1 minute read

Roller Circle Assembly

Stored Energy Decals

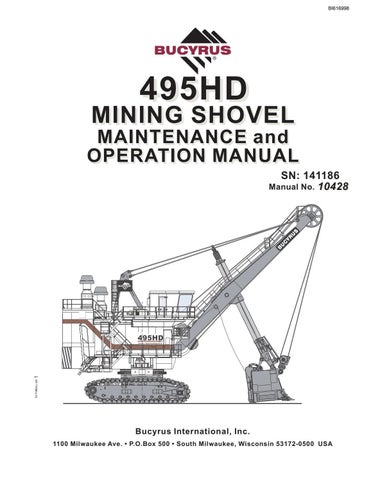

MACHINE OVERVIEW

This Mining Shovel is designed and constructed to provide efficient service under the most severe conditions. The machine is built to the highest possible standards and will provide trouble free operation if properly maintained. This section of the manual introduces the machine and its functional capabilities and limitations.

LOWER WORKS

The lower works is comprised of the truck frame, right and left crawler frames, crawler belts, propel machinery, swing rack and roller circle.

Truck Frame and Crawlers

CRAWLERS

This machine is provided with a crawler system composed of 2 independently-driven crawler frame assemblies, one on each side of the truck frame. Each crawler has its own belt driven by a sprockettype drive tumbler. Individual crawler links are heavy alloy steel castings connected by heat treated pins.

Innovative drive tumblers made from large diameter steel castings have lugs extending beyond the tumbler rims. They are mounted on forged alloy steel shafts which turn on large anti-friction bearings mounted within the crawler frame. The sprocket type lugs provide a large area of contact against the crawler links, extending the life of both links and tumblers.

Lower rollers rotate on forged steel shafts mounted within the crawler side frames. Eight smaller rollers and 1 large roller per frame are specially suited to withstand the periodic single point ground reaction caused by uneven pit floors. Slide bars on top of each frame support the upper crawler belt, reducing propel friction and drag. These side frames are stress relieved weldments comprised of steel castings and cold weather steel plates.

The crawler assemblies are bolted to the truck frame with large diameter rods and torque nuts. Each crawler belt can be independantly adjusted for tension.

Right Crawler Assembly (Left Opposite)