1 minute read

Deck Plan

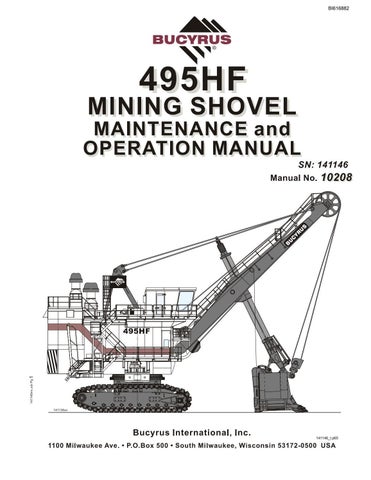

CRAWLERS

This machine is provided with a crawler system composed of 2 independently-driven crawler frame assemblies, one on each side of the truck frame. Each crawler has its own belt driven by a sprockettype drive tumbler. Individual crawler links are heavy alloy steel castings connected by heat treated pins.

Innovative drive tumblers made from large diameter steel castings have lugs extending beyond the tumbler rims. They are mounted on forged alloy steel shafts which turn on large anti-friction bearings mounted within the crawler frame. The sprocket type lugs provide a large area of contact against the crawler links, extending the life of both links and tumblers.

Lower rollers rotate on forged steel shafts mounted within the crawler side frames. Eight smaller rollers and 1 large roller per frame are specially suited to withstand the periodic single point ground reaction caused by uneven pit floors. Slide bars on top of each frame support the upper crawler belt, reducing propel friction and drag. These side frames are stress relieved weldments comprised of steel castings and cold weather steel plates.

The crawler assemblies are bolted to the truck frame with large diameter rods and torque nuts. Each crawler belt can be independantly adjusted for tension.

Right Crawler Assembly (Left Opposite)

TRUCK FRAME

The truck frame is a stress relieved welded cellular box structure which utilizes impact resistant steel in the major load carrying members. The low temperature toughness of the steel assures adequate strength and durability across a wide range of temperatures frequently encountered in machine applications. A fabricated support structure welded integrally into the truck frame supports the center pintle hub area.

The inner diameter of the hub is machined to accept the center pintle bushing. Truck frame surfaces which mate to crawler side frames and swing rack are shop machined to assure proper alignment and solid foundation.