1 minute read

Conveyor Push Distance Behind Advanced Shields

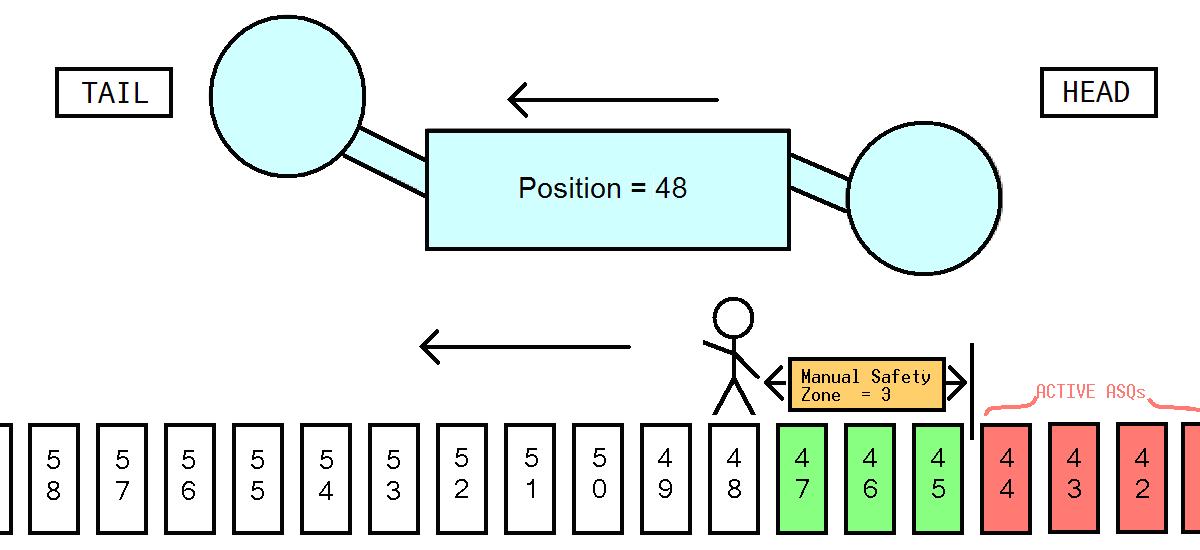

The shields will advance to within a certain distance from the shearer position set by the operator. That distance is determined by the parameter “Manual Safety Zone”. If this is set to 2, then there will be 2 shields between the operator and the shields that advance.

Parameter “Manual Safety Zone”

When running in this mode there is no safety zone around the shearer to protect the operators. The shield operator will determine how close to the shearer that the shields are allowed to advance by determining when and where to enter a new shearer position. Any automatic functions are allowed around the shearer. As can be seen from the picture below, increasing the size of the manual safety zone allows the operator to move further toward the center of the machine and still advance shields in the same location in relation to the drum or shearer operator. This is very flexible and will allow the operator to stand at a preferred location to stay out of the dangers of the shearer and the dust.

After shields advance, the conveyor must be pushed. There must be some distance between the shields that are not advanced yet and the shields where the conveyor is pushing. This is so the pushing effect of the conveyor will not move the relay bars on a shield that is not yet advanced. If this happened it could possibly cause a pan connection pin to become overstressed. This distance is set by SRB parameter “Push