2 minute read

Check

4. Remove oil filter (7). After you remove the oil filter, discard the oil filter. The oil filter will contain oil. 5. Clean the housing base for the oil filter. Make sure that all of the old filter seal has been removed. 6. Apply a thin film of clean oil to the seal of the new oil filter. 7. Install the new oil filter hand tight until the seal of the oil filter contacts the base. Note the position of the index marks on the filter in relation to a fixed point on the filter base. Note: There are rotation index marks on the oil filter that are spaced 90 degrees or 1/4 of a turn away from each other. When you tighten the oil filter, use the rotation index marks as a guide. 8. Tighten the oil filter according to the instructions that are printed on the filter. Use the index marks as a guide. For non-Caterpillar filters, refer to the installation instructions that are provided by the supplier of the filter.

Note: You may need to use a Caterpillar strap wrench, or another suitable tool, in order to turn the filter to the amount that is required for final installation. Make sure that the installation tool does not damage the filter.

Reference: Refer to Operation and Maintenance Manual, "Transmission and Hydraulic System Oil Level - Check" for additional information. 9. Tighten hydraulic tank filler cap (6). 10. Close the protection cover.

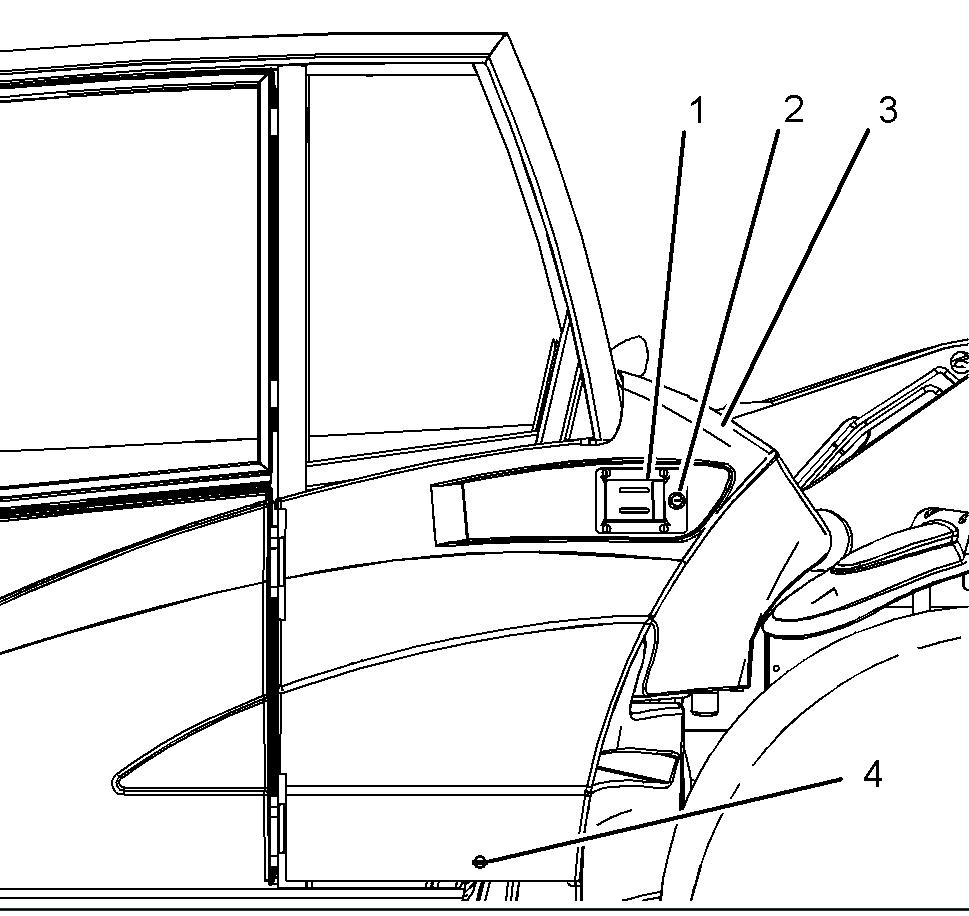

Before you check the level of the hydraulic oil, perform the following procedures: • Park the machine on a level surface. • Retract the boom. • Lower the work tool to the ground. • Fully raise the stabilizers.

Illustration 295 g01202853

An oil level gauge is located behind protection cover (3) on the left side of the machine. In order to open the protection cover, unlock lock (2) and turn lock (4) counterclockwise. Then, pull latch (1) outward.

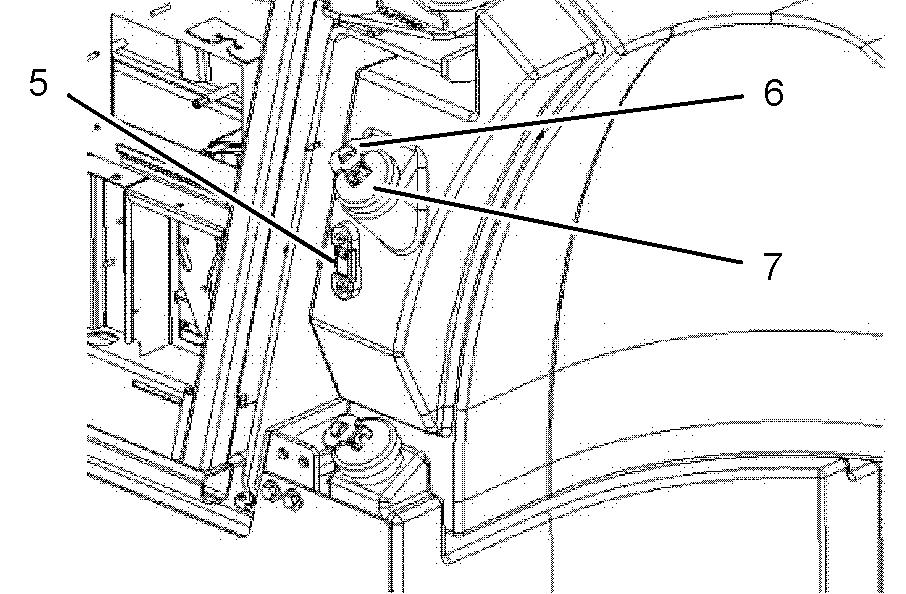

Illustration 297 g01205930 SLE3000-UP

Note: Run the machine for at least five minutes in order to pressurize the hydraulic system.

You should look at oil level gauge (5) in order to check the level of oil in the hydraulic system. The oil level of the hydraulic system is correct when the oil level has reached the line that is marked "MAX" or if the oil level is halfway between the red line and the blue line on the oil level gauge. If necessary, add Caterpillar TDTO to the correct oil level by the following method: 1. Lift latch (6), and loosen hydraulic tank filler cap (7) slowly in order to relieve the pressure in the hydraulic system. Remove the hydraulic tank filler cap. 2. Top up the hydraulic oil to the required level and install the hydraulic tank filler cap. Clean up any oil that has spilled. Refer to Operation and