1 minute read

7.14.3 Section R-23LS lowering valve disassembly procedure

End of Table 7.14 Failure, external manifestations, cause Troubleshooting

Spontaneous lifting of RLL (lifting without a command received from the instrument panel or remote control buttons)

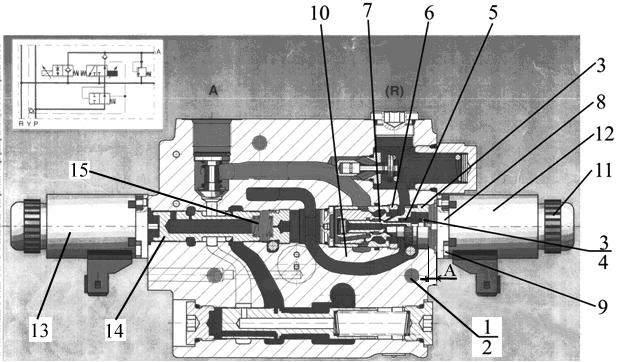

Deadlock of the lift spool of a regulatory section R-23LS (if integrated unit BOSCH is installed) Elimination of failure should be carried out directly in tractor, without the need of integrated unit disassembly, for which perform the following: - thread out four screws fastening lower solenoid 13 (Figure 7.14.1) then withdraw the solenoid ; - withdraw the lift spool 14 and the spring 15, rinse the mentioned components and the bore in the section housing; - assemble the lift valve in reverse sequence

Deadlock of the lift spool of a regulatory section (if hydraulic unit 70-1523.1 is installed) To eliminate failure contact your dealer

Failure diagnostics signaling device located on the RLL control panel reports numerical error codes

Damage in electrical wiring, solenoids, corrosion of terminals, sensors failure (force or position) of RLL ECS. Eliminate the failure according to the subsection 7.13 “Possible failures in the electronic control system of RLL, and guidelines for troubleshooting”

7.14.3 Section R-23LS lowering valve disassembly procedure

1 – counter nut; 2 – worm; 3 – worm gear wheel; 4 – washer; 5 – spring; 6 – lock nut; 7 – lowering valve assembled; 8 – solenoid; 9 – screw; 10 – section housing; 11 –cap; 12 – coil; 13 – solenoid; 14 – lift spool; 15 – spring. Figure 7.14.1 – Regulatory section R-23LS