20 minute read

Section 5 MERCEDES-BENZ Euro 4 / 5 Engine Supplement

Page IMPORTANT NOTICE ABOUT THIS BOOK CONTACT MBAuP II II III

Section 1 OVERVIEW, REGULATIONS & STANDARDS 1-1

DAIMLER TRUCKS AUSTRALIAN PRODUCT LINE UP 1-3 VEHICLE MODIFICATIONS 1-3 APPLICATIONS 1-3 RATINGS 1-3 VEHICLE IDENTIFICATION AND INFORMATION PLATES 1-5 MBAUP – ISO VIN BREAKDOWN 1-5 TYRE PLACARD 1-8 REGULATIONS AND STANDARDS 1-9 VEHICLE STANDARDS INFORMATION SOURCES 1 -10 ADR VEHICLE CATEGORIES 1-11 ALL ADR’S APPLICABLE TO BUS’S AND TRUCKS 1-12 OVERVIEW OF HCV RELATED ADR’S 1-15 INDUSTRY STANDARDS AND REFERENCES SOURCES 1-27 WEIGHT DISTRIBUTION AND THE LEGAL REQUIREMENTS 1-28 NOISE 1-29 RECORDS 1-30 VEHICLE STORAGE 1-30

Section 2 GENERAL GUIDELINES 2-1

INTRODUCTION 2-3 INSTALLATION PRECAUTIONS 2-4 CHASSIS ELECTRICAL WIRING 2-12 SPECIAL INSTALLATION GUIDELINES 2-20 FIFTH WHEEL MOUNTING 2-22 BULLBAR AND BUMPER BAR GUIDELINES 2-24 BODY MOUNTING 2-26 VEHICLE MODIFICATION 2-34 VEHICLE LEAN 2-38

Section 3 BRAND SPECIFIC GUIDELINES 3-1

FREIGHTLINER 3-2 STERLING 3-6 MERCEDES-BENZ 3-11

Section 4 REFERENCE FINAL INSPECTION CHECK LIST VEHICLE STORAGE GUIDELINES WEB SITE LINKS 4-1

Section 5 MERCEDES-BENZ Euro 4 / 5 Engine Supplement 5-1

INTRODUCTION 1-3

DAIMLER TRUCKS AUSTRALIAN PRODUCT LINE UP 1-3 VEHICLE MODIFICATIONS 1-3 APPLICATIONS 1-3 RATINGS 1-3

VEHICLE IDENTIFICATION AND INFORMATION PLATES 1-5

BREAKDOWN OF MBAuP’S ISO VIN 1-5 VEHICLE COMPLIANCE AND ID PLATES 1-6 TYRE PLACARD 1-8

REGULATIONS AND STANDARDS 1-9

VEHICLE STANDARDS INFORMATION SOURCES 1-9 AUSTRALIAN DESIGN RULES (ADR) VEHICLE CATEGORIES 1-11 ADR’S APPLICABLE TO BUS’S AND TRUCKS 1-12 KEY TRUCK APPLICABLE ADR’S 1-14 OVERVIEW OF THE ADR’S 1-15 BODY BUILDER ADR CHECKLIST 1-26 INDUSTRY STANDARDS AND REFERENCES SOURCES 1-27

NOISE 1-29

RECORDS 1-30

Notes ……………………………………………………………………………………………………………………………………

If you have noted any updates, corrections or requirements for new information, please let us know either by contacting MBAuP Truck Engineering or faxing this sheet to:- Data Book Update (03) 9566 6282 for inclusion in the next edition. We value your input, please include your details:- Notes by ………………………… of ……………………………, Contact # ………………………….

INTRODUCTION

DAIMLER TRUCKS AUSTRALIAN PRODUCT LINE UP.

The range of models and variants now available from Daimler Trucks as “standard” models allow operators to select a specific configuration for their proposed vehicle application. The collective knowledge of Authorised MBAuP Truck Dealers plus support from MBAuP personnel is available to help an operator select an appropriate configuration. However, the range of vehicle applications and operating conditions may require changes, major or minor, to the vehicles as originally built.

Vehicle modifications remain the responsibility of the vehicle modifier and must comply with all Federal and local laws and regulations, including Vehicle Standards Bulletins issued by DoTaRS, Australian Standards and any applicable industry codes of practice.

VEHICLE MODIFICATIONS

MBAuP shall not, nor shall it be obliged to, give approval to any modification which alters vehicle ratings or compliance with Australian Design Rules or any other legislative requirements and which, in MBAuP’s opinion, is not acceptable within the parameters of vehicle build level and proposed operation.

APPLICATIONS

The MBAuP model line has been specified by MBAuP to satisfactorily perform a variety of applications. Any one model cannot be expected to carry out an unlimited number of functions, for example, a truck designed to carry a concrete agitator may not be suitable for continuous long distance haulage. Over application of running gear (engine, transmission, axles, suspensions) may lead to reduced service life and increased maintenance costs. Similarly over specifying of components may mean excess tare mass and reduced payloads.

RATINGS

As a manufacturer, MBAuP rates it’s vehicles – Gross Vehicle Mass/Gross Combination Mass based on either one or a combination of • Industry based group ratings – usually G.V.M. or payload ratings. • Regulated (legislated) ratings – based on National or State limits. • Axle/Axle group maximum loading limits. • Bridge Formula ratings (distance between axles). • Maximum vehicle rating – Based on the ratings of the components that make up the vehicle.

Example – Rear axle/suspension rated by suppliers at 18,000 kg. Legal limit for tandem axle 16,500 kg. Therefore a vehicle fitted with a 6 tonne steer axle could be rated at 24,000 kg G.V.M. by MBAuP, but 22,500 kg G.V.M. for registration purposes.

B DOUBLE/ROAD TRAIN RATINGS

Re-rating to B-Double or Road Train level from a vehicle not originally built to the applicable specifications is outside the scope of this book. Australian Design Rule 64 includes the requirements for these applications. Specific inquiries should be directed to the State or Territory regulatory body or to a recognised consulting engineer.

All vehicle components have a maximum rating, and sometimes performance limitations applied by their manufacturer/supplier. The vehicle manufacturer has the responsibility of balancing component levels with their own items on the vehicle and determining the vehicle rating and operating limitations (if any) for a particular vehicle line or model.

Although some tolerances in limits may be available, the total vehicle must be reviewed when mass ratings or major operating changes are planned. Variations between the figures quoted as the vehicle mass ratings may cause some concern to operators.

VEHICLE IDENTIFICATION AND INFORMATION PLATES

ISO VIN

(International Standard Organisation Vehicle Identification Number) ISO VIN comprises 17 characters/numbers. The last 11 characters are used as a vehicle “Prefix/Serial” number.

Locations: • Freightliner - LHS, top flange of chassis rail behind the steer wheel (visible when bonnet is open. Additionally it is on a decal attached to the LHS door “B” Pillar. Additional the Chassis number (the last digits of the ISO VIN) are stamped on the lower back cab panel, driver’s side. • Sterling HN80 (Pre 2005.5 build) – LHS, side of chassis rail behind the steer wheel. Sterling HX (Post 2005 build) - top flange of chassis rail behind the steer wheel (visible when bonnet is open. Additionally it is on a decal attached to the LHS door “B” Pillar. Additional the Chassis number (the last digits of the ISO VIN) are stamped on the upper front cab firewall, driver’s side. • Mercedes-Benz – RHS, side of chassis rail behind of the steer wheel and is stamped vertically down the rail. Additionally it is on a decal attached to the LHS door “B” pillar.

BREAK DOWN OF THE ISO VIN

Typical examples

WMI Variant Code Brand

Character 1-3 4-9

Positions Freightliner 1FV JAWCK9 Sterling 2FZ JAZCG44 Mercedes-Benz WDB 930145 Note WMI = World Manufacturer Identifier.

Method or Plant & Year of Manufacturer 10-11

4L AN 2K or 2L

Serial or Chassis #. 12-17

000001 000001 000001

Location

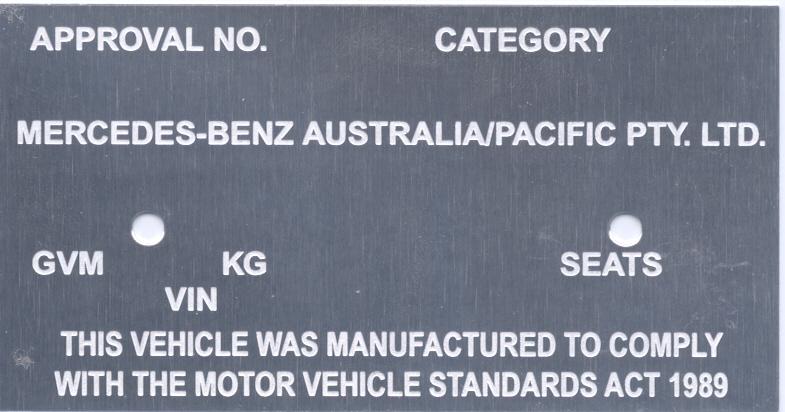

VEHICLE COMPLIANCE PLATE – ADR PLATE

The Compliance Plate defines the Vehicle’s Gross Mass, the permitted seating (as the vehicle left the production plant), the truck’s Compliance Approval Number, Vehicle Category and the ISO VIN.

Location:- LHS Door Frame Kick/Door Sill Panel – Freightliner LHS B Pillar - Sterling RHS B Pillar – Mercedes-Benz for the above metal plates LHS B Pillar – Mercedes-Benz for labels

VEHICLE PLATE

This plate identifies the vehicle’s capacity, the totals (GVM/GCM) and the capacity of axles. Additionally for the trucks with higher GCMs will have an additional clarifier of either “B-Double” or “Road Train”, which define the maximum gradient of the route as being 8% or 5% respectively.

Location:-- LHS Door Frame Kick Panel/Door Sill – Freightliner LHS B Pillar - Sterling RHS B Pillar – Mercedes-Benz for the above metal plates LHS B Pillar – Mercedes-Benz for labels

Daimler Truck Plates and Labels

NOTE:- All plates and labels will transition to Mercedes-Benz Australia/Pacific Pty Ltd with the name change of the legal company entity as of the 1/Dec/07.

Additional State Required Plating for 26 m B-Double

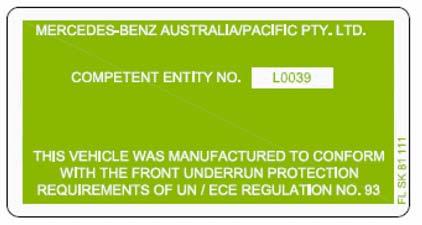

1 - ECE R29 Cab Strength Plate 2 - ECE R93 Front Under Run Protection Plate - Cab

3 - ECE R93 Front Underrun Protection Device Plate

4 – ADR Emission Label

1 - ECE R29 Cab Strength Plate To be fitted to all trucks plated after 1 st January, 2006.

2 - ECE R93 Front Underrun Protection Plate – Cab This Plate is to be fitted to the cab when a Mercedes-Benz Australia/Pacific Pty Ltd. approved Front Underrun Protection Device has been installed as instructed by MBAuP.

3 - ECE R93 Front Underrun Protection Plate This Plate is to be fitted to the device when required by MBAuP. Further information will be supplied for the fitment requirement and location.

4 – ADR80/01 or ADR80/02 Engine Emissions compliance label.

Plates 1, 2 & 4 are located near to the ADR Compliance Plate, while 3 is on the device

RFS (Road Friendly Suspension) Plate

Located next to the ADR plate.

Daimler Truck Plates and Labels

NOTE:- All plates and labels will transition to Mercedes-Benz Australia/Pacific Pty Ltd with the name change of the legal company entity as of the 1/Dec/07.

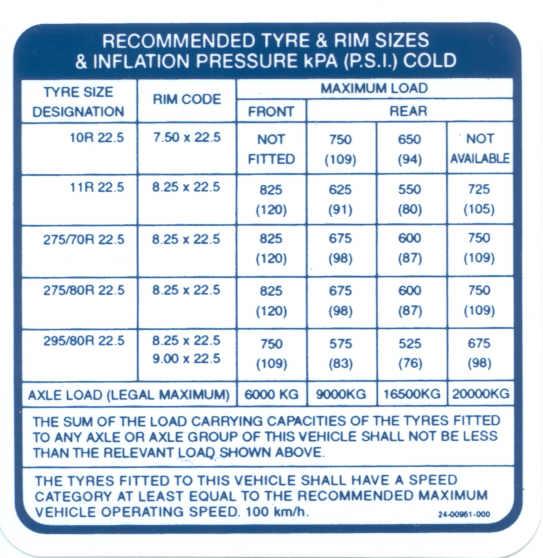

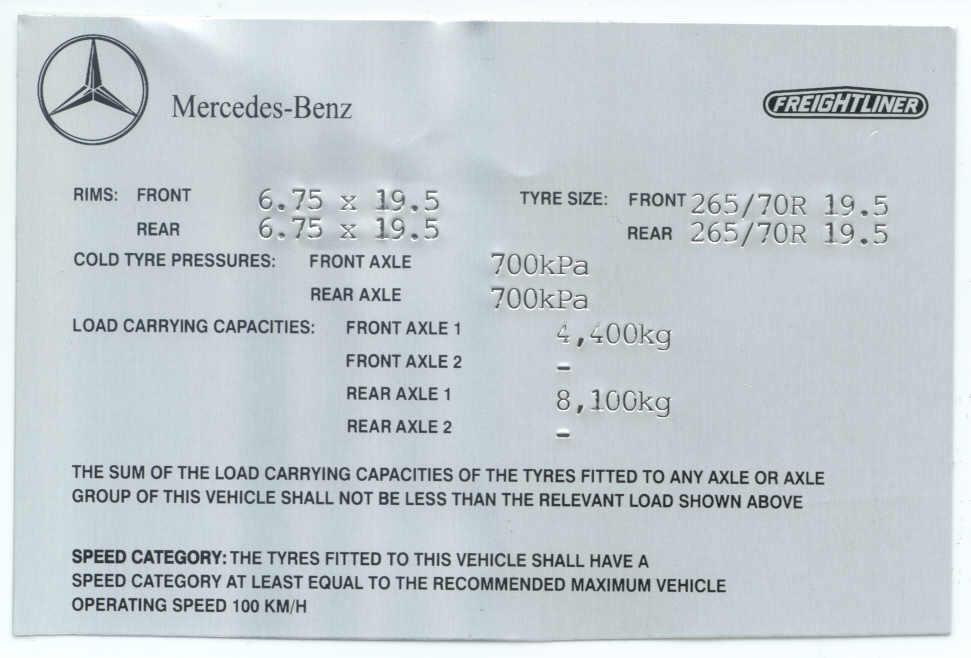

Tyre Placard

The function of this Australian Design Rule was to specify requirements for tyres and rims appropriate to vehicle load capacity, rim size and speed characteristics. The placard details the tyres that can legally be fitted to the vehicle, their maximum load carrying capacity with the required inflation pressure for that load, for the front and rear axles with the recommend rim size. A tyre placard was required by ADR 24/02 to be fitted to any light vehicle, however it is no longer legally required for NC trucks and therefore may be phased out. This standard ceased to have effect as from 9 December 2003. The vehicle’s owners manual or the tyre manufactures recommendations should be referred to in conjunction with Federal and State regulations.

Location:- Near to the ADR/ID Plates, when fitted. LHS Door Frame Kick Panel – Freightliner LHS B Pillar - Sterling RHS B Pillar – Mercedes-Benz

Generic plate used for Mercedes-Benz and specialist tyres for Freightliner.

REGULATIONS AND STANDARDS – INTRODUCTION

THE MOTOR VEHICLE STANDARDS ACT 1989 REQUIRES THAT ANY VEHICLE MODIFIED BEFORE ITS FIRST REGISTRATION MUST CONTINUE TO COMPLY WITH THE AUSTRALIAN DESIGN RULES (ADR’S).

Daimler Truck models intended for the Australian market have an approved compliance plate which shows that, at the date of its release, the vehicle complied with all the ADR’s applicable to Chassis Cab vehicles. (See Page 1-11)

Vehicle Compliance Plates

The Australian Design Rules (ADR’s) set down the performance and design requirements for motor vehicle safety and have been in place since 1969. The ADR’s take force nationally under the Motor Vehicle Standards ACT (1989) and are administered by the Department of Transport and Regional Services (DoTaRS). The Act applies to vehicles prior to first supply to the Australian market. Control of vehicles which are already in service is the responsibility of the States and Territories. The first edition of ADR’s was distributed for discussion purposes but was not adopted as law in National, State or Territory legislation. The second edition came into effect on 1 January 1969. The third edition was introduced in January 1988 and became the minimum national standard in the Motor Vehicle Standards Act 1989. The third edition of ADR’s was developed under the auspices of the Australian Transport Advisory Council (ATAC) between February 1983 and December 1986. It has since had additions and amendments to reflect the further needs of the community. The ADR’s apply to both manufacturers and importers of vehicles for the Australian market.

Section 14 of the Act makes it an offence to supply vehicles to the market that do not comply with the national standards. It is also an offence, under Section 16, to make a standard vehicle non-standard when first supplied to the market.

When Daimler Trucks leave the factory, they still require the addition of other equipment (e.g. load bodies, fifth wheels, etc.) and in some cases further modifications before they can be used in a work performing function. Such fitments and modifications are carried out by a wide variety of organisations including dealers, body builders, secondary manufacturers, specialist equipment installers or even the fleet operator.

It is important that the ADR’s are understood and complied with even after the vehicle has left the manufacturer and is on the road. This is because these rules cover safety and environmental issues – any failure to abide by them may create a safety hazard and may incur significant financial penalties. Service manuals that mechanics use to maintain motor vehicles do not usually refer to the ADR’s. However, the service manual is written in such a way that, if it is followed exactly, the standards established by the ADR’s will be maintained. This continued compliance with the ADR’s may be seriously compromised if substitute parts are used when a vehicle is serviced. Hence, mechanics need to follow service manual instructions explicitly to ensure compliance with the ADR’s.

As Australian Design Rules are a necessarily complex set of standards, it is usual to use extracts, summaries or guides for public use or general circulation. The information contained in this publication is intended as a guide only.

Specific inquiries should be directed to the State (or Territory) regulatory body or to a recognised consulting engineer.* *State and Territory Transport Authorities (or equivalent body) maintain systems which often list recognised consulting engineers in reference to vehicle modifications.

In addition to Australian Design Rules, there are a number of regulatory or quality control requirements which may be applicable to vehicles entering service or which are modified. It is not sufficient for persons involved in the modification of Daimler Trucks vehicles to rely only on this guide. They should also be familiar with all relevant Australian Design Rules and other regulatory requirements before proceeding, to ensure the completed modification is fully compliant.

Information regarding such requirements may be obtained from the following regulatory bodies:

VEHICLE STANDARDS INFORMATION SOURCES

WESTERN AUSTRALIA Vehicle Safety Branch Licensing Division Main Roads

SOUTH AUSTRALIA Driver & Vehicle Operations Section Transport SA

QUEENSLAND Vehicle Standards Queensland Transport AUSTRALIAN CAPITAL TERRITORY Vehicle Safety Road Use Management NORTHERN TERRITORY Vehicle Compliance Road Transport Services Department of Planning and Infrastructure TASMANIA Vehicle Standards & Compliance Department of Infrastructure, Energy and Resources

Department of Urban Services NEW SOUTH WALES Standards Advice Roads & Traffic Authority VICTORIA Vehicle Safety Branch VicRoads

MODIFYING A VEHICLE

The Motor Vehicle Standards Act makes it an offence to modify a new vehicle before it is first supplied to the market for use in transport so that it no longer complies with the ADRs. As a result of this, the States and Territories have developed procedures to control such modifications through a single, national code of practice that serves the requirements of both Federal and State/Territory authorities. This is known as Vehicle Standards Bulletin No.6 – Heavy Vehicle Modifications (VSB 6) which is available on the following web site:

http://www.dotars.gov.au/

The Federal Office of Road Safety has designated “road vehicles” by two character category code. The categories range from pedal cycles through passenger cars, buses and trucks to trailers.

ADR’s define the National Standards on Safety, Emissions and Theft for a vehicle. Different ADRs apply to different Classes & Sub-Classes. Within an ADR, differential standards may also applied to different Classes & Sub-Classes.

Classes:-

o Two & Three Wheeled Vehicles

AA, AB, LA, LB, LC, LD, LE.

o

o

o

Passenger Vehicles (Other Than Buses) Cars - MA, Vans - MB, Off Road 4x4’s - MC.

Omnibuses

Light - MD,

Heavy - ME GVM ≥ 5 tonne.

Goods Vehicles

Light - NA GVM ≤3.5 tonne, Medium - NB GVM ≤ 12 tonne, Heavy NC GVM > 12 tonne.

o

Trailers

Light - TA/TB GTM ≤ 3.5 tonne, Medium - TC GTM ≤ 10 tonne, Heavy - TD GTM > 10 tonne.

The following list indicates the ADR’s applicable to Daimler Truck models (Category NC & NB2 vehicle) at time of printing. Normal practice is to use a “/xx” suffix with Design Rule numbers to indicate the release level of the Rule.

Bus and Truck Applicable ADRs, as of 01/01/2007.

Vehicle Category Code MD3 MD4 ME NB1 NB2

ADR #

1/00 2/00 2/01 3/01 3/03 4/03 4/04 5/04 5/05 6/00 8/01 11/00 13/00 14/02 18/02 18/03 28/01 30/01 34/01 35/02 42/04 43/04 44/02 45/01 46/00 47/00 48/00 49/00 50/00 51/00 52/00 58/00 59/00 61/02 62/01 64/00 65/00 66/00 68/00 74/00 80/00

80/02

80/03

83/00 Class Description

GVM (tonne)

Reversing Lamps Side door Latches & Hinges Side door Latches & Hinges Seat Anchorages Seat Anchorages Seat Belts Seat Belts Seat Belt Anchorages Seat Belt Anchorages Direction Indicator Lamps Safety Glass Internal Sun Visors Installation of lighting Rear Vision Mirrors Instrumentation Instrumentation External Noise (to be superseded by ADR 83/00) Diesel Exhaust Smoke Child Restraint Anchorage & Anchor Fittings Commercial Vehicle Braking System General Safety Requirements Vehicle Configuration & Dimensions Specific Purpose Vehicles Lighting Devices not covered by ADR13 Headlamps Reflex Reflectors Rear Registration Plate Lamp Position (Side), Stop & End Outline Lamps Front Fog Lamps Filament Globes Rear Fog Lamps Requirements for Omnibuses Omnibus Rollover Strength Vehicle Marking Mechanical Connections between Vehicles Road Train & B Double Vehicles Speed Limiting of Heavy Vehicles Seat & Anchorage Strength in Omnibuses Occupant Protection in Buses Side marker lamps Emission Control For Heavy Vehicles (with Euro 3 or EPA 98/MY2000) Emission Control For Heavy Vehicles (with Euro 4 & OBD or EPA 04) Emission Control For Heavy Vehicles (with Euro 5 & OBD or EPA 07) External Noise Light Omnibus

>3.5, =4.5 X - - - # X #, @ X #, @ X X X X X X $, @ X X X X X X X X X X X X O X O X X X O - - X X %, O

X > 4.5, =5.0 X - - - # X #, @ X #, @ X X - X X X $, @ X X X X X X X X X X X X O X O X X X O - - X X %, O

X Heavy Bus

>5.0 X - - - # X #, @ X #, @ X X - X X X $, @ X X X X X X X X X X X X O X O X X X O - X X X %, O

X Medium Goods Vehicle

> 3.5, =4.5 X X @ X #, @ X #, @ X #, @ X X X X X X $, @ X X - X X X X X X X X X O X O - - X O - - - - %, O > 4.5, =12.0 X X @ - # X #, @ X #, @ X X - X X X $, @ X X - X X X X X X X X X O X O - - X O - - - - %, O

X X NC

Heavy Goods Vehicle

>12.0

X X @ - # X #, @ X #, @ X X - X X X $, @ X X - X X X X X X X X X O X O - - X O O X - - %, O

X

Key: - X = mandatory 0 = optional / if fitted @ = Manufacturer can chose to comply with this vehicle standard or continue to comply with earlier versions of this vehicle standard as applicable for particular vehicle categories. # = applicable to new model vehicles as of 01/07/2008. $ = applicable to new model vehicles as of 01/07/2007. % = required on motor vehicles with an overall Width over 2.1 meters and a total Length over 7.5 metres. * = applicable to new model vehicles as of 01/01/2007, and all vehicles as of 01/01/2008. & = applicable to new model vehicles as of 01/01/2010, and all vehicles as of 01/01/2011.

KEY TRUCK APPLICABLE ADR’S

Some typical fitments or modifications, which have ADR and legal implications:

FIFTH WHEEL FITMENT ADR 62/

REAR WHEEL GUARDS

REAR REGISTRATION PLATE HOLDER ADR 42/

ADR 61/

VERTICAL EXHAUSTS

ADR 42/ VIC, TAS & NSW EPA

DIMENSIONS ADR 43/ width, length, height, rear overhang, ground clearance, turning circle.

WHEELS AND TYRES ADR 24/

REAR MARKING PLATES ADR 13/, ADR 45/

LIGHTING correct positioning of reversing lamps, rear direction lamps, rear reflex reflectors, rear registration plate illuminating device, rear position (side) lamps and rear stop lamps. ADR 13/

LIGHTING additional lamps fitted (e.g. an increase in vehicle length ADR 13/, 1/, 6/, 45/ may require side marker lamps or additional side reflex reflectors, or 46/, 47/, 48/, 49/, fitment of a bull bar may require additional lamps). 50/, 50/, 51/, 52/

SEAT ANCHORAGE design integrity may be adversely affected with ADR 3 the installation of a non-standard seat. Approval of the non-standard seat specification should be obtained from MBAuP or a recognized consultative engineer.

SLEEPER CAB ADR 42/

ADDITIONAL AXLE/REVISED GVM

CHANGES TO BRAKE SYSTEM ADR 35/

ADR 35/

CHANGES TO WHEEL BASE ADR 35/, STATE REGULATIONS

ADDITIONAL FUEL TANKS ADR 17/

CHANGES TO OVERALL LENGTH VARIOUS

OVERVIEW OF ADR’S

Below is a brief outline each ADR rule. Because of potential adverse effects on compliance with ADR’s, the items should not be changed without being assessed by MBAuP Product Engineer as to whether the modification complies with the relevant Design Rule, or a new submission will be required following appropriate testing and assessment.

ADR 1/00 Reversing Lamps (Colour, number & location to ADR 13/00). The function of this national standard is to specify the photometric requirements for reversing lamps which: (a) warn pedestrians and other road users that the vehicle is about to move, or is moving, in the reverse direction; and (b) aid the driver in reversing manoeuvres during the hours of darkness.

ADR 2/00 Side Door Latches & Hinges (Door latch , Latch striker & Door hinge assemblies) The function of this national standard is to specify requirements for side door retention components, including latches, hinges, and other supporting means, to minimise the likelihood of occupants being thrown from a vehicle as a result of impact.

ADR 3/02 Seat & Seat Anchorages The function of this national standard is to specify requirements for 'Seats', their attachment assemblies, and their installation to minimise the possibility of occupant injury due to forces acting on the 'Seat' as a result of vehicle impact.

ADR 4/03 Seat Belts (replaces ADR 32A) The function of this national standard is to specify requirements for seatbelts to: restrain vehicle occupants under impact conditions, facilitate fastening and correct adjustment, assist the driver to remain in his 'Seat' in an emergency situation and thus maintain control of the vehicle, and protect against ejection in an accident situation. Seat belt and buckle assemblies Seat anchor strap assemblies Type 4N retractors

ADR 5/04 Anchorages for Seat Belts (replaces ADR 32A) The function of this national standard is to specify requirements for 'Anchorages' for both 'Seatbelt Assemblies' and 'Child Restraints' so that they may be adequately secured to the vehicle structure or 'Seat' and will meet comfort requirements in use. Belt anchorages including plates in floor and pillars Seat assemblies Belt attachment bolts Cab assemblies Relative location of seat and anchorages points And Child Restraints

ADR 6/00 Direction Turn Signal Lamps The function of this Australian Design Rule is to specify the photometric requirements for direction indicators which will provide adequate warning to other road users of the intention to perform a turning manoeuvre. (Colour, number & location to ADR 13/00) Turn signal lamp assemblies.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual . • You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to

CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL