be observed. –Observe all general rules concerning safety and accident prevention. –When using public roads, observe the appropriate regulations! –Before starting the diesel engine, ensure that the transmission is in neutral and all guards are installed and in their correct position. –Always sound the horn before starting the diesel engine and engaging the main drive. –Only start the diesel engine from the driver's seat.

The diesel engine must not be started by shortcircuiting the electrical connections on the starter, as the machine may immediately start to move. –Do not let diesel engine run in enclosed spaces. –The mechanic's clothing must be tight-fitting.

Avoid loose clothing! –Handle fuel with care. – Increased fire hazard. –Never refuel the machine in close proximity to open flames or sparks that may cause ignition. –Do not smoke during refuelling. –Always stop the diesel engine and remove the ignition key before refuelling. Fill the fuel tank outdoors. –Clean up any spilled fuel immediately. –Prevent fires by keeping the machine clean. –Take care when handling brake fluid and battery acid. Battery acid is toxic and caustic. –Only carry out work beneath the raised machine if machine is securely supported. –After maintenance and repair work, refit all safety devices!

First aid measures

123242-003

Inhaling: –Give the person fresh air and consult a doctor depending on his or her symptoms.

740-001

32

–Remove the person from the danger area. Contact with the eyes: –Rinse the eyes thoroughly with large amounts of water for several minutes. Consult a doctor if required. Contact with the skin: –Wash thoroughly with plenty of water and soap, remove polluted and soaked clothing immediately, consult a doctor if the skin is irritated (e.g. reddening). Swallowing: –Do not induce vomiting; consult a doctor immediately.

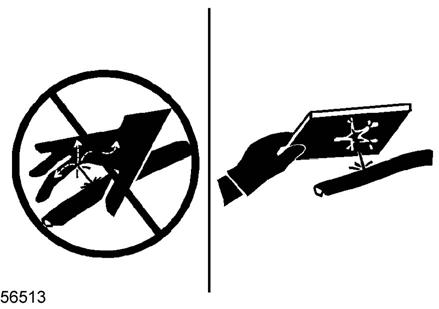

Risk of injury from hydraulic fluid

123239-003

4167-003

DANGER!

Fluids under high pressure. Fluids penetrate the skin and cause serious injuries. –Work on the hydraulic system must only be carried out by CLAAS sales partners. –Check the hoses and other hydraulic components regularly. –Search for leakage points with a piece of wood or cardboard. –Take care not to redirect the oil jet towards the body. –Replace damaged hoses and components. –Replace hose lines a maximum of 6 years after the date of manufacture.

4186-003

DANGER!

Incorrect handling of injuries caused by hydraulic fluid. Death or serious injury. Even a pinhead-sized hole can lead to serious injuries. –If any hydraulic fluid penetrates the skin or eyes, the injury should be treated immediately by a medical specialist.

614659 1

5298-001

33

123235-003

Leaving the machine

•When leaving the machine, ensure that it will not roll away (apply the parking brake, fit the wheel chocks). Stop the engine, remove the ignition key and lock the cab if required. •When shutting down the machine for an extended period, switch off the battery isolating switch. •Never leave the machine unattended while the engine is still running. •Lower the front attachment completely to the ground before leaving the machine.

123247-004

Putting the machine out of operation

Before work is carried out on the machine, perform the following steps: –Stop the diesel engine. –Apply the parking brake. –Remove the ignition key. –Remove the key of the battery isolating switch. –Wait for all machine parts which run on to come to a halt. –Secure the machine using wheel chocks. –Ensure that the machine cannot be started by any third persons.

Jacking up the machine

123246-003

1676-001

DANGER!

Jacking up the machine. Death or serious injury. –Use jack / jack stand with sufficient capacity. –Use reliable jack / jack stand. –Use jack / jack stand on solid and level ground. –Apply the jack / jack stand at the position of the machine intended for this purpose.

The jacking points for jacks / stands are marked by symbol (1) on the axles.

123238-002

Adjustment and maintenance operations

The machine drives are not automatically secured after stopping the engine due to their functions. Moreover, adjustment operations may require that drives be rotated.

For these reasons, the following must be observed: •Prior to adjustment, cleaning and maintenance operations as well as removing malfunctions: -Stop the chopper unit. -Stop the engine. -Disconnect the battery isolating switch. •Prior to adjustment, cleaning and maintenance operations as well as removing malfunctions on the hydraulic system, lower the front attachment and/or the feeder unit completely to the ground. •When working on the electric system, always disconnect the battery isolating switch. •After stopping the chopper unit, the drives continue rotating. Absolutely wait for these machine parts to come to a complete halt. •It must be ensured that other persons cannot start the machine or rotate the drives. •Liquids escaping under high pressure (fuel, hydraulic oil etc.) may penetrate the skin and cause serious injury. For this reason consult a doctor immediately as otherwise serious infections may result! •Repair work on the hydraulic system may be carried out only by specialist workshops. •Be careful when opening the radiator cap. When the engine is hot, the radiator is under pressure! •The installation of tyres requires sufficient knowledge and proper tools! •Dispose of oils, fuels and filters in a proper way! •Retighten wheel nuts at regular intervals!

123159-002

Welding work

Before carrying out welding work, observe the information provided in the current Operator's Manual of the machine!