1 minute read

SWARCOBLAST FOR SURFACE FINISHING

Circular Economy

The world is changing. Climate change, resource scarcity and global supply chain bottlenecks are disrupting existing structures and putting economic cycles at risk. Is it time to turn these economic cycles into a truly circular economy? This concept, which calls for preserving value and using resources responsibly, offers exciting solutions indeed.

Advertisement

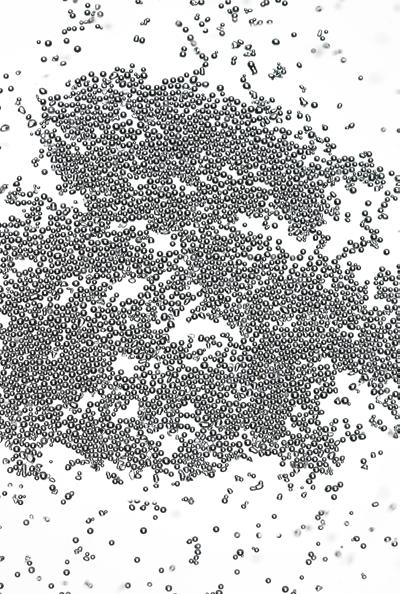

SWARCOBLAST glass blasting beads are a high-grade non-metallic mineral fine blasting medium made of glass and are sought after internationally. Cleaning, surface finishing, shot peening, and deburring are ideal areas of application for this innovation from SWARCO Advanced Industry Systems.

Here, cleaning refers to processes such as desanding, or the removal of residues, solder and welding residues, or temper colours. Surface finishing includes smoothing, lapping and polishing. In this area of application, SWARCOBLAST helps to reduce surface roughness, remove toolmarks, and provide anti-reflective finishing, matting, and satin finishing.

SWARCOBLAST glass blasting beads from SWARCO Advanced Industry Systems

In shot peening processes, these glass blasting beads are a perfect fit for achieving surface hardening and increasing endurance, fatigue strength and dimensional accuracy. SWARCOBLAST is also used to improve lubricating film adhesion, reduce notch sensitivity and prevent stress corrosion cracking. Last but not least, the application portfolio also includes deburring. Here, burrs are removed that are formed when metal workpieces are manufactured through processes such as punching, milling or turning. SWARCOBLAST is also an ideal product for a smooth transition to a circular economy (see column on the right).