20 minute read

2.5 EXTERNAL CONTROLS ........................................................................................................ H

3 MOTOR INFORMATION PLATE

Motor information plate

The engine identification plate (3) can be seen from behind the mount (2) (Right-hand side of the engine). This plate contains the engine type and serial number.

2 3

101msn07

Type :

Serial number:

The emissions certification label (1) is located on the front right side of the cylinder head cover. This label provides information on the engine (Manufacturer data). 3

101msn10

1

101msn05m

4 CAB IDENTIFICATION PLATE

Plate (1) is located behind the rear panel.

1

6566

A - Reception number per EMC type (Electromagnetic compatibility). B - Absorption ratio. C - Homologation number per cab type. 1

e2

XXXXXX A

X,XX B

841msn03m

S e2

XXX

C

841hsn01m

5 EUROPEAN REGULATION

CLAAS tractors put in circulation in the European Community meet modified European Directive 2003/37. A certificate of conformity is supplied when each tractor is delivered. Hence, the tractor's manufacturer ensures conformance of the tracor with the CE directive mentioned previously upon initial marketing. In countries outside the European Union, apply the appropriate national provisions.

6 SAFETY

6.1 SAFETY INSTRUCTIONS

6.1.1 Appropriate use

6568

CLAAS tractors and farm tractors have been designed exclusively for professional use in line with the recognised rules governing farming practices and agricultural work. CLAAS farm tractors have been designed and adapted to tow, move or carry tools / equipment / loads authorised by the manufacturer, and to control certain tools or compact using tools (weights) authorised by the manufacturer in the field and on public highways in line with the provisions of the highway code. The agricultural tractor must be used, serviced and overhauled only by persons with perfect knowledge of the tractor, and informed of any risks. A use conforming with the purpose presumes compliance with the instructions in the user manual, as well as rules of use, maintenance, and overhaul indicated by the manufacturer. The user and owner is liable for complying with particular accident prevention instructions, as well as general rules in terms of safety, occupational medecine, and road legislation. Any use other than that defined above is considered to be non-compliant with the purpose, and waives the manufacturer from any liability in case of damage ; the user will support alone any risks resulting from such a use. Please call CLAAS for detailed and customised information to ensure compliant use in particular cases.

6.1.2 Use non conformant with the purpose

6569

Any use not foreseen by the manufacturer shall be considered to be inappropriate, and therefore incorrect. The manufacturer waives any liability in case of damage ; the user will support alone any risks resulting from such a use. Examples of incorrect use of CLAAS tractors / farm tractors: - Use of surfaces and spaces not defined as being work or maintenance zones in the user manual. - Adjustment, cleaning, and maintenance operations contrary to the indications in the user manual. - Performing repair and maintenance work while the system is on and / or the engine running. - Non-compliance with the warnings on the tractor and in the user manual. - Overhauling and repairing by staff not trained to this effect. - Arbitrary modifications made to the tractor. - Installation of unauthorised optional equipment. - Use of spare parts not manufactured by CLAAS. - Use of devices / equipment not authorised by the manufacturer. - Use of the tractor to participate in sports events. - Exceeding the total technical weight acceptable. - Transporting persons outside of the seats intended for this purpose (Depending on the tractor equipment, a passenger seat may be used to transport one person).

6.1.3 Precautions to be taken before starting up

Caution is the best guarantee against any risk of accident. Before starting the operation of the tractor, read the operator's manual and all safety tips. Take into account all this information when using the tractor. This rule applies to everyone who uses the tractor involved in its maintenance, maintenance or inspections. When the tractor is used by a person other than the owner, the latter must provide all explanations necessary to ensure risk-free work. The driver's position must be clean (Dashboard - Steering wheel - Floor - Pedals - Windscreen - Rear view mirrors - etc.).

Foosteps must always be clean (no mud) to avoid slipping when climbing or descending. To climb into the tractor: - Turn towards the driving position. - Open the left-/right-hand door (Depending on equipment fit). - When climbing the steps, always use the handles/ handrails provided: - Only move one hand when both feet are supported. - Only move one foot when gripping with both hands. - Sit in the driver's seat. - Close the door (Depending on equipment fit). - Buckle your seatbelt. Do not climb into/out of a moving tractor. Do not use the front wheels or any other accessory to climb into or out of the tractor. Before starting the engine, make sure that all controls are in the neutral position, particularly the power take-off lever.

001hsn25

001hsn26

Only run the engine in well ventilated areas. Make sure there is nobody nearby before starting the tractor. Fully release the handbrake before moving the tractor forward. Do not start work if the tractor is not working properly. To climb down the tractor: - Check that all commands are in neutral. - Lower the tools against the ground. - If required, stop the engine. - Apply the handbrake. - Remove your seatbelt. - Open the door (Depending on equipment fit). - Turn round to face the driving position when leaving the tractor. - When descending the steps, always use the handles/handrails provided:

- Only move one hand when both feet are supported. - Only move one foot when gripping with both hands. - Close the door (Depending on equipment fit). Do not exit the tractor by jumping.

6.1.4 Tractor state

5748

Maintaining the tractor in the best possible condition, by carrying out all routine maintenance (oil changes, level checks, overhauls, adjustments and thorough cleaning) will allow it to be used in the safest and most profitable way. Check the following items first: - High temperature components: - Check that airborne particles such as straw, grass, wood chips etc., do not accumulate in high temperature areas. - Clear debris from around the engine and the exhaust system. - For tools attached to the front or the side of the tractor, inspect and clean the areas around the attachments for the various supports. - Brakes: - Check that the brakes work properly. - Check the operation of the hand brake and foot brake. - Check that the front axle of the tractor is engaged when the brakes are actuated (service brakes or handbrake) (For tractors with 4 wheel drive). - Steering: - Check the operation of the hydrostatic steering.

001hsn27

- Transmission: - Check the transmission fluid level (especially if external services are used). - Hydraulic system: - Check the condition of the system (unions, pipes, hoses), particularly the hoses to the steering actuators. - Electrical system: - Check the condition of the electrical system (batteries, wiring, headlights, indicator lights, hazard lights, rotating beacons, windscreen wipers, etc.). - Lighting - indicators: - All lighting and indicating equipment must not only be in working order, but must be fully visible; clean them. - Carry a spare set of bulbs. - Replace any defective element.

001hsn28

Only fit genuine CLAAS parts. Your CLAAS approved shop is available to supply all parts and products required for maintaining your tractor in perfect condition. Using components not authorised by CLAAS reduces the machine operating capacity, as well as driving and operating safety.

001hsn29

6.1.5 Adjustment or maintenance tasks - repairs 6.1.5.1 General rule

Stay away from the tractor's hot parts. For example: - Engine - Exhaust - Transmission For any intervention on hot or pointed parts, wear gloves or use a rag. Wear safety goggles. Only carry out operations well within your capabilities. A number of simple adjustments are described in the manual (clutch and brake free travel, etc.). Never attempt to work on your tractor unless you have perfectly understood the procedure and have all the basic equipment required. Removing, disassembling, reassembling and refitting vital parts (e.g. cab, engine, transmission or front axle) require specific equipment. Only the use of adapted equipment allows safe intervention while guarnateeing to achieve the results expected. Please refer to CLAAS approved workshops for all these interventions. CLAAS approved workshops have specific tools, the skills required and original spare parts. To secure your repairs and adjustments, call a CLAAS approved workshop.

001hsn30

6.1.5.2 Use of axle stands

If the tractor is to be placed on axle stands, always work on a flat, horizontal, hard surface.

Check the axle stands are suitable for the load. For information, refer to chapter K to check that the props and the lifting device are suited to the load to be lifted. - To place the rear axle on axle stands, position the axle stands under the rear axle tubes. - To place the front axle on axle stands, position the axle stands under the front axle on either side of the differential housing. 4-4-wheel drive tractor: - If the rear axle is on stands, do not start the engine (Risk of the tractor moving if the brakes are activated (foot brake or hand brake)). - If the rear axle is laid on props, and if the engine must be started, the front axle must also be laid on props.

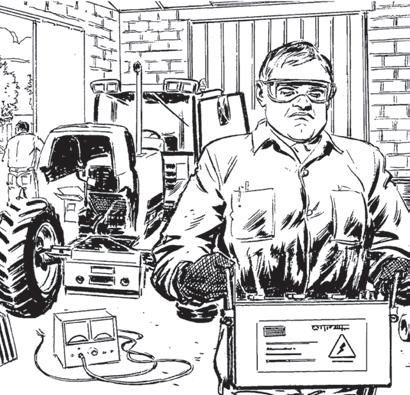

6.1.5.3 Electrical services

001hsn31

5753

Knowledge and skill are required to work on the electrical system. If required (installation of miscellaneous accessories, radio accessories, etc.), call your CLAAS approved workshop . Moreover: - Always disconnect the battery negative terminal before working on the electrical system. - Never replace a defective fuse with a larger calibre fuse.

Risk of fire. - Never intervene on elements such as the alternator or fan when the engine is running. - Comply with safety instructions when welding (See chapter L).

001hsn32

- Avoid generating sparks or open flames next to the battery. - Handle the battery with great care because it contains sulphuric acid that must not come into contact with the eyes or skin. Wear gloves and goggles. In case of projection of acid on your skin or in your eyes, thoroughly rinse with water immediately, and call a doctor. Use a torch to check the level of electrolyte. Do not check the battery's charge by placing a metallic object between the terminals. Use a voltmeter or acidimeter.

6.1.5.4 Fuel

6574

- Always switch off the engine before refuelling. - Do not smoke while refuelling and stay away from any flame or source of sparks. - Before filling the fuel tank, check that no cell phone is nearby.

- Stand in a well vented location. - Wipe immediately any spilled combustible. - To prevent any risk of fire, remove any built-up grease or dirt. - Before filling the tank, always carefully clean around the fuel cap to remove any pieces of straw, twigs, etc. which could help start and then propagate a fire.

Important: When transporting fuel, use containers intended for this purpose. Your container must only be used for this purpose.

6.1.5.5 Coolant

- Do not work on the cooling system when the engine is hot. - Engine stopped, remove the drain plug only when it is cool enough to be turned by hand. Start by turning the plug at the first notch to eliminate pressure, then remove it completely. - Fluid leaking from the cooling circuit may cause severe burns. Wear gloves and goggles. - In case of projection of coolant on your skin or in your eyes, thoroughly rinse with water immediately, and call a doctor.

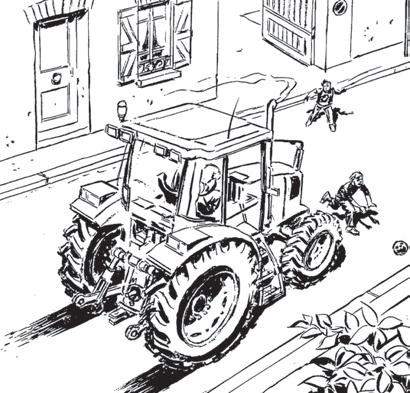

6.1.6 Road use - Use for transport

In all circumstances, apply the legislation on driving wheel-fitted farming tractors applicable in your country. Never exceed the maximum transportation speed of the machine. If in doubt, consult the police or insurance companies. - Never exceed the load permitted tractor (See chapter

K). - Never exceed the allowed masses of the tractor (See chapter K). Before any movement: - Check effectiveness of the tractor brakes. - Check the effectiveness of the rolling tools if they are fitted with a braking system. Before each trip, check the braking. When driving on the public road the doors must be closed and latched. Before driving the tractor on the road, check that the rearview mirrors are clean and correctly adjusted. Make sure that the equipment is hitched correctly and safely locked in position. Whenever possible, avoid using busy roads. When transporting equipment on a public road, use the warning device required by the highway code. All indicators must be clean and in working order. The working lights must not be lit. Brake pedals must be coupled together. Do not use the hand accelerator when the tractor is running on the road.

001hsn34

Do not use the differential lock on the road or in bends. Disengage the front and rear power take-offs. Putting tools coupled, semi-mounted or carried in the transport position. If the tool has transport wheels, use them. The instructions on wearing the driver's and passenger's seat belt are set by the traffic regulations in the country of use. Comply with the regulations in force in the country where the tractor is used. Reduce speed on rough roads or tracks.

001hsn35

When the tractor is parked by necessity or accidentally on the public road and is hazardous for traffic, always: - Activate the warning lights. - Install a warning triangle upstream the hazardous area (According to the regulations in force in the country). Slow down before changing direction. When travelling downhill, always remain in gear: never declutch. The gear selected should be the same as would be used to climb an equivalent gradient. Changing the tyres size may: - Require a new calibration of the terminal in order to meet the values authorised by CLAAS and the speed limits authorised by the country traffic regulations (refer to chapter B for instrument panel calibration). - Require new approval for tyres not originally provided for the model concerned. The following 3 conditions should be observed when hitching a trailer or tool: - The value limits authorised by the ladder and the jaw drawbar (such values are mentioned in chapter G). - The maximum authorised tow weights are indicated on the tractor's identification plate (These values are also found in the table detailing the tractor's specifications). - The limit values authorised by the country's traffic regulations. Beyond a certain size, the trailer or rolling tool hitched to the tractor must be fitted with a braking device. Using a trailer or rolling tool fitted with a pneumatic or hydraulic braking system (For further information, refer to the attached tool operaror's manual): - If the tool is fitted with a hydraulic braking system, connect the hydraulic braking hose to the hydraulic pressure tap of the braking valve at the back of the tractor (Refer to chapter E in the operator's manual). - If the tool is fitted with a pneumatic braking system, connect the braking pneumatic hoses to the pneumatic coupling head(s) at the back of the tractor (Refer to chapter E in the operator's manual). Check that (hydraulic or pneumatic) pressure delivered by the braking device on the tractor trailer is compatible with pressure accepted by the rolling tool. Regularly check or have checked the condition of the brakes on the rolling tools hitched to the tractor (A rolling tool with a faulty braking device will jeopardise the safety of the convoy by overloading the tractor's braking device). CLAAS waives any liability in case of inappropriate maintenance (or adjustment) of the braking device on the rolling tool hitched to the tractor.

6.1.7 Using the tractor 6.1.7.1 General rule

6433

CLAAS tractors were designed for farming applications. However, certain working environments, likely to tipping over the tractor, must be banned:

- Unstable river banks. - Steep slopes. This list is not comprehensive. Evaluate permanently the risks taken in the work space. Check nobody is standing in the risk zone between the tractor and tool. Check nobody is standing next to the lifting zone. Check nobody is present on the level of the wheels before using the tractor. Before leaving the tractor, lower the front and rear tools to the ground. As a general rule, always use equipment in good condition, suitable for the size of the tractor and the type of work. The loads on the front and rear axle must not exceed the maximum acceptable loads specified in this user manual. Extended exposure to a high noise level may cause hearing conditions, even deafness. To protect against noise, wear hearing protections, such as ear plugs. Keep sufficient distance between high voltage power lines and the tractor. Always check that nobody is inside the tool deployment zone. Before using external controls, ensure nobody is present in the tool deployment zone, and that the engine is running at minimum speed.

6.1.7.2 Wheel track

To limit the risk of tipping over, always use the maximum track width possible for the work to perform.

6.1.7.3 Hitching tools

Carefully follow the instructions in the operator's manual for the machine mounted on the tractor, the towed machine or trailer, and do not use the tractor/machine assembly if the instructions have not been followed in full. If the tool is jammed or fails, apply the operating mode described in the tool's user manual to allow safe releasing. To hitch or unhitch a tool, set the gear lever to neutral and apply the handbrake. Use a low gear for all tractor manoeuvres. Sufficient front-end ballast must be used if the implement is heavy, to prevent the tractor rearing-up. Towing bar: This is not intended as a trailer towing hitch and is not designed to carry vertical loads. Use the safety equipment provided to hitch implements (towing jaw, towing stub, retaining pins, etc.). When coupling or uncoupling tools, check that nobody is located between the tractor and the tool. The front towing clevis must be used only to tow the tractor using a towing bar on solid ground. In no event should it be used to pull a swamped tool or tractor.

001hsn36

6.1.7.4 Driving

Do not enter or leave the tractor when it is in motion. Adapt speed to the conditions offered by the environment the tractor is used in. On downhill routes, use the motor brake and maintain appropriate speed. Consider the wheelbase and the inertia mass coupled tools. Avoid risk of overturning. Do not turn sharply when working on slopes. Maximum slope allowed while working: See chapter K. During a break in work, even if only brief, stop the engine and apply the handbrake. Before leaving the tractor, lower the front and rear tools to the ground.

In bends: - Consider the wheelbase and the inertia mass coupled tools. - Turn early enough. - Do not correct the tractor's steering suddenly when turning. - When changing direction, observe traffic carefully on the left and right. - When driving with a trailer or towed tool, check the steering angle to avoid any contact with the tractor (e.g. the tractor's tires). In case of contact, decelerate the convoy immediately. If necessary, stop the tractor, reverse and take the bend with a wider radius. - With large steering angles, tools may protrude the outer edge of the curve. Beware any persons or obstacles on the edge of the road as well as traffic in the opposite direction. In the case of malfunctions on the major security components such as steering or brake: - Stop tractor. - Stop the engine. - Before reusing the tractor, have any defects repaired by a CLAAS approved workshop.

6.1.7.5 Work in a fixed position

5762

If the tractor must be used for stationary work (e.g. driving a stationary tool such as a pump), it is essential to: - Position the tractor on flat, horizontal and stable ground. - Set the tractor's transmission to neutral. - Apply the handbrake. - Chock the wheels of the tractor. - Make the application safe: To prevent accidents, ensure that suitable protection is available on parts which present a risk. - Monitor continuously.

6.1.7.6 Work with tools driven by the power take-off

5763

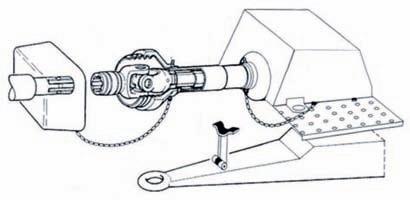

- Do not wear loose-fitting clothing. Loose-fitting clothing could be caught by moving parts. - Before performing any operations (repair work, adjustments, lubrication, etc.) on the hitched tool or on the universal drive shaft of the hitched tool: - Immobilise the tractor safely. - Stop the power take-off. - Stop the tractor engine. - Ensure that nobody comes near to the rotating universal drive shaft. - Check regularly that there is enough free space around the universal drive shaft to enable the universal drive shaft to move freely without making contact with peripheral components. Configuring the upper stop of the front/rear linkage may make it possible to prevent interference. - Do not force the universal drive shaft to follow excessive angles. Configuring the upper stop of the front/rear linkage may help to prevent these angles from being reached. Be particularly careful: - When manoeuvring at the end of the field. - When raising or lowering the front/rear linkage.

001hsn37

- When starting the tractor, the power take-off may perform several rotations. Ensure that there is nobody in the area surrounding the tractor or the hitched tool. - To use the power take-off, all of the power take-off protection devices must be positioned correctly: 1 - Protection shield (Tractor side). 2 - Cardan shaft protection. 3 - Protection casing (Tool side). 4 - Device maintaining the protection (2) in position. - Any faulty element of the protection device must be changed immediately. - Check that all the elements protecting the universal drive shaft overlap - Observe the sliding length of the cardan shaft. - Carefully turn the tractor's wheels fully: The tyre studs should not touch the protection devices of the universal drive shaft. - If it is no longer necessary to use the power take-off: - Stop the power take-off. - Remove the universal drive shaft from the tractor's power take-off and attach it to the tool. - Refit the protective sleeve onto the power take-off fitting. - After disengaging the power take-off, the tool may continue turning due to momentum. Wait for the tool to be completely stopped to approach the tool. - Check that the speed and rotation direction of the tractor’s power take-off match the speed and rotation direction accepted by the tool to be driven.

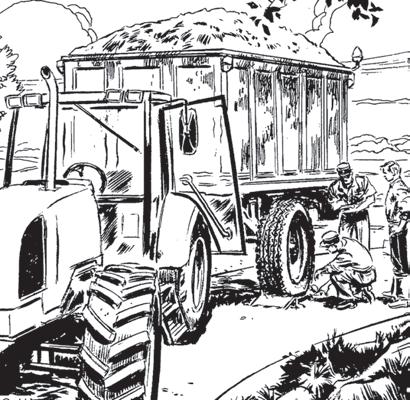

6.1.7.7 Severe applications

1

4 2 3

461msn00m

Always call a CLAAS approved dealer when planning severe use (e.g. twinning, transport with public works trailor, use of combined tools, etc.) to check the availability of reinforced wheels, and if required request their installation.. Subsoilers,subsoilers and ditchers and trench ploughs always work at great depth. Their use requires high tractive forces and often causes considerable overloading which, in the long term, can damage your tractor. To use your tractor normally: - Carefully adjust the tractor's ballast. - Never exceed the load capacity of the tractor.