18 minute read

Electrical Systems (7000

All tests of the electrical components should be made using the digital Fluke Model 77 Multimeter. Replace any component that does not have a test value within specifications. NOTE: Whenever using a digital-style tester, “open

(infinite resistance)” denotes an overload and the meter reading will be OL since the meter is not calibrated to register resistance values of that magnitude.

NOTE: Always check the appropriate fuse before

testing a component for failure.

SPECIAL TOOLS A number of special tools must be available to the technician when servicing the electrical systems. NOTE: When indicated for use, each special tool

will be identified by its specific name, as shown in the chart below, and capitalized.

NOTE: Special tools are available from the Arctic

Cat Service Parts Department.

Description

Arctic Cat Diagnostic System Manual Laptop Diagnostic Tool Actuator Test Harness

p/n

2256-974 0744-048 0644-518

Fluke Model 77 Multimeter

0644-559 MaxiClips 0744-041 Throttle Position Sensor (TPS) Adjustment Tool Kit 3639-891 CCU Diagnostic Test Kit 0644-517

Ignition System

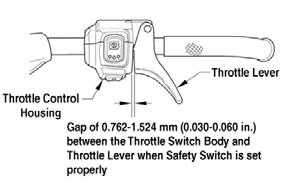

NOTE: There must be 0.75-1.5 mm (0.030-0.060 in.)

free-play between the throttle lever and the control housing.

TROUBLESHOOTING 1.Remove the spark plugs and visually check their condition. Replace any fouled plug. Attach the spark plugs to the high tension leads and ground them to the engine.

CAUTION

Before checking for spark, place all the engine switches in the deactivated position. In the event the engine could be flooded, engage the starter several times to clear the engine of excess fuel.

CAUTION

Never crank the engine over without grounding the spark plugs. Damage to coils and/or CDI/ECM may result.

NOTE: Make sure the ignition switch and the emer-

gency stop switch are in the ON position.

2.Crank the engine over and check for spark. If no spark is present, check to make sure the throttle cable is properly tensioned. Compress the throttle control and while holding the throttle control in this position, crank the engine over and check for spark. If spark is now present, adjust the throttle cable tension. 3.If still no spark is present, the problem is either one or more of A-D below.

A.Defective emergency stop switch. B.Defective safety switch in throttle-control housing. C.Grounded or shorted wire connection at the throttle-control housing or main wiring harness. Corroded or loose wire connection at the handlebar, hood, or main wiring harness. D.Defective ignition switch.

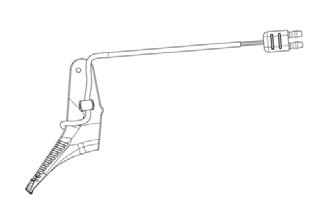

TESTING Throttle Control Switch 1.Disconnect the handlebar harness connector; then connect the red meter lead to the yellow wire; then connect the black meter lead to the black wire.

2.With the throttle lever in the idle position, the meter must read less than 1 ohm. If the meter reads OL (infinite resistance), replace the control assembly. 3.Move the throttle lever to the wide open position.

The meter must read OL (infinite resistance). If the meter reads less than 1000 ohms, replace the control assembly.

0752-478

NOTE: These engines are equipped with a throttle

position sensor have a protective feature called “fail-safe” ignition timing preventing engine damage should the TPS fail. If the TPS does fail, the engine may run normally at low RPM but will run poorly at high RPM allowing the operator to get the snowmobile to safety with no engine damage. The engine will continue to operate this way until the TPS is adjusted or replaced.

VERIFYING TPS ADJUSTMENT TOOL Before using the TPS adjustment tool, verify its battery condition. The battery used in the tool is a 9-volt battery. To check battery condition, use a digital volt/ohmmeter set on DC volt scale. Test between the adjustment tool black and red jacks. Insert the red lead of the digital voltmeter into the red jack of the adjustment tool and the black lead of the digital voltmeter into the black jack of the adjustment tool. The green power light of the analyzer should now be illuminated. If voltage is found below 4.9 volts, replace the battery. NOTE: The Test Harness must be plugged into the

analyzer for testing voltage. Always verify battery voltage is at least 4.9 DC volts before testing TPS.

CHECKING TPS NOTE: If the snowmobile is in warranty, breaking

the seal on the idle screw jam nut or the Phillips-head screws on the TPS will void warranty. If the TPS is tested out of specification, the throttle body must be replaced. If the snowmobile is out of warranty, proceed to Adjusting TPS.

NOTE: The TPS should only be checked using the

CATT II Tool. Instructions will be included with the tool.

ADJUSTING TPS NOTE: The TPS should only be adjusted using the

CATT II Tool. Instructions are included with the tool.

REPLACING TPS NOTE: If the snowmobile is in warranty, removing

or adjusting the TPS will void warranty. If the TPS is tested out of specification, the throttle body must be replaced. If the vehicle is out of warranty, the TPS can be adjusted.

NOTE: Replacing the TPS is for out of warranty

snowmobiles only.

Removing 1.Disconnect TPS wiring harness from the TPS; then noting the TPS position, remove the screws and washers securing TPS to the throttle body housing and remove the sensor.

Installing 1.Install the new TPS onto the throttle shaft by aligning the “flats” on the throttle shaft cam with the alignment points of the sensor; then rotate the sensor until properly positioned on the throttle body.

YM-067

2.Install the screws with washers securing the sensor to the throttle body. Do not tighten at this time. 3.Adjust the TPS using the CATT II Tool. Instructions will be included with the tool.

NOTE: Before installing the TPS harness connector,

apply dielectric grease to the connector pins.

Electrical Resistance Tests

NOTE: Replace any component that does not have a

test value within specifications. If the component tests satisfactorily but is suspected to be faulty, connect the red meter lead to a component lead and the black meter lead to ground. Check for continuity between the component and ground. If continuity is observed, replace the component.

NOTE: The following test should be made using

MaxiClips and the Fluke Model 77 Multimeter set to OHMS scale.

CAUTION

Always disconnect the battery when performing resistance tests to avoid damaging the multimeter.

Magneto Coil 1.Disconnect the three-white-wire connector.

2.Connect the red meter lead to one white wire; then connect the black meter lead to another white wire (a total of three tests). 3.Resistance must be 0.15-0.23 ohm.

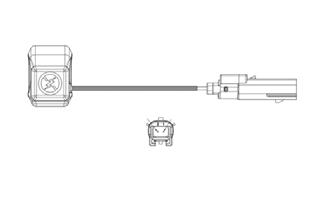

Crankshaft Position Sensor 1.Disconnect the sensor.

2.Connect the red meter lead to the gray wire; then connect the black meter lead to the black wire.

3.Resistance must be 336-504 ohms.

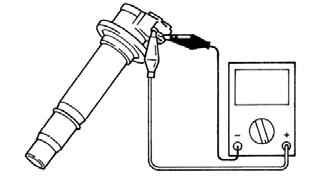

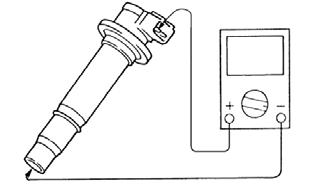

Ignition Coil 1.Disconnect an ignition coil connector. 2.Connect the red meter lead to one terminal; then connect the black meter lead to the other terminal. Primary coil resistance must be 1.19-1.61 ohms.

SNO-655

3.Connect the red meter lead to one of the terminals; then connect the black meter lead to the bottom of the coil. Secondary coil resistance must be 8.5k-11.5k ohms.

SNO-656

4.Repeat the test on the other two ignition coils. NOTE: If resistance is not within specification, the

coil must be replaced.

Injection Coil (1) 1.Test between the red/blue and the red/black wires from the injection coil. 2.Resistance must be 86.4-105.6 ohms.

Injection Coil (2) 1.Test between the red/blue and the green/black wires from the injection coil. 2.Resistance must be 86.4-105.6 ohms.

Injection Coil (3) 1.Test between the red/blue and the blue/black wires from the injection coil. 2.Resistance must be 86.4-105.6 ohms.

Fuel Injector 1.Disconnect the fuel injector wiring harness. 2.Test between the two injector terminals. Resistance must be 86.4-105.6 ohms.

Coolant Temperature Sensor 1.Disconnect the coolant temperature sensor wiring harness from the main harness.

2.Test the resistance between the two leads from the sensor.

3.Compare the resistance reading to the Voltage/Resistance Chart – Coolant Temperature in this section.

Air Temperature Sensor NOTE: The component temperature must be

known before conducting this test. Allow the engine to reach room temperature.

1.Disconnect the wiring harness from the air temperature sensor.

2.Set the meter selector in the OHMS position and test the sensor connector. Compare with the Voltage/Resistance Chart – Air Temperature in this section.

NOTE: The air temperature sensor utilizes a therm-

istor. Resistance will change as temperature varies.

Voltage Regulator/CCU Tests

NOTE: The following test should be made using

MaxiClips and the Fluke Model 77 Multimeter set to DC Volt scale.

This test should be made at the three-pin connector of the regulator/rectifier.

! WARNING

Most voltages generated by the ignition system are sufficient to interrupt pacemakers! All technicians, especially those using pacemakers, must avoid contact with all electrical connections after the engine has been started.

NOTE: Test the connector that comes from the

engine.

1.Set the meter selector to the DC Voltage position. 2.Connect the red tester lead to the positive battery post; then connect the black tester lead to the negative battery post. 3.With the engine running at 2500-3000 RPM, the meter must show 12-14.5 DC volts.

4.Set the meter selector to the AC Voltage position. 5.Test between the three yellow wires for a total of three tests.

6.With the engine running at 2500-3000 RPM, all wire tests must be within 36-44 volts.

NOTE: If tests failed, check all connections, etc.,

and test again. If no voltage is present, replace the stator assembly.

Testing Fuel Gauge Sender

NOTE: Before testing the sender, verify the harness

from the sender to the gauge is satisfactory.

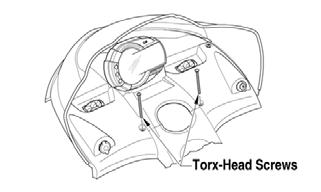

1.Remove the Torx-head cap screws securing the console to the steering support; then move the console out of the way. 2.Disconnect the fuel gauge sender unit from the main wiring harness; then connect the ohmmeter leads to the two blue sender wires.

3.Compare the reading to the chart following.

Full <20 ohms 1/2 40-56 ohms Empty 76-105 ohms

Emergency Stop Switch

TESTING 1.Disconnect the stop switch connector from the main harness; then set the selector to the OHMS position. 2.Connect one tester lead to one pin; then connect the other tester lead to the other pin.

ONS-118

4.With the switch in the up (ON) position, the meter must read less than 1 ohm resistance.

5.With the switch in the down (OFF) position, the meter must read OL (infinite resistance)

Starter Relay Solenoid

TESTING NOTE: The electric start solenoid may be tested

using either one of the following methods.

Method #1 1.Disconnect the solenoid connector from the main wiring harness. 2.Place the ohmmeter leads across the solenoid coil terminals. The ohmmeter must read 3-5 ohms. NOTE: An in-line ammeter would measure between

2 and 4 amps of solenoid coil current flow with the battery connected.

CAUTION

NEVER connect an in-line ammeter with the large starter cables because the 200 amps of current flow will instantly damage most ammeters.

Method #2 1.Using the multimeter set to the DC Voltage position, check the relay as follows. 2.Connect the red tester lead to the positive battery terminal; then connect the black tester lead to the starter cable connection on the starter relay. The meter must show battery voltage. NOTE: Engage the brake lever lock and place the

emergency stop switch in the RUN position.

3.Engage the starter while observing the multimeter.

The multimeter should drop to 0 volts and a “click” should be heard from the relay. NOTE: If a “click” is heard and more than 1 volt is

indicated by the multimeter, replace the starter relay. If no “click” is heard and the multimeter continues to indicate battery voltage, proceed to step 4.

4.Disconnect the two-wire plug from the starter relay; then connect the red tester lead to the green wire and the black tester lead to the black wire.

5.Depress the starter button and observe the multimeter.

NOTE: If battery voltage is indicated, replace the

starter relay. If no voltage is indicated, check fuse or relay.

Fuse

TESTING 1.Remove the fuse from the fuse holder.

2.Connect the ohmmeter across the fuse end-caps. 3.The ohmmeter must read less than 1 ohm of resistance.

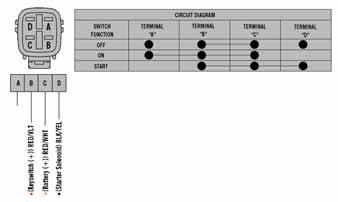

Ignition Switch

TESTING

CAUTION

To prevent ohmmeter damage when testing circuits on snowmobiles equipped with an electric start, be sure to disconnect the battery before testing.

1.Disconnect the wiring harness from the ignition switch; then remove the switch from the console.

2.Using the ohmmeter, test the connections indicated in the following charts. If the meter reads more than one ohm of resistance between connected terminals or less than 1 ohm of resistance on non-connected terminals, the switch must be replaced.

746-246A

NOTE: If the ignition switch tests good, verify bat-

tery voltage to the harness side of the switch plug-in. If there is no voltage, troubleshoot the battery, switch fuse, or starter relay solenoid.

If battery voltage is present at the plug-in and the starter fails to activate, use the following procedure: 1.With the ignition switch plugged in, place the emergency stop switch to the OFF position. 2.Connect the red tester lead to the black/yellow wire; then connect the black tester lead to a suitable ground. 3.Rotate the key to the START position and verify battery voltage. NOTE: If no battery voltage is present, troubleshoot

the harness and/or the starter relay solenoid.

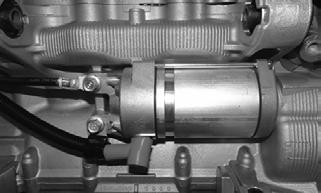

REMOVING 1.Open the hood and remove the access panels. 2.Remove the drive clutch, drive belt, driven clutch, gas tank. 3.Remove the starter motor and battery cables from the engine.

YM-060

INSTALLING 1.Install the starter motor into the engine; then with the negative battery cable positioned to the top mounting hole, install the two cap screws (threads coated with blue Loctite #243) and tighten to 19 ft-lb. 2.Install the positive cable to the starter motor and tighten securely. Secure the positive and negative cables with cable ties as noted during disassembling. 3.Install the drive clutch, drive belt, driven clutch, gas tank, hood and access panels.

Troubleshooting Electric Start

Problem: Hot or Smoking Wires Condition Remedy

1. System wired incorrectly 1.Check wiring against wiring diagram

Problem: Starter Does Not Turn Over Condition Remedy

1. Battery discharged 1.Check/charge the battery 2. Connection loose 2.Check tightness of all connections 3. Grounding improper 3.Check ground connections 4. Fuse blown — not installed 4.Check — replace fuse

Magneto

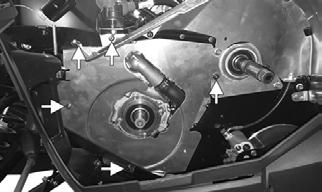

REMOVING NOTE: Prior to removing the magneto, the engine

oil and cooling system must be drained.

1.Remove the cap screws, nuts, and springs securing the resonator.

2.Remove all clamps and hoses to gain access to the magneto cover.

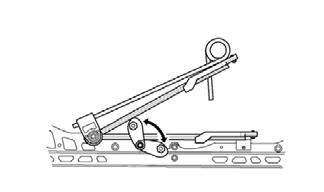

BC316

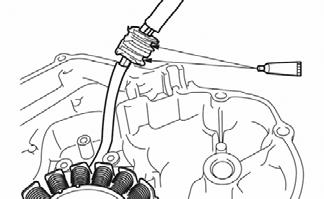

3.Remove the screws securing the magneto cover to the engine; then remove the cover and account for two dowel pins and the gasket. Disconnect the stator from the voltage regulator. NOTE: Note the location of the black screw and

retaining clip as they must be installed in the same location as which they were removed.

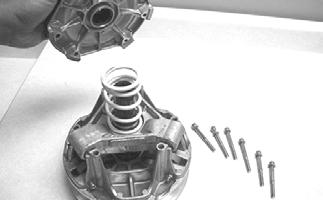

4.Remove the cap screws securing the harness clamp to the magneto cover. Remove the three cap screws securing the magneto to the cover; then remove the magneto assembly.

YM-057A

NOTE: Be sure to apply a small amount of sealant

to the grommet before pressing it into the cover.

SNO-380

2.Install the two alignment pins in the engine for the magneto cover; then with a new gasket, install the cover and with a crisscross pattern, tighten the screws to 8.7 ft-lb.

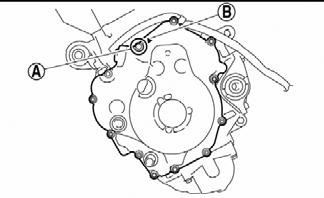

NOTE: The black screw (A) indicated by the black

arrow (B) must have blue Loctite #243 applied to the threads. Tighten to 8.7 ft-lb.

YM-057A

INSTALLING 1.Place the magneto into position on the cover; then install and tighten the three cap screws (threads coated with blue Loctite #243) to 7.2 ft-lb. With the harness routed properly, install the timing sensor and harness clamp and tighten (threads coated with blue

Loctite #243) to 7.2 ft-lb.

SNO-381A

3.Secure all coolant hoses and oil hoses using the existing clamps; then secure the left-side support using the existing cap screws and nuts. Tighten securely.

BC316

4.Install the resonator and secure using existing hardware.

NOTE: At this point, fill and bleed the oil and cool-

ing systems.

Brake Light Switch

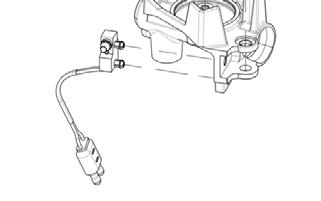

TESTING/REMOVING 1.Disconnect the brake light switch gray and brown two-wire connector (located near the brake lever). 2.To test the brake light switch, connect one tester lead to the brown terminal; then connect the other lead to the gray terminal.

ONS-116

3.With the brake lever compressed, the meter must read 1 ohm or less resistance. With the brake lever released, the meter must read OL (open). If the meter does not read as specified, the brake light switch is defective and must be replaced. 4.To remove the switch, pry the brake switch from the brake assembly.

ONS-117

INSTALLING 1.Press the switch into the brake assembly making sure it is fully seated. 2.Connect the switch harness to the main wiring harness. Position the wires so they will not be either pinched or come in contact with any moving components. Cable tie as needed. Start the engine and check the switch for proper operation.

Testing Headlight Dimmer Switch

1.With the key off, open the hood; then disconnect the 12-pin handlebar connector from the main harness. 2.Read continuity between the red/yellow and the blue wires for the high beam (red/yellow to white should be open circuit). 3.Read continuity between the red/yellow and the white wires for the low beam (red/yellow to blue should be open circuit). 4.Voltage check, can read red/yellow to black, 12-15

VDC feeding the control. On high beam, blue (+) to black (-) 12-15 VDC, on low beam white (+) to black (-) 12-15 VDC.

Testing Tether Switch

NOTE: Resistance will vary due to temperature;

therefore, this test should be made at room temperature of 22° C (72° F).

1.Disconnect the two-wire connector from the tether switch. 2.Connect one ohmmeter lead to one pin; then connect the other ohmmeter lead to the other pin. 3.With the tether cord installed on the switch, the meter must read less than 1 ohm of resistance. With the tether cord removed from the switch, the meter must read OL (infinite resistance).

Testing Handlebar Warmer Elements

NOTE: Resistance will vary due to temperature;

therefore, this test should be made at room temperature of 20° C (68° F).

1.Disconnect the handlebar warmer two-wire connector.

2.In the element connector, connect one ohmmeter lead to the green lead; then connect the other ohmmeter lead to the white lead.

3.The meter must read between 12.6-15.4 ohms.

4.In the element connector, connect the ohmmeter between the green/blue and green lead wires. 5.The meter must read between 6.3-7.7 ohms.

6.Replace any element measuring less than or more than the specified amount. 7.Connect the leads; then install the handlebar control assembly and secure the handlebar pad (if applicable).

Testing Thumb Warmer Element

NOTE: Resistance will vary due to temperature;

therefore, this test should be made at room temperature of 20° C (68° F).

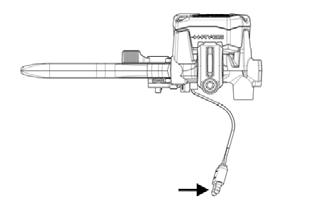

1.Disconnect the thumb warmer two-wire connector.

ONS-120

2.Connect one ohmmeter lead to the one lead; then connect the other ohmmeter lead to the other lead.

3.The meter must read 40 (±4) ohms.

Testing Handlebar Warmer/Thumb Warmer Switch

NOTE: The switch should only be checked using the

CATT II Tool. Instructions will be included with the tool.

Testing Passenger Handwarmer Switch

1.Disconnect the lead wires from the switch.

2.With the switch in the LO position, connect one ohmmeter lead to the green/white wire at the connector; then connect the other ohmmeter lead to the red/black wire at the connector. The meter must read less than 1 ohm of resistance.

3.With the switch in the HI position, connect one ohmmeter lead to the green/blue wire at the connector; then connect the other ohmmeter lead to the red/black wire at the connector. The meter must read less than 1 ohm of resistance.

Testing Passenger Handwarmer Elements

NOTE: During this test, resistance will vary due to

temperature; therefore, this test should be made at room temperature of 20° C (68° F).

1.Disconnect the lead wires from the main wiring harness.

2.For the LO position, connect one ohmmeter lead to the green/white wire from the element; then connect the other ohmmeter lead to the green wire from the element. The meter must read between 23.8-32.2 ohms.

3.For the HI position, connect one ohmmeter lead to the green/blue wire from the element; then connect the other ohmmeter lead to the green wire from the element. The meter must read between 8.7-11.7 ohms.

Testing Seat Heater Switches

NOTE: The seat heater elements cannot be tested.

OPERATOR HEATER SWITCH – Resistance NOTE: The element connectors are located at the

rear of the front seat beneath the flap.

1.Disconnect the main harness/element connector.

2.Connect one ohmmeter lead to the red/black main harness wire; then connect the other ohmmeter lead to the green/red main harness wire. The meter must read the following (± 5%):

LO HI 4.53K ohms 5.90K ohms

NOTE: If resistance is not within specification, trou-

bleshoot the switch connector located below the steering support. If the switch connector tests good, replace the switch.

PASSENGER HEATER SWITCH – Resistance 1.Disconnect the main harness/element connector.

2.Connect one ohmmeter lead to the red/black main harness wire; then connect the other ohmmeter lead to the green/red main harness wire. The meter must read the following (± 5%):

LO HI 4.32K ohms 3.75K ohms NOTE: If resistance is not within specification, trou-

bleshoot the switch connector located beneath the seat. If the switch connector tests good, replace the switch.

OPERATOR/PASSENGER SWITCHES – Voltage 1.Disconnect the main harness/element connector.

NOTE: For this procedure, test the main harness

side of the connector, not the element side of the connector.

2.Connect one meter lead to the red/black main harness wire; then connect the other meter lead to the black main harness wire.

3.Start the engine. The meter must read 12-15 volts. NOTE: If this voltage test does not read within spec-