1 minute read

OPERATING INSTRUCTIONS RH 400

Inspection and servicing

Crawler Tracks

Cleaning

3659732

Clean tracks, track and support rollers, sprockets and idlers regularly and whenever required. Cleaning is especially important in winter to prevent the tracks from being thrown off oil from leaking out of track and support rollers, sprockets and idlers excessive wear the track from breaking.

To clean the tracks: raise one side of the excavator with the working equipment and allow track to turn; clean the side member supporting the track; clean track and support rollers (1 and 2 ,Fig. 3-117:) thoroughly; clean the sliding planes on the idler guides.

BA 6090FS (3 659 450.01)-EN

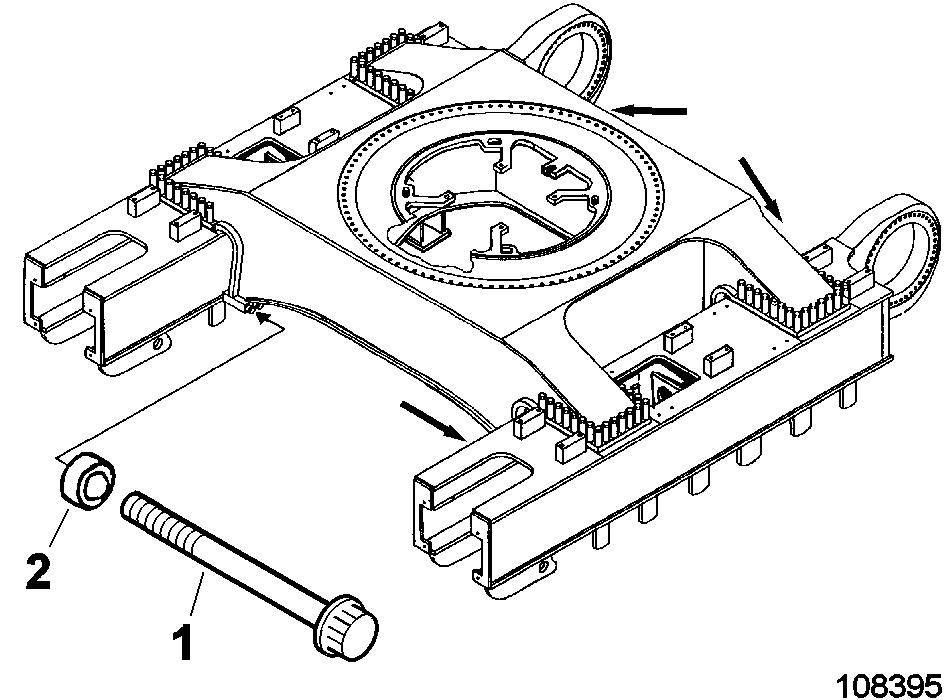

Carbody-crawler frame fastening bolts, replace

The fastening bolts as well as the tempered disks (1 and 2, Fig. 2a) must be replaced any time that they are removed or after 30.000 operating hours of the machine.

Do not re-use removed bolts.

To tighten these bolts to the prescribed tightening torque, heavy hydraulically driven equipment is necessary.

For more detailed information see:

- Service Manual, chapter 2.9 "Tightening Procedure for bolts" for tightening torques used,

- Service Manual, chapter 3.2.1 "Torque Tools" for description of hydraulic torque tools,

- Service Manual, chapter 4 “Undercarriage” for bolts replacement procedure.