3 minute read

TECHNOLOGY

IN THE YARD

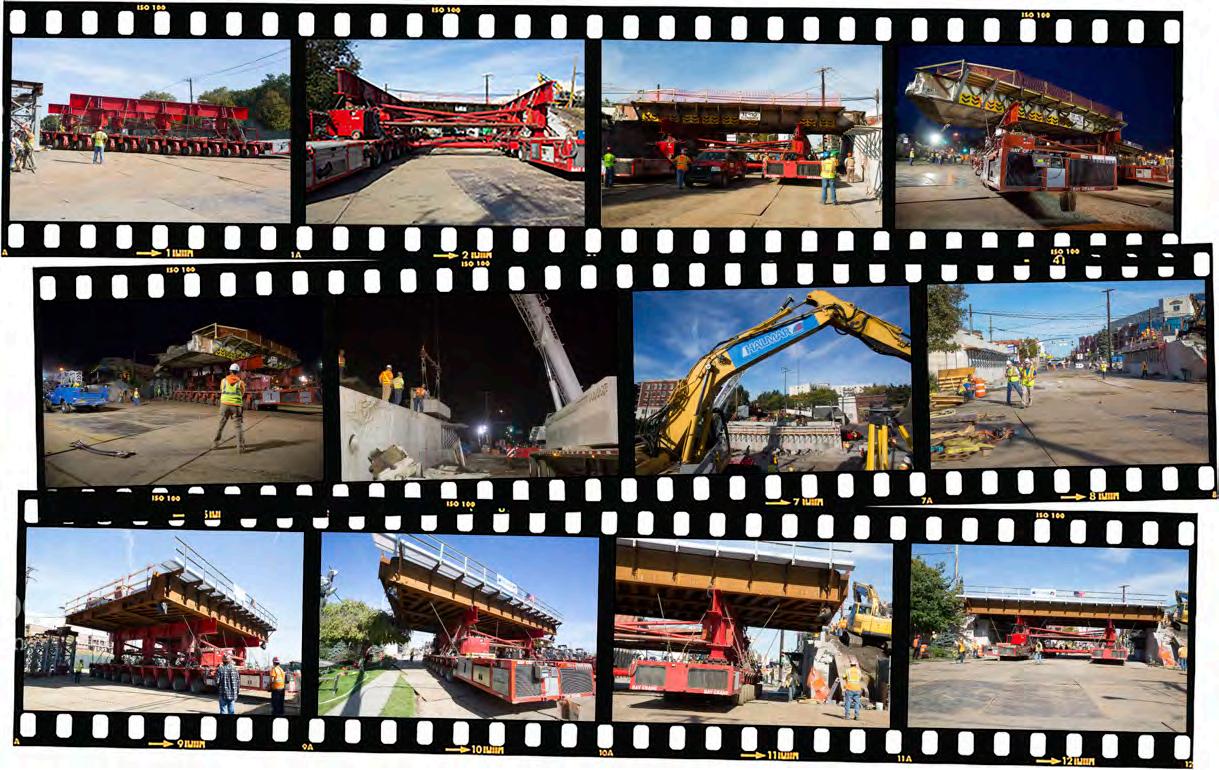

THE IMPORTANCE OF THE RIGHT APPROACH SUPPORTED BY THE RIGHT EQUIPMENT: HALMAR’S POST AVENUE BRIDGE REPLACEMENT PROJECT

Advertisement

Halmar and its design partner McLaren The SPMT unit used on this project was provided by Bay Crane, Engineering Group was awarded the Long Island and had to be ordered 6 months in advance to assure it availabiliRail Road Design-Build Post Avenue Bridge Replacement ty. Boasting a lifting capacity of 1.2M pounds, the SPMT consists of project in December 2016. The original approximately 100+ year an articulated arrangement of multi-axle platforms each of which old 2-track plate girder bridge was due for replacement primarily can be individually pivoted 360 degrees and is computer operated to allow for the greater width required for the additional mainline via a walk along operator with a radio control system. The Bay unit track, as a first preparatory step for the LIRR Third Track project. used on this project had 80 wheels on 20 axles, to support these Additionally, the bridge was built at a time when the vertical clear- very large and heavy loads. The original bridge structure to be ance provided for truck traffic was significantly lower than today’s removed weighed in at roughly 700,000 pounds, while Halmar’s higher capacity vehicles. As a consequence, over the decades the new wider structure weighed approximately 600,000 pounds. The bridge had been struck innumerable times replacement sequence began with the SPMT being maneuvered by trucks traveling on Post Avenue passing from the adjacent station parking lot, out under the bridge, on occasion more than once a day. The Bay unit used onto the street while negotiating a 90 degree turn in very constrained space. The SPMT was The design-build contract required that the on this project had aligned under the old bridge, lifted off its abutoriginal bridge be removed and the new bridge installed and ready for operation over 80 wheels on 20 ments, transported back to the parking lot, and set down on waiting temporary supports the course of one weekend service outage, which the LIRR scheduled for the weekend of October 21st and 22nd 2017, beginning axles, to support these very large structures. Overnight the upper portion of the east and west abutments, which needed to be modified with new precast segments to Friday October 20th at midnight, and ending on Monday morning at 5am, a window of and heavy loads. achieve the higher elevation and accept the new wider bridge structure, were set in place. just 53 hours. On the next day, the new bridge was lifted With the design work well underway, Halmar mobilized and began and transported around the same sharp turn, down the street and work at the site in June of 2017. Site work and preliminary saw into position, setting it gently and precisely down on the newly cuts of the east and west abutments were performed to acceler- modified abutments 12 hours ahead of the bridge’s required ate the work that was to take place during the weekend outage. start of service. Once the bridge was in place LIRR force account To facilitate the quickest possible removal and replacement of the personnel installed the re-graded track and ballast. Thanks to bridge, Halmar opted to use a relatively new concept in acceler- this unique approach, the LIRR was able to re-open the tracks to ated bridge replacement projects, made possible by a piece of service by 5am as planned. equipment called a Self-Propelled Modular Transporter (SPMT). from its temporary supports in the parking lot The use of an SPMT for bridge replacement projects had only been All the equipment was transported to the site on standard high utilized a few times previously in the U.S. flat/low boy trailers. No road or lane closures were required. Bay Crane assembled the units onsite in the station parking lot the