2 minute read

Deck Extensions and Ballast Box - Plan View

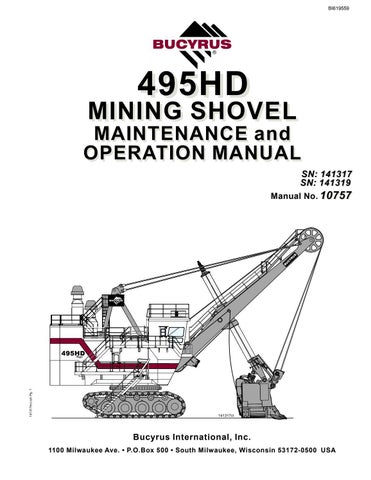

from CAT Electric Rope Shovel 495HD MIINIINNG SHOVEL MAINTENANCE and OPERATION MANUAL - PDF DOWNLOAD

Cast take-up tumblers are mounted on each end of the take-up axle. These tumblers are fitted with manganese-bronze bushings protected by a sealed hubcap. A vee-ring face seal protects the take-up bushing from dirt contamination.

A square take-up axle fits into rectangular slots in the crawler frame which permits the axle to be moved forward and backward for belt adjustment. Shims are inserted fore and aft of the axle in these slots to position, tension and locate the tumbler and crawler belt.

Crawler & Truck Frame Section View

TRUCK FRAME

The truck frame is a stress relieved welded cellular box structure which utilizes impact resistant steel in the major load carrying members. The low temperature toughness of the steel assures adequate strength and durability across a wide range of temperatures frequently encountered in machine applications. A fabricated support structure welded integrally into the truck frame supports the center pintle hub area.

The inner diameter of the hub is machined to accept the center pintle bushing. Truck frame surfaces which mate to crawler side frames and swing rack are shop machined to assure proper alignment and solid foundation.

SWING RACK

The swing rack is a large diameter external tooth gear mounted on the top of the truck frame concentric with the center pintle bore. The rack is constructed of a one-piece forged steel rim welded to a cast support core and welded to the truck frame during erection.

Swing Rack and Roller Circle

ROLLER CIRCLE

The roller circle is comprised of upper and lower rails, 56 tapered rollers and inner/outer roller frames. Lower rail segments are secured to the top surface of the swing rack forming a continuous rolling path for the rollers. Upper rails attach to the bottom of the revolving frame, fore and aft of the center pintle. Upper rail ends are tapered to provide a smooth approach for the rollers. Rollers are tapered to ensure non-skid contact with rails. The rollers are spaced and aligned with pins and low maintenance polyurethane bushings.

Roller Circle Assembly

PROPEL MACHINERY

The propel machinery is driven by two AC motors, each horizontally mounted to a shelf, cantilevered off the truck frame. The motors are coupled to twin planetary gearcases high up off the pit floor for protection from water and rock damage. The planetary gearcases bolt to the crawler frames. One low-inertia, spring-set, air-released, disc-type air brake is mounted to each of the two motors. The dual planetary configuration with separate drive motors permits straight ahead or reverse propel as well as counter rotation steering.