4 minute read

ROLL-OVER PROTECTIVE STRUCTURE (ROPS

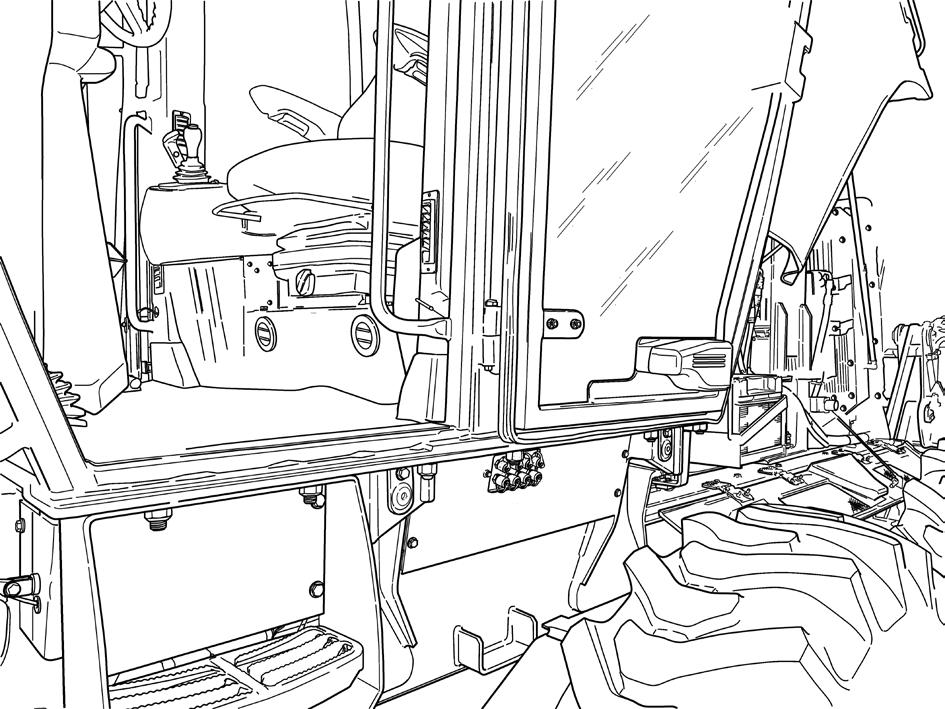

AYour machine is equipped with an operator Protective Structure, such as: a Rollover Protective Structure (ROPS) or Falling Object Protective Structure (FOPS) or Cab with ROPS. A ROPS may be a cab frame or a twoposted or four-posted structure used for the protection of the operator to minimize the possibility of serious injury. The mounting structure and fasteners forming the mounting connection with the machine are part of the ROPS. A ROPS label shows the serial number of the ROPS, gross weight, approval, regulation, and model numbers of the machine. See Identification Numbers in this manual.

ROPS CANOPY LABEL

The Protective Structure is a special safety component of your machine. Before you operate this machine, always make sure that the ROPS and operator’s seat belts are correctly installed. DO NOT attach any device to the Protective Structure for pulling purposes. DO NOT drill holes to the Protective Structure. The Protective Structure and interconnecting components are a certified system. Any damage, fire, corrosion or modification will weaken the structure and reduce your protection. If this occurs, the Protective Structure MUST be replaced so that it will provide the same protection as a new Protective Structure. Contact your dealer for Protective Structure inspection and replacement. After an accident, fire, tip or roll over, the following MUST be performed by a qualified technician before returning the machine to field or job site operation: •

The Protective structure MUsT be replaced.

The mounting or suspension for the Protective Structure, operator seat and suspension, seat belts and mounting components and wiring within the operator’s protective system MUST be carefully inspected for damage.

All damaged parts MUsT be replaced.

WARNING: Do not weld, drill holes, attempt to straighten or repair the protective structure. Modification in any way can reduce the structural integrity of the structure which could cause death or serious injury in the event of fire, tip, rollover, collision or accident.

The seat belt is an important part of your ROPS. You must wear the seat belt at all times when you operate the machine. 1. Keep the seat belts away from objects that can damage them. 2. Check the seat belts for damage. Replace all parts that are damaged. 3. Make sure that the mounting bolts of the seat belts are tight. See Torque Specifications for Seat in this manual. 4. Keep the seat belts clean. Wash the seat belts only in soap and water. 5. Do not put the seat belts in bleach or dye.

Maintenance and Inspection of ROPs

After the first 20 hours of operation and after every 500 hours of operation, do the following: 1. Check the torque of the ROPS 20 mounting bolts. If necessary, tighten the bolts to the correct torque (see torque specification the bolts to follow).

2.

3. Check the operators seat and the mounting parts for the seat belt. Tighten the bolts to the correct torque. See Torque Specifications in this manual. Replace parts that have wear or damage. Check for cracks, rust, or holes in the ROPS and ROPS parts. Age, weather, and accidents can cause damage to the ROPS and ROPS parts. If you have any doubt about the ROPS system, see your CAse Dealer.

Torque Specifications for ROPS Cab and ROPs

TORQUE OF 20 BOLTS ROPS CAB AND ROPS : 587 N.M (60 kgf.m; 435 lb.ft.).

Damage to the ROPs

If the machine has rolled over or the ROPS has been in some other type of accident (such as hitting an overhead object during transport), you must replace the damaged ROPS components to get as much protection as you had originally. After an accident, check the following for damage: a. ROPS canopy or cab. b. Operators seat. c. Seat belt mounting bolts and seat belt. Before you operate the machine, replace all ROPS components that are damaged. See the Parts Catalog or your dealer for components that are replaceable. IMPORTANT: DO NOT TRY TO WELD OR STRAIGHTEN THE ROPS.

WARNING: Improper ROPS inspection or maintenance can cause injury or death. Do the recommended ROPS inspection shown in this manual. If you must replace the ROPS, ROPS parts, or ROPS mounting hardware, use only the replacement parts shown in the CASE parts catalog for this machine.

WARNING: Do not modify ROPS in any manner. Unauthorized modifications such as welding, drilling, cutting or adding attachments can weaken the structure and reduce your protection. Replace ROPS if subjected to roll-over or damage. Do not attempt to repair.

WARNING: If you operate this machine without a ROPS and the machine rolls over, you can be injured or killed. Remove the ROPS only for service or replacement. Do not operate this machine with the ROPS removed.

WARNING: Adding additional weight (attachments, etc.) to the machine can cause injury or death. Do not exceed the gross weight printed on the ROPS label.

WARNING: Always fasten the seat belt securely before starting the Engine.