304 minute read

TYPICAL MACHINE SPECIFICATIONS

COMPONENT WEIGHTS

Weight Ea. Qty. (Lbs.) BASE FRAME ASSEMBLY (Tub) ...........................................................948,400 Center Section...................................................................1...................102,350 Intermediate Inner Section .................................................2.....................51,100 Intermediate Outer Section................................................2.....................22,030 Rail/Gear Segment Section...............................................5.....................58,150 Base Frame Outer Section (typ.)......................................7.....................42,960 Base Frame Outer Sect, Elec...........................................1.....................43,070 Center Journal Pin.............................................................1.......................8,600 Roller Circle Assembly......................................................1.....................58,550 Roller ...............................................................................143........................330 Rail Segment (typ.)...........................................................24......................2,300 Gear Segment (typ.).........................................................18......................6,300 Thrust Rail Segment (typ.)................................................24.........................170 ROTATING FRAME ASSEMBLY ......................................................... 1,820,300 Hook Shoe .........................................................................2.....................13,150 Main Collector Rings..........................................................1.......................3,180 House Rear Door Assembly..............................................4.....................19,500 Air Filter..............................................................................5.......................6,820 Air Cleaner, Filter............................................................5..........................300 M.G. Set.............................................................................2...................172,800 Air Compressor.................................................................1.......................1,200 Deck Winch.......................................................................2.......................2,050 Auxiliary Transformer .........................................................1.....................12,600 Lighting Transformer..........................................................1..........................750 Switch Panel Board, Main..................................................1..........................600 Motor Control Center.........................................................1.......................5,000 Air Conditioner / Heater (Cab)............................................1..........................900 Generator...........................................................................1.......................8,950 Water Tank.........................................................................1..........................800 Ballast................................................................................1...................690,000

ROTATING MACHINERY

Rotating Gearcase Assembly............................................4.....................22,000 Main Rotating Shaft............................................................4.......................9,450 Pinion, Main Rotating .........................................................4.......................2,300 Coupling, Swing.................................................................4..........................425 Rotating Motor....................................................................4.....................15,700 Motor Brake, Swing............................................................4.......................1,450

Weight Ea. Qty. (Lbs.)

HOIST/DRAG MACHINERY

Hoist/Drag Gearcase Assembly........................................2...................118,500 Gearcase Structure, 4-Motor.............................................2.....................63,900 Gearcase Cover................................................................4.......................2,900 Hoist/Drag Drum Shaft Assembly......................................2...................153,000 Hoist/Drag Drum Gear.......................................................2.....................30,950 Drum Lagging....................................................................4.....................37,260 Drum End, Hoist/Drag.......................................................4.....................31,700 Bearing Housing, Intmd. Shaft...........................................4.......................3,130 Bearing Housing, Drum Shaft............................................4.......................5,160 Intermediate Pinion ............................................................4.......................5,000 Intermediate Shaft..............................................................4.......................8,860 First Intermediate Gear......................................................4.......................6,250 Motor Extension Shaft........................................................8..........................500 Gear Guard........................................................................2.......................1,000 Hoist/Drag Motor................................................................8.....................15,700 Motor Brake, Hoist/Drag.....................................................8.......................1,200

PROPEL MACHINERY

Walking Shoe.....................................................................2...................183,950 Walking Arm.......................................................................2.....................72,100 Stabilizer Link.....................................................................2.......................8,310 Pin, Arm to Stabilizer..........................................................2.......................5,350 Pin, Stabilizer to Frame.....................................................2.......................8,320 Shaft, Walking Shoe..........................................................2.......................6,560 Main Propel Shaft...............................................................2.....................32,530 Main Propel Gear ...............................................................2..................... 48,110 Gear Hub ...........................................................................2.....................12,530 Cam, Eccentric, Walking...................................................2.....................42,830 Main Propel Pinion Shaft Assembly...................................2.......................8,450 Main Propel Pinion Shaft....................................................2.......................5,000 Propel Gearcase................................................................2.....................42,360 Gearcase Structure...........................................................2.....................20,170 Gearcase Cover................................................................2.......................6,620 1st Intermediate Gear........................................................2.......................3,700 1st Intermediate Shaft........................................................2.......................1,630 2nd Intermediate Gear .......................................................2.....................11,460 2nd Intermediate Shaft.......................................................2.......................4,700 Motor Extension Shaft........................................................2..........................400 Propel Motor ......................................................................2.....................15,700 Motor Brake, Propel...........................................................2.......................1,200

Weight Ea. Qty. (Lbs.) FAIRLEAD ASSEMBLY.....................................................1...................306,020 Fairlead Structure..............................................................1...................151,100 Pin, Fairlead Foot...........................................................2..........................900 Backleg, Fairlead...............................................................2.......................9,000 Pin, Backleg, Upper.......................................................2.......................1,000 Pin, Backleg, Lower.......................................................2..........................410 Swivel Sheave Assembly, Lower.......................................2.....................42,300 Swivel Frame Assembly, Lower.........................................2.....................24,700 Swivel Frame.................................................................2.....................24,050 Shaft, Lower Swivel.......................................................2.......................3,700 Pin, Swivel Frame..........................................................4.......................1,050 Swivel Sheave Assembly, Upper.......................................2.....................18,750 Sheave, Fairlead Upper/Lower......................................4.....................12,150 Shaft, Upper Sheave Assembly.....................................2.......................4,900 Snubber, Lower Fairlead....................................................2..........................300 Snubber Collar Plate, Fairlead...........................................4..........................270 TRI-STRUCTURE ASSEMBLY ..............................................................573,350 Structure Assembly............................................................1...................355,380 Backleg..............................................................................2.....................70,900 Hoist Deflecting Sheave Assembly....................................2.....................18,150 Backleg Safety Rope.........................................................2.......................8,390 Boom Raising Sheave Assembly......................................4.......................6,330

BOOM ASSEMBLY (Less Walkways)

Boom Structure..................................................................1...................580,400 Boom Structure, Point.......................................................1.....................68,730 Boom Structure, Center.....................................................1...................395,650 Boom Structure, Foot-Left/Right........................................2..................... 30,520 Boom Point Sheave Assembly..........................................1.....................51,120 Boom Point Shaft...........................................................1.......................5,680 Boom Point Sheave.......................................................2.....................12,150 Trunnion, Boom Point Sheave...........................................1.....................11,600 Bearing Block, Trunnion - Rear......................................1.......................4,440 Bearing Block, Trunnion - Front.....................................1.......................1,400 Boom Support Rope Assembly.........................................2.....................38,770 Boom Support Rope Pendant............................................4.....................10,000 Intermediate Suspension Pendant.....................................2.......................2,120 Intermediate Suspension Adjuster.....................................2.......................2,350 Hoist Rope.........................................................................2.....................24,720 Guard, Hoist Rope, Boom point.........................................1..........................730 Drag Rope.........................................................................2.....................17,180

TYPICAL MACHINE SPECIFICATIONS

This specification describes the principal mechanical features of a standard Bucyrus International, Inc. 8200 Walking Dragline. NOTE: THESE ARE TYPICAL MACHINE SPECIFICATIONS.

WORKING RANGES

Boom Length ································································································ 355'-0" @ 34.25o ······························· 102.1 M Boom Point Sheave, Pitch Diameter················································································· 120" ················3353 cm A Boom Angle, Approx.····························································································34.25o ···································· 34.25o B Dumping Radius ··································································································· 287'-0" ····················87.5 M C Dumping Height ···································································································· 167'-0" ····················50.9 M D Depth ···················································································································· 197'-0" ····················60.0 M

Maximum Allowable Load ··············································································385,000 lb. ···········249,425 kg.

Hoist Drum, Pitch Diameter······················································································· 100" ················3048 mm

Hoist Ropes, Twin, Single Hitch, Diameter····························································· 4.00" ···············111.1 mm

Drag Drum, Pitch Diameter······················································································· 100" ················3048 mm

Drag Ropes, Twin, Single Hitch, Diameter······························································ 4.00" ···············111.1 mm

BASE

E Outside Diameter, Nominal ····················································································· 67’-0" ····················20.9 M

Bearing Area, Effective ······················································································3685 ft2 ····························· 342.3 m2

Bearing Pressure ······························································································· 19.0 PSI ········1.34 Kgs./cm2

Rail Circle, Mean Diameter····················································································· 50'-0" ····················15.2 M

Circle Rollers, Mean Diameter····················································································12"·················30.5 cm

Main Swing Gear, Pitch Diameter, Approx.···························································· 40'-5" ·················12.32 M

WALKING TRACTION

F Width of Shoe········································································································ 13'-0" ·························4.0 G Length of Shoe······································································································ 70'-0" ······················· 21.3 H Width over Both Shoes·························································································· 97'-0" ······················· 29.6

Bearing Area of Both Shoes·············································································· 1820 ft2 ····························· 169.1 M2

Bearing Pressure @ 80% of Working Weight··················································· 30.8 PSI ········2.17 Kgs./cm2

Length of Step, Approx.··························································································· 7'-6" ······················2.3 M

ROTATING FRAME

J Width @ Rear End································································································· 77'-4" ····················23.6 M K Length ·················································································································· 101'-0" ····················30.8 M

Depth Sill Members·································································································· 106" ·············2629.4 cm L Clearance Radius, Rear End ················································································· 78'-0" ····················23.8 M M Clearance Under Frame··························································································· 8'-5" ······················2.6 M N Center Rotation to Boom Foot················································································ 21'-6" ······················6.6 M P Ground to Boom Foot····························································································· 15'-6" ······················4.7 M

WEIGHTS

Domestic Shipping Weight (Inc. Bucket)·····························································9,244,000 lb.·········4,193,000 kg Working Weight. ································································································10,104,000 lb.·········4,583,000 kg Ballast (Furnished by Customer) ···········································································860,000 lb.············390,000 kg Shipping Weight Subject to 5% Variation.

BI616884

Section 2 Operation

Table of Contents

GENERAL INFORMATION ............................................................................................................3 8200 Nomenclature .....................................................................................................................3 Deck Plan ...................................................................................................................................4 OPERATOR’S CAB AND ANTEROOM.........................................................................................5 Operator’s Cab - Anteroom..........................................................................................................5 OPERATOR’S CONTROLS ...................................................................................................6 PRIMARY CONTROLLERS..........................................................................................................7 Operator’s Seat ...........................................................................................................................7 PLUGGING THE MOTION .......................................................................................................9 SECONDARY CONTROLS..................................................................................................10 Operators Controls .....................................................................................................................10 Left-hand Operator’s Controls .....................................................................................................11 Right-hand Operator’s Controls ...................................................................................................13 WINDSHIELD WIPER...........................................................................................................15 Windshield Wiper Assembly Operator’s Cab..............................................................................15 OPERATOR’S DISPLAY.............................................................................................................16 OPERATOR’S DISPLAY IN THE CAB...................................................................................16 Operator’s Display ......................................................................................................................16 DISPLAY AREA & INDICATORS......................................................................................17 CAB DISPLAY SCREENS.....................................................................................................17 Operator’s Cab Title Screen.......................................................................................................17 Operator’s Main Menu Screen.....................................................................................................18 Display Information Screen ........................................................................................................18 Active Alarms Screen................................................................................................................19 Alarm History Screen .................................................................................................................19 Walking Shoe Positions and Error Screen .................................................................................20 Hoist/Drag Limit Calibration Screen ...........................................................................................20 Walking Shoe Encoder Calibration Screen ................................................................................21 Fault Counters and Operating Hours Screen ..............................................................................21 Tightline Parameters & Operating Data Screen ..........................................................................22 Operator’s Screen ......................................................................................................................22 Maintenance Menu Screen .........................................................................................................23 Master Switch Calibration Screen ...............................................................................................23 POWER CONTROL ROOM (PCR) DISPLAY SCREENS....................................................24 Power Control Room Screen ......................................................................................................24 Power Control Main Menu Screen ...............................................................................................24 Set Panel Date/Time Screen......................................................................................................25 Communications and I/O Screen ...............................................................................................25 Electrical Menu Screen ..............................................................................................................26

HOIST/DRAG LIMIT CALIBRATION.......................................................................................27 HOIST LIMIT ....................................................................................................................27 DRAG LIMIT.....................................................................................................................28 OPERATOR CONTROLS IN THE MACHINERY HOUSE...........................................................29 Power Control Room ..................................................................................................................29 MACHINERY HOUSE REAR DOORS..................................................................................31 MACHINERY HOUSE REAR DOORS ........................................................................................32 DOOR OPERATION.......................................................................................................33 DOOR OPERATING SEQUENCE..................................................................................34 CONTROL PANEL for the HOUSE REAR DOORS ....................................................................34 PRE-START INSPECTION.........................................................................................................36 TYPICAL START-UP...................................................................................................................37 TYPICAL DIGGING CYCLE .........................................................................................................39 OPERATOR’S CONTROLS ........................................................................................................39 GROUND PREPARATION ..........................................................................................................41 WALKING/PROPEL OPERATION...............................................................................................42 WALKING MACHINERY.........................................................................................................42 WALKING MACHINERY CONTROL......................................................................................43 WALKING ..............................................................................................................................44 SHUTDOWN...............................................................................................................................47 PARTIAL SHUTDOWN..........................................................................................................47 COMPLETE SHUTDOWN....................................................................................................47

Section 2 Operation

GENERAL INFORMATION

This section of the manual is designed to assist the owner in the operation of this machine. It provides the operator with the location and explanation of the controls, instructions for machine operation, and certain maneuvering techniques.

Throughout this section, and the remainder of the manual, the use of the terms “LEFT, RIGHT, FRONT, and REAR” refer to machine locations as viewed by the operator sitting in the operator’s seat in the cab.

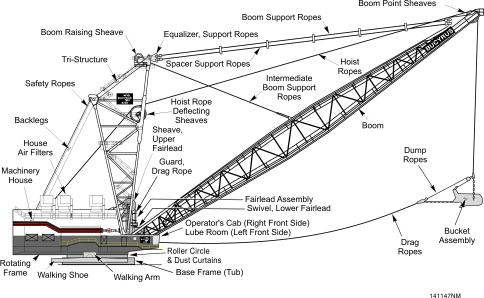

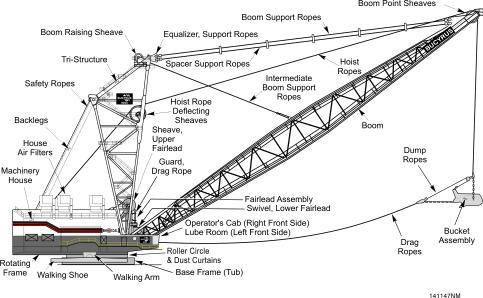

8200 Nomenclature

Deck Plan

OPERATOR’S CAB AND ANTEROOM

The Operator’s Cab and Anteroom extend from the right front corner of the rotating frame. This position provides the operator with an unobstructed view of the pit and spoil area, plus the boom point and bucket. The cab and anteroom area provides a controlled environment for the operator, crew, and electronic equipment.

Operator’s Cab - Anteroom

The cab contains the controls, switches, and indicators necessary for machine operation. These machine controls have been positioned in the cab to provide the operator with comfortable operation of the primary controls and easy access to all the secondary controls.

The operator’s cab has two video monitors linked to seven closed circuit television camera’s located strategically around the machinery house. This will provide the operator with the ability to see in locations normally not visible while facing the work area.

The operator’s cab has a phone system connected to receivers located at strategic points inside the machinery house and around the machine. This system provides easy communication between persons in the cab and elsewhere about the machine.

A combination heater-defroster/air conditioning unit is mounted on the cab roof. Ducts from it to the floor area surround the operator for comfort and visibility. The control for this unit is on forward side of the operators cab rear wall.

The ceiling, walls and floor of both rooms are insulated. Adequate lighting is provided and the control switches are conveniently placed. The ceiling and walls are easily made of a stainless material and are easy cleaned. The floor covering deadens sound and is easily maintained.

CAUTION: There is a drop from the cab floor to the walkway on the outside of the cab.

The front windshield is sloped out at top to reduce reflection, dirt adherence, and rain streaks. The safety-glass area extends from the cab floor to almost ceiling level for boom and ground visibility.

OPERATOR’S CONTROLS

The operating controls for this machine are all grouped around or are a part of the operator’s station in the cab. The machine start-up controls are located inside the machinery house.

The operator’s seat has adjustments for positioning it to the best location to suit individual operators. The operator should always adjust the seat to suit before taking over the controls. See the adjustment procedure following later in this section.

DANGER: DO NOT ATTEMPT TO OPERATE THIS MACHINE UNLESS YOU UNDERSTAND ALL THE MACHINE CONTROLS. NEVER LEAVE THE OPERATOR’S SEAT WITHOUT FIRST SETTING ALL MOTION BRAKES AND “DROPPING OUT” (DE-ENERGIZING) LINE EXCITATION BY PUSHING THE EXCITATION STOP PUSHBUTTON.

The machine’s operating motions - HOIST, DRAG, PROPEL and SWING - are controlled by the operator using the 2 Joysticks positioned on the right and left armrests of the operator’s seat. These are the primary controls. Moving any of these off their neutral position, when the drives are activated, will initiate motion.

The secondary controls are mounted in the console on each side of the operator. They are the necessary lights, switches, pushbuttons, and controller programs to support the primary controls. Also located here are components that signal the operator and announce faults in selected systems on-board.

PRIMARY CONTROLLERS

The 2 primary controllers for machine operation are the manually-operated joysticks (masterswitches) situated on each side of the operator’s seat. NONE OF THE MACHINE MOTION CONTROLS ARE OPERABLE UNTIL LINE EXCITATION HAS BEEN ACTIVATED AND ENGAGED, as is indicated by the green light in the excitation start pushbutton on the Operator Console.

For emergency exits, there is a smaller door located on the right side of the cab, just behind the operator’s seat. This door can be opened from either inside or outside the cab, by pushing down on the handle.

Operator’s Seat

The LEFT JOYSTICK operates the drag or propel machinery, depending on the machine drive mode selected.

• When in the DRAG mode: moving the left joystick forward from its neutral will result in the drag ropes “paying out” off the drum and the bucket will move away from the machine.

•Moving the left joystick rearward from its neutral position will cause the drag ropes to wind onto the drum and the bucket will “drag in” (move toward the machine).

•The Hoist Tension pushbutton, on top of the left joystick, applies reduced hoisting power to the hoist drum (to remove hoist rope slack and to hold the rigging off the bucket while dragging).

• When in the PROPEL mode: holding the left joystick in its FULL FORWARD position from its neutral results in the shoes going through their walking step and propelling the machine in the direction away from the boom (front end).

•Moving the left joystick rearward from its neutral position when in propel is done ONLY to back up the shoes as needed to place them in their top dead center location after a step has been completed.

THE MACHINE WILL NOT PROPEL TOWARD THE BOOM. Refer to WALKING MECHANISM, in this section.

The RIGHT JOYSTICK operates the hoist machinery (fore and aft lever movement) as well as swing motion (left and right movement). The hoist control is activated during DRAG mode.

•Moving the right joystick forward from its neutral will result in the hoist ropes unwinding from the drum and the bucket will lower toward the ground.

•Moving the right joystick rearward from its neutral position will cause the hoist ropes to wind onto the drum and the bucket will be raised toward the boom point.

•The pushbutton on top of the joystick is for the air horns.

The RIGHT JOYSTICK also controls machine rotation. Moving the lever to the RIGHT rotates the entire machine to the right. Moving the lever to the LEFT rotates the entire machine to the left. When no pressure is applied to the controller, it automatically returns to the neutral position.

The hoist and drag drives are speed controlled. This means that the further the joystick is moved fore or aft from its neutral position, the faster the drive will go. Practically full torque (or line pull) is obtained with the slightest movement of the joystick from its neutral. Lever movement should be only enough to obtain the desired speed. Never move either hoist or drag joystick too far and then back it off. Always use a smooth, steady lever movement. “Jockeying” the joystick is not required and only results in machinery overuse and motor overheating.

The swing drive is torque controlled. This means that the further the controller is moved, the more torque the swing drive will develop, thus increasing the machine’s swing-acceleration rate. Full swing speed is obtained at any position of the controller. THIS CONTROL SHOULD NOT BE “JOCKEYED” DURING OPERATION.

PLUGGING THE MOTION

PLUGGING machinery motion is the use of motor torque, applied in the opposite direction of motor rotation, to slow or stop the motion. This process is recommended only on the swing motion on this machine. Plugging is accomplished when the operator positions the controller to swing the machine in the opposite direction of the current machine rotation. As the machine slows to a stop, the amount of plugging effort is gradually reduced to provide a smooth stop. Continued plugging effort will reverse the direction of the motion. Plugging rapidly dissipates the energy of heavy moving parts by regenerating into the power source. When the hoist or drag controllers are returned to neutral with the machinery in motion, the motions automatically plug to slow the machinery. Only a small amount of plugging is required for the hoist and drag motions.

SECONDARY CONTROLS

The secondary controls are located on the control panels beside the operator. They consist of the necessary lights, switches, and pushbuttons to support the primary controls. A fault warning buzzer, and a signal bell notify the operator of potential machine problems or get his attention. The phone set for the operator is mounted on the OIT stand behind the operator. Two pairs of jacks are located on the left side of the stand. They are wired into the Power Control Room and used to monitor the circuits for boom lowering, etc.

Operators Controls

Left-hand Operator’s Controls

The following items are on the LEFT CONTROL PANEL

1. EARTH CONTINUITY LOCKOUT - 2-position, lockable, pushbutton used for Ground Test / Lockout.

2. WINSHIELD WIPERS, LEFT - (On, Off) A 2-position selector switch for controlling the wiper assembly on the left-front cab window.

3. WINSHIELD WIPERS, FRONT - (On, Off) A 2-position selector switch for controlling the wiper assembly on the front cab window.

4. WINSHIELD WIPERS, RIGHT - (On, Off) A 2-position selector switch for controlling the wiper assembly on the right-front cab window.

5. SHOE PARK - (Set, Release) A green illuminated pushbutton used to initiate the automatic parking function. When lit it will indicate that the walking shoes are in their PARKED position. See OPERATING WALKING MECHANISM in this section.

6. ROPE LIMIT BYPASS - A pushbutton used to back out of a final hoist, drag or tightline limit. A light will flash when in a first stage limit and be steady on a shutdown.

7. TEMPERATURE - (Cold to Hot) A rheostat used to set the desired temperature for the operator’s cab heater / air conditioner unit.

8. HVAC - (Vent, Heat, Cool, De-Mist) A 4-position selector switch used to set the heating / cooling mode for the operator’s cab heater / air conditioner unit.

9. HVAC FAN SPEED - (Off, Low, High) A 3-position selector switch used to set the fan speed for the operator’s cab heater / air conditioner unit.

10. CABIN LIGHTS - A 3-way dimmer switch used to control the interior cab lights.

The following items are located on the RIGHT CONTROL PANEL:

1. EMERGENCY STOP - A red mushroom type pushbutton that will set ALL brakes and deenergize ALL controllers on the machine when pressed.

2. MACHINE SHUTDOWN - A red flush-mounted pushbutton used to initiate machine shutdown.

3. HOIST BRAKE - A green light that indicates when the HOIST brakes are set.

Right-hand Operator’s Controls

4. DRAG BRAKE - A green light that indicates when the DRAG brakes are set.

5. SWING BRAKE - A green light that indicates when the SWING brakes are set.

6. PROPEL BRAKE - A green light that indicates when the PROPEL brakes are set.

7. DRAG MODE - A green light that indicates the machine is in DRAG mode.

8. PROPEL MODE - A green light that indicates the machine is in PROPEL mode.

9. EXCITATION STOP - A pushbutton that DE-ENERGIZES the hoist, drag and swing controllers and also the solenoid circuits.

10. HOIST BRAKE - (Set, Release) This switch sets or releases the HOIST brakes.

11. EXCITATION START / FAULT RESET - A green illuminated pushbutton that ENERGIZES the hoist, drag and swing controllers and also the solenoid circuits. It is also used to clear all faults after the problem has been solved.

12. DRAG BRAKE - (Set, Release) This switch sets or releases the DRAG brakes.

13. PROPEL TRANSFER - (Drag, Propel) A 2-position switch to transfer the machine betwen

DRAG mode and PROPEL mode.

14. SWING BRAKE - (Set, Release) This switch sets or releases the SWING brakes.

15. AIR COMPRESSOR - (Off, On) A 2-position selector switch to turn the air compressor on or off.

16. PROPEL BRAKE - (Set, Release) This switch sets or releases the PROPEL brakes.

17. SEAT CONSOLE POSITION - (Left to Right) A selector switch used to adjust the left-to-right position of the operator’s seat.

NOTE: The motion brakes are HOLDING BRAKES ONLY and are not intended to retard or stop any drive motion EXCEPT in an emergency situation. See Plugging the Motion. Always bring any drive motion to a halt before applying these brakes.

WINDSHIELD WIPER

Windshield Wiper Assembly Operator’s Cab

The cab’s front window assembly is equipped with an electric powered wiper to assist with visibility in inclement weather. Its control is on the console next to the operator.

The wiper control is located on the LEFT control console. The wiper motor and gear reducer mounts on the upper right hand corner on the inside of the window. Adjust the rod from the gear reducer to center the wiper blade on the window.

Maintain pressure of the wiper on the glass with the adjusting nut on the spring rod located at the top of the wiper arm on the outside of the window.

OPERATOR’S DISPLAY

OPERATOR’S DISPLAY IN THE CAB

The Operator’s Display is a CTR panel used to provide the operator with an interface to the machine and it’s functional areas. From this informational display the operator can make inputs that effect machine operation, monitor systems and make system adjustments. Through this display terminal the operator will receive pertinent fault data to identify potential problems and prevent machine damage.

Operator’s Display

The display panel is mounted on a tilt-swivel bracket on the left side of the operator. Individual operators can position the screen in any desired position.

DISPLAY AREA & INDICATORS

The display area of the monitor screen is the large area in the center of the screen. This area is “touch sensitive.” All information will be displayed on this area in either a text format or in the form of visual icons. The buttons and icons that appear on the screen will respond to touching the screen in the appropriate area of the icon. These icons and buttons will react by activating the screen, switch activation or display information relevant to the icon.

All the machine controls can be found on the Operator’s Display Panel touch sensitive screen or the left and right Control Consoles of the operator’s seat.

CAB DISPLAY SCREENS

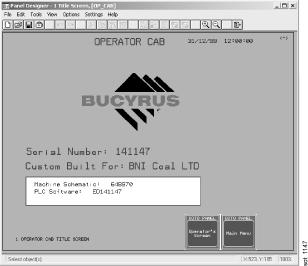

The Title Screen display appears when the machine is initially started.

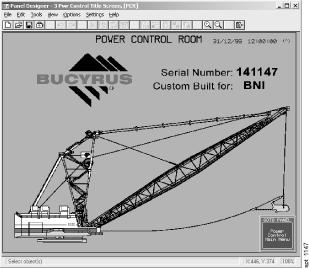

Operator’s Cab Title Screen

The information provided in the central area of the screen is machine specific and lists the machine serial number, the customer name and a listing of important documents and drawings associated with the machine.

The 2 buttons available, if touched, will cause the display to refresh with the information of the desired screen.

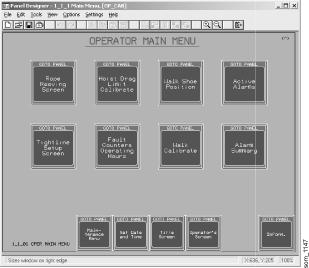

Operator’s Main Menu Screen The Main Menu screen will provide the operator with a choice of several buttons to select. Touching the screen in any of these button areas will cause the display to change to the requested option. Many of these screens will be displayed in the following pages. Several screens have an INFO button which will provide more detailed information concerning the functionality of listed buttons and switches.

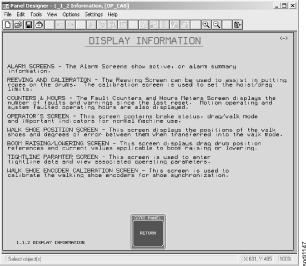

Display Information Screen The Main Menu Information screen provides information about the various display screen options available through the Main Menu screen.

Active Alarms Screen

The Active Alarm screen will provide a list of all active alarms and faults that have been initiated on the machine.

Alarm History Screen

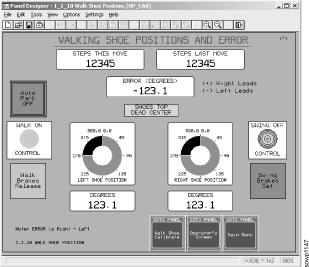

Walking Shoe Positions and Error Screen

Hoist/Drag Limit Calibration Screen

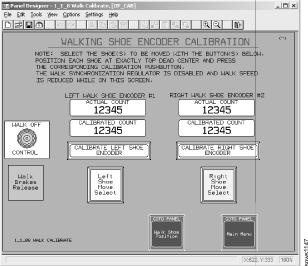

Walking Shoe Encoder Calibration Screen

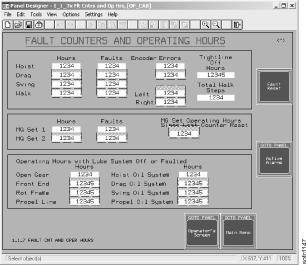

Fault Counters and Operating Hours Screen

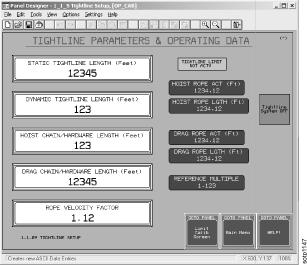

Tightline Parameters & Operating Data Screen

Operator’s Screen

The Operator’s Screen is the primary operational information tool to be visible to the machine operator during daily use of this machine. The controls available on this screen will provide the operator with the information needed to view “at a glance” the status of items required for digging and make changes in control settings.

Maintenance Menu Screen

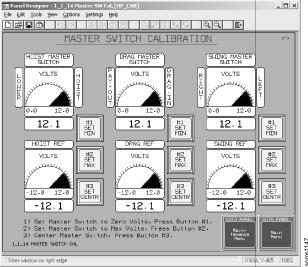

Master Switch Calibration Screen

POWER CONTROL ROOM (PCR) DISPLAY SCREENS

Power Control Room Screen

Power Control Main Menu Screen

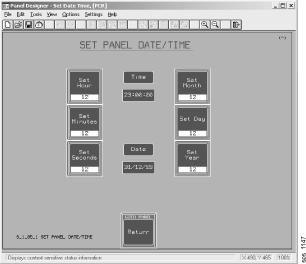

Set Panel Date/Time Screen

Communications and I/O Screen

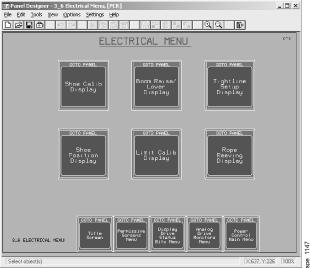

Electrical Menu Screen

HOIST/DRAG LIMIT CALIBRATION

An encoder attached to the end of the hoist and drag drum shafts continually monitors the drum position during operation. As the bucket nears the preset limits, reference is gradually removed until the drum rotation is stopped. To prevent tight-lining or pulling the bucket into the boom, the sum of the hoist and drag ropes payed out in monitored. If this sum reaches a preset length, the hoist or drag functions will be stopped.

The limits must be recalibrated after changing the ropes or anytime maintenance is performed which alters the encoder versus drum rotation. Recalibration is required on the function, hoist or drag, being serviced.

HOIST LIMIT

To set the hoist limit:

1. Select the main screen via the Operator’s display.

2. Tie a flag on the hoist rope 33 feet from the socket at the dump blocks and hoist the bucket until the flag touches the boom point sheave.

3. Set the hoist and drag brakes, turn excitation OFF.

4. Place the hoist controller in the HOIST position and turn the rope zero switch on the right console to HOIST. Hold for 5 seconds. The Rope Limit Bypass LED will flash then go solid. The HOIST rope display on the OIT will display 32.78 feet.

5. To set the hoist lowering limit, lower the bucket until 2 turns of rope remain on the drum. Repeat steps 2 and 3 above.

6. Place the hoist controller in the lowering position and turn the rope zero switch to HOIST. Hold for 5 seconds. The HOIST rope display on the Operator’s display will blink and then indicate the length of rope payed out in feet.

After completing the above steps, the upper and lower hoist limits are set and the machine can be returned to service.

DRAG LIMIT

To set the drag-in limit:

1. Select the main screen via the Operator’s display.

2. Tie a flag on the drag rope 33 feet from the crows-foot socket and drag in the rope until the flag touches the lower fairlead sheave.

3. Set the hoist and drag brakes and turn excitation OFF.

4. Place the drag controller to drag in and turn the rope zero switch to DRAG. Hold for 5 seconds. The Rope Limit Bypass LED will flash then go solid. The DRAG rope display on the OIT will display 32.78 feet.

5. To set the drag-out limit, payout the drag rope until 2 turns of rope remain on the drum and repeat steps 2 and 3 above.

6. Place the drag controller in the drag-out position and turn the rope zero switch to DRAG. Hold for 5 seconds. The DRAG rope display on the Operator’s display will blink and then indicate the length of rope payed out in feet.

After completing the above steps, the drag in and out limits are set and the machine can be returned to service.

OPERATOR CONTROLS IN THE MACHINERY HOUSE

Power Control Room

The Power Control Room (PCR) encloses the electrical control components, preventing contamination from dirt, grease and dust. The segregation of control components into a room type module centralizes the responsibility of the electrician, thus improving maintenance.

The Power Control Room is supplied with a constant source of clean, filtered air which is under pressure to afford the ideal environment for the efficient operation of the electrical components.

The Starting Panel Controls used by the operator to start up and shut down the machine are located in the machinery house, near the center of the rear wall of the Power Control Room (PCR).

The following are the controls on the Starting Panel:

1-4. MG SET NO. 1 Controls and Indicators:

1. FIELD APPLIED - A green light that indicates the MG set motor fields have been applied.

2. VCB CLOSED - A green light that indicates the Vacuum Circuit Breaker for the MG set motor has closed.

3. START - A green pushbutton to start the MG set.

4. STOP - A red pushbutton to stop the MG set.

5-8. MG SET NO. 2 Controls and Indicators (same as for MG SET no. 1).

9. PHASE SEQUENCE - A green light that indicates that the phase sequence is okay.

10. START CYCLE - A green pushbutton that indicates its okay to start the M.G. sets.

11. BLOWERS - A pushbutton used to start or stop the motor blowers. A green light indicates the blower is operating.

12. AIR COMPRESSOR NO. 1 - A 2-position (OFF/ON) blue selector switch to turn the air compressor off or on for automatic operation.

13. OIL PUMPS - A pushbutton used to start or stop the oil circulating pump motors. A green light indicates the motors are running.

14. PROPEL OIL PUMPS - A green light that indicates that the propel oil pumps are operating.

15. SPACE HEATER - A 2-position (OFF/AUTO) green selector switch which turns the anticondensation heater off or on for automatic operation.

16. EXHAUST FANS - A pushbutton used to start or stop the MG set motor cooling fans. A green light indicates the fans are operating.

17-21. FILTER FANS NO. 1-5 - A pushbutton used to start the bleed duct fans and after a 5 second delay start each of the main filter fans. A green light indicates that the main fans are operating.

MACHINERY HOUSE REAR DOORS

The rear doors of the machinery house consists of a set of 3 doors on each half of the rear wall. Each set of doors includes 1 top door, and a left and right side door. The doors are opened and closed by hydraulic cylinders, actuated by manual hydraulic valves, one for each door, located at the center of the rear machinery house wall. Refer to the figure on the following page.

Either set of doors or both can be opened, however each set must be opened in sequence and closed in the opposite sequence.

CAUTION: DO NOT ATTEMPT TO OPERATE THE REAR DOORS UNTIL THE GREEN LIGHT IN ILLUMINATED, INDICATING THE DOOR LATCHES HAVE BEEN RELEASED.

CAUTION: DO NOT OPEN OR CLOSE THE REAR DOORS OUT OF THE SEQUENCE SHOWN. FAILURE TO FOLLOW THE SEQUENCE WILL RESULT IN DAMAGE TO THE DOORS.

CAUTION: DO NOT OPERATE THE MACHINE (DIG OR PROPEL) WITH THE REAR DOORS OPEN.

CAUTION: DO NOT LEAVE THE REAR DOORS OPEN DURING INCLEMENT WEATHER. FAILURE TO FOLLOW THIS CAUTION MAY RESULT IN DAMAGE TO THE DOORS OR TO THE EQUIPMENT INSIDE THE MACHINE.

MACHINERY HOUSE REAR DOORS

DOOR OPERATION

(Refer to the nameplate located near the control panel on the rear wall.)

To OPEN one of the doors:

1. Press the START button on the control panel to activate the hydraulic system.

2. Press the UNLOCK button for the particular door to be opened. The green indicator light be lit.

3. Open the top door using Valve #1 on the same side of the machine as the door to be opened.

4. Open the inboard side door using Valve #2.

5. Open the outboard side door using Valve #3.

6. Press the STOP button on the control panel to deactivate the hydraulic system.

To CLOSE one of the doors:

1. Press the START button on the control panel to activate the hydraulic system.

2. Close the outboard side door using Valve #3 on the same side of the machine as the door to be closed.

3. Close the inboard side door using Valve #2.

4. Close the top door using Valve #1.

5. Press the LOCK button for the particular door to be closed. The green indicator light should go out.

6. Press the STOP button on the control panel to deactivate the hydraulic system.

DOOR OPERATING SEQUENCE

CONTROL PANEL for the HOUSE REAR DOORS

Items on the control panel:

1. START - A yellow pushbutton which starts the rear door hydraulic system.

2. STOP - A red mushroom head pushbutton which stops the rear door hydraulic system.

3. LEFT SIDE UNLOCK - A black pushbutton which releases the upper and lower door latches.

4. LEFT SIDE UNLOCK - A green light which, when lit, indicates that the door latches are released.

5. LEFT SIDE LOCK - A black pushbutton which sets the upper and lower door latches.

6. RIGHT SIDE UNLOCK - A black pushbutton which releases the upper and lower door latches.

7. RIGHT SIDE UNLOCK - A green light which, when lit, indicates that the door latches are released.

8. RIGHT SIDE LOCK - A black pushbutton which sets the upper and lower door latches.

PRE-START INSPECTION

Visual inspection of the machine should be performed by operator and oiler at the beginning of each shift. A potential problem may be prevented if discovered early.

The following check lists can be used to help with the inspection.

General (all areas of the machine):

•Are guards, cover plates and safety devices secured in place? •Are all loose pieces stored in proper compartments or removed? •Check all hardware for tightness, missing bolts, nuts, pins, etc. •Is the proper lube supplied to all bearings and lube points? •Is all lube piping connected and filled? •Are all lube (grease) spills wiped up? •Is the machine thoroughly clean?

Tub ~ Check for the following items:

•Cracks, broken welds; •Deformed bottom plates; •Bent or damaged bulkhead plates; •Hook shoe(s) adjustment, with pin lock(s) in place; •No obstructions in roller path or main rotating gear; •Trail cable in correct position.

Machinery House ~ Check the following items:

•Automatic lube system with adequate lube supply; •All gearcases have proper oil level and all filters installed; •Air compressor crankcase oil level and drive belts’ tension; •Main house crane hoist not parked on a crossover beam.

Front End ~ Check the following items:

•Bucket - for wear, worn, broken or missing teeth, loose or missing pins, weld cracks; •Boom - for cracks, bent pipes; •The condition of the boom support ropes; •The intermediate boom support ropes with correct tension; •The condition of the hoist and drag ropes; •The condition of the fairlead components.

NOTE: If any problems are found after going through the above check lists, notify maintenance at once so that correction can be made.

TYPICAL START-UP

To start up the machine from a complete shutdown, use the following procedure. DO NOT start this machine unless you are completely familiar with the various controls. Perform the Pre-Start Inspection given on the previous page.

1. All the circuit breakers for the applicable controls and equipment must be closed and power on before proceeding with start-up. These are located primarily on the outside of the Power Control Room (PCR) and in the Operator’s Cab/Anteroom.

CAUTION: DO NOT use circuit breakers as ON/OFF switches. Make sure that all the circuit breakers are ON before starting the machine.

2. Go to the rear of the PCR and to the Starting and Metering Cabinet. Observe the various meters and the start-up controls and that the PHASE CHECK light is on.

IMPORTANT NOTE: During each component start-up always be ready to immediately stop it if there are any unusual sounds, smells, or visual effects. Always let the system being started come up to its normal operating speed before starting the next system. Any time a problem arises, check the OIT display in the Operators cab for assistance.

4. Start the motor blowers by pressing and releasing the START pushbutton. These blowers are used in cooling the DC motors. Check that the green indicator is lit and for the sound of the blowers.

5. Start the No. 1 M.G. Set by fully pressing and releasing the START pushbutton. Be sure that both green indicators are lit and that all meters are stabilized.

6. Start the No. 2 M.G. Set in a similar manner to the No. 1 M.G. Set.

IMPORTANT NOTE: If the vacuum breaker for the synchronous motor on the M-G set does not stay closed when the start button is released, repeated attempts to start the set should not be made. On a motor of this type, only attempt two successive starts if the motor is at ambient temperature. More than two attempts to start without success can damage the motor windings. Before attempting another start, the vacuum breaker starting circuitry or mechanism should be inspected by qualified personnel and its proper operation verified.

7. Start the Machinery House Filter Fans. Fully press and release the pushbutton. This will start the bleed duct fans. In approximately 5 seconds the main fans will automatically start and then the light will come on. These fans introduce clean air into the machinery house to cool the dragline operating equipment. They also maintain a positive pressure within the house to prevent dust entry if all the access doors are kept closed.

8. When the above systems have been started and are operating correctly, go to the Operators cab and observe the air pressure indicator in the OIT. This indicator provides a visual reference for the air system pressure and should indicate from 95 to 115 PSI during machine operation.

10. Sit into and adjust the operators seat.

11. Check the Hoist, Swing, Drag, and Propel Brake selector switches. If they are not at their

SET positions, put all of them there now, even if the red light in the switch is on.

12. Check to be sure that the hoist and drag controllers are in their NEUTRAL position and that there is no pressure applied to the swing pedals.

IMPORTANT NOTE: This machine is equipped with an electronic rope limit control system. This system is designed to aid the operation in avoiding serious mechanical damage to the machine due to hoist or drag bucket overtravel or bucket tight-lining. However, the system is not a substitute for careful operating procedures. The rope limit control system should be verified for proper operation on a daily basis. It is EXTREMELY important that the system be recalibrated after any rope or bucket rigging changes have been made. Refer to the Electrical Service Manual for this machine for proper procedures.

13. Press the EXCITATION START pushbutton on the operator’s console.

14. Turn the Hoist, Drag and Swing drag brake selector switches to the RELEASE position.

DANGER: THE MACHINE IS NOW OPERATIONAL. DO NOT LEAVE THE OPERATORS SEAT UNLESS THE CONTROLLERS ARE DEENERGIZED AND THE BRAKES ARE SET.

The operator controls the machine. PLEASE KEEP SAFE OPERATING PROCEDURES IN MIND AT ALL TIMES.

TYPICAL DIGGING CYCLE

Start a digging cycle with the bucket - on the ground, in the pit, and under the boom point. If the machine tends to rotate freely, apply just enough swing effort with the RIGHT controller in the opposite the direction of machine movement, to hold the machine steady.

OPERATOR’S CONTROLS

Begin dragging the bucket in by pulling back on the drag (left) controller. The more the controller is moved off its neutral position, the faster the bucket will be pulled toward the machine. As the bucket is dragged in, take care to remove any slack from the hoist rigging. Do not allow the spreader bar to rest on the bucket. Additional hoist pull can be applied to reduce the cutting depth and wear on the bucket heel. Do not drag the bucket any further than necessary to fill it. Dragging a full bucket wastes time and energy.

With the bucket full, a correct combination of hoist and drag controller movement will increase the hoist speed (right controller back) and decrease the drag speed (left controller forward) to lift the bucket out of the pit. Keep just enough tension on the drag ropes to prevent the bucket dumping. Too much rope tension tightens the “line of bucket carry” and positions the bucket close to the boom. This adds strain to the boom and slows down the hoist speed.

As soon as the bucket clears the digging face, slowly move the swing lever in the desired direction of machine rotation. A correct combination of hoist and drag effort with swing motion added avoids any excessive bucket and rope swing. Swing the machine and lift the bucket at the same time so that the bucket reaches the dump height and spoil location at the same time.

CAUTION: USE EXTREME CARE WHEN SWINGING TO INSURE THE BUCKET CLEARS ALL OBSTRUCTIONS AND THAT CLEARANCE EXISTS AROUND THE MACHINE.

Upon approaching the dump point, reverse the swing motion to bring the machine to a smooth and accurate stop. Co-ordinate the hoist and pay-out so that the bucket dumps as the machine stops swinging, and the bucket is empty as it starts back to the pit.

All the drives are “plugged” while digging to bring each motion to a stop and control the bucket as desired. There are no “operating” brakes on this machine. All the brakes on the drives are “parking” brakes only.

Release the drag rope tension by paying out some rope off the drum. This dumps the bucket. As the bucket dumps, move the right controller just slightly forward of its neutral position. Be cautious - do not allow an excessive amount of drag rope to pay out.

Never hold the load any longer than necessary to complete the dumping cycle. Once the material clears the bucket, slowly swing the machine back over the work area and lower the bucket into the pit, using a combined effort of the hoist and drag motions to place the bucket at its new dig site.

CAUTION: NEVER LOWER A FULL BUCKET OVER AN EXTENDED DISTANCE. DOING SO COULD CAUSE SEVERE DAMAGE TO THE ELECTRIC DRIVE COMPONENTS ON THIS DRAGLINE.

While operating the machine, observe its components for problems. Look for loose bucket pins; broken or frayed strands on the boom support, hoist, drag, and dump ropes; and bucket and rigging damage or wear. Keep an eye on the boom and the boom point. Report any maintenance requirements promptly to the appropriate personnel for attention so that unnecessary downtime can be minimized.

GROUND PREPARATION

Ground preparation is very important. The walking dragline requires a properly prepared ground base for operation. The tub and walking shoes must have full contact with the ground when the machine is digging or propelling. With the machine weight distributed over the entire tub bottom or the partial tub bottom and the two walking shoes area, moderate ground bearing pressure is obtained and the machine components are less stressed.

The ground supporting a walking dragline must be as near level as possible, firm, and dry. Sand, clay, and topsoil can be leveled easily with a dozer or grader. Sharp rocks and boulders cause point loading which will damage the tub and shoes structures and should be removed if possible. Where this is impractical, cover the working area with fill dirt to a sufficient depth that will eliminate the effects of the rocks.

This walking dragline can be propelled up or down a grade or ramp. Ramping the machine, moving it from one level to another, requires exercising great care because this situation subjects the tub and rotating frame to stresses much greater than experienced while digging. For a new machine, ramping should be restricted to no greater than a 5% grade (See Note). Later, this can be increased up to a 10% grade maximum. It is possible to traverse (cross) a 5% grade with this machine; however, AVOID CROSSING ANY GRADE IF POSSIBLE.

NOTE: When beginning to propel the machine, the transition from one grade to the next should gradual, no more than 2% over the length of the walking shoes (for this machine is approx. 70 feet). For example, starting from level ground, the machine should travel at least 3 shoe lengths before reaching a 5% grade.

The 8200 dragline design incorporates a calculated balance between boom length, boom angle, allowable bucket load, machine weight, and ballast used. During normal digging cycles, the center of gravity shifts from the front to the rear within a specific area called the “kern”. The machine maintains stability and relatively even ground bearing pressure over the entire tub area. If, for any reason, the digging radius or load increases to cause the center of gravity to extend out of the kern to the tub perimeter, an undesirable rocking motion will occur due to the cone shape that will develop in the ground under the tub. This results in an unstable machine and concentrated ground bearing pressure at the center of the tub. This condition is very detrimental to the machine and must be eliminated. Contact Bucyrus for consultation on this problem immediately.

WALKING/PROPEL OPERATION

WALKING MACHINERY

Two separate but identical propel machinery assemblies are located at each side of the rotating frame. These assemblies operate independently but are tied together electrically by encoders and a monitoring system to synchronize them during the step.

Each propel assembly consists of a DC drive motor, shafts and gearing, an eccentric, a walking arm with a stabilizing arm, and a walking shoe. The walking arm connects to the shoe through a ball joint that allows the shoe to swivel in all directions. It also permits limited lateral movement. Consequently, each shoe can adapt to ground contour within its design range.

A walking step is created when the eccentric rotates. During a walking step, the top of each eccentric turns toward the rear of the machine (away from the boom). The eccentric turns the walking arm in a path restricted by its stabilizer arm that generates the walking step through the shoes. Hook shoes, attached to the underside of the rotating frame, lift the rear of the tub during the step.

The walking process can be separated into 4 distinct phases, as follows:

• During the first quarter turn of the eccentric, the walking shoe moves from its “top dead center” or parked position toward the rear of the machine and down until it contacts the ground. Refer to PHASE 1 on the previous page. Just before the eccentric turns into the second quarter of its rotation, the rear of the machine and the rear edge of the tub raise and move slightly forward. This movement raises the tub out of any depression formed while digging and breaks any suction between the tub and the ground.

• During the second quarter turn of the eccentric, (PHASE 2) the shoes cause the machine to move rearward, dragging the front edge of the tub along the ground.

• The third quarter turn of the eccentric (PHASE 3) completes the propel movement of the machine. Near the end of this quarter turn, the machine is slowly lowered and the tub settles down onto the ground again.

• The fourth and final quarter turn of the eccentric raises the shoes into their park position (top dead center). The shoe return mechanism on each shoe realigns it parallel to the rotating frame as it is raised.

WALKING MACHINERY CONTROL

The Drag-Propel Contactors, located in a cabinet on the machinery deck in front of MG set #1 on the left side of the machine, electrically move the drag motors and the propel motors into and out of the drag generators loop, depending on what machine control mode the operator selects. In the DIG mode, the drag (left) controller in the cab controls the drag motors for digging. In the PROPEL mode, this same lever controls the propel motors for walking.

The walking shoes at each side of the machine are not mechanically connected. The position of the two shoes is electrically monitored to keep them in time/synchronized. This timing system detects when one shoe gets ahead of the other and generates an error signal to slow down the leading shoe and speed up the trailing shoe. This timing system functions to align the shoes only when they are approaching or have lifted off the ground and when the tub is nearing the ground after the step. This provides a smooth, shock-free propel movement. Once the shoes have contacted the ground and commenced the propel motion, the timing system will not alter their speed. The propel portion of the step will be completed. The encoders in this timing system are also used to detect when the shoes are at their “top dead center” or PARK position.

WALKING

Some preparations are required before moving the dragline. Its travel path must be adequately prepared. See the previous sub-section GROUND PREPARATION. The bucket must be positioned to suit the ground conditions. The machine must be rotated so its rear faces the desired direction of travel. Provision must be made for safely and correctly handling the trail cable during the move. DO NOT USE A WALKING SHOE TO PULL OR MOVE THE TRAIL CABLE to avoid damaging the trail cable.

The position at which the bucket is carried when the machine is propelled contributes considerably to the walking operation and is dependent upon the condition of the ground. When traversing firm,evel surfaces, the bucket should be suspended from the boom point approximately 1/3 the dump radius of the machine. The same position is used when propelling up a ramp. When propelling down a ramp, carry the bucket below the boom point. In all cases, the bucket should be high enough so that it will not touch the ground during a walking step.

“Heeling” the bucket while walking is done by letting the rear of the bucket contact the ground during the step and slide along when the tub slides rearward in the direction of travel. As the tub is lowered to the ground, the bucket is picked up as the boom point raises. THE BUCKET SHOULD NOT BE JERKED OFF THE GROUND. Heeling is useful while traversing dry, sandy, or powdery soil conditions to reduce the ground pressure under the sliding area of the tub and stop soil build up behind the tub’s front edge or to avoid shoe slippage on the ground.

Each operator will learn through experience where to carry the bucket while propelling to suit the ground conditions encountered. The above are general guidelines for any operator to follow initially for positioning the bucket for walking.

When all is ready for the machine to be moved, transfer the machine control from DIG to PROPEL mode. Refer to TYPICAL START-UP in this section for the procedure. Sound the signal horns to indicate the machine will propel.l

IMPORTANT NOTE:

The operator should check that the drag machinery is inoperative and that the transfer to PROPEL is complete. This is done by moving the left controller (drag) slightly forward off neutral and then back to neutral to see if the drag or the propel machinery moves. This check can avoid inadvertent damage to the boom or front end in case the drag motion is still activated when the controller is moved full forward to take a step.

Move the left controller forward and hold it there during the entire propel period. This controller is pulled back from neutral while in PROPEL ONLY to realign the two shoes if they get out of sync or to position them at top dead center for parking.

As the first walking step commences and the shoes move off their PARK position, the swing and hoist brakes will automatically set if they had not already been set manually. During extended travel over long distances, it sometimes becomes necessary to alter the direction of travel or reposition the bucket. This can be done without transferring to the DRAG mode. Stop the walking shoes in their PARK position. Check that the CLEAR TO SWING indicator is lit and the drag/propel brakes are set. Release the Hoist and/or Swing brakes then press the EXCITATION ON pushbutton. To continue propelling, set the hoist and swing brakes, release the drag/propel brakes and press the EXCITATION ON pushbutton.

During walking, if a ground roll develops at the front edge of the tub, “heel” the bucket for a couple of steps. If the tub roll persists, swing the machine 30o-40o to one side and propel one or two steps. This will spread the roll over the ground. Then return to the line of travel desired.

When the machine is walking, both shoes should contact the ground at the same time. If one of the shoes sets down on a high spot, or does not contact the ground, or steps into a soft ground area that will not support it, then the machine will rotate in relation to the tub if the walking step is completed. If this occurs and the operator can, he should stop the step before the machine is lifted and reverse the shoes up to top dead center position. He can then change machine travel direction with the swing motion and walk around the problem ground area.

SHUTDOWN

PARTIAL SHUTDOWN

A partial shutdown, for shift change or a lunch break, begins with a full machine rotation to reposition the roller circle and promote even wear.

Lower the bucket to the ground. Place both controllers in their NEUTRAL position. Place hoist, drag, propel, and swing brake selectors in the SET position (red indicator lights out). De-activate the controller circuits by pushing the STOP button on Operator Console (green light in START button will go out).

COMPLETE SHUTDOWN

A complete shutdown procedure starts with the steps listed under PARTIAL SHUTDOWN. Then the operator must go to the controls at the START-UP AND METERING cabinet located outside the power control room (PCR).

To completely shut down the machine perform the following to the controls on the START-UP panel:

• Press the M.G. set STOP buttons.

• Press the motor blowers STOP buttons.

• Press each filter fan pushbutton to STOP. • Turn each air compressor selector to OFF ~ only if the machine is to be stopped for an extended period of a week or more.

The machine is now shut down and ready for inspection, maintenance, etc.

CAUTION: INCOMING ELECTRICAL POWER EXISTS TO THE TRANSFORMERS, CABINETS, COLLECTOR RINGS, ETC. SO OBSERVE CORRECT CAUTIONS AND WARNINGS, AS INDICATED THROUGHOUT THE MACHINE AND SPECIFIC EQUIPMENT MAINTENANCE MANUALS. SAFETY FIRST IS BEST.

Section 3

Lubrication

Table of Contents

LUBRICATION PRINCIPLES.........................................................................................................5 LUBE POINTS ON D.C. MOTORS.........................................................................................7 LUBING ELECTRIC MOTOR BEARINGS WITH EMG LUBRICANT.......................................7 BEARING LUBRICATION DATA ..............................................................................................8 AUTOMATIC LUBRICATION SYSTEM ..........................................................................................9 Lube Point Chart .........................................................................................................................9 Lube Room (Plan View) ..............................................................................................................11 AUTO LUBE CONTROL PANEL (ELECTRIC)......................................................................12 Auto Luber COntrol Panel ~ Electric..........................................................................................12 OPERATION .........................................................................................................................13 IMPORTANT NOTES ON SYSTEM OPERATION...........................................................14 MANUAL LUBE REEL MPG OPERATION .............................................................................14 AUTOMATIC OPERATION ....................................................................................................15 FAULT DETECTION AND INDICATION .................................................................................15 PROGRAMMABLE CONTROL.............................................................................................15 RECOMMENDED CYCLE and ALARM SETTINGS ....................................................................16 LUBE CIRCUIT PRESSURE SWITCHES............................................................................17 SAFETY UNLOADER VALVES..............................................................................................17 LUBE CONTROL PANEL......................................................................................................18 4-WAY VALVE (Section View)....................................................................................................18 Schematic ~ AUTO LUBE PANEL GREASE.............................................................................19 Schematic ~ AUTO LUBE PANEL AIR ......................................................................................19 AIR OPERATED LUBE PUMPS............................................................................................20 Powermaster 4 Air Operated Lube Pump ...................................................................................21 AUTO LUBE RESERVOIR ~ Typcal..........................................................................................22 AUTO LUBE ~ MPG....................................................................................................................23 ROTATING FRAME ...............................................................................................................23 ROTATING FRAME CONTROL PANEL, Line-A .........................................................................23 Schematic - ROTATING FRAME (MPG).....................................................................................24 FRONT END CONTROL PANEL ~ LINES A AND B........................................................25 BOOM...................................................................................................................................25 FRONT END CONTROL PANEL ~ LINES A and B....................................................................25 Schematic - BOOM (MPG) .........................................................................................................26 Schematic - TRI-STRUCTURE (MPG) .......................................................................................27 Schematic - Fairlead (MPG).......................................................................................................28 ROLLER CIRCLE LUBE OPERATION...........................................................................28 Auto Lube - LUBE GUN (MPG)..................................................................................................29 AUTO LUBE ~ OGL....................................................................................................................30 OPEN GEARS......................................................................................................................30 Schematic - OPEN GEARS (OGL)............................................................................................30