1 minute read

CHECKING OPERATIONS.............................................................................................................................................A0

Test procedure

List of checks

The purpose of this procedure is to check a number of points before and after dynamometer testing. It is suited to engines with electronic control(TIER2).

Failure to carry out these tests may lead to an incorrect power reading.

Always check the following points before starting a PTO power test. Reminder: Wait until the running-in period has elapsed (minimum 100hours) before testing an engine on the dynamometer. This period is necessary to ensure that measurements are carried out under suitable conditions.

1. Visual checks

Make sure that the supply and return lines are correctly fitted (not trapped or kinked on installation, etc.). Check that the engine serial n° read with Métadiag is the same as the one indicated on the engine identification plate and if there are any error codes.

2. Engine oil

Check the level: Normal operating level: Upper part of the hatched area. Below mark (A): Top up before restarting the engine.

A B

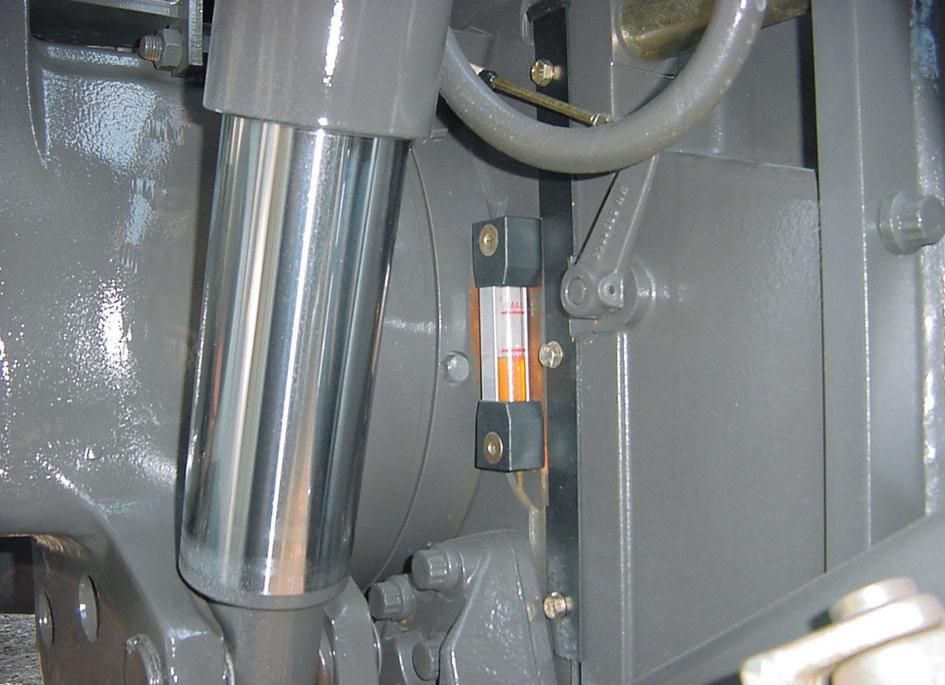

3. Hydraulic /transmission oil level

Check the level: Mark(K): Minimum level. Mark(J): Maximum level. A level above level(J) affects engine power and increases temperature. Example: Overfilling will significantly affect performance during high speed road operation.

111hsn01

13 l 1 3 l J

K

Fig.1

542hsn03 Fig.2