3 minute read

Driving decarbonisation

Ahead of the revised British Standard for Concrete (BS 8500), which will come into force later this year, Craig Williamson, Director for Commercial Cement at CEMEX, explains the importance of revised regulations and industry standards to drive the circular economy and accelerate the critical race to decarbonisation.

The new year heralds the dawn for some important new industry regulations, some of which have been a long time in the making but are now critical for the circular economy and to accelerate our collective decarbonisation journey. To reach the goal of a net-zero built environment by 2050, an important move for the concrete and cement industry is the eagerly awaited revision to BS 8500, later in 2023.

As the most resilient and ubiquitous building material on the planet, there is no doubt that concrete will continue to play a vital role in our built environment, forming the backbone of our future-state building schemes and infrastructure. However, with that also comes great responsibility. As an industry we will be accountable to a new set of stringent standards, which will demand new ways of developing and improving our practice and products in our quest for net-zero and beyond.

Revision to BS 8500

Later this year, the UK concrete industry will publish a new version of the British Standard for Concrete BS 8500, which will work even harder to move the industry forward in hot pursuit of decarbonisation.

The incoming revision will also allow the expanded use of a new generation of low-carbon cements.

A key strategy for reducing concrete’s embodied carbon involves replacing a proportion of cement content or clinker with limestone and other industrial by-products, using up materials that might otherwise go to waste. Cement clinker is a material produced in the manufacture of Portland cement.

The introduction of such an approach is one of many small steps that will take us to net-zero, along with the increased effort to reduce the embodied carbon within the clinker and increase the use of alternative fuels.

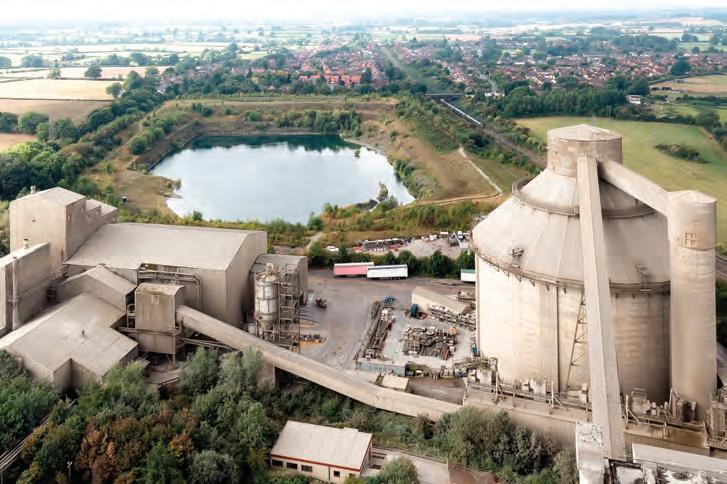

The typical use of fossil fuels to heat cement kilns across industry are responsible for approximately 40% of direct CO2 emissions of the cement manufacture process. Replacing fossil fuels entirely through alternative fuels such as waste derived fuels, hydrogen and solar energy is a gamechanger in the industry’s efforts to achieve carbon neutrality by 2050. CEMEX is firmly committed to the use of alternative fuels across Europe and in the UK at our trailblazing Rugby plant, with other large-scale adoption sites coming soon.

Industry-first net-zero concrete

In the UK, the revised concrete standards will serve to keep us on track with our decarbonisation goals to meet customer needs, without compromising on performance. Following the introduction of CEMEX’s industry-first net-zero CO2 concrete and low carbon cement products in 2020, we have the ongoing responsibility to deliver low carbon products at scale.

Globally, we recently set an ambitious goal for our Vertua low-carbon cement and concrete products of reaching more than half of all cement and concrete sales by 2025.

New Industry Packaging Waste Directive

The Extended Producer Responsibility (EPR) came into force on 1st January 2023 and signalled strong intent by UK Govt for all industries to deliver a more circular economy and take greater responsibility for the packaging they place on the UK market, at the end of its life.

EPR now requires producers to pay the full costs of dealing with the waste they produce, which includes the cost of collection, treatment, and of course recycling. It is hoped the new regulations will lower the environmental impact of products throughout their life cycle, as well as the amount of packaging produced in the first place.

In turn this will reduce the impact of packaging waste in landfill and increase the amount of packaging waste that is recycled.

CEMEX has been making sustainable improvements to its packaging for over a decade. In 2012, CEMEX was the first cement company in the world to provide verified carbon labels for its cements produced in the UK. We continue to invest heavily across the business to enable us to make rigorous improvements, from new and improved packaging and labelling solutions, to localised interventions such as 100% paperless delivery systems for our Readymix business, through to major plant investments.

ISO 50001 Energy Management System

To increase energy efficiency and performance across our UK operations, CEMEX has committed to improved standards with the roll out of the ISO 50001 Energy Management System. This is an international standard created by the International Organisation for Standardisation (ISO) which specifies the requirements for establishing, implementing, maintaining and improving an energy management system.

It enables organisations to follow a systematic approach in achieving continual improvement of energy performance, including energy efficiency, energy security and energy use and consumption. Benefits of this system include improved reputation, reduced energy related taxes, increased energy efficiency and reduced energy costs.

Future In Action

CEMEX’s Future in Action environmental strategy was relaunched in 2020 to reflect a robust commitment to developing and providing more sustainable products and services so that the built world of the future is more sustainable and circular. Our Future In Action programme is continuously pioneering ways to reduce CEMEX’s environmental impact whilst providing merchants and customers with a broad range of sustainable products and solutions.

n For more information on CEMEX’s sustainability commitments, its product range and its support services for merchants, enter the shortcode www.rdr.link/mas005